Vibrating sieve plate and its cleaning device

A technology of cleaning device and sieve plate, which is applied in the direction of filter screen, solid separation, grille, etc., can solve problems such as plugging holes, and achieve the effects of improving screening efficiency, reducing the probability of material blocking holes, and increasing vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0019] In order to describe the present invention more intuitively, vividly and concisely, only the vibrating screen panel including the cleaning device will be described below, and the vibrating screen panel will not be described separately.

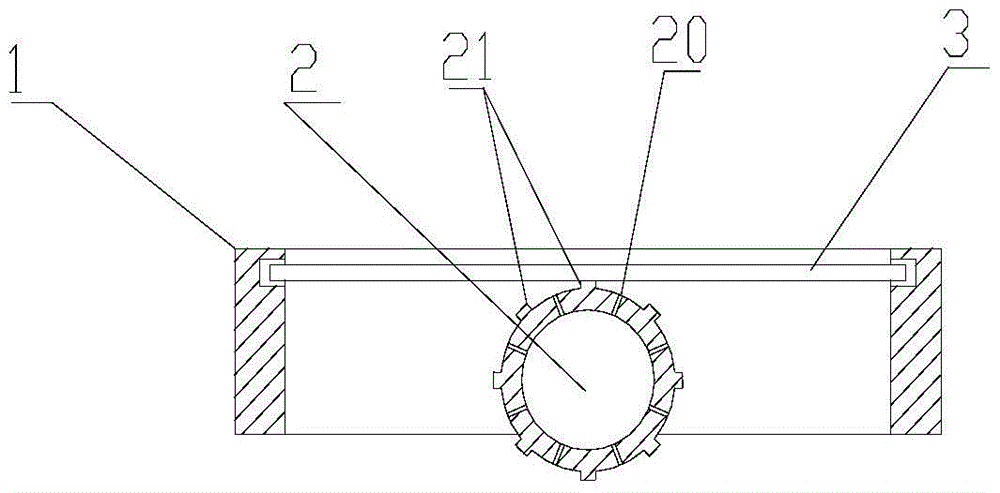

