Patents

Literature

52results about How to "Reduce plugging rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

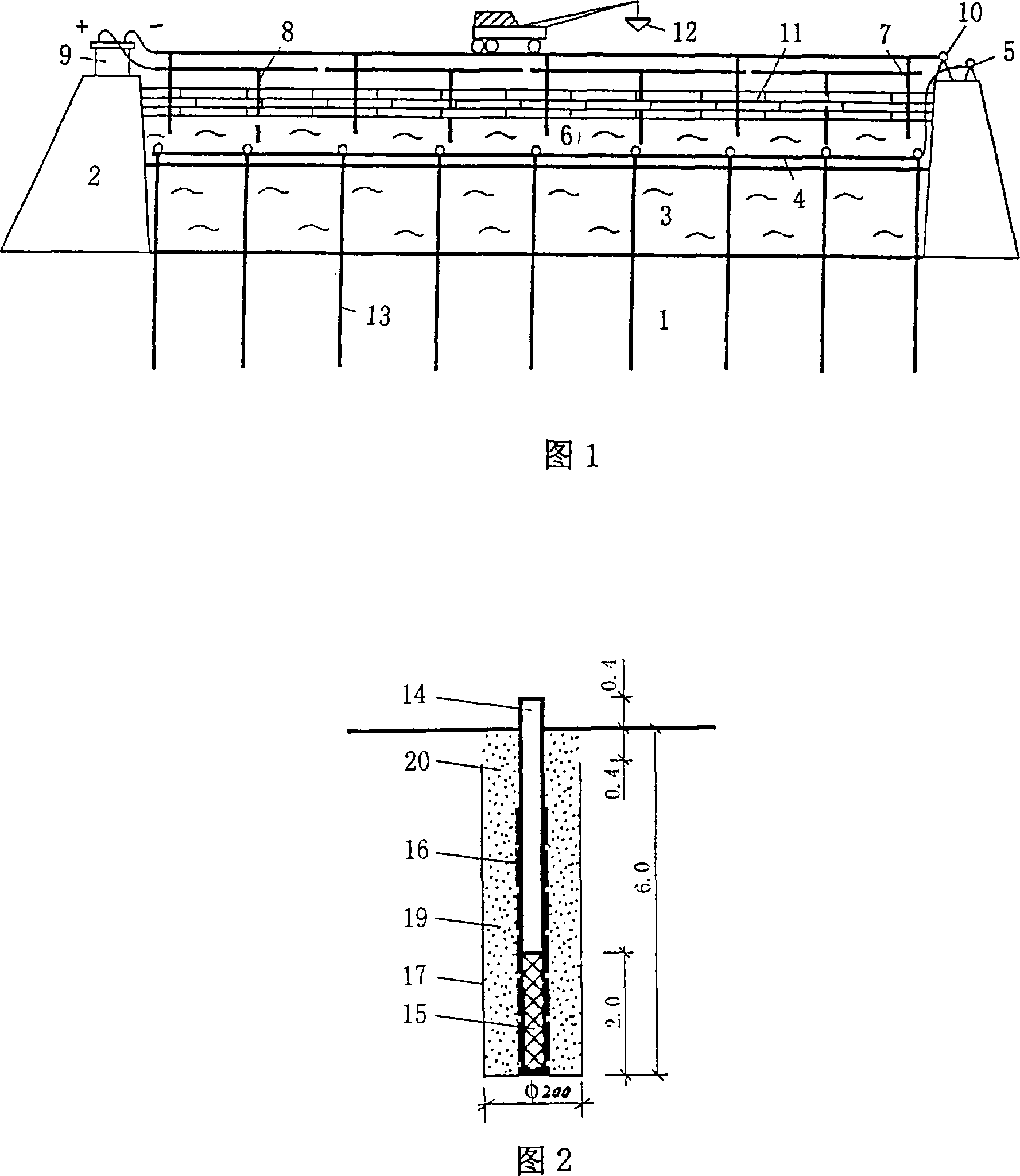

Method for double-vacuum self-loading prepressing and earthwork composite filling low-energy strong-ramming reinforcing soft soil

InactiveCN101100852ALow costEliminate recharge phenomenonSoil preservationMaterials sciencePrecipitation

A ground reinforce procedure includes the steps of: A. low position vacuum self-loading pre-press; B. vacuum well point precipitation; C. vacuum electroosmosis precipitation and complex stuffing paving simultaneously; D. low power strong tamp; E. vibrate rolling; F. smoothing.

Owner:张志铁 +1

Deep hole blasting filling method

The invention discloses a deep hole blasting filling method. The deep hole blasting filling method includes the steps that the bottom of a blast hole is filled and blocked with cement, and meanwhile the bottom resistance line is reserved; a pre-designed amount of first explosive is loaded to the bottom of the blast hole, and meanwhile a first double-detonator and detonating cord igniting explosive package and a first detonator are loaded into the blast hole along with the first explosive; the position on the top of the first explosive is filled with an appropriate amount of river sand; a pre-designed amount of second explosive is continuously loaded to the top of the river sand, and meanwhile a second double-detonator and detonating cord igniting explosive package and a second detonator are loaded into the blast hole along with the second explosive; after all the explosive is loaded into the blast hole, the top of the second explosive is filled with fine river sand, and then two water bags are hoisted into the blast hole and press on the top of the fine river sand. The deep hole blasting filling method solves the problems that according to an original filling scheme, the number of plug holes is large and a large amount of dust is generated.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿

