Preparation and application of high strength anti-tear magnetic hydrogel

A magnetic water and anti-tearing technology, applied in the direction of magnetism and catheter of organic materials/organic magnetic materials, can solve the problems of high hardness, limited application, large friction, etc., and achieve excellent mechanical properties, easy operation, and repeatability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

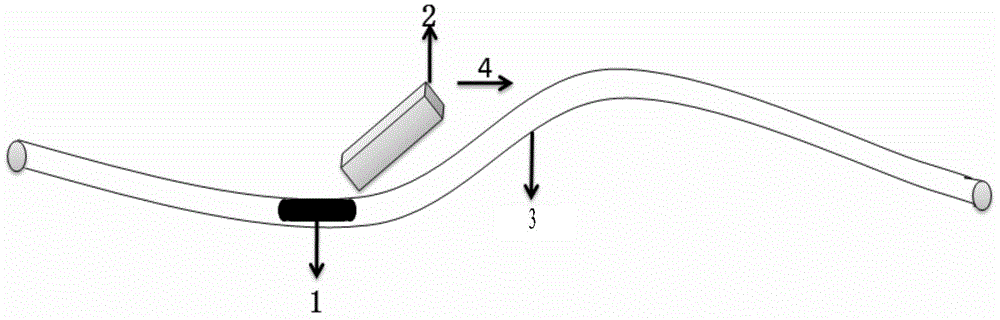

Image

Examples

Embodiment 1

[0024] This embodiment includes the following steps:

[0025] Step 1: First, dissolve the powder of acrylamide and sodium alginate in sodium alginate@Fe 3 o 4 In the magnetic fluid, the above solution was carefully stirred for 1 h to obtain a uniform black magnetic fluid; then, N, N-methylenebisacrylamide crosslinking agent and ammonium persulfate initiator were added in sequence, and the Fe 3 o 4 Nanoparticles account for 5.0wt% of the total weight of the hydrogel, the weight ratio of acrylamide and sodium alginate is 8:1, the total weight of acrylamide monomer and sodium alginate accounts for 14wt% of the total weight of the hydrogel, N, The molar ratio of N-methylenebisacrylamide to acrylamide monomer is 0.028%, and the molar ratio of ammonium persulfate to acrylamide monomer is 0.031%; the prepared solution is transferred to a glass mold, and then the mold Put it into a 50°C water bath and heat it for 6h to form a gel to obtain Fe 3 o 4 @Sodium alginate-polyacrylamide...

Embodiment 2

[0029] This embodiment includes the following steps:

[0030] Step 1: First, dissolve the powder of acrylamide and sodium alginate in sodium alginate@Fe 3 o 4 In the magnetic fluid, the above solution was carefully stirred for 1 h to obtain a uniform black magnetic fluid; then, N, N-methylenebisacrylamide crosslinking agent and ammonium persulfate initiator were added in sequence, and the Fe 3 o 4 Nanoparticles account for 10.0wt% of the total weight of the hydrogel, the weight ratio of acrylamide and sodium alginate is 8:1, the total weight of acrylamide monomer and sodium alginate accounts for 16wt% of the total weight of the hydrogel, N, The molar ratio of N-methylenebisacrylamide to acrylamide monomer is 0.028%, and the molar ratio of ammonium persulfate to acrylamide monomer is 0.031%; the prepared solution is transferred to a glass mold, and then the mold Put it into a 50°C water bath and heat it for 6h to form a gel to obtain Fe 3 o 4 @Sodium alginate-polyacrylamid...

Embodiment 3

[0034] This embodiment includes the following steps:

[0035] Step 1: First, dissolve the powder of acrylamide and sodium alginate in sodium alginate@Fe 3 o 4 In the magnetic fluid, the above solution was carefully stirred for 1 h to obtain a uniform black magnetic fluid; then, N, N-methylenebisacrylamide crosslinking agent and ammonium persulfate initiator were added in sequence, and the Fe 3 o 4 Nanoparticles account for 5.0% of the total weight of the hydrogel, the weight ratio of acrylamide and sodium alginate is 6:1, the total weight of acrylamide monomer and sodium alginate accounts for 10wt% of the total weight of the hydrogel, N, N - The molar ratio of methylenebisacrylamide to acrylamide monomer is 0.028%, and the molar ratio of ammonium persulfate to acrylamide monomer is 0.031%; the prepared solution is transferred to a glass mold, and then the mold is placed Put it into a 50°C water bath and heat it for 6h to form a gel, and get Fe 3 o 4 @Sodium alginate-polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com