A kind of preparation method of superhydrophobic superlipophilic ultralight sponge

A super-lipophilic and super-hydrophobic technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of high cost of chemical modification reagents, cumbersome process, and increased preparation and use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

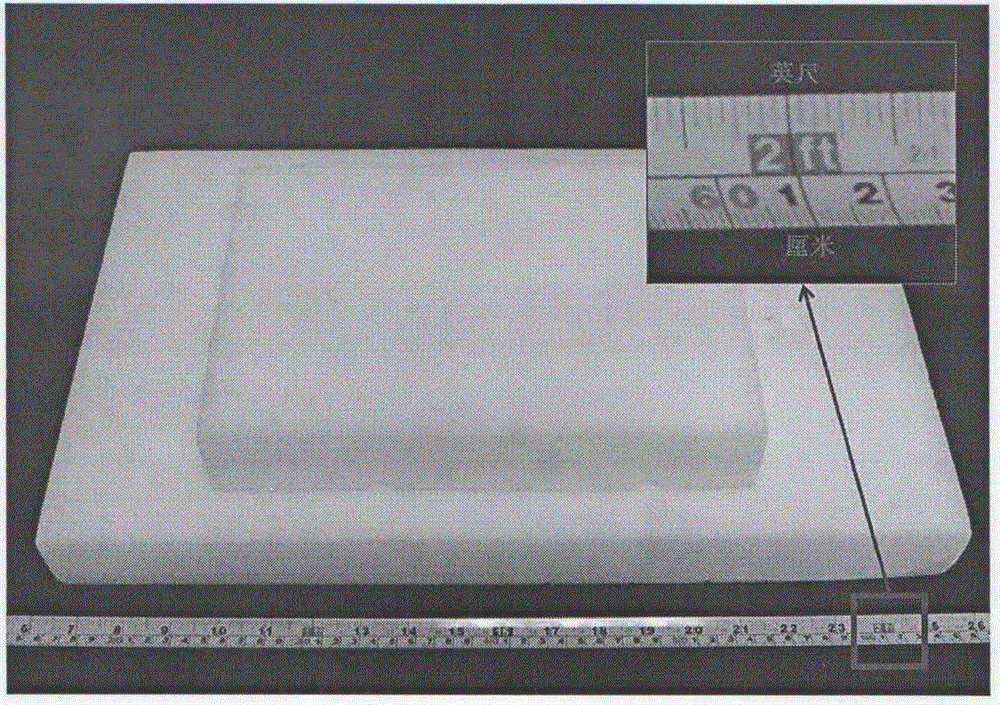

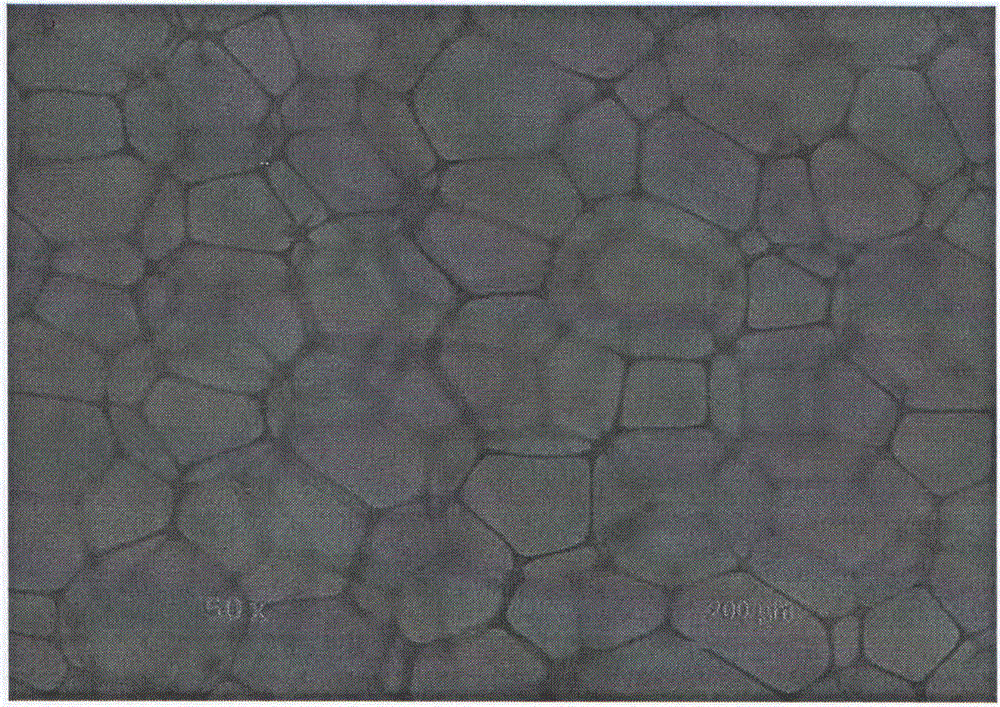

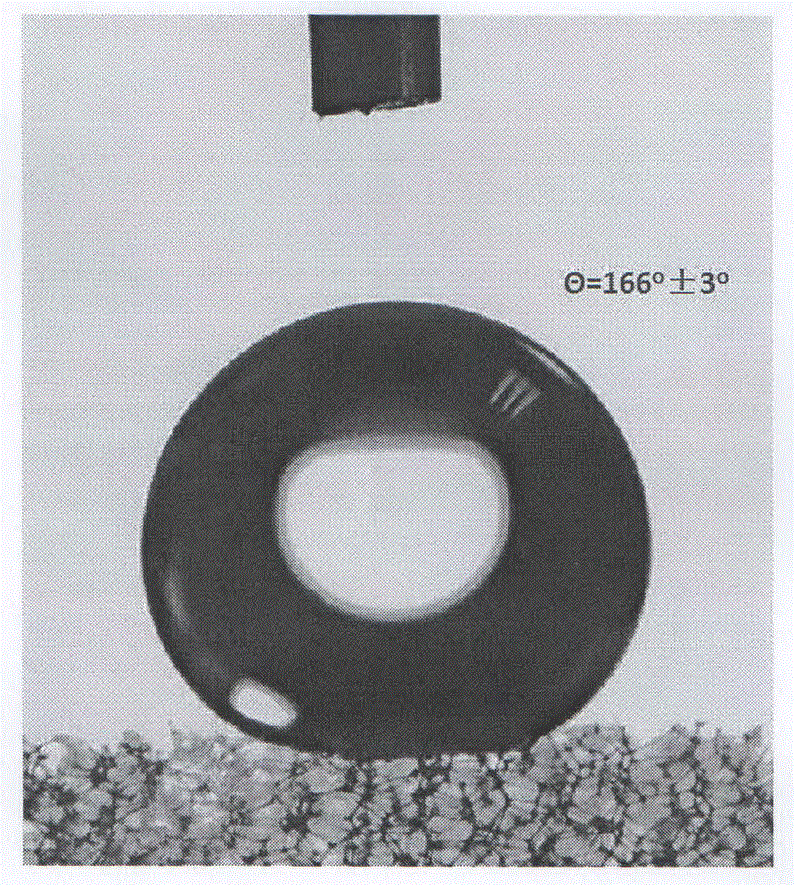

Embodiment 1

[0019] a. Preparation of binary siloxane hydrolysis system: The hydrolysis system of binary siloxane is dimethyldimethoxysilane containing difunctional alkoxysilane and tetramethoxysilane with tetrafunctional alkoxysilane , methanol-water system with pH=10; the mass of dimethyldimethoxysilane and tetramethoxysilane accounts for 1.5% of the mass of the hydrolysis system, and the mass of dimethyldimethoxysilane accounts for 0.5% of the mass of the hydrolysis system %, the quality of tetramethoxysilane accounts for 1% of the hydrolysis system; the quality of methanol-water accounts for 98.5% of the hydrolysis system, wherein methanol accounts for 88.5% of the hydrolysis system quality, and water accounts for 10% of the hydrolysis system quality; Sodium hydroxide adjusts the pH of the hydrolysis system to 10; hydrolyze the prepared binary siloxane system at a temperature of 50°C for 6 hours to obtain a binary siloxane hydrolysis system for use; among them, sodium hydroxide can be r...

Embodiment 2

[0023] a. Preparation of binary siloxane hydrolysis system: The hydrolysis system of binary siloxane is diethyldiethoxysilane containing difunctional alkoxysilane and tetraethoxysilane containing tetrafunctional alkoxysilane And pH = 8 ethanol-water system; the quality of