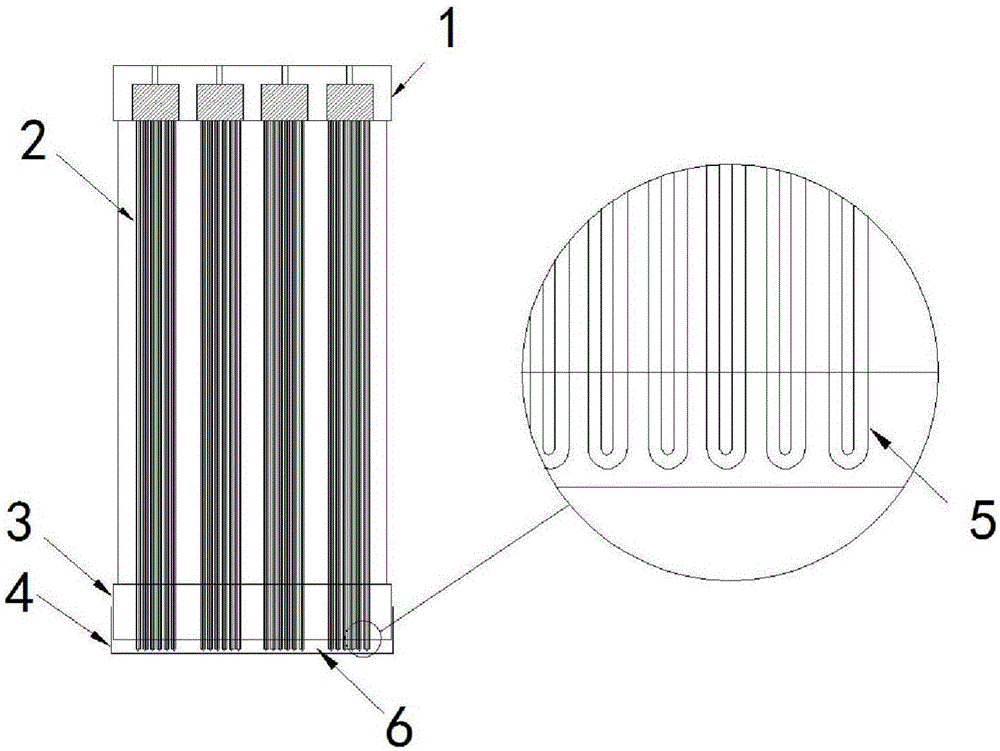

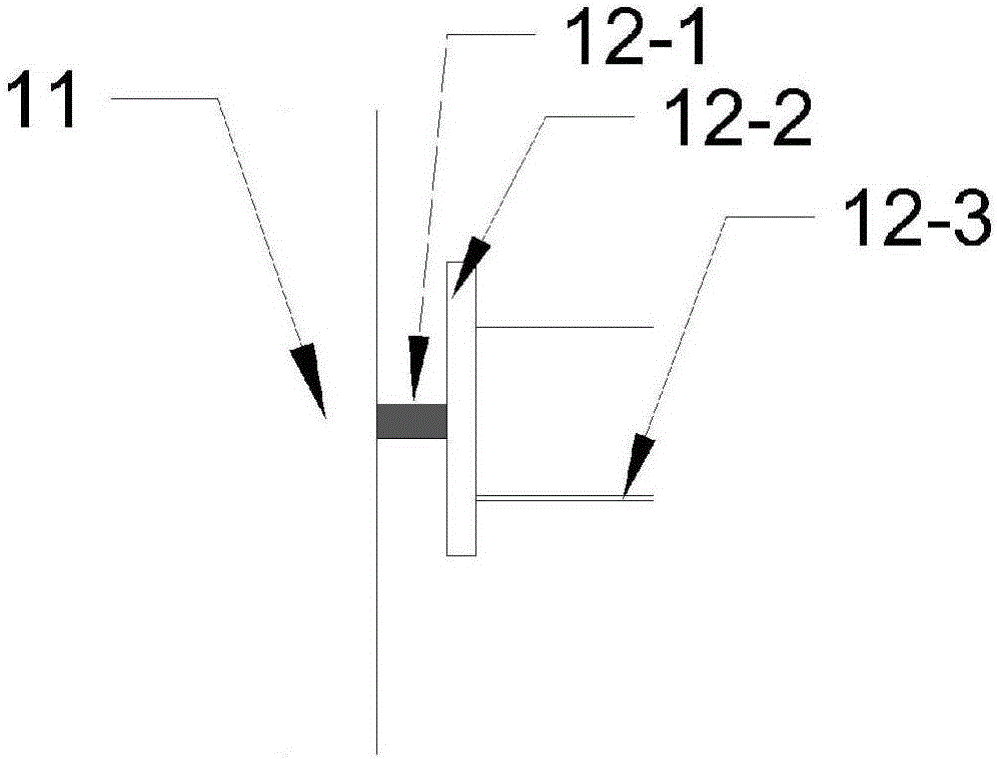

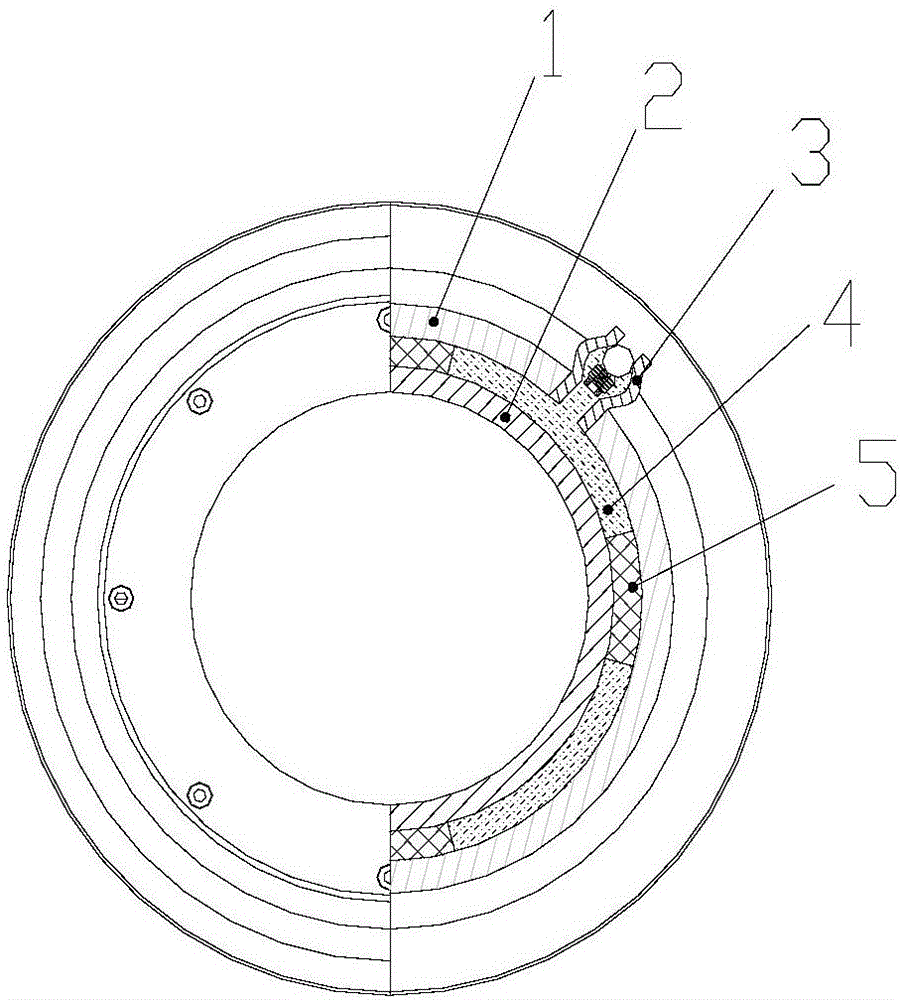

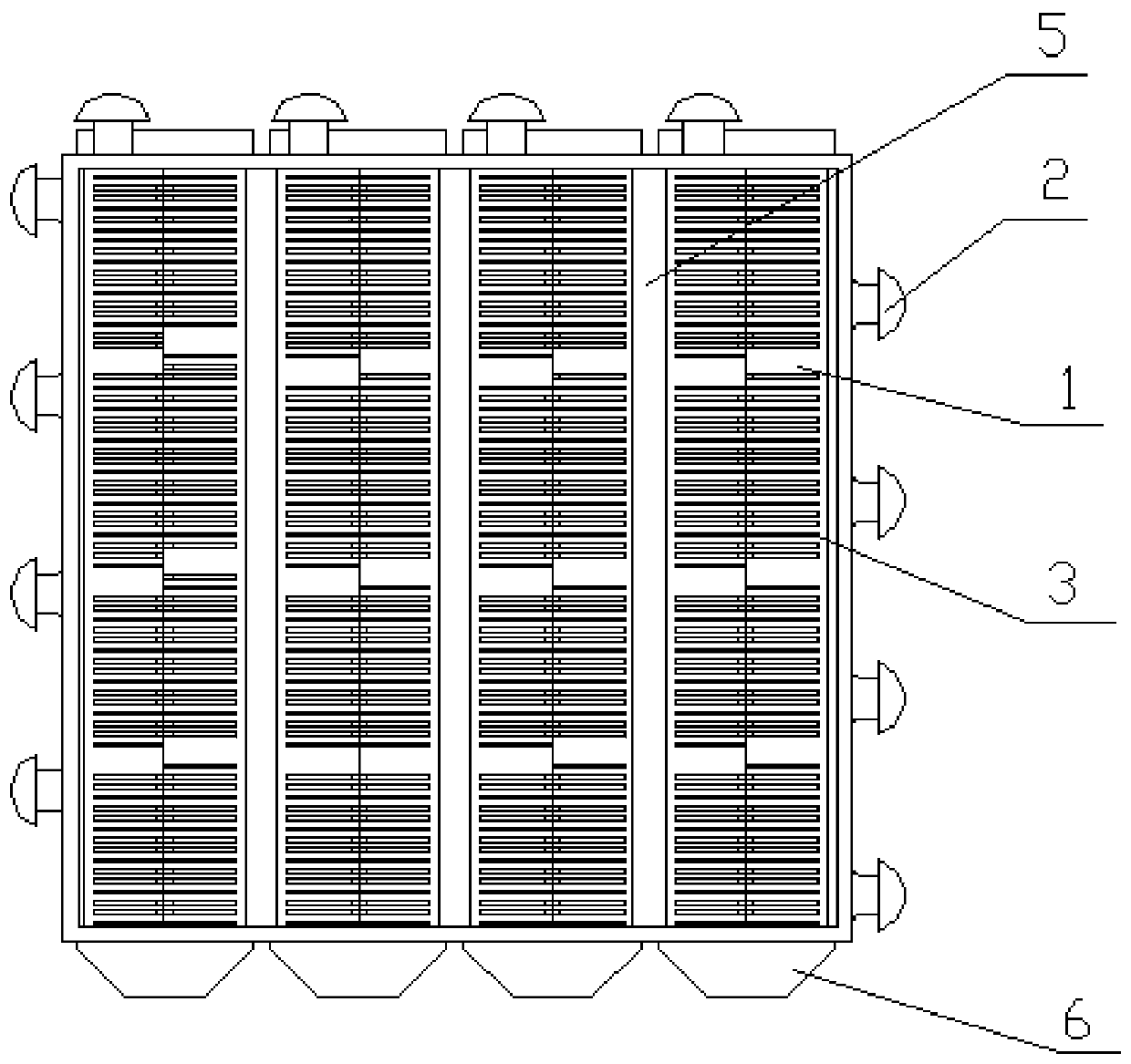

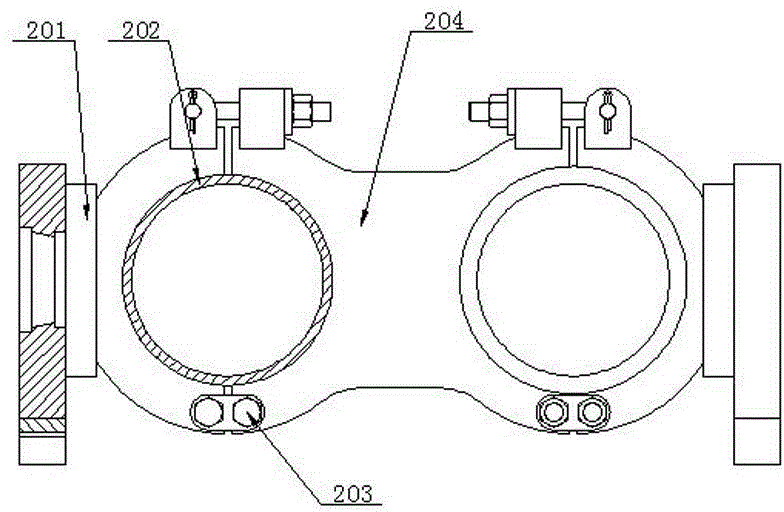

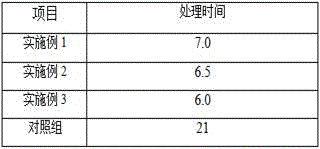

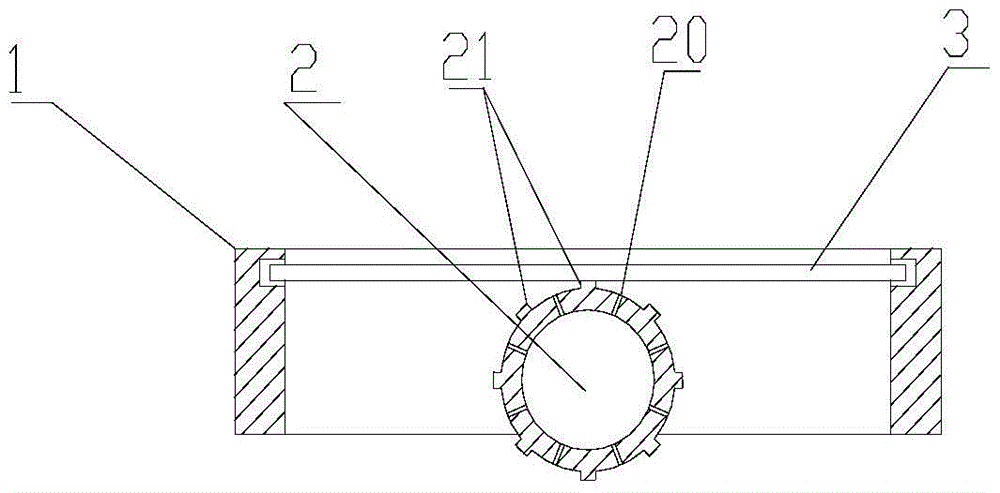

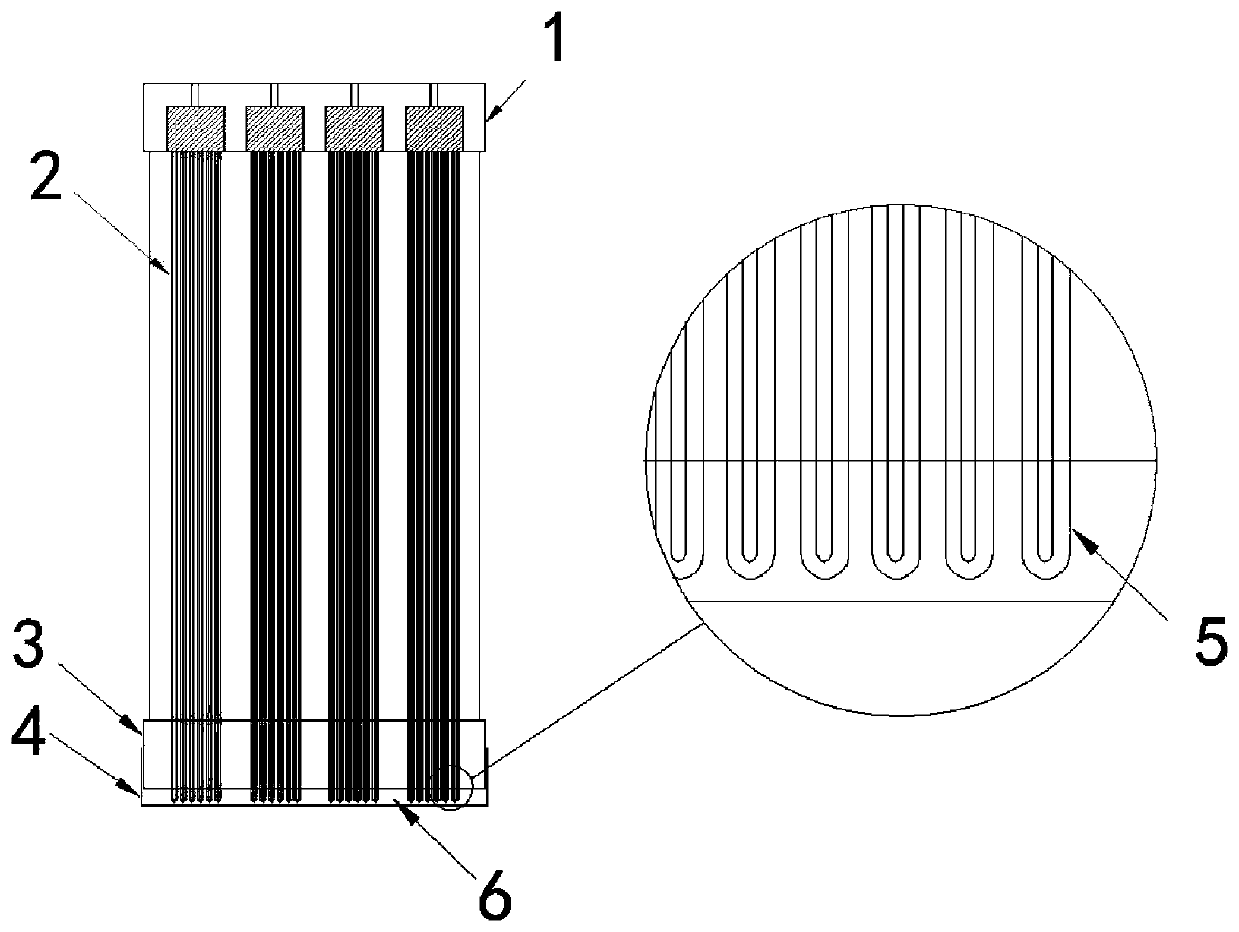

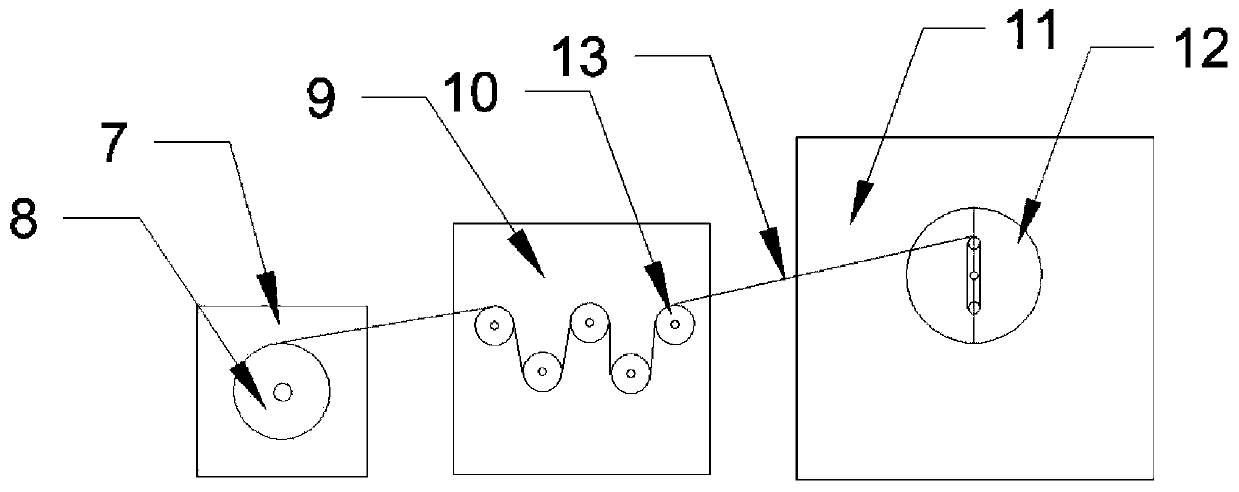

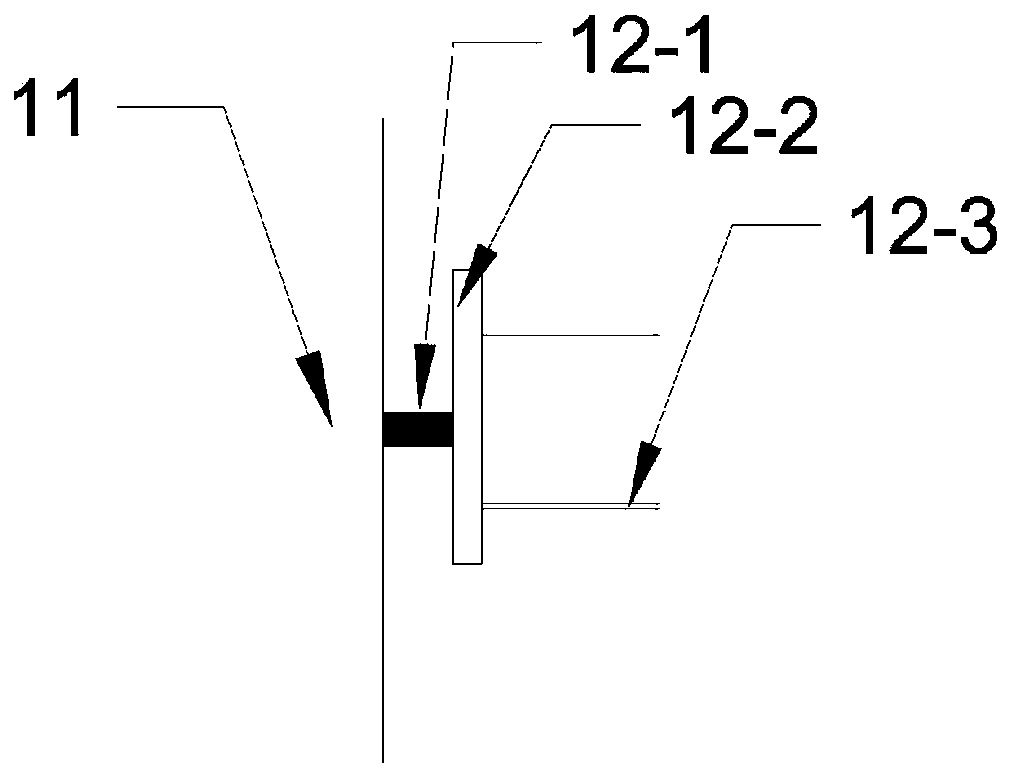

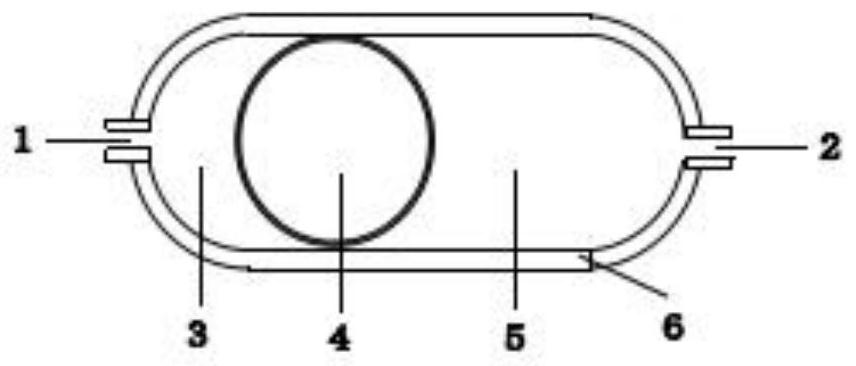

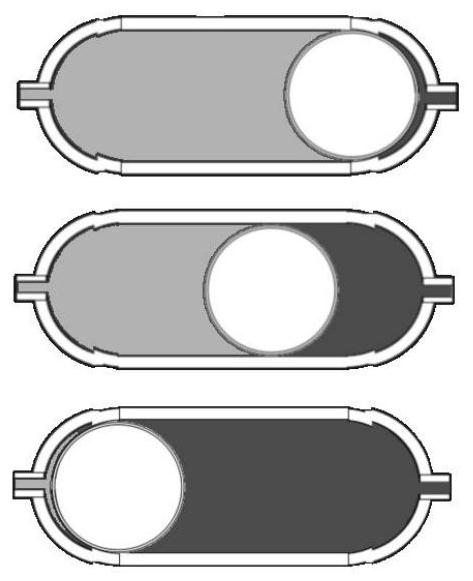

Columnar hollow fiber membrane module manufacturing method and columnar hollow fiber membrane module manufacturing device

ActiveCN106362595AIncrease profitReduce plugging rateSemi-permeable membranesUltimate tensile strengthCost savings

The invention belongs to the technical field of separation membranes and relates to a columnar hollow fiber membrane module manufacturing method and a columnar hollow fiber membrane module manufacturing device. The method includes steps: manufacturing of U-shaped membrane filament bundles, to be more specific, winding hollow fiber membrane filaments to form the U-shaped membrane filament bundles in required length, wherein the head of one end of each U-shaped membrane filament bundle is bent; glue injection, to be more specific, subjecting the U-shaped membrane filament bundles to single-end (the other ends of the bent heads) glue injection to form independent pouring unit bundles; assembly, to be more specific, fixing the pouring unit bundles into membrane shells (pressure type membrane modules) or membrane frames (immersed modules); glue feeding and pouring, to be more specific, directly mounting glue injection end caps at the U-shaped ends of the bent heads of the pouring unit bundles to perform glue feeding and pouring; solidifying and cutting, to be more specific, after glue solidification, cutting glue surfaces to perforate membrane filaments, so that membrane module manufacturing is finished. The columnar hollow fiber membrane module manufacturing method and the columnar hollow fiber membrane module manufacturing device have advantages that hollow fiber membrane filament utilization rate and membrane module pouring and end sealing quality in a columnar hollow fiber membrane module manufacturing process are increased, and membrane filament blockage rate is decreased; work intensity is relieved, and efficiency improvement, cost saving, simplicity and convenience are achieved.

Owner:BEIJING ORIGIN WATER FILM TECH

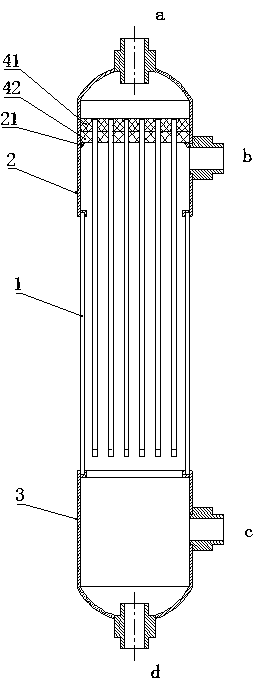

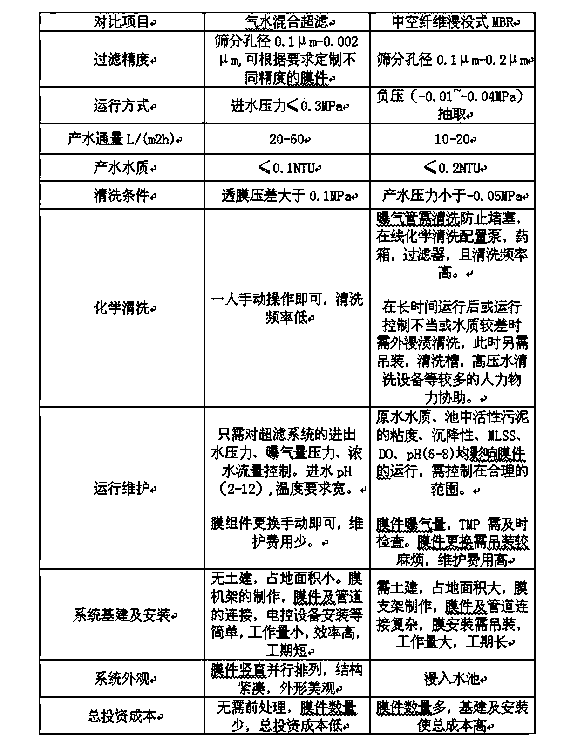

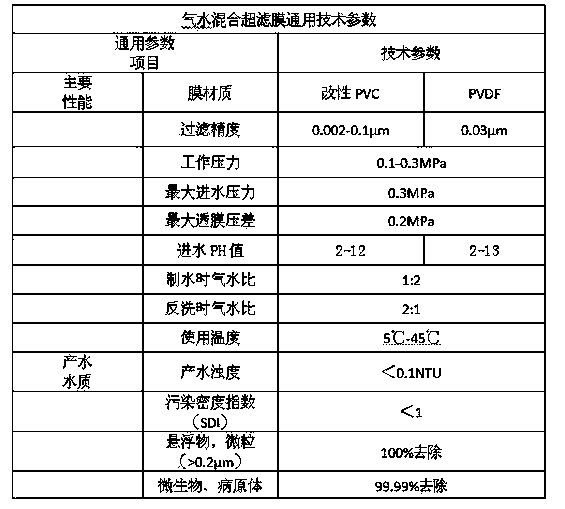

Gas-water mixed membrane ultrafiltration device

InactiveCN103739113AWell mixedReduce plugging rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical oxygen demandUltrafiltration

The invention relates to a gas-water mixed membrane ultrafiltration device, which is innovated in that a housing is formed by connecting the upper and lower ends of a cylinder to upper and lower end sockets, respectively, the upper end socket is provided with a filtered water outlet and a gas-water mixed outlet, the lower end socket is provided with a sewage inlet and an aeration opening, an adhesive layer is located between the filtered water outlet and the gas-water mixed outlet of the upper end socket, an ultrafiltration membrane bundle is composed of a plurality of tubular ultrafiltration membranes which are distributed evenly, the upper ends of the tubular ultrafiltration membranes are fixed in the housing by the adhesive layer, the upper-end tubular mouths of the ultrafiltration membranes are communicated with an upper chamber, and the lower-end tubular mouths of the ultrafiltration membranes are plugged. The gas-water mixed membrane ultrafiltration device has the advantages that during working, filtering is carried out by using external pressure, and simultaneously, aeration is realized through the aeration opening, so that gas and sewage are in a high-frequency and sufficient contact oxidization state, as a result, COD (Chemical Oxygen Demand) in the sewage can be reduced, and in the meantime, the ultrafiltration membranes swing under double action of the water flow and the gas flow, and high cross flow operation causes the probability of polluting substances being attached on membrane filaments to block holes to be greatly reduced, and moreover, the attachment action of the pollutants on the membrane filaments is reduced.

Owner:NANTONG BEICHEN MACHINERY EQUIP MFGCO

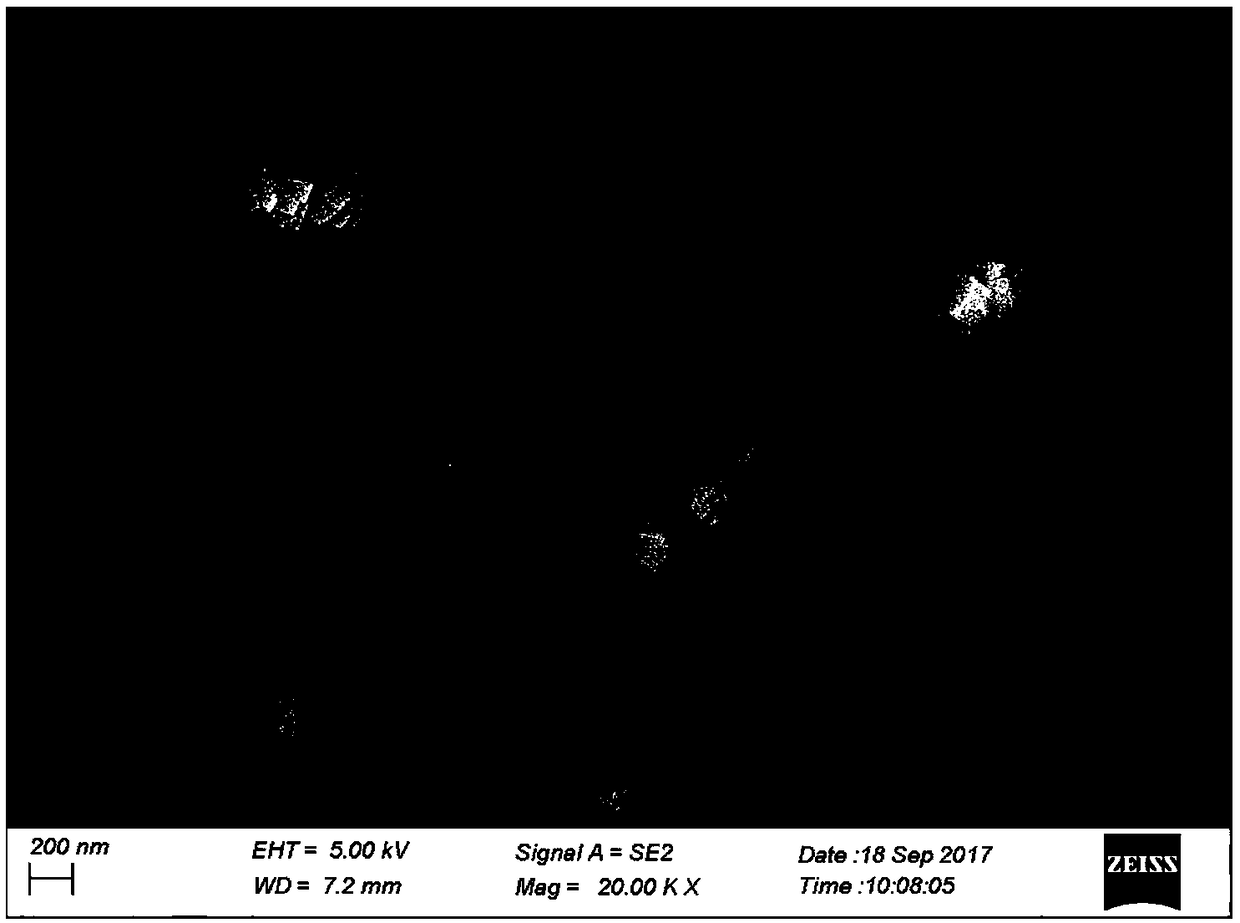

Porous membrane and lithium ion battery

ActiveCN110364667AImprove adhesionReduce plugging rateSecondary cellsNegative electrodesPhysical chemistryPorous membrane

The invention provides a porous membrane and a lithium ion battery. The porous membrane provided by the invention has excellent cohesiveness, and the pore structure of the porous membrane can be wellmaintained after being soaked in an electrolyte, so that the probability of pore blockage of the porous membrane is reduced, the lithium ion battery has high ion conductivity, the dynamic performanceof the lithium ion battery is greatly improved, and the provided lithium ion battery has the excellent rate capability and cycle performance.

