Gradient porous magnesium-based metal component body for bone tissue engineering and preparation method thereof

A technology of bone tissue engineering and gradient porosity, which is applied in tissue regeneration, prosthesis, medical science, etc., can solve problems such as high dependence on pressure equipment, residual pore-forming agents, and single porous magnesium structure, so as to avoid adverse effects and quickly Degradation rate, effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

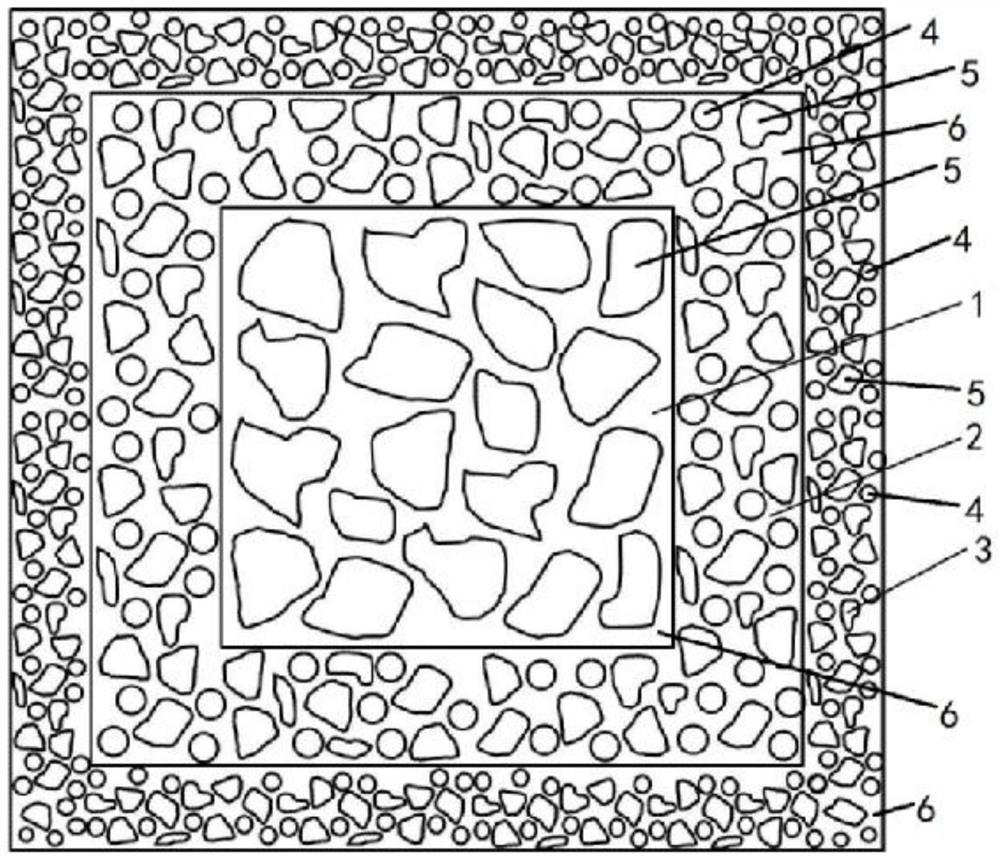

[0028] Such as figure 1As shown, the bone tissue engineering gradient porous magnesium-based metal component body of the embodiment of the present invention includes an inner core preform 1, an intermediate preform 2 and an outer layer preform 3, wherein the intermediate preform 2 is located at the periphery of the inner core preform 1, and It is ring-shaped; the outer layer prefabricated body 3 is located on the periphery of the middle layer prefabricated body 2 and is ring-shaped; the above-mentioned inner layer prefabricated body 1, middle layer prefabricated body and outer layer prefabricated body 3 all have pores, and the inner layer prefabricated body 1, the middle layer prefabricated body 1, the middle layer prefabricated body The body 2 and the outer layer preform 3 are connected through their respective pores. The porosity refers to the ratio of the pores inside the material to the total volume in the apparent volume of the granular material. In this embodiment, the in...

Embodiment 2

[0037] The difference between this embodiment and the above-mentioned embodiment 1 is only that: the matrix material of the ball-milled magnesium powder or the gas-atomized magnesium powder is different, and the constant external pressure adopted is different.

[0038] The preparation method of the above-mentioned gradient porous magnesium-based metal component for bone tissue engineering in this embodiment includes the following steps in sequence:

[0039] First, the extruded Mg-Sr binary alloy is selected as the base material to prepare gas-atomized magnesium powder 4 and ball-milled magnesium powder 5; wherein the alloy is used as the base material for gas-atomization to obtain gas-atomized magnesium powder. Magnesium alloy powder, the ball-milled magnesium powder obtained after ball-milling the alloy as the base material is ball-milled magnesium alloy powder; secondly, an electric cold isostatic press is used to adjust the constant external pressure to 50MPa, and the ball-m...

Embodiment 3

[0042] The difference between this embodiment and the above-mentioned embodiment 1 is only that: the matrix material of the ball-milled magnesium powder or the gas-atomized magnesium powder is different, and the constant external pressure adopted is different.

[0043] The preparation method of the above-mentioned gradient porous magnesium-based metal component for bone tissue engineering in this embodiment includes the following steps in sequence:

[0044] First, the extruded Mg-RE-Zr ternary alloy is selected as the base material to prepare gas atomized magnesium powder 4 and ball milled magnesium powder 5; wherein the alloy is used as the base material for gas atomization to obtain gas atomized magnesium powder as the gas Atomized magnesium alloy powder, the ball milled magnesium powder obtained after ball milling the alloy as the base material is ball milled magnesium alloy powder; secondly, an electric cold isostatic press is used to adjust the constant external pressure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com