Polyvinyl alcohol-heparin polymer as well as preparation method and application thereof

A polyvinyl alcohol and polymer technology, which is applied in the fields of polyvinyl alcohol-heparin polymer and its preparation, and anticoagulant implant materials, can solve the problem of lack of physiological anticoagulant substances, easily obstructed blood flow, life-threatening, etc. problems, to achieve the effects of excellent mechanical properties and biocompatibility, excellent structural stability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

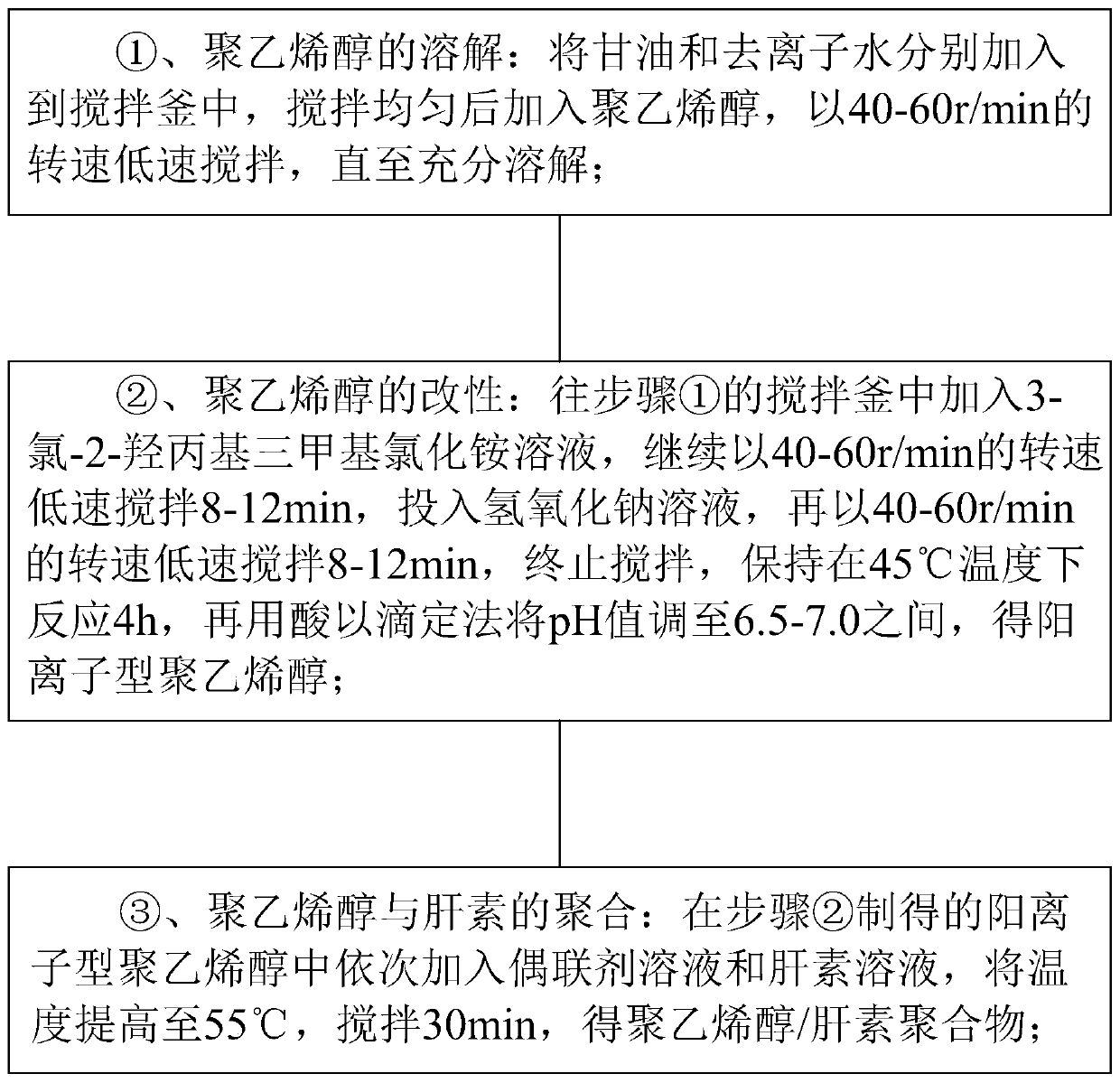

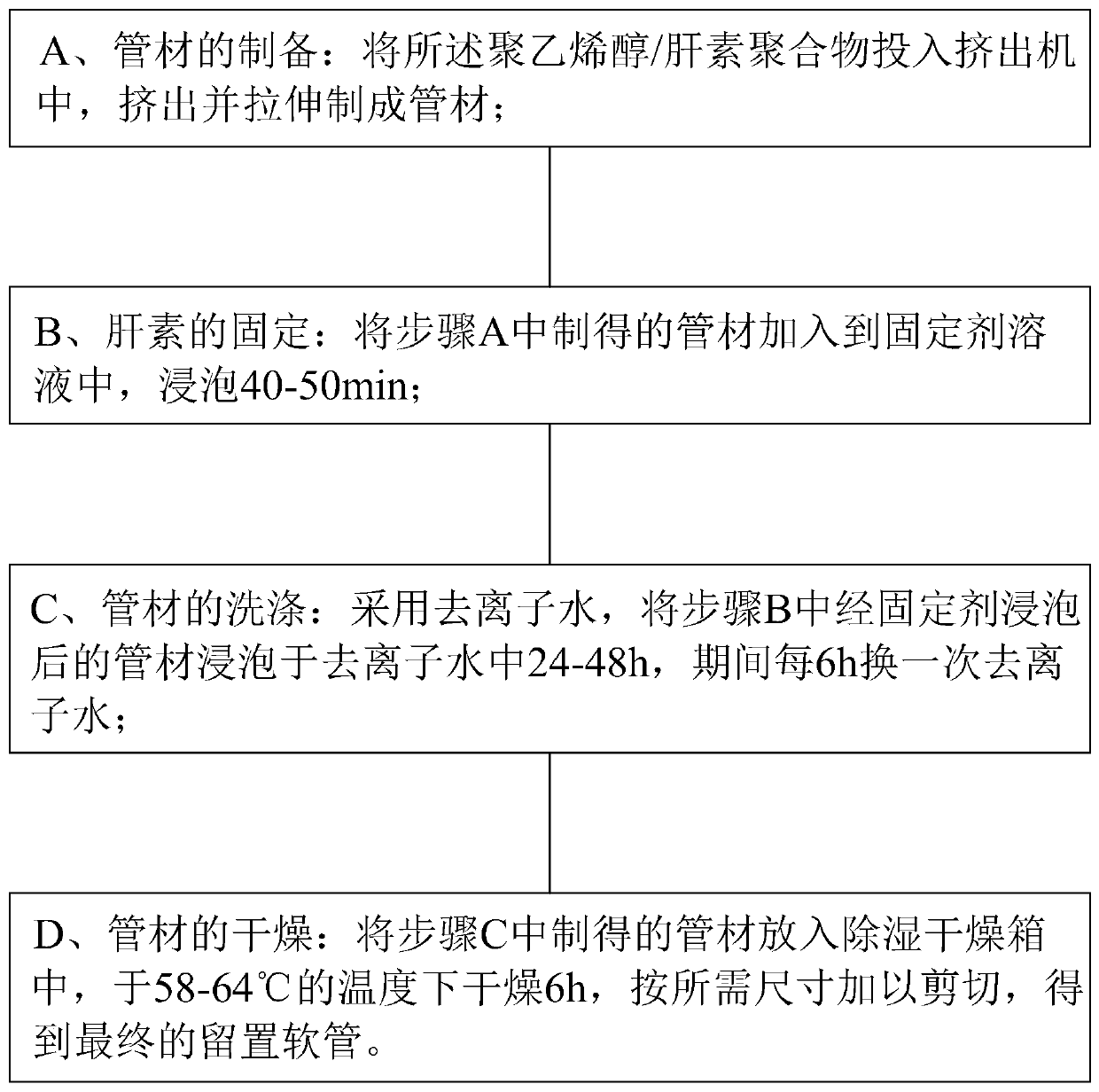

Method used

Image

Examples

preparation example Construction

[0086] Preparation of spares

[0087] 3-Chloro-2-hydroxypropyltrimethylammonium chloride solution: add 600g of 3-chloro-2-hydroxypropyltrimethylammonium chloride to 2400g of ethylene glycol to fully dissolve, and set aside at room temperature;

[0088] Sodium hydroxide solution: add 30g of sodium hydroxide to 200g of deionized water to fully dissolve, and set aside at room temperature;

[0089] Triethylenediamine solution: add 450 grams of triethylenediamine to 2550 grams of deionized water to fully dissolve, and set aside at room temperature;

[0090] Heparin solution: add 20 grams of heparin to 880 grams of deionized water to disperse and dissolve, and set aside at room temperature;

[0091] 1M hydrochloric acid solution: measure 86.0mL of 36% hydrochloric acid, dilute to 1000mL with deionized water, and set aside at room temperature; 0.5M sulfuric acid solution: measure 27.2mL of 98% sulfuric acid, pour into appropriate amount of deionized water , and finally dilute to 10...

Embodiment 2-6

[0104] Embodiments 2-6 are all based on the method of Example 1, and the weight ratio (heparin addition amount) of polyvinyl alcohol to heparin, the polymerization degree and alcoholysis degree of polyvinyl alcohol, and the average molecular weight of heparin are adjusted, and the specific adjustment See Table 2 below for details.