Owner:NINGDE AMPEREX TECH

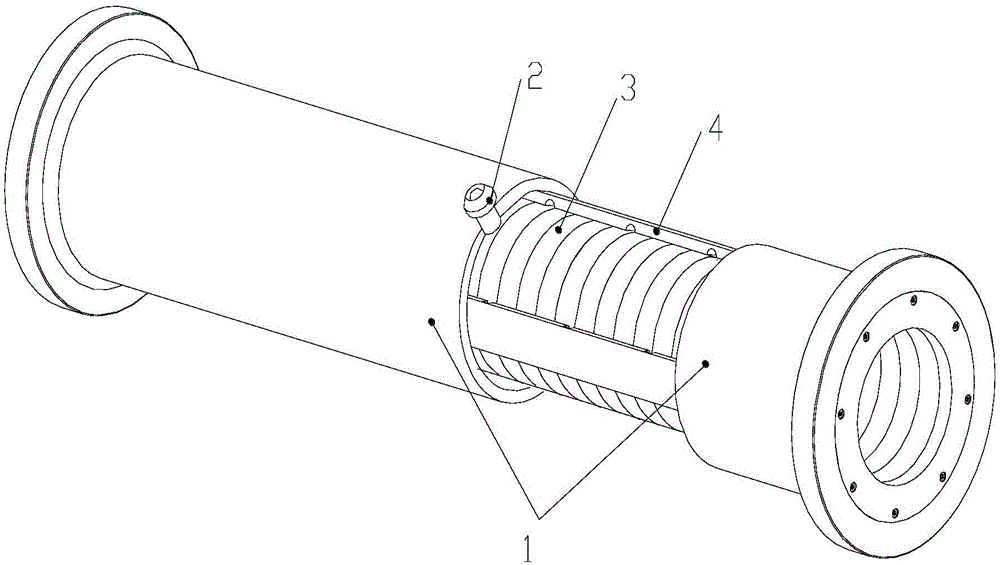

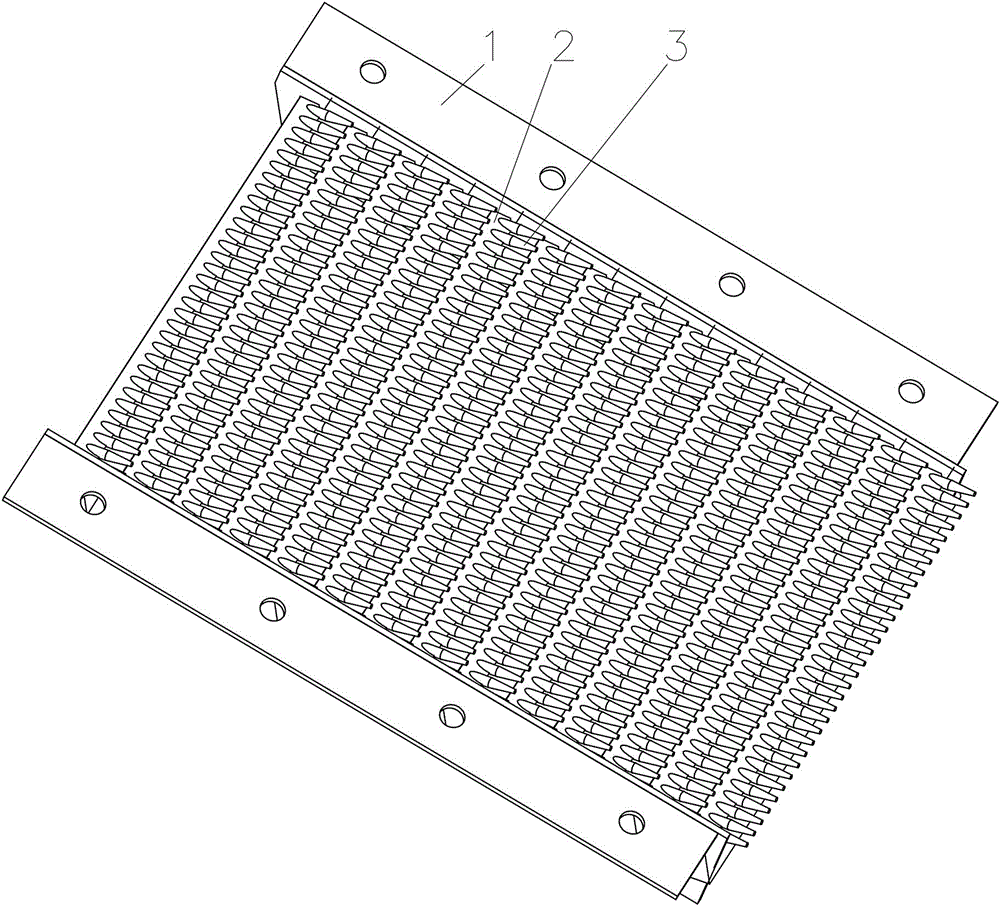

Elastic-inner-wall anti-plugging concrete high-pressure delivery pump pipe and application method thereof

ActiveCN106049877AContinuous movementSmooth motionBuilding material handlingOuter CannulaHigh pressure

The invention discloses an elastic-inner-wall anti-plugging concrete high-pressure delivery pump pipe and an application method thereof. The pump pipe comprises an outer sleeve, an inner sleeve arranged in the outer sleeve, a plurality of elastic supports and an oil injecting nozzle. The inner sleeve is made from closely-winding spiral pipes, a gap is formed between the inner sleeve and the outer sleeve so that an annular cavity can be formed between the inner sleeve and the outer sleeve, and the two ends of the inner sleeve are connected with the two ends of the outer sleeve in a sealed mode; the multiple elastic supports are arranged between the inner sleeve and the outer sleeve in the axial direction so that the annular cavity is divided into a plurality of arc cavities, and an elastic-support oil hole for being communicated with the adjacent two arc cavities is formed in each elastic support; an outlet of the oil injecting nozzle is communicated with the annular cavity. By means of the elastic-inner-wall anti-plugging concrete high-pressure delivery pump pipe and the application method thereof, the occurrence probability of concrete pipe plugging is effectively reduced through self-adaption deformation of the inner sleeve and injection of lubrication media.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

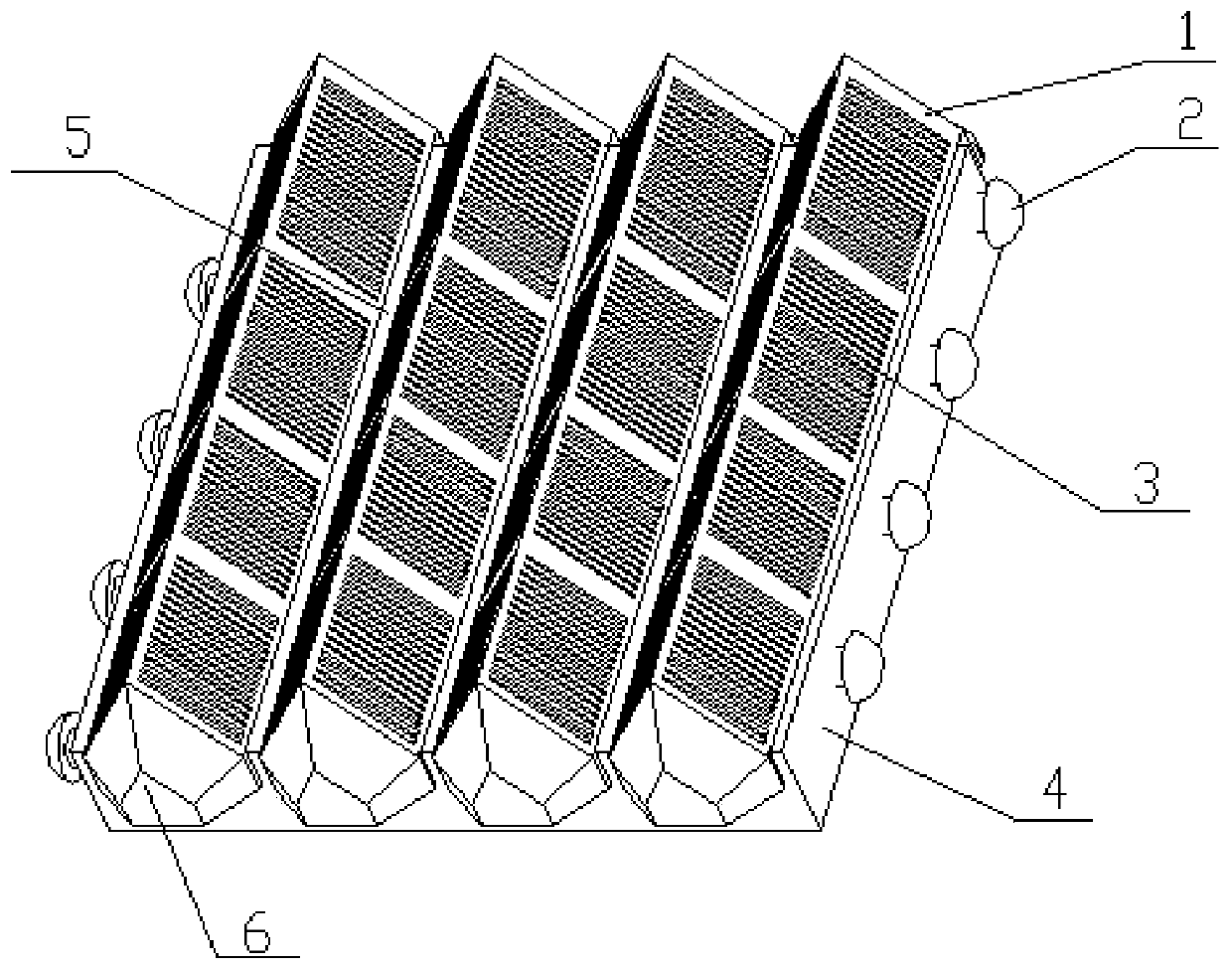

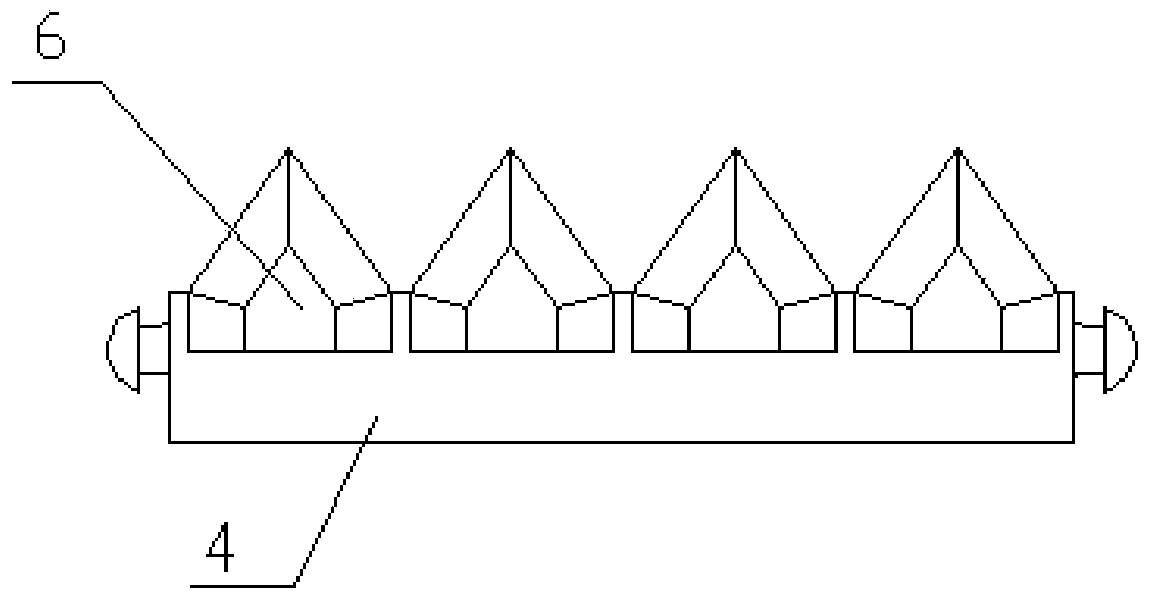

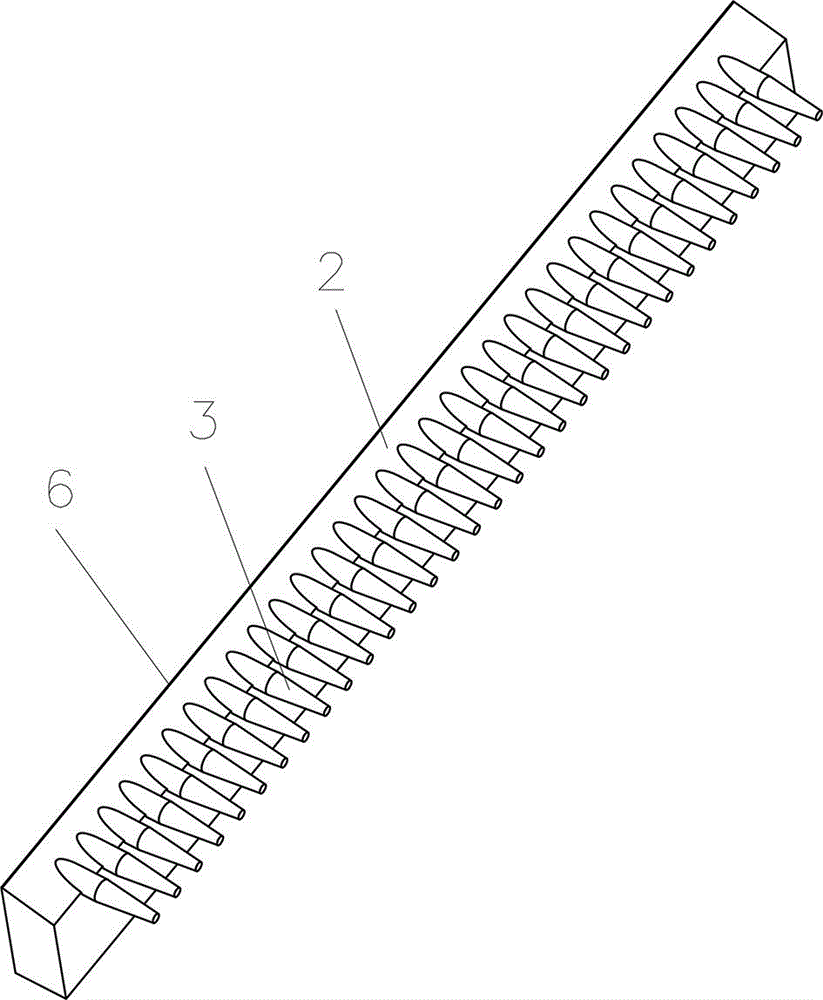

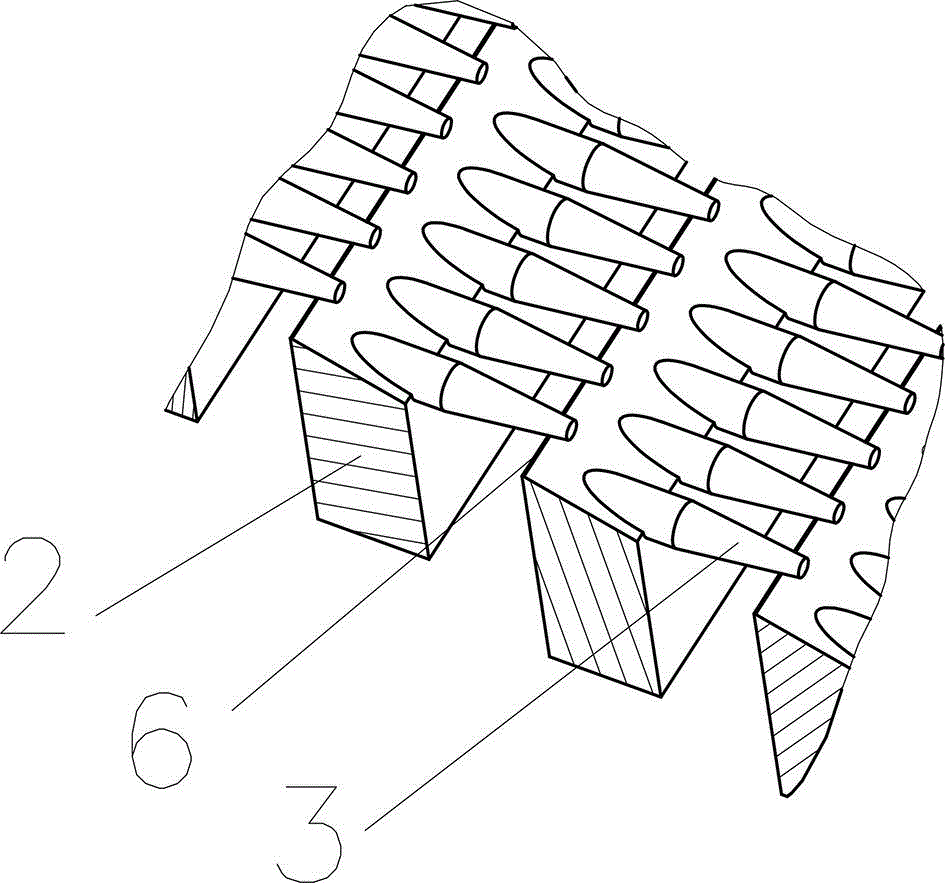

Wave-shaped sieve plate and production processes thereof

PendingCN110116090AMultiple contact opportunitiesIncrease sieving rateSievingScreeningWave shapePulp and paper industry

The invention provides a wave-shaped sieve plate which comprises a sieve plate mounting seat and a plurality of sieve plate modules; each sieve plate module is fixed on the sieve plate mounting seat and comprises a base and a plurality of sieve plate units; each base and the plurality of sieve plate units are integrally formed; the plurality of sieve plate units are arranged at the upper end of each base side by side; each sieve plate unit is of a long triangular body structure with an upward tip; sieve holes with same number and shape are uniformly distributed on the two sides of the tips; and a flow guide channel is formed between every two adjacent sieve plate units. The invention also provides two production processes, namely a casting process and an injection molding process. Comparedwith a sieve plate with a similar size, for the wave-shaped sieve plate, the aperture ratio of the sieve plate is multiplied by a wave-shaped sieve surface, so that the production efficiency of sieving machinery, particularly the efficiency of a dehydration sieving machine, is greatly improved; and the special tip structure of each module vibrates along with the sieving machine to exert the effect of loosening a material bed layer from the bottom, so that adjustment of the bed layer structure and material advancing are assisted to a certain extent, and the probability of hole blocking and thelabor cost for cleaning and maintaining are reduced.

Owner:莫图泰克筛分系统(天津)有限公司

Honeycombed catalyst and preparation method and application thereof

ActiveCN108889295AIncrease upload volumeReduce the chance of sheddingGas treatmentHeterogenous catalyst chemical elementsSlurryChemistry

The invention discloses a honeycombed catalyst and a preparation method and application thereof. The preparation method includes the step of applying SCR (selective catalytic reduction) catalyst slurry to honeycombed ceramics after electromagnetic shock dispersion. With the method, the honeycombed catalyst with high uploading rate, low expulsion rate and low blocking rate is obtained.