diethyldiethoxysilane and tetraethoxysilane accounted for 9% of the hydrolysis system quality, wherein the quality of diethyldiethoxysilane accounted for 3% of the hydrolysis system %, the quality of tetraethoxysilane accounts for 6% of the hydrolysis system; the quality of ethanol-water accounts for 91% of the hydrolysis system, wherein ethanol accounts for 71% of the hydrolysis system quality, and water accounts for 20% of the hydrolysis system quality; Ethylenediamine adjusts the pH of the hydrolysis system to 8, and hydrolyzes the prepared binary siloxane system at a temperature of 60°C for 2 hours to obtain a binary siloxane hydrolysis system for use; among them, ethylenediamine can be replaced by ethylam...

Embodiment 3

[0027]a. Preparation of the binary siloxane hydrolysis system: the hydrolysis system of the binary siloxane contains trifunctional alkoxysilane as methyltriethoxysilane and tetrafunctional alkoxysilane as tetrapropoxysilane and Ethanol-water system with pH=3; the quality of methyltriethoxysilane and tetrapropoxysilane accounts for 0.6% of the mass of the hydrolysis system, wherein the quality of methyltriethoxysilane accounts for 0.2% of the hydrolysis system, four The quality of propoxysilane accounts for 0.4% of the hydrolysis system; the quality of ethanol-water accounts for 99.4% of the hydrolysis system, wherein ethanol accounts for 94.4% of the hydrolysis system quality, and water accounts for 5% of the hydrolysis system quality; pH=3; hydrolyze the prepared binary siloxane system at a temperature of 40°C for 12 hours to obtain a binary siloxane hydrolysis system for use; among them, methyltriethoxysilane can be replaced by methyltrimethoxy Silane, hydrochloric acid can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com