[0105] The parameter table of polyvinyl alcohol and heparin in table two embodiment 1-6

[0106]

Embodiment 7-9

[0108] Examples 7-9 are all based on the method of Example 1, and the production process parameters of the polyvinyl alcohol-heparin polymer and the production process parameters of the indwelling hose are adjusted. For specific adjustments, see Table 3 below.

[0109] Table 3 The preparation process parameters of polyvinyl alcohol-heparin polymer and indwelling hose in Examples 7-9

[0110]

[0111] 2.4, Embodiment 10

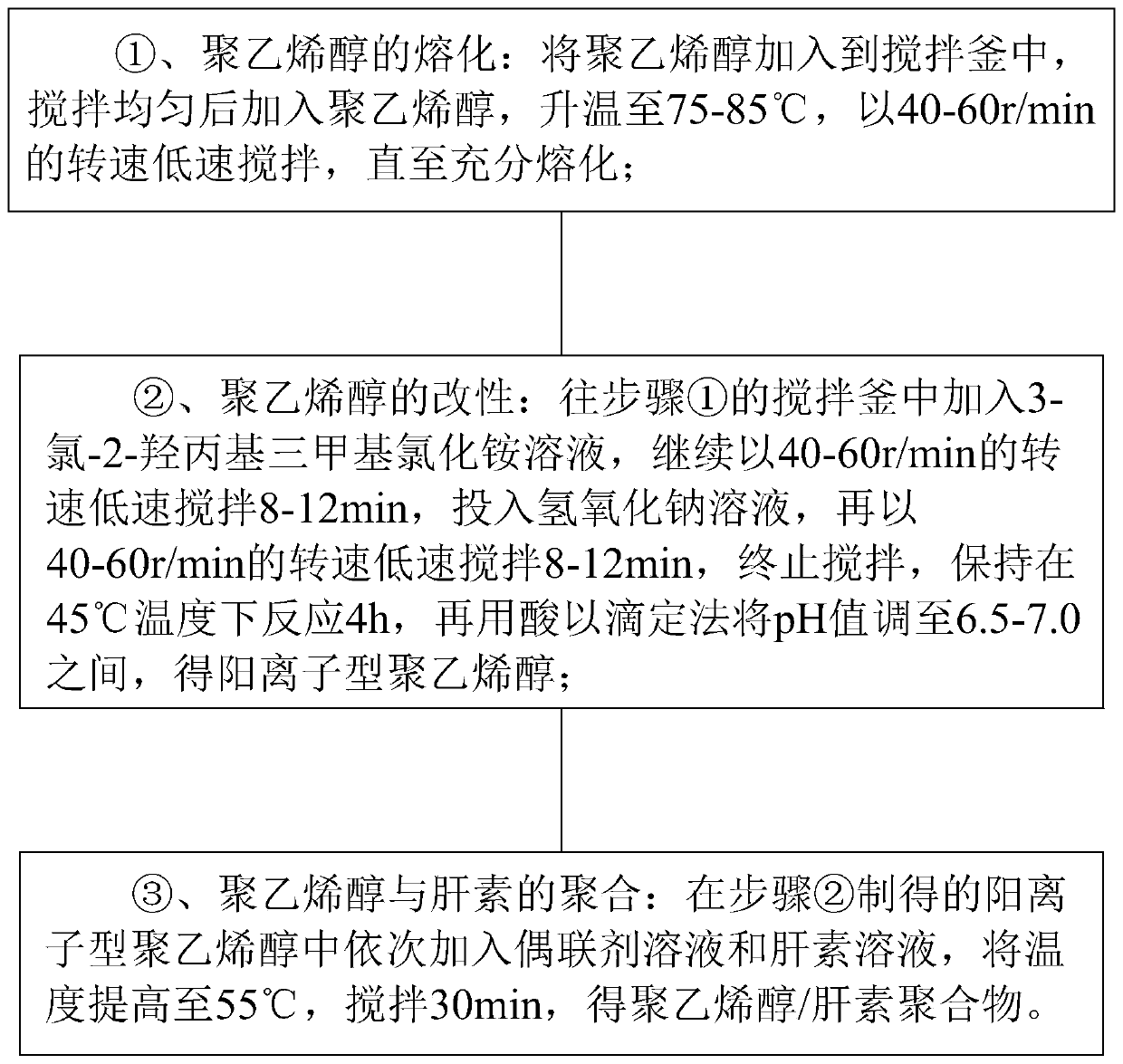

[0112] In this example, on the basis of the method in Example 1, the preparation method of polyvinyl alcohol-heparin polymer is adjusted, and the original water-soluble method is changed to a melting method. Specifically include the following steps:

[0113] ① Melting of polyvinyl alcohol: Add polyvinyl alcohol into the stirring tank, stir evenly, add polyvinyl alcohol, heat up to 80°C, stir at a low speed of 50r / min until fully melted; the melting temperature can be set at Fluctuates between 75-85°C;

[0114] ②Modification of polyvinyl alcohol: Add 3-ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com