Owner:BAOTOU RES INST OF RARE EARTHS +1

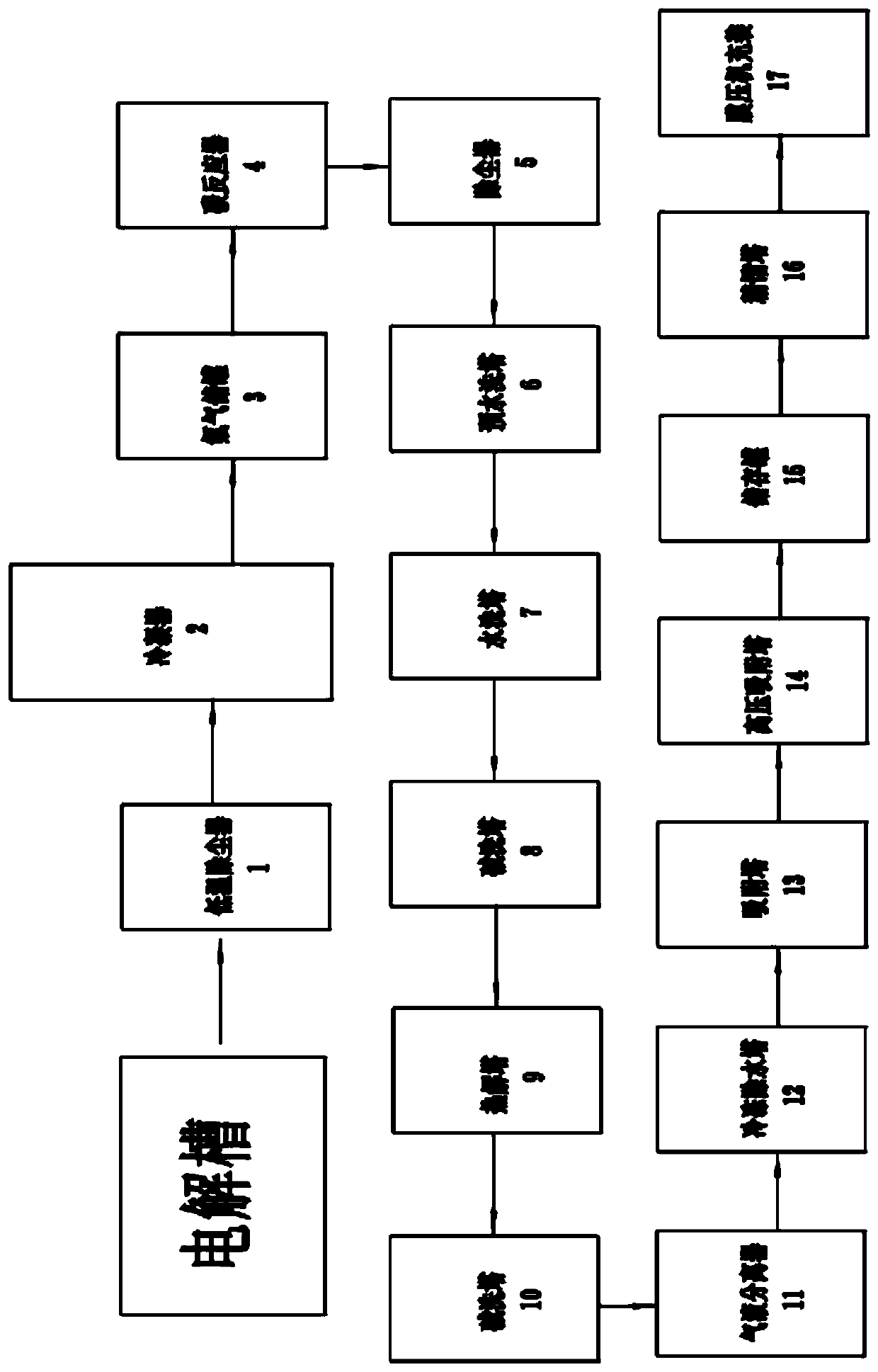

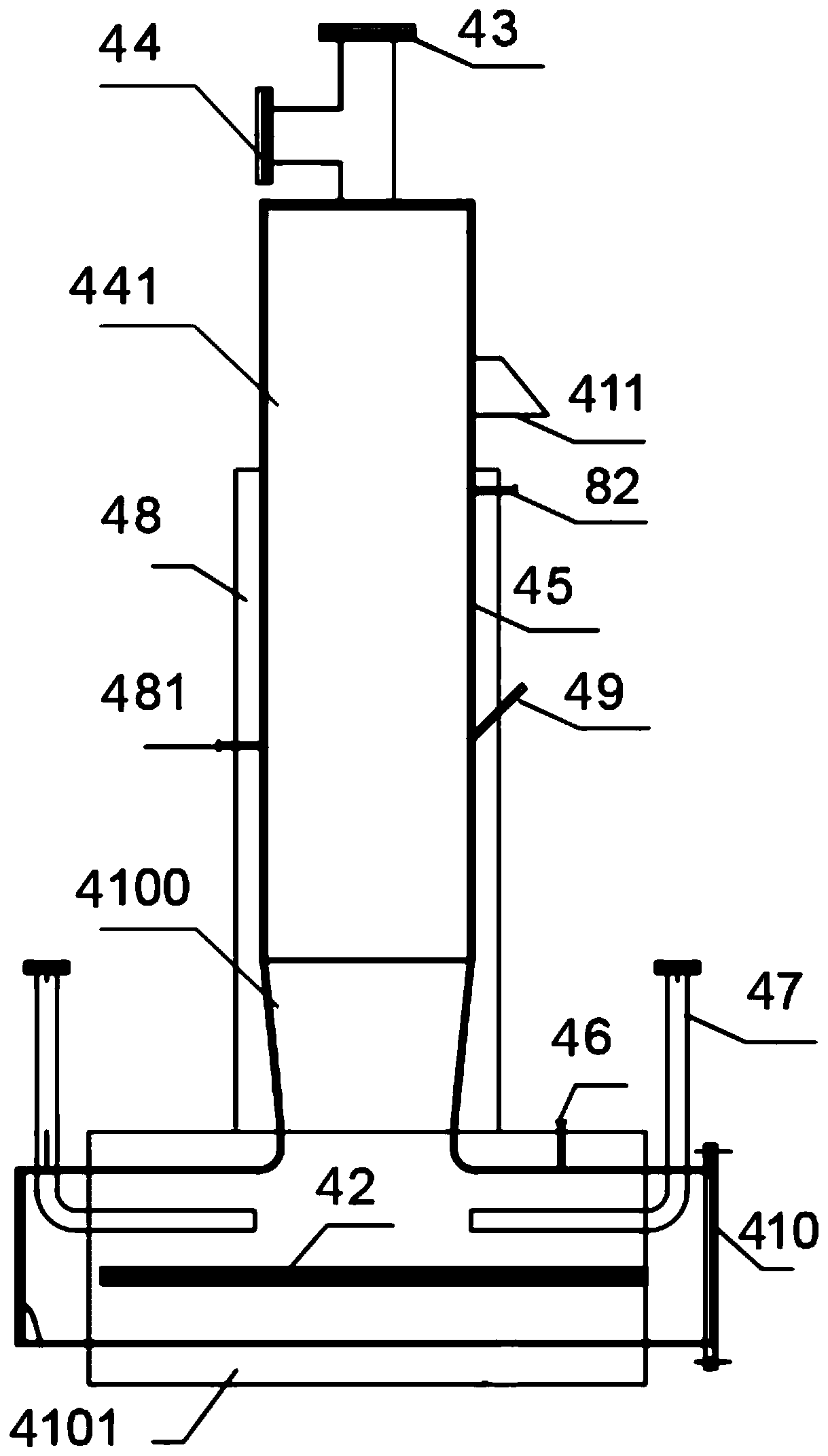

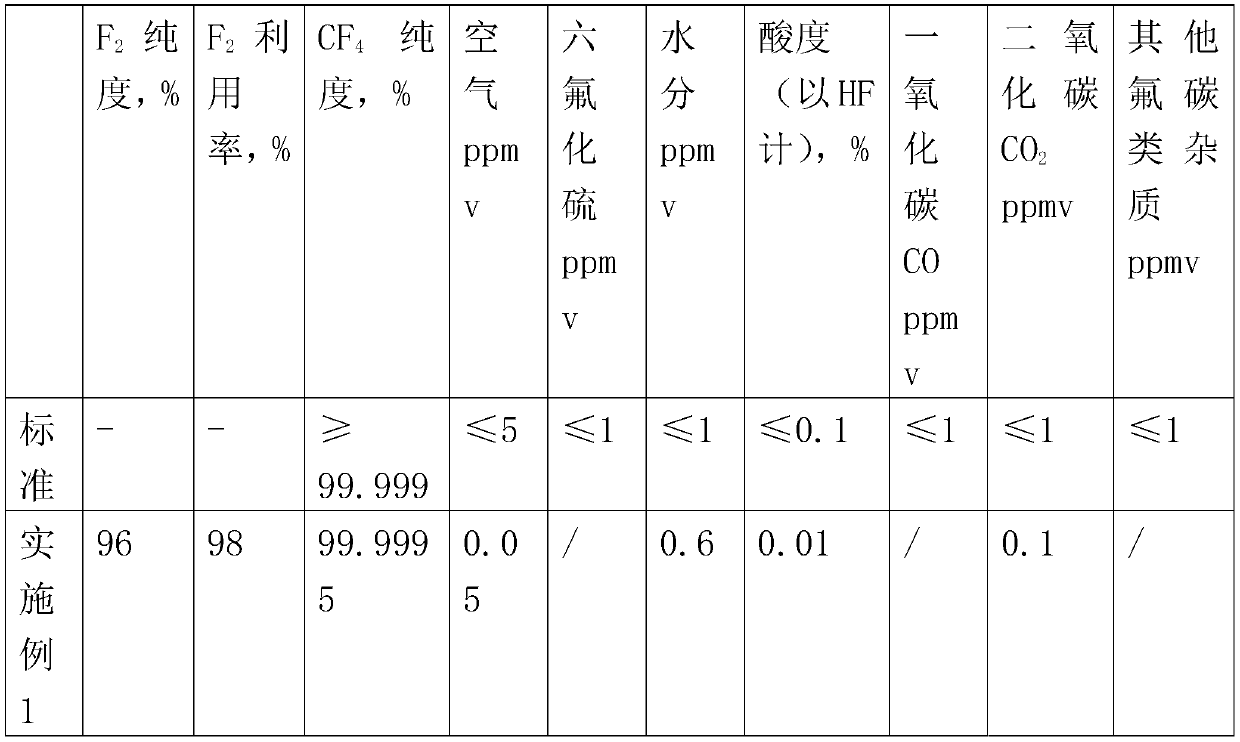

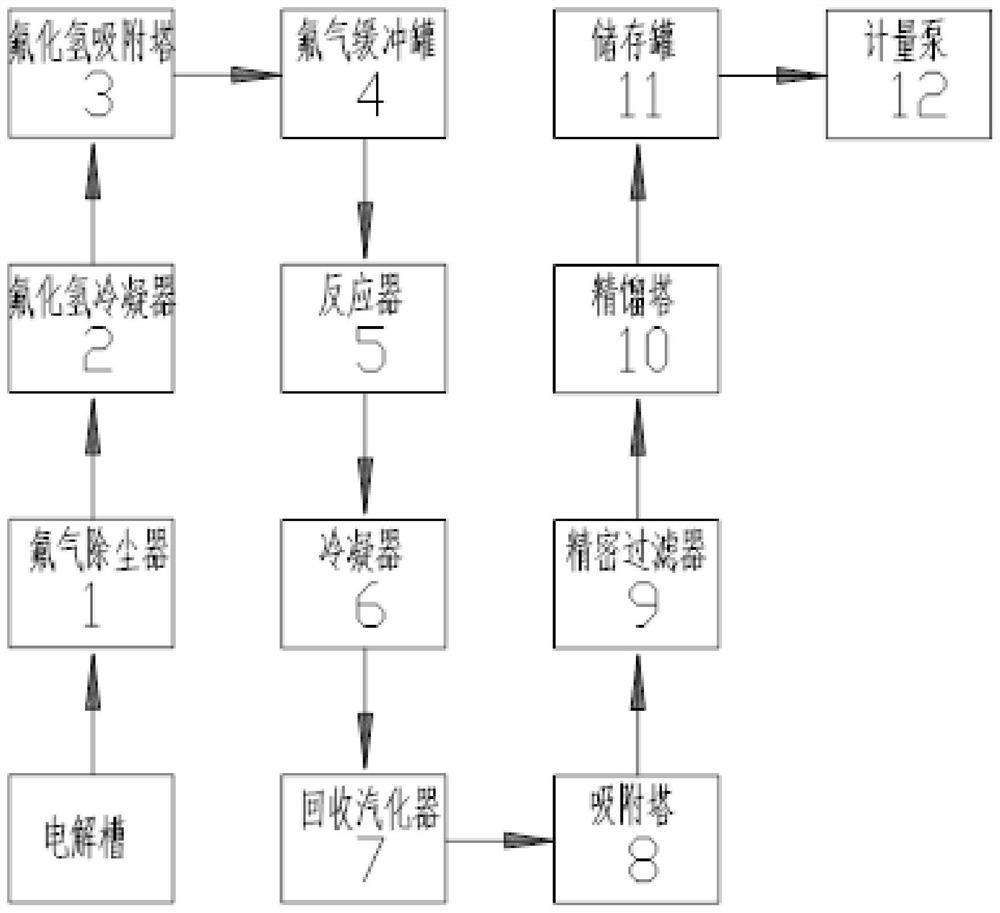

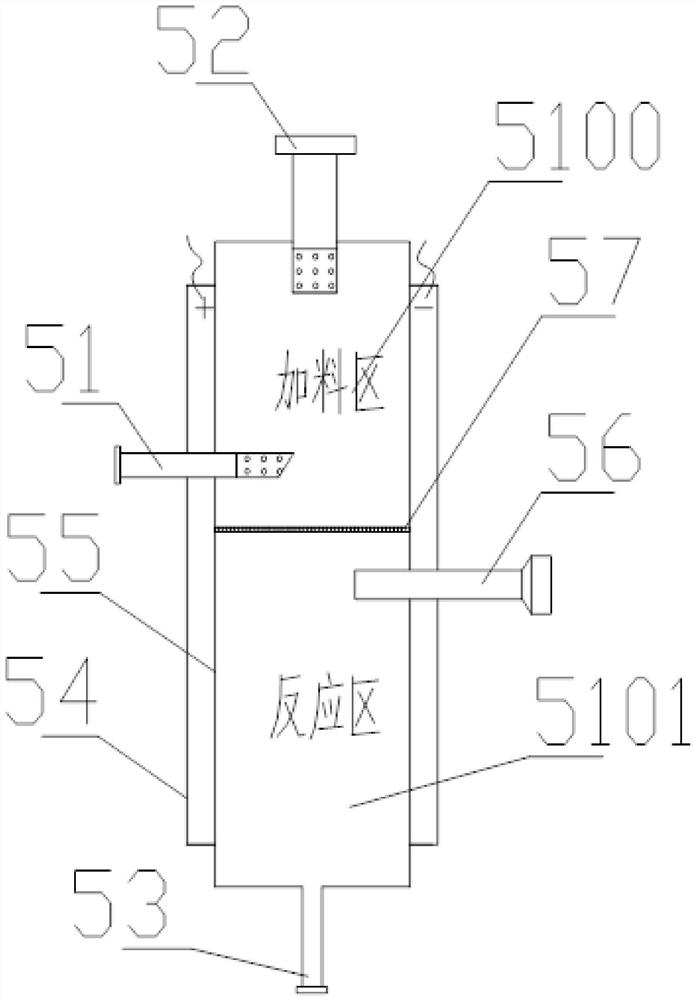

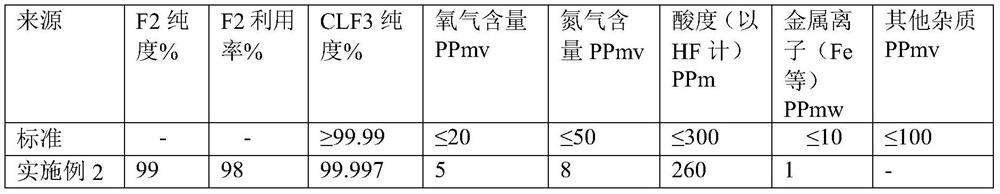

Preparation system and method of electronic-grade carbon tetrafluoride

ActiveCN111039749AEfficient removalReduce plugging rateElectrolysis componentsHalogenated hydrocarbon separation/purificationHydrogen fluorideCarbon monofluoride

The invention provides a preparation system of electronic-grade carbon tetrafluoride. The system comprises a fluorine gas source, a reaction device and a purification system, wherein the fluorine gassource is hermetically connected with the reaction device; and the reaction device is hermetically connected with the purification system; the fluorine gas source comprises an electrolytic cell, a low-temperature dust remover 1, a condenser 2 and a fluorine gas buffer tank 3; the electrolytic cell is provided with an automatic system; the feeding mode is liquid level interlocking automatic feeding; a hydrogen fluoride emptying device is arranged at the bottom end of the condenser; the reaction device comprises a carbon reactor and a dust removal device; and the carbon reactor further comprisesa secondary reactor. The invention further provides a preparation method of the electronic-grade carbon tetrafluoride. By using the above system in preparing the carbon tetrafluoride, the fluorine gas utilization rate is 98% or above.

Owner:FUJIAN DEER TECH CORP

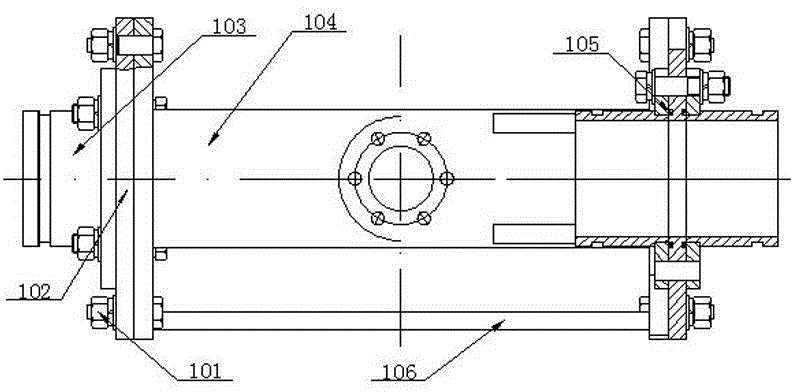

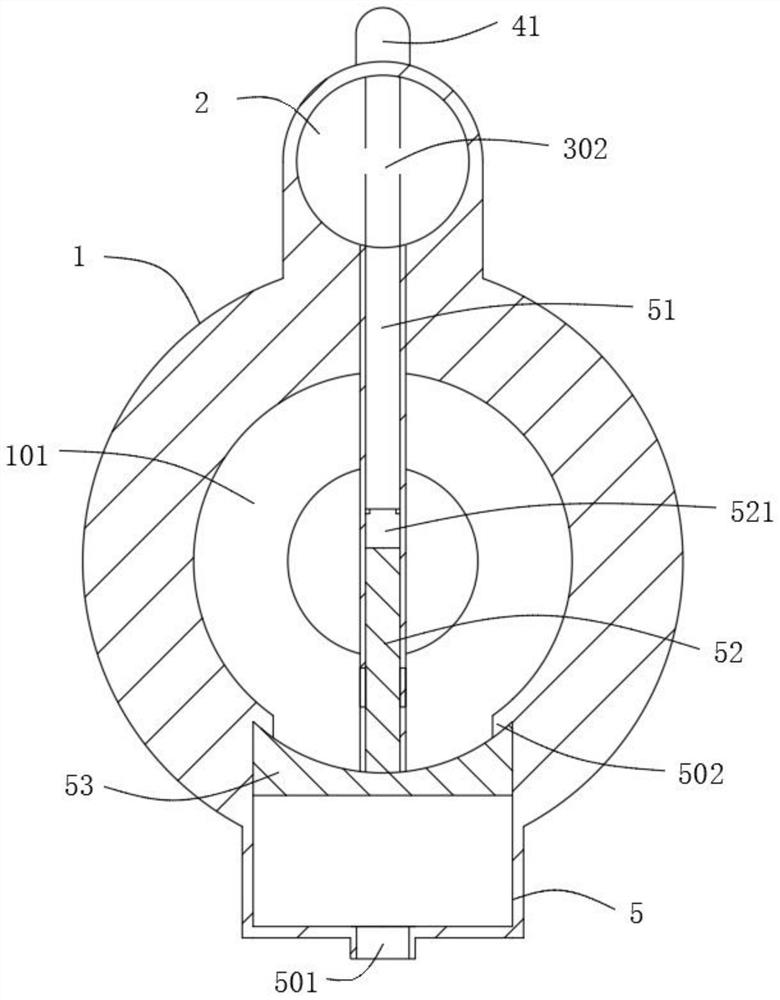

Tube sealing injection device avoiding venous indwelling needle blockage

InactiveCN104208770AControl propulsion speedPrevent seepageInfusion syringesInfusion devicesVeinGynecology

The invention relates to a tube sealing injection device avoiding venous indwelling needle blockage. The tube sealing injection device comprises an injection needle head with a connecting hose, a hollow tube body and a hollow piston-like structure, a nipple structure is arranged at one end of the hollow tube body, an internal thread is arranged on the inner surface of the hollow tube body, accurate volume scales are uniformly formed on the outer surface of the hollow tube body at intervals, an accurate external thread is arranged on the outer surface of the piston-like structure, the nipple structure and the other end of the connecting hose are hermetically and coaxially mounted together in a communicated manner, and the hollow tube body and the piston-like structure are coaxially mounted together by thread engagement. Liquid advance speed can be effectively controlled by the thread structure, stable and low advance speed is beneficial to effective tube sealing and blockage prevention, liquid medicines can be effectively prevented from seeping from the hollow tube body, operation difference of staff can be decreased, and the problems of untight tube sealing, tube blockage and the like caused by operation difference of the staff can be effectively reduced.

Owner:朗思佳(北京)医疗科技开发有限公司

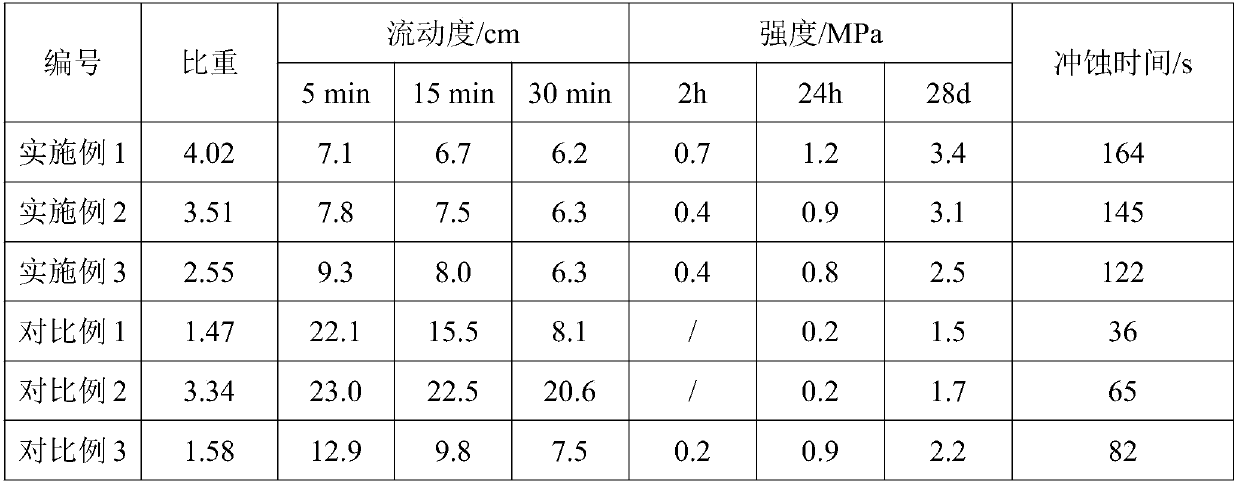

Anti-seepage and reinforcing paste slurry capable of resisting water flow erosion

Anti-seepage and reinforcing paste slurry capable of resisting water flow erosion comprises a clay powder, cement and water, and also comprises a thickening agent, a weight-increasing agent and a tackifier, wherein the thickening agent is water-absorbing resin; the weight-increasing agent is a mixture of at least one of barite powder and iron ore powder and steel sand; the tackifier is vegetable gelatin. The paste slurry has low initial consistence and large specific gravity, avoids separation and layering, has high viscosity and high flowing water erosion resistance, is simple and convenientto slurry, low in cost and easy to operate, and has a wide market prospect.

Owner:湖南宏禹工程集团有限公司

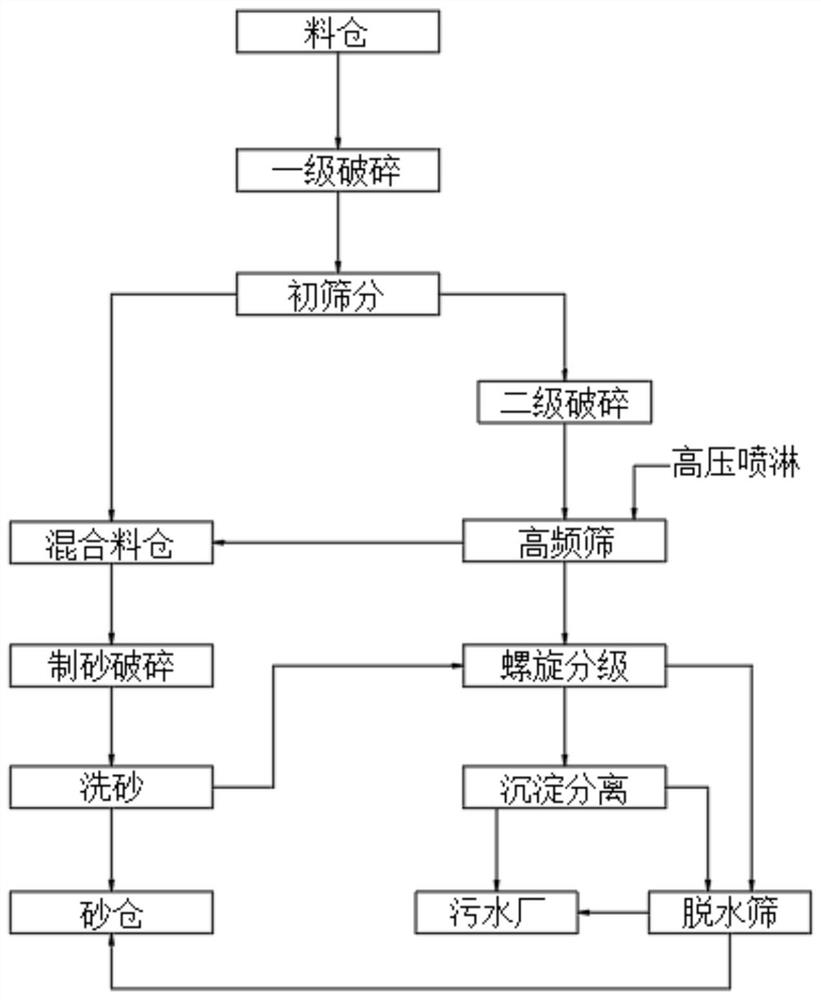

Gravel production process capable of suppressing dust and preventing sand flying under strong wind condition

PendingCN112916181AAvoid it happening againPrevent cavitiesGrain treatmentsWet separationCrushed stoneProcess engineering

The invention provides a gravel production process capable of suppressing dust and preventing sand flying under a strong wind condition. The gravel production process comprises the following steps of: performing primary crushing, performing primary screening after crushing, enabling small stone materials to enter a mixing bin, and enabling large stone materials to enter secondary crushing; conveying the materials subjected to secondary crushing to a high-frequency screen by using a sealing-tape machine, spraying at an outlet of the sealing-tape machine by using a high-pressure spraying pipe, conveying the stone materials on the screen surface to the mixing bin to be mixed with the small stone materials, and enabling screened slurry to enter a spiral classifier to recover gravel; and enabling the mixed stone materials to enter a sand making crusher to be crushed, washing out stone powder by washing sand after crushing, and finally enabling the crushed stone materials to enter a sand bin. By adopting the gravel production process, the generation of flying dust is effectively prevented, the hole blocking probability is greatly reduced, the screening effect and the gravel quality are guaranteed, and energy is saved. By mixing the stone materials, the water content of the feeding materials of the sand making crusher is lower than 2 percent, the cavity blocking of the crusher is prevented, the production efficiency is guaranteed, and the potential safety hazard is reduced.

Owner:SINOHYDRO BUREAU 9

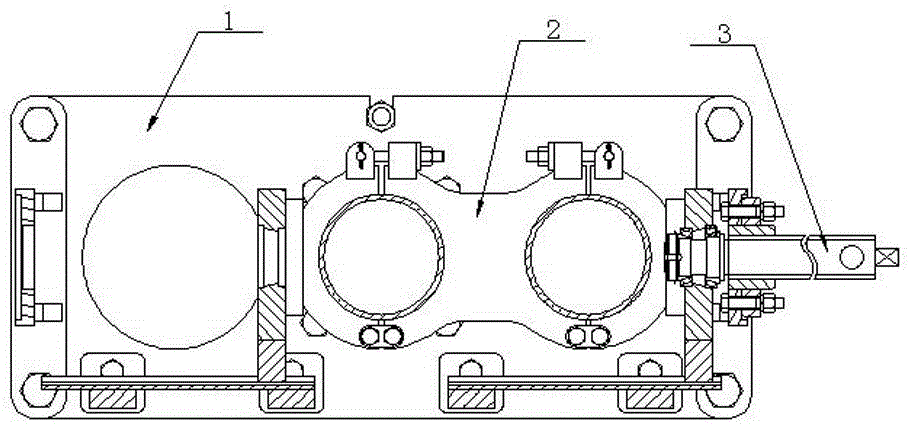

Ball inserting device for concrete pumps

InactiveCN105298129ASolve the difficulty of loading the ballSolve the chipping problemBuilding material handlingEngineeringConcrete pump

The invention discloses a ball inserting device for concrete pumps, and relates to the technical field of construction. The ball inserting device is characterized in that a valve element is mounted in a shell, a power transmission gear is connected with the valve element, a transverse shelf is arranged at the lower end of the shell, a valve plate is connected with a connecting standard pipe and a butting support plate by fasteners, and a sealing ring is arranged on the valve plate; valve element pipes are arranged on a valve element connecting plate, connecting pieces are arranged on a side of each valve element pipe, hoops are arranged at two ends of the valve element connecting plate, nuts are mounted on the butting support plate, and the power transmission gear and the hoop at an end of the valve element are connected with each other to form a rotation pair. The ball inserting device has the advantages that the probability of pipe blocking can be greatly lowered, raw materials can be saved, the ball inserting device is simple and reasonable in structure and can be operated safely, easily and conveniently, and the operation time can be saved.

Owner:王立平

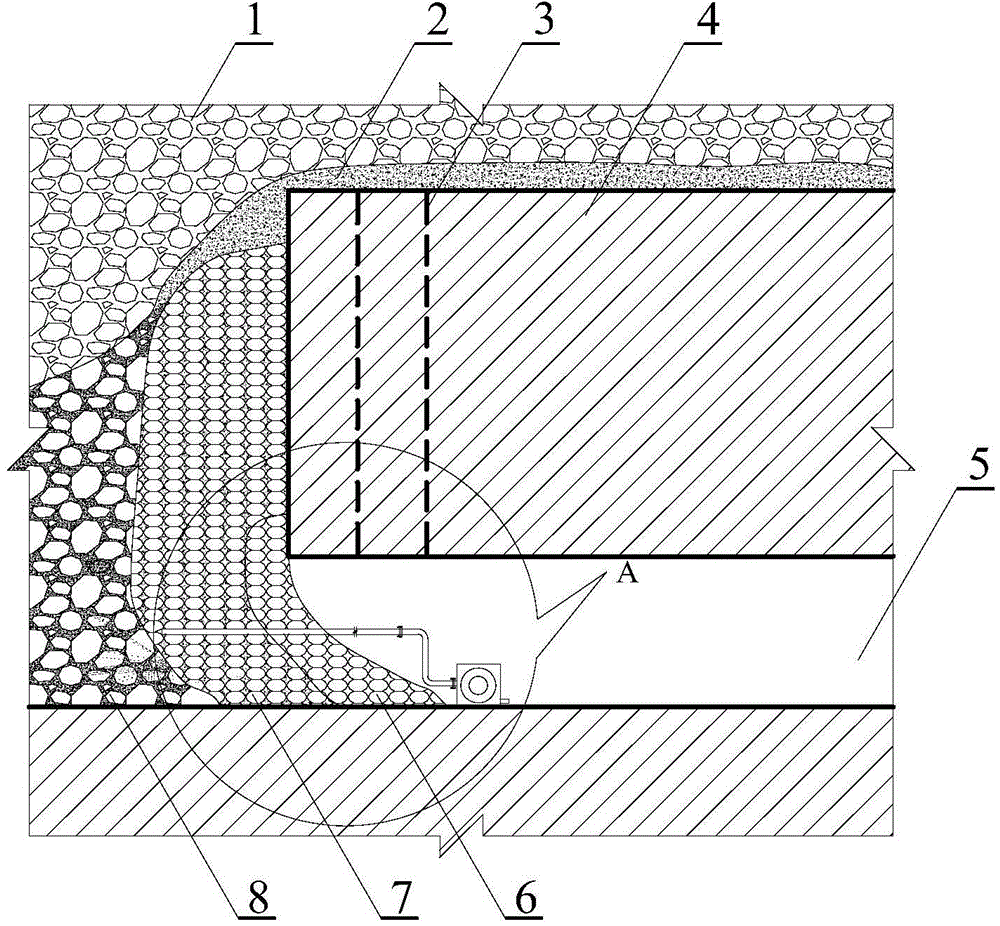

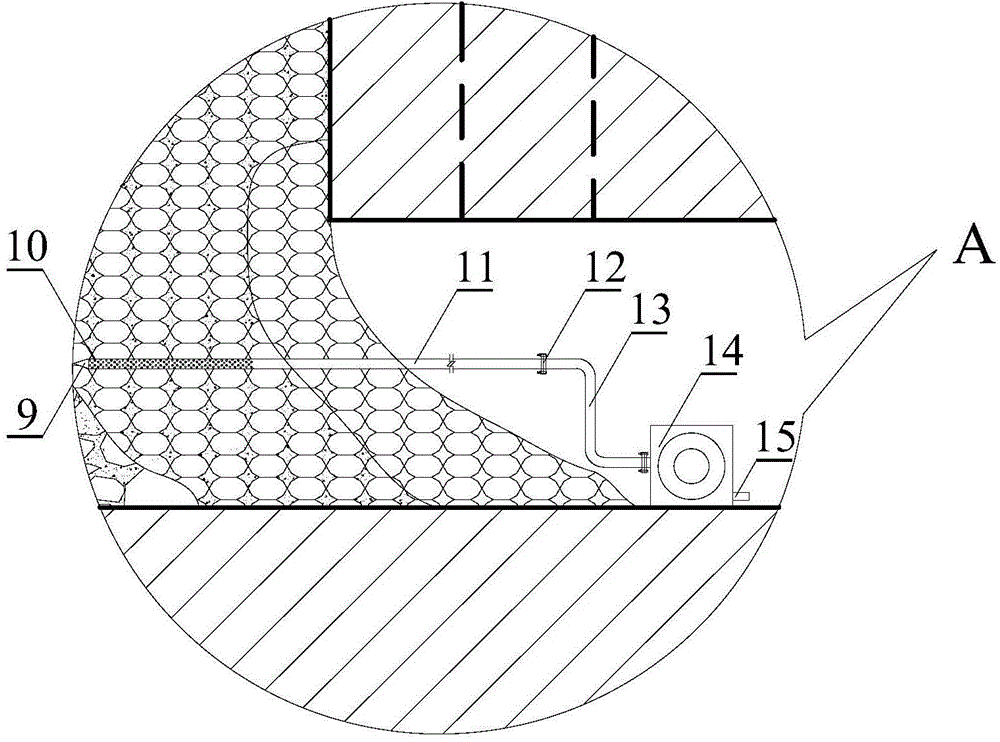

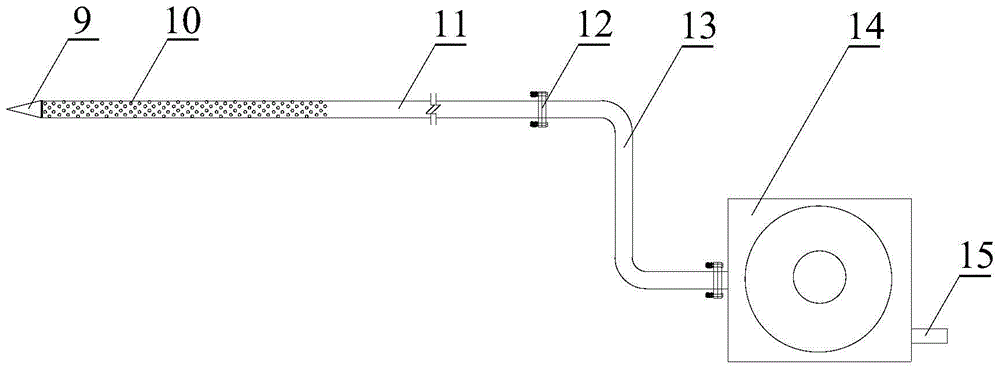

Stope debris flow treatment method in caving mining method and device thereof

ActiveCN104879129ASimple technologyEasy constructionUnderground miningSurface miningWater dischargeWater filter

Owner:CENT SOUTH UNIV

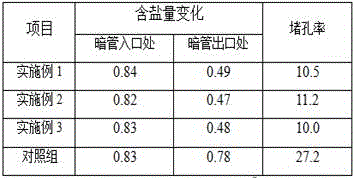

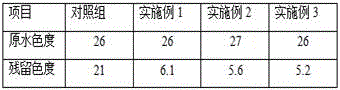

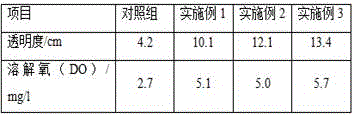

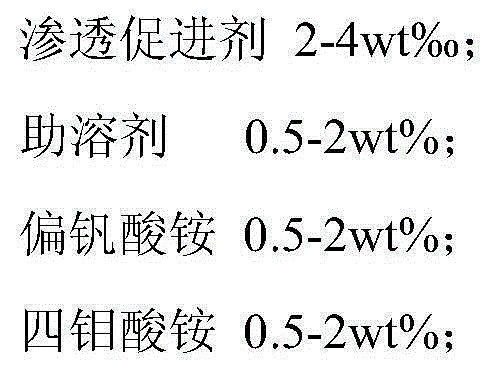

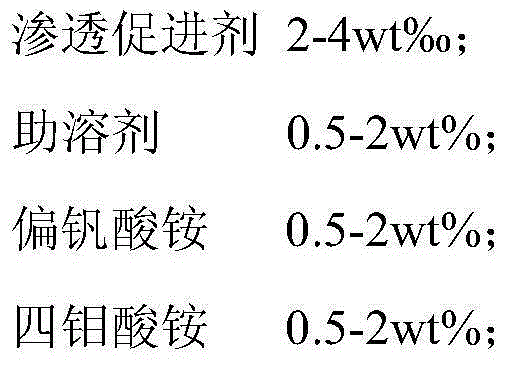

Bacillus megatherium-containing desilting agent and application thereof in salt eliminating underground pipe

InactiveCN106010809AReduce plugging rateImprove dredging effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAdhesiveOxygen

The invention provides a bacillus megatherium-containing desilting agent which comprises a biocatalyst, a nonionic surfactant, centella extract, ginger extract, liquorice extract, a bio-enzyme activator, ammonium molybdate, malic acid, protocatechuic acid, a vitamin complex, a matrix, a porous sodium activated zeolite powder carrier, halophilic bacteria, bacillus megatherium and an adhesive. The invention also provides an application of the bacillus megatherium-containing desilting agent in a salt eliminating underground pipe. By adopting the desilting agent provided by the invention, the chroma of water in the salt eliminating underground pipe is reduced that the residual chroma is reduced to 5.2-6.1 degrees after treatment; the salt content of water in the salt eliminating underground pipe is reduced that the salt content of water at an exit of the salt eliminating underground pipe is reduced to 0.47-0.49%; the hole blocking rate of the salt eliminating underground pipe is reduced that the hole blocking rate of water in the salt eliminating underground pipe is reduced to 10.0-11.2%; the desilting effect is good; and after one year of desilting, the dissolved oxygen (DO) in the water is as high as 5.0-5.7mg / l.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Vibrating screen

The invention discloses a vibrating screen comprising a screen frame. More than one screen teeth are arranged on the frontal surface of a cross beam side by side in the same direction to form a screen strip unit. The back parts of the screen teeth are fixedly connected with the cross beam; and the ends are suspended. The structure adopts a whole single material; the front part at least has one section as a rotating curved surface structure; the cross section thereof is gradually decreased from the back end to the front end; an included angle between the tangent line of at least one point of the generatrix, coplanar with a rotating shaft, of the rotating curved surfaces of the screen teeth and a revolving shaft is greater than 5.5 degrees and smaller than 45 degrees; multiple screen strip units are arranged in a front-back manner, and the screen teeth are fixedly connected to the screen frame in the same direction; the screen teeth of the screen strip units at the back part are positioned above the cross beams of the previous screen strip units; and the front ends of the screen teeth are beyond of the back surfaces of the cross beams of the previous screen strip units. The screen teeth are rigid, and the surfaces are smooth curved surfaces, so that the vibrating screen has the advantages of high screening precision and low hole blockage rate, and totally solves the defects in the prior art.

Owner:WUHAN MOLINHAN ELECTROMECHANICAL EQUIP +1

A kind of deep hole blasting and filling method

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿

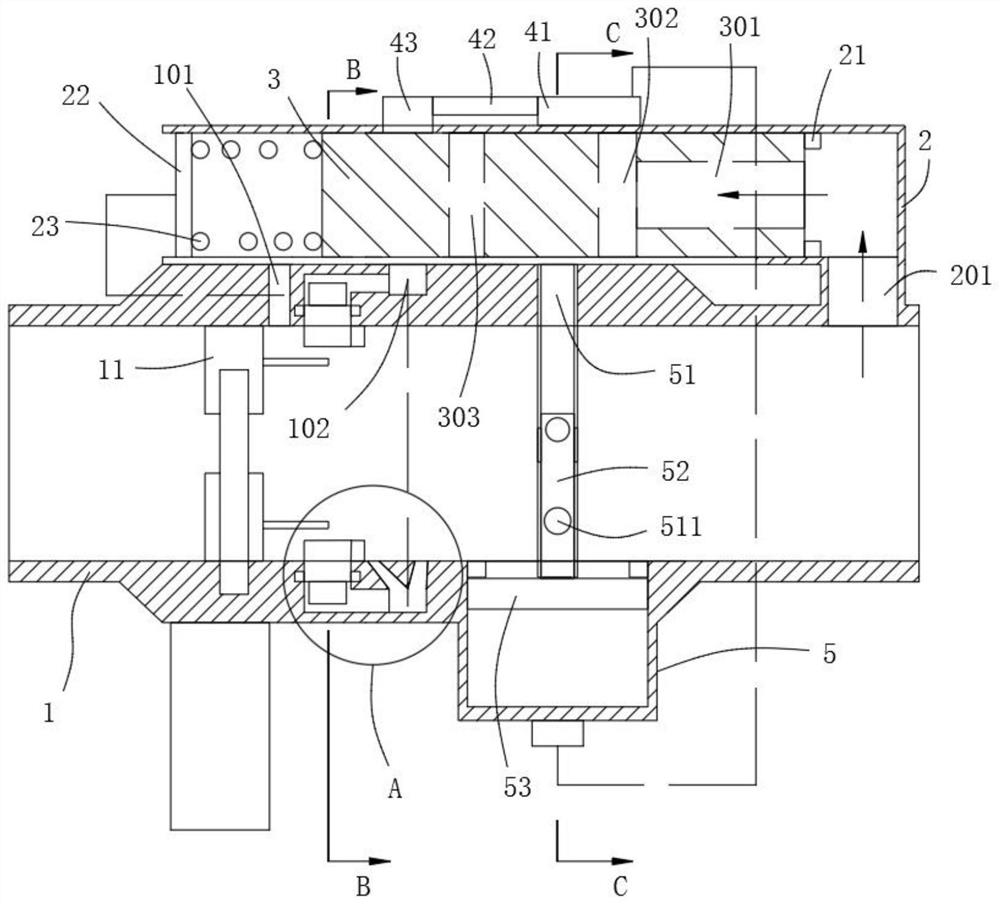

Purification method and preparation method of high-purity chlorine trifluoride

PendingCN113371681AReduce contentRecyclabilityInter-halogen compoundsHigh concentrationPurification methods

The invention provides a purification method and a preparation method of high-purity chlorine trifluoride, and relates to the technical field of chemical engineering. According to the method, high-purity chlorine trifluoride gas with the purity of 99.995% or above is obtained through condensation, vaporization, adsorption, filtration, rectification and filling. The purification method has the advantage that the purity of the chlorine trifluoride gas prepared by the purification method reaches 99.995%. According to the preparation method, the temperature and acidity of an electrolytic bath are controlled, and a HF adsorption tower is additionally arranged, so that the prepared fluorine gas can reach the optimal concentration, the utilization rate of the fluorine gas reaches 98% or above, and more favorable conditions are provided for subsequently providing chlorine trifluoride with higher concentration.

Owner:鹤壁德瑞科技有限公司

Mechanical automatic controlled range constant pressure dredging valve

ActiveCN111720659AEasy to transportPromote fragmentationHollow article cleaningPipe elementsAutomatic controlEngineering

The invention relates to the technical field of material conveying valves, in particular to a mechanical automatic controlled range constant pressure dredging valve. The dredging valve comprises a valve installed in a conveying pipeline, a pressure cylinder is installed on the outer wall of the conveying pipeline, a movable plug which is pressed to move in the axial direction is arranged in the pressure cylinder, one end of the pressure cylinder is communicated with the conveying pipeline through an air inlet cavity, and the distance between the air inlet cavity and the valve is at least 20 cm. According to the mechanical automatic controlled range constant pressure dredging valve, the pressure difference of the conveying pipeline is used for enabling the movable plug to act, the pressureat the far end of the pipeline is used for transmitting the dredging assembly, a capacity increasing component is used for increasing the capacity of the blocked space, a pressurizing component and astirring component are used for stirring and crushing the blocked position, and the blocked position is filled into the capacity increasing space; and dense materials at the blocked position are gradually loosened and can distribution from the valve, dredging can be completed without large external pressurization, the crushing effect of the blocked materials after dredging is good, and the subsequent pipe blocking probability is reduced.

Owner:SUZHOU BATAO INFORMATION TECH CO LTD

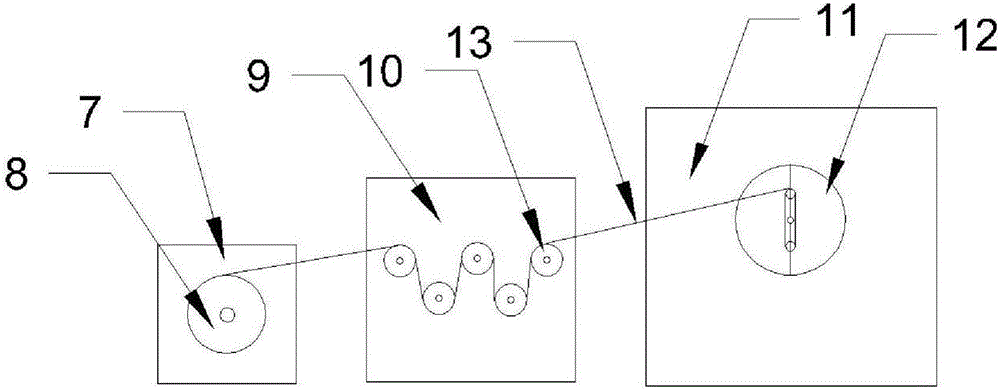

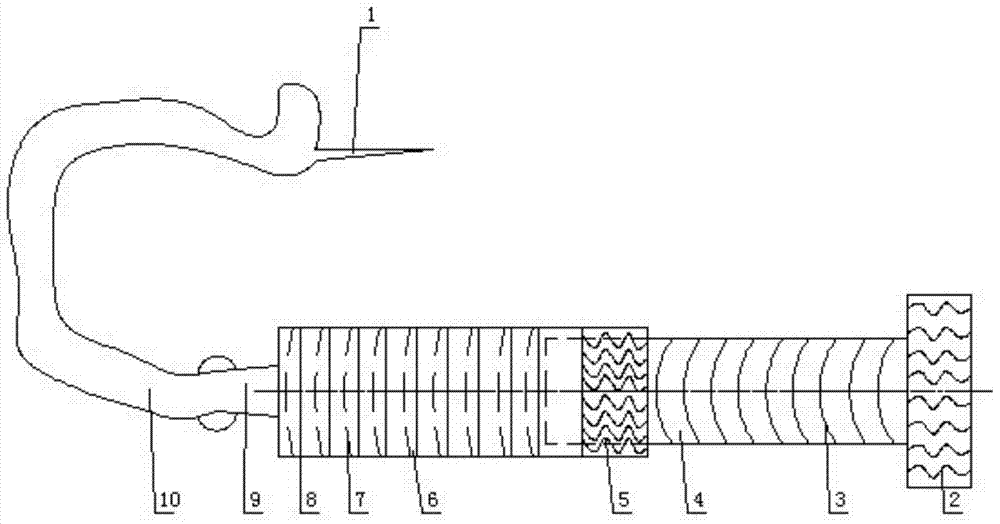

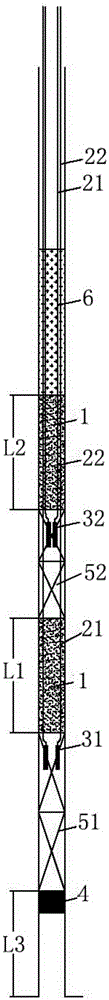

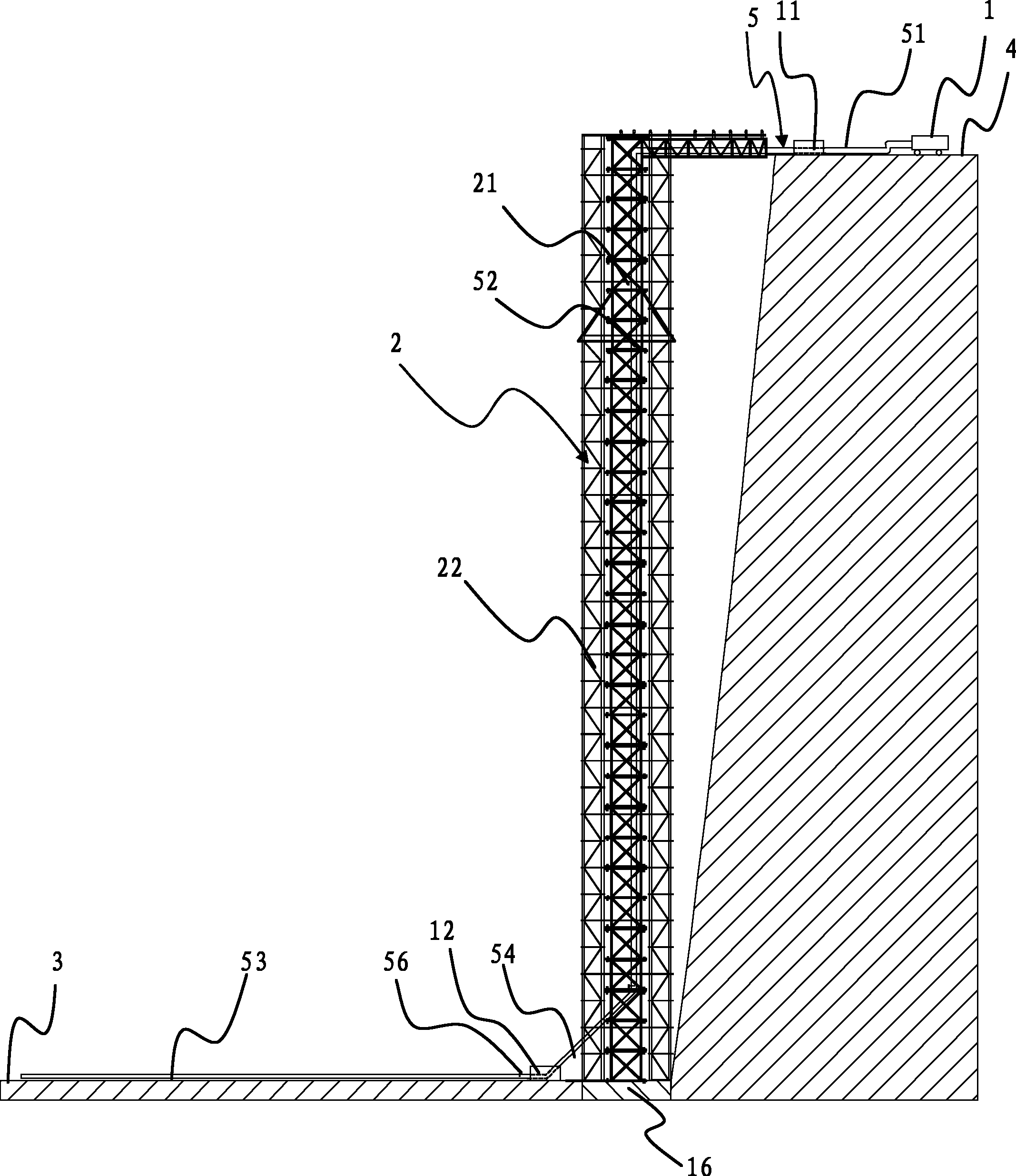

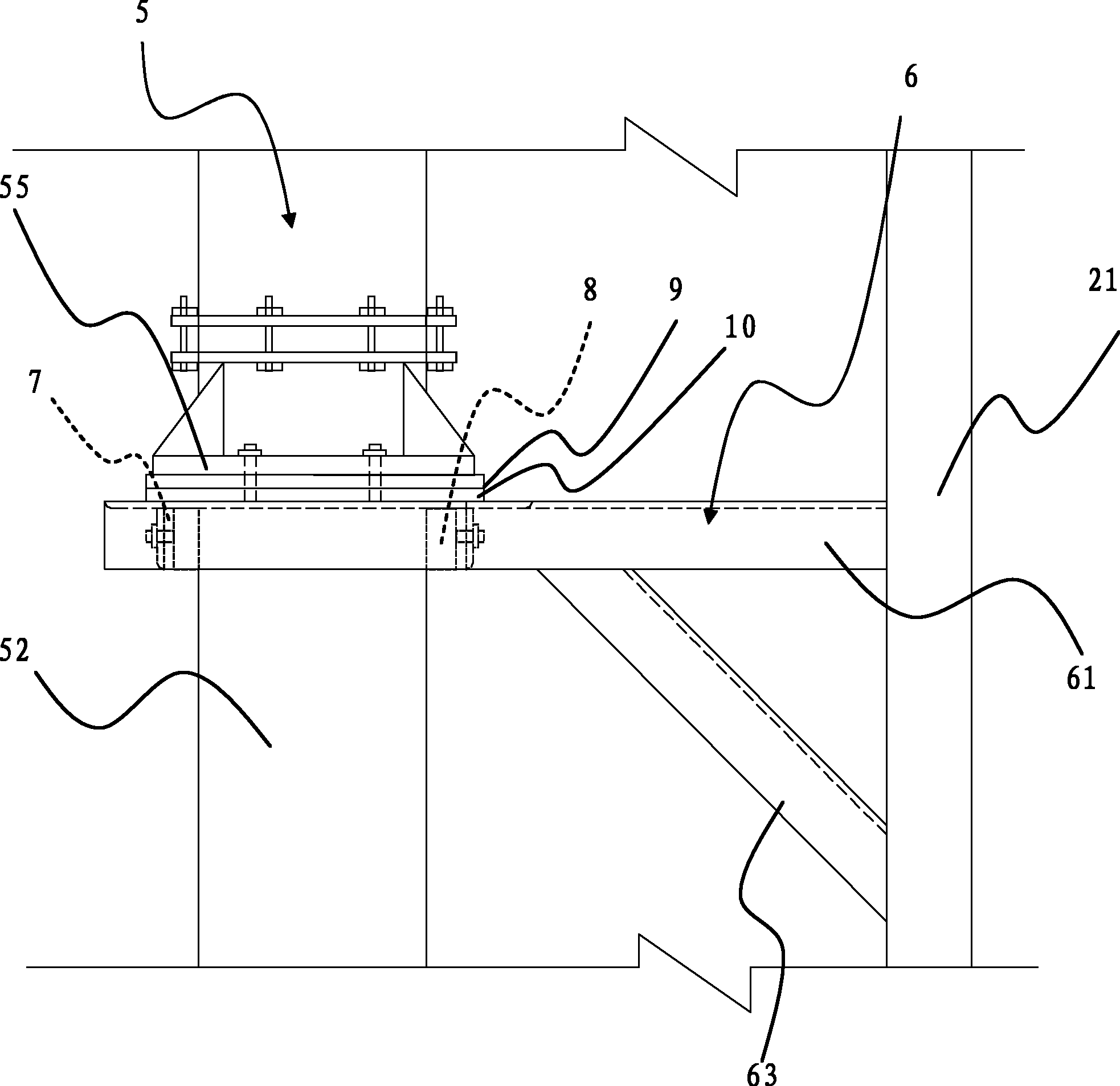

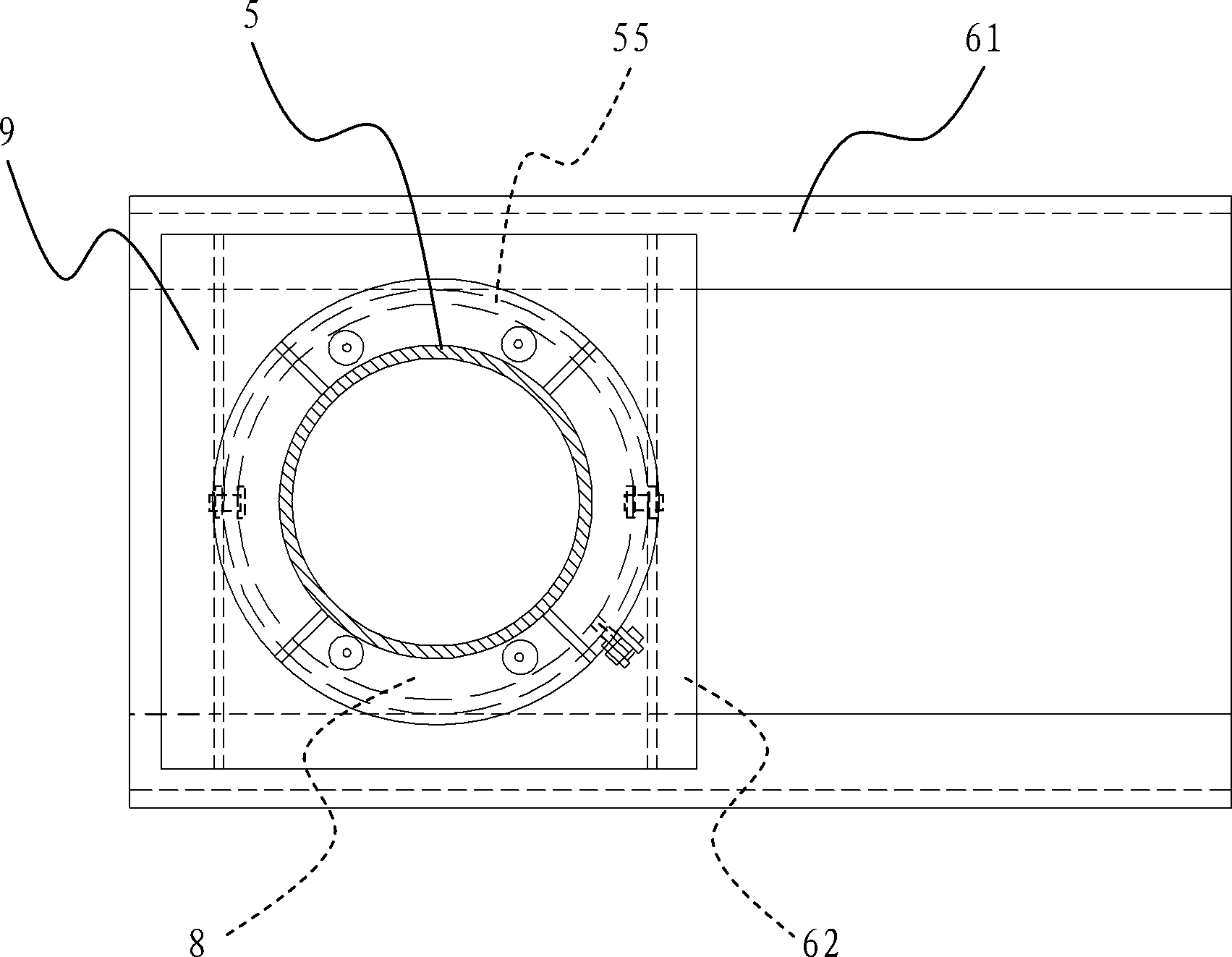

Extra-deep downward concrete pumping system

ActiveCN102493457BMitigate internal shocksReduce plugging rateFoundation engineeringBuilding material handlingStructural engineeringTower crane

The invention discloses an extra-deep downward concrete pumping system which is used for pumping concrete from a high terrace to a lower terrace. The extra-deep downward concrete pumping system comprises a conveying pump, a pylon and a pump pipe, wherein the conveying pump is fixedly arranged on the high terrace; the bottom of the pylon is fixedly supported on a bearing platform positioned at the lower terrace; the top of the pylon is respectively fastened on a pair of concrete piers positioned at the high terrace through a pair of tower crane attached legs; the pump pipe is erected on the pylon; and the input end of the pump pipe is connected with a pump mouth of the conveying pump. Due to the adoption of the extra-deep downward concrete pumping system disclosed by the invention, the system for conveying the concrete downward to an extra-deep area is realized; and the extra-deep downward concrete pumping system has the advantages of high conveying efficiency, stability and safety for conveying, low possibility of blocking the pipe and easy overhaul.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

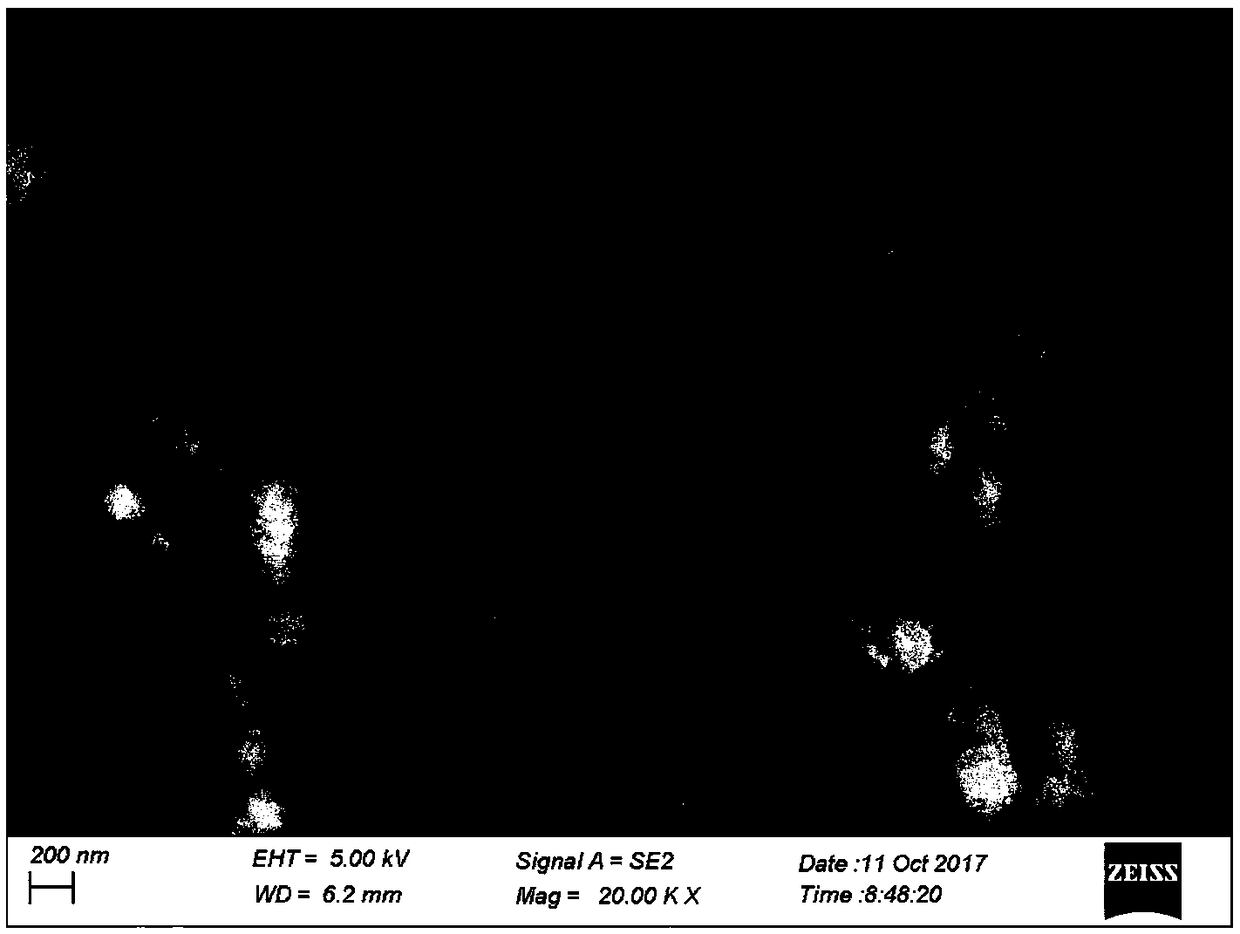

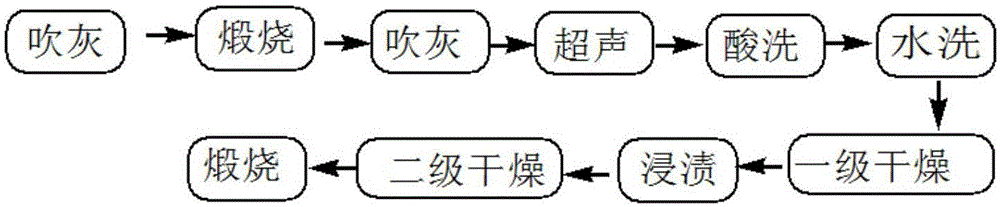

Regeneration impregnation liquid and regeneration technology for vanadium-titanium corrugated plate type denitrification catalyst

InactiveCN105148940AReduce plugging rateReduce difficultyMetal/metal-oxides/metal-hydroxide catalystsTitaniumDenitrification

The invention discloses a regeneration impregnation liquid and a regeneration technology for a vanadium-titanium corrugated plate type denitrification catalyst. The hole blocking rate of the denitrification catalyst treated with the treatment technology is reduced by more than 90%, and the denitrification activity of the regenerated catalyst is higher than 95% of that of a fresh catalyst. The difficulty in industrialization of the treatment technology is lower, and large-scale regeneration of inactive reproducible denitrification catalysts can be realized.

Owner:TIANHE BAODING ENVIRONMENTAL ENG

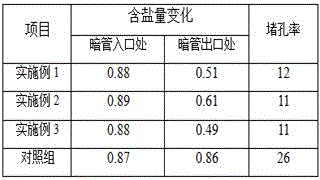

Thermoactinomyces-vulgaris-containing desilting agent and application thereof in salt drainage concealed pipes

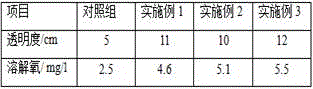

InactiveCN106010808AReduce salt contentReduce plugging rateOrganic detergent compounding agentsSurface-active detergent compositionsAlkali soilWater transparency

The invention provides a Thermoactinomyces-vulgaris-containing desilting agent which comprises a biocatalyst, a nonionic surfactant, an aloe extracting solution, a purslane extracting solution, a Herba Centellae extracting solution, a bioenzyme activator, borax, shikimic acid, humic acid, a vitamin complex, a substrate, a porous sodium-type activated zeolite powder carrier, halophile, Thermoactinomyces vulgaris and a crosslinking agent. The invention also provides application of the Thermoactinomyces-vulgaris-containing desilting agent in salt drainage concealed pipes. The desilting agent lowers the salt content of water in the salt drainage concealed pipe, and the salt content of water at the outlet of the salt drainage concealed pipe is lowered to 0.49-0.61%. The desilting agent lowers the plugged hole percentage of the salt drainage concealed pipe, and the plugged hole percentage of water in the salt drainage concealed pipe is lowered to 11-12%. The desilting agent enhances the saline-alkali soil silt treatment speed, and the time for treating 8cm-thick saline-alkali soil silt is 6-7.0 days. The desilting agent has favorable desilting effect; and one year after desilting, the water transparency is up to 10-12cm, whereas the transparency of the control group is 5cm.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Vibrating sieve plate and its cleaning device

InactiveCN103785607BIncrease vibration amplitudeReduce plugging rateSievingScreeningVibration amplitudeGrating

The invention provides a vibrating screen sieve plate and a cleaning device of the vibrating screen sieve plate. The cleaning device comprises a rapper bar which is of a columnar hollow structure, a plurality of protruding bosses for striking a grating of the sieve plate, a plurality of blowholes and an installing component are arranged on the surface of the rapper bar, wherein the installing component is used for making the rapper bar installed below the grating of the sieve plate. Due to the fact that the rapper bar is arranged below the grating of a vibrating screen and continuously raps the grating, high-pressure gas continuously blows the grating, the vibration amplitude of the grating can be increased, materials easily stuck to the grating can be vibrated and scattered or blown away, and it can be guaranteed that holes are not blocked. Thus, the vibrating screen sieve plate and the cleaning device can reduce the hole blockage probability of materials and improve screening efficiency.

Owner:BEIJING ELECTRIC POWER AUTOMATION EQUIP CO LTD

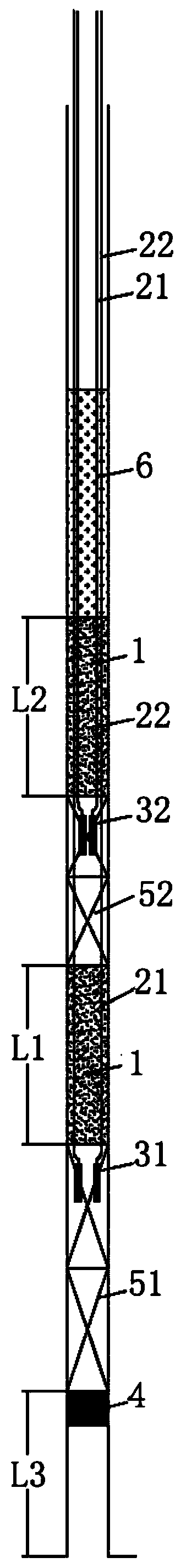

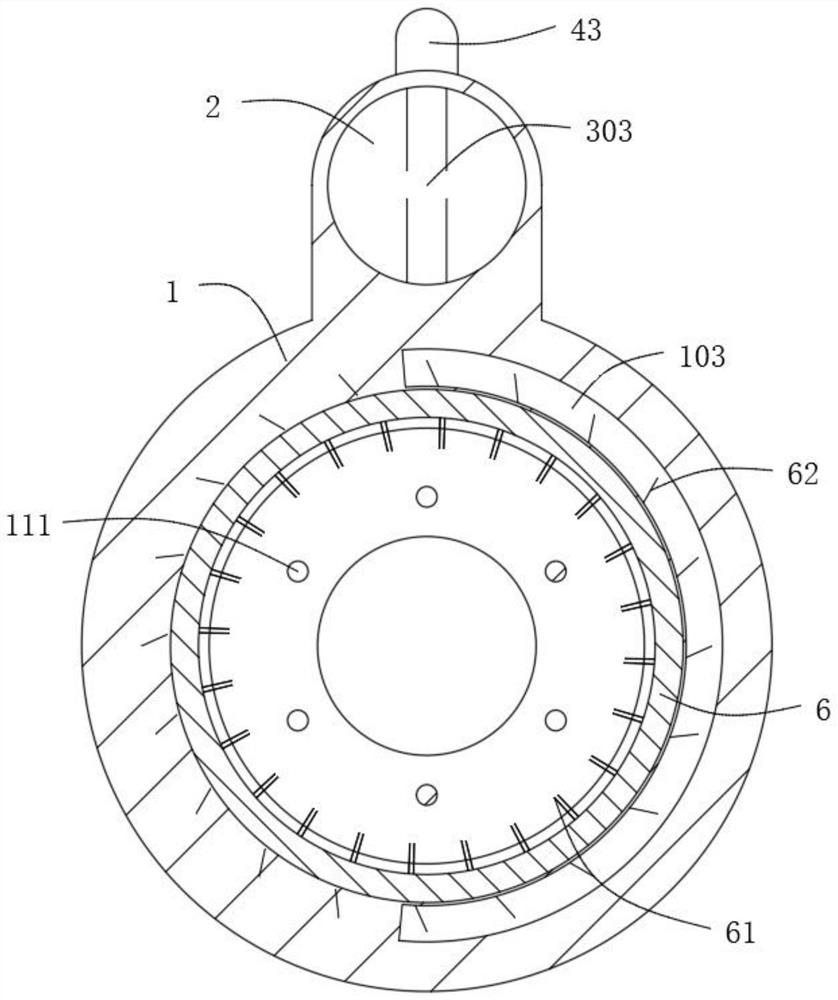

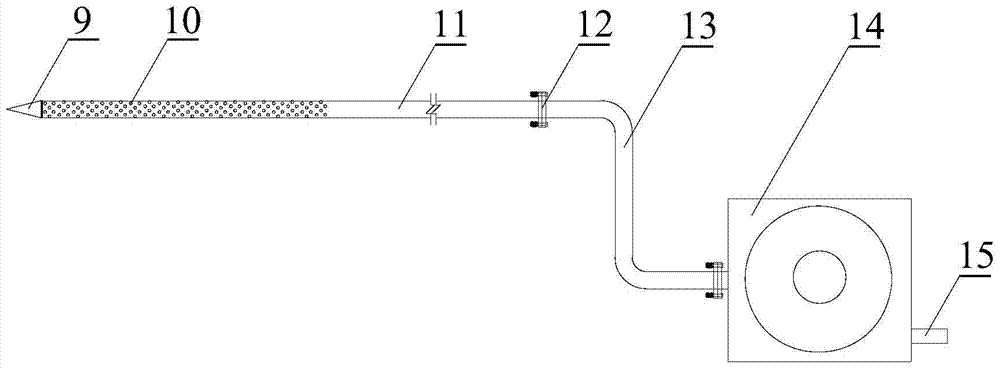

Method and device for manufacturing columnar hollow fiber membrane module

ActiveCN106362595BIncrease profitReduce plugging rateSemi-permeable membranesUltimate tensile strengthHollow fiber membrane

The invention belongs to the technical field of separation membranes and relates to a columnar hollow fiber membrane module manufacturing method and a columnar hollow fiber membrane module manufacturing device. The method includes steps: manufacturing of U-shaped membrane filament bundles, to be more specific, winding hollow fiber membrane filaments to form the U-shaped membrane filament bundles in required length, wherein the head of one end of each U-shaped membrane filament bundle is bent; glue injection, to be more specific, subjecting the U-shaped membrane filament bundles to single-end (the other ends of the bent heads) glue injection to form independent pouring unit bundles; assembly, to be more specific, fixing the pouring unit bundles into membrane shells (pressure type membrane modules) or membrane frames (immersed modules); glue feeding and pouring, to be more specific, directly mounting glue injection end caps at the U-shaped ends of the bent heads of the pouring unit bundles to perform glue feeding and pouring; solidifying and cutting, to be more specific, after glue solidification, cutting glue surfaces to perforate membrane filaments, so that membrane module manufacturing is finished. The columnar hollow fiber membrane module manufacturing method and the columnar hollow fiber membrane module manufacturing device have advantages that hollow fiber membrane filament utilization rate and membrane module pouring and end sealing quality in a columnar hollow fiber membrane module manufacturing process are increased, and membrane filament blockage rate is decreased; work intensity is relieved, and efficiency improvement, cost saving, simplicity and convenience are achieved.

Owner:BEIJING ORIGIN WATER FILM TECH

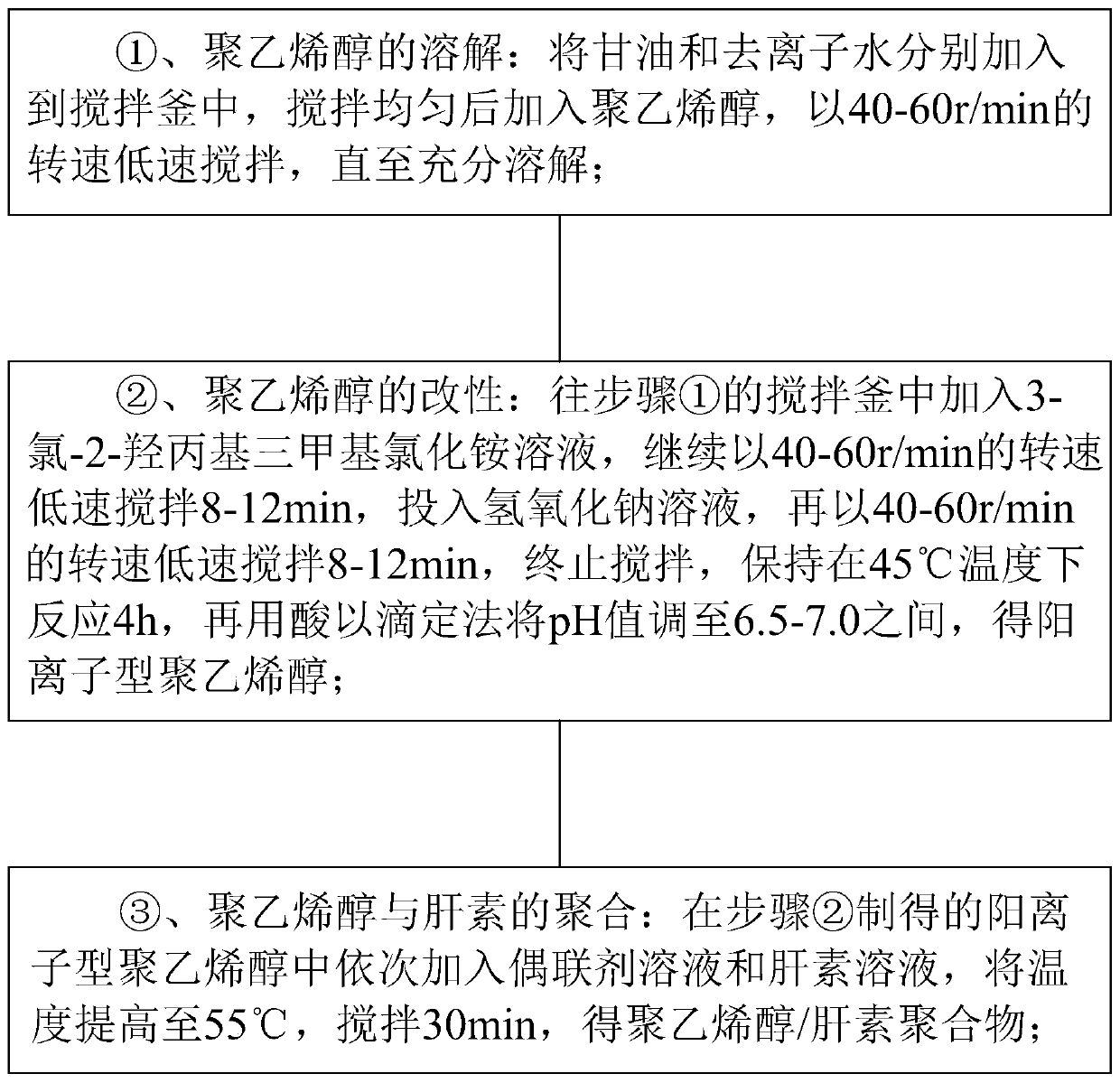

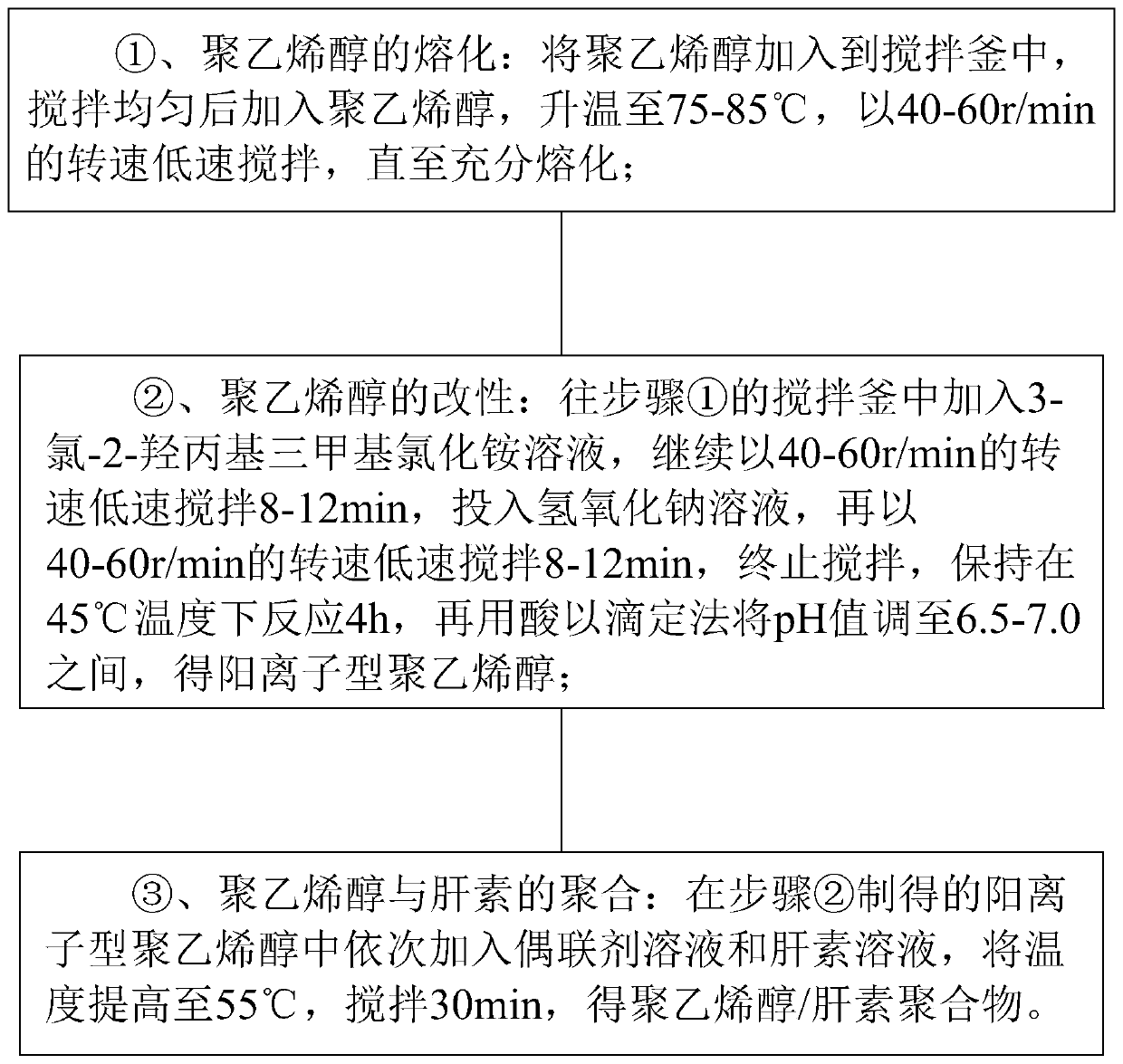

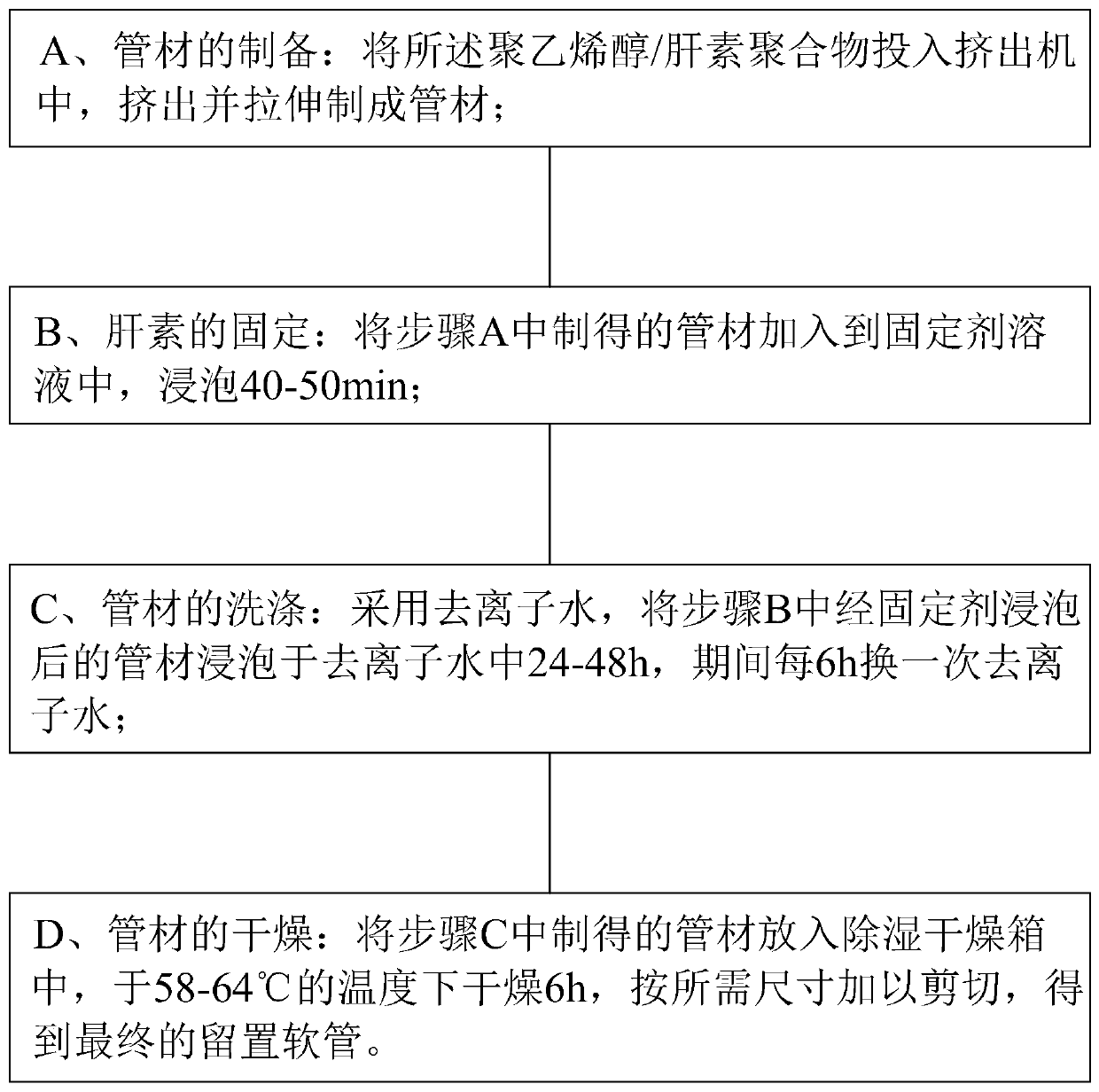

Polyvinyl alcohol-heparin polymer as well as preparation method and application thereof

ActiveCN110372869AImprove mechanical propertiesExcellent anticoagulant propertiesBiocompatibility TestingPVA - Polyvinyl alcohol

The invention relates to a biomedical material in the fields of medicine and medical instruments, in particular relates to an anticoagulation implant material, and in particular relates to a polyvinylalcohol-heparin polymer as well as a preparation method and application thereof. The polyvinyl alcohol-heparin polymer is formed by connecting polyvinyl alcohol and heparin through ionic bonds formedbetween the polyvinyl alcohol and the heparin, the polyvinyl alcohol is quaternary ammonium salt-modified cationic polyvinyl alcohol, and the modification conditions of the cationic polyvinyl alcoholare as follows: pH is 11.0-12.5, temperature is 50-55 DEG C, and reaction time is 4 h. The polyvinyl alcohol-heparin polymer provided by the present application can be used to process a soft and elastic indwelling hose, and the indwelling hose has excellent mechanical properties, anticoagulation properties and biocompatibility, and can effectively reduce the probability of blocking the hose and blood vessels and effectively reduce damage to human bodies, thereby effectively reducing suffering of patients.

Owner:SIBIKANG XIAMEN NEW MATERIALS CO LTD

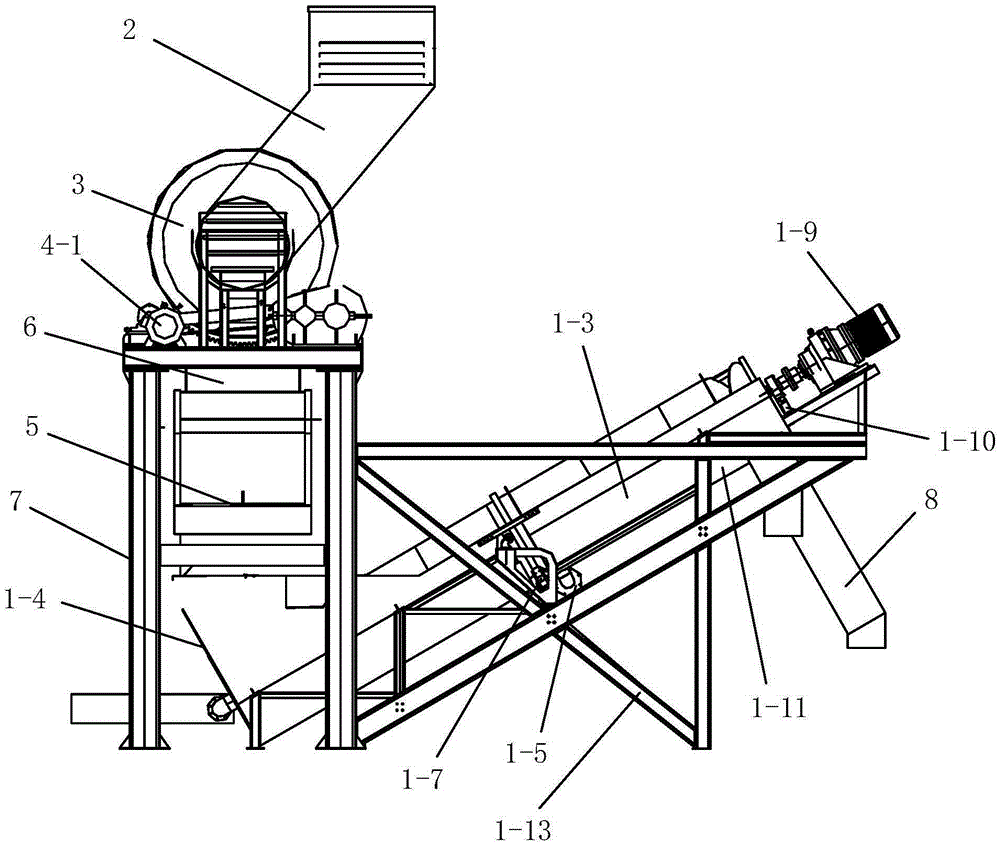

A construction waste removal and classification auger and a complete set of construction waste treatment equipment

InactiveCN103586260BSimple structureReasonable designConstruction waste recoverySolid waste disposalMotor driveLitter

The invention discloses a classification auger for impurity removal of construction wastes and complete construction waste processing equipment. The classification auger comprises a screen drum, a spiral feed mechanism mounted in the screen drum, and a rinsing bath for rinsing construction wastes to be processed before the construction wastes are fed to the screen drum, wherein the screen drum includes an inlet end at one end and a discharge end at the other end; the inlet end is positioned in the rinsing bath; a motor drive mechanism for driving the spiral feed mechanism to rotate continuously is arranged on the outer side of the discharge end; the spiral feed mechanism and the screen drum are arranged coaxially. The complete construction waste processing equipment comprises a rotary screen with an inlet on the front side, a vibrating screen below the rotary screen, and the classification auger for rinsing an oversize material on the vibrating screen to remove impurities, wherein the screen drum is arranged slantwise; the rinsing bath is positioned below the vibrating screen. The classification auger and the complete construction waste processing equipment provided by the invention have the advantages of simple structure, reasonable design, convenience in installation and arrangement, simplicity in use and operation, and good use effect, and can solve the problems, such as single function, high mechanical failure rate and poor use effect, of the conventional construction waste processing equipment.

Owner:程建中

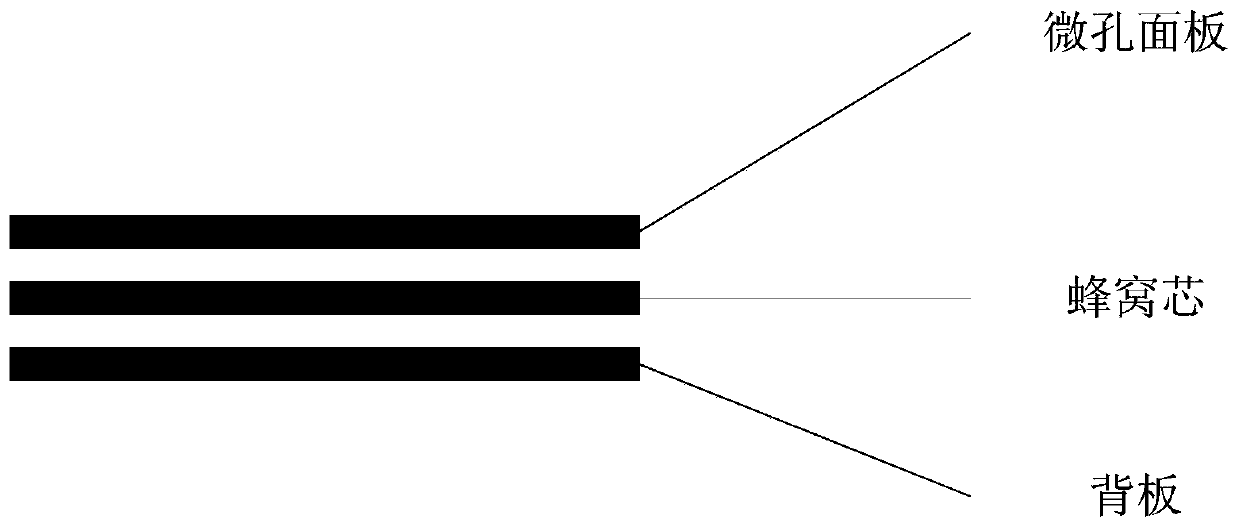

A composite material sound-absorbing and noise-reducing lining and its preparation method

ActiveCN107804046BAchieve structural weight reductionHigh specific strengthLamination ancillary operationsSynthetic resin layered productsEpoxyAcoustic noise reduction

The invention provides a composite material silencing and noise-reducing acoustic liner and a preparation method thereof, belongs to the technical field of structural / functional integrated composite material molding, and mainly relates to a composite material microporous panel honeycomb sandwich structure silencing and noise-reducing acoustic liner assembly, a molding process method and applications thereof, specifically to layer spreading of aramid fiber and glass fiber reinforced epoxy resin-based composite prepreg, application of a polymer acoustic separation membrane material, and hot press tank curing molding. According to the present invention, a large number of micro-pores are processed on the composite material layer plate through the laser processing method; and the Nomex aramid paper honeycomb core, the composite material panel and the back plate are adhered and cured by the film-like adhesive to form the micro perforated plate composite material silencing and noise-reducingacoustic liner, wherein the silencing and noise-reducing acoustic liner can be the single-freedom-degree acoustic liner structure and the multi-freedom-degree acoustic liner structure, and can achievethe acoustic noise reduction function of aero engines.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

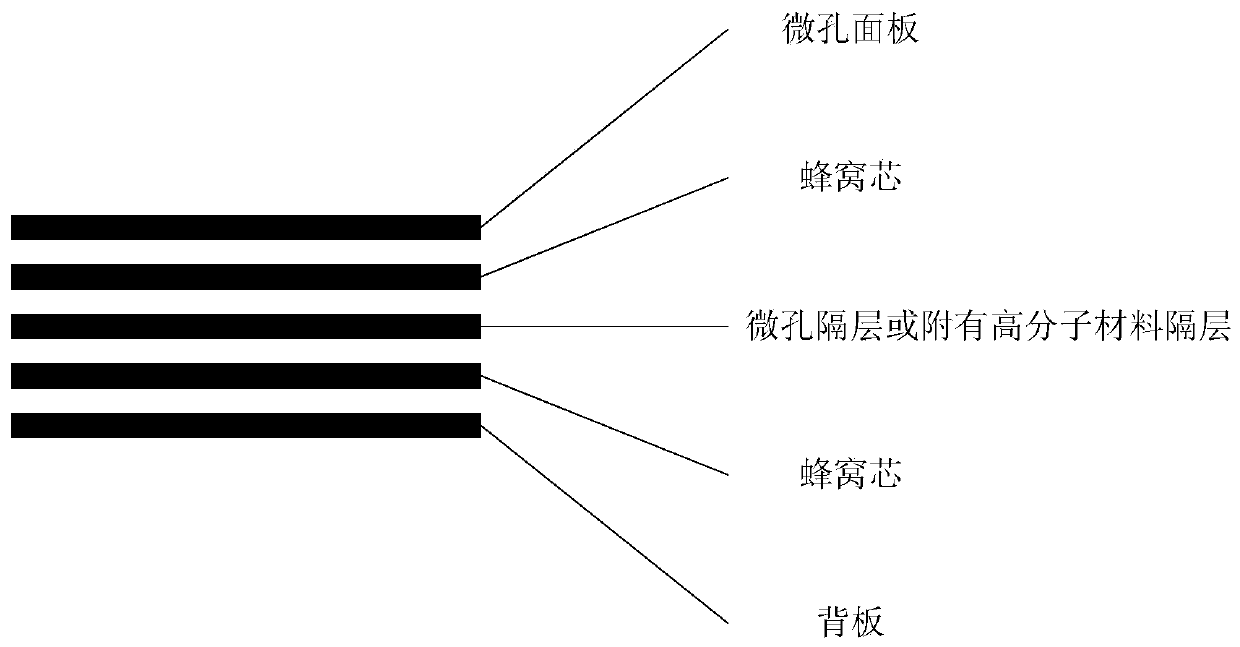

Cerebrospinal fluid quantitative shunt system and shunt method

ActiveCN111760175BPrevent backflowPrevent siphonOperating means/releasing devices for valvesNon-electrical signal transmission systemsAbdominal cavityCerebrospinal fluid shunt valve

The invention discloses a cerebrospinal fluid quantitative shunt system and a shunt method. The system comprises a cerebrospinal fluid shunt valve, a liquid inlet pipe from the brain ventricle or the lumbar cistern to the cerebrospinal fluid shunt valve, a liquid outlet pipe from the cerebrospinal fluid shunt valve to the abdominal cavity, and a body surface control The device; the cerebrospinal fluid shunt valve includes a cavity and a magnetic induction valve, the cavity is divided into two chambers by a piston, and the two sides of the cavity are connected with the liquid inlet pipe and the liquid outlet pipe through the magnetic induction valve; the piston moves horizontally in the cavity under the hydraulic pressure difference ; The electromagnetic field controls the rotation angle of the magnetic induction valve in different phases, and then switches the connection between the liquid inlet pipe and the liquid outlet pipe. The external induction control card obtains the time from the opening time point to the filling time point of the chamber connected to the liquid inlet pipe, calculates the time required for a quantitative shunt, and obtains the shunt speed, thereby calibrating the upstream and downstream hydraulic pressure difference of the chamber. The invention judges whether the pressure of the ventricular system of the patient is in the normal range by calculating the pressure value of the patient's ventricular system, and avoids the occurrence of siphon, excessive shunt and cerebrospinal fluid backflow.

Owner:兴化市人民医院 +2

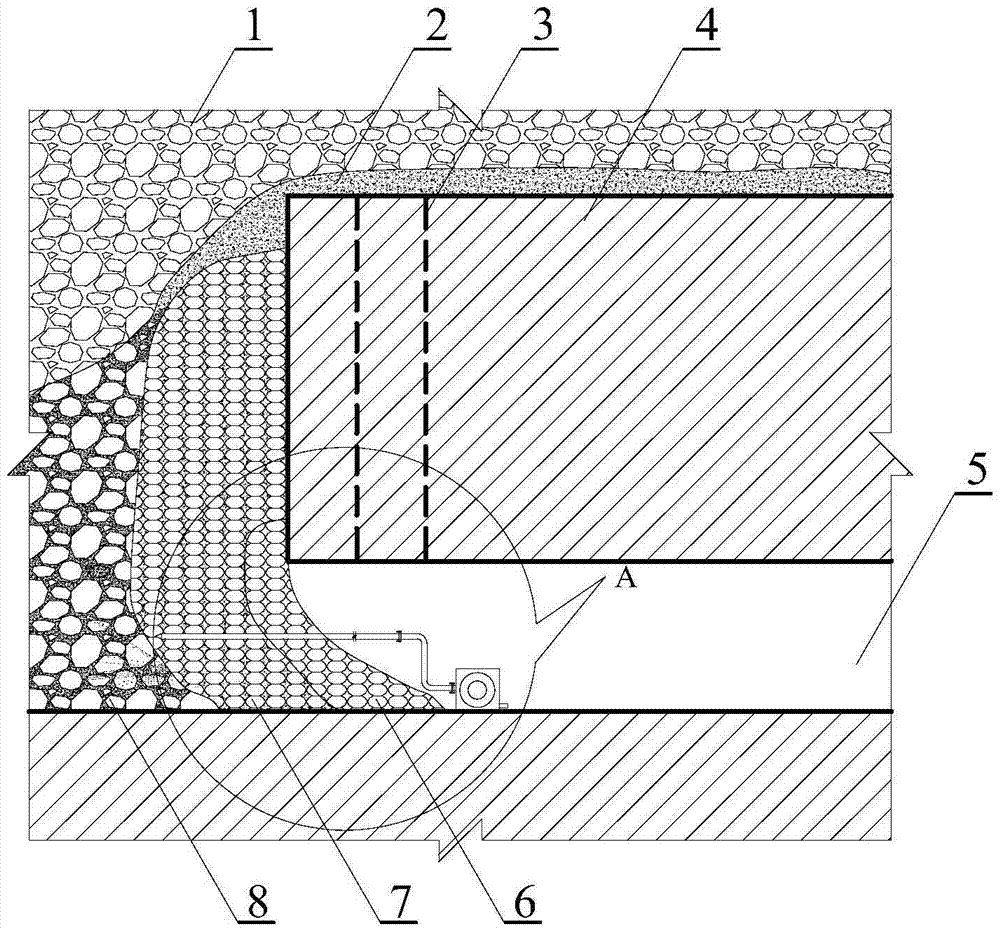

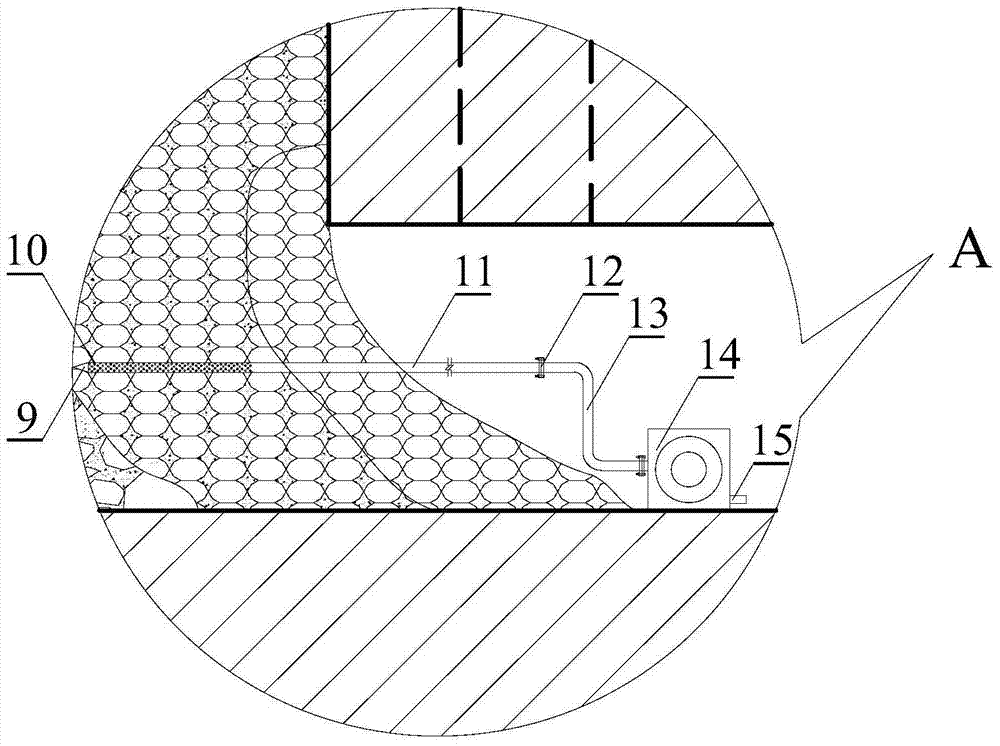

Method and device for controlling stope debris flow in caving mining method

ActiveCN104879129BSimple technologyEasy constructionUnderground miningSurface miningWater dischargeSludge

The invention discloses a control method and device for stope mud-rock flow in caving mining method. At the position of the ore outlet of the caving stope, before the stope is out of the mine, the impactor is used to drive the water filter steel pipe into the caving ore heap that is endangered by debris flow to be out of the mine, and the front end of the water filter steel pipe is evenly distributed with filter holes. The tail end of the water filter steel pipe is connected with the suction end of the mud pump through a rigid flange, the mud pump is started, and the vibration and negative pressure applied to the water filter pipe by the mud pump are used to eliminate the blockage of the debris flow slurry in the mine heap to the water filter pipe , discharge the mud and water in the ore heap as soon as possible, and then continue to use the impactor to drive the water filter steel pipe into the deeper position of the ore heap with debris flow hazards, and use the mud pump to discharge the muddy water, and so on, until the amount of muddy water in the stope ore heap It is greatly reduced, and the hazard of debris flow in the stope is eliminated. The invention has the advantages of simple operation, low probability of mud-rock blockage, fast drainage and mud-discharging speed, good control effect of stope mud-rock flow, recyclable water filter steel pipe, and the like.

Owner:CENT SOUTH UNIV

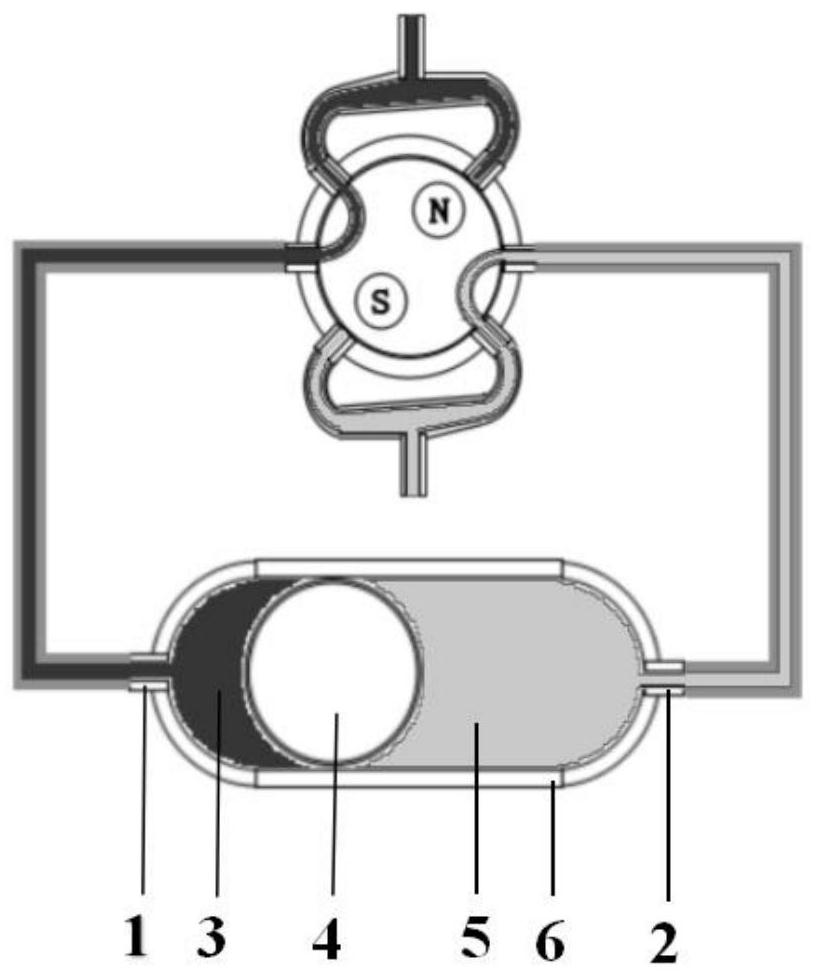

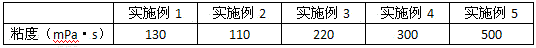

Attapulgite Clay Slurry for Li-ion Batteries

The invention discloses attapulgite clay slurry for lithium ion batteries. The slurry is applied to coating of ceramic diaphragms of the lithium ion batteries. The attapulgite clay slurry consists of 40-60wt% of attapulgite clay, 0.1-5wt% of a water-based adhesive, 0.1-2wt% of a water-based dispersant and the balance being water. The slurry disclosed by the invention is stable in viscosity and not easy to settle; the attapulgite clay slurry is infiltrative for polymer diaphragms of the lithium ion batteries prepared by adopting a dry process and a wet process, and is significant in cost advantage compared with universal aluminum oxide, zirconium oxide or colloid ceramic diaphragm slurry.

Owner:JIANGSU QINGTAO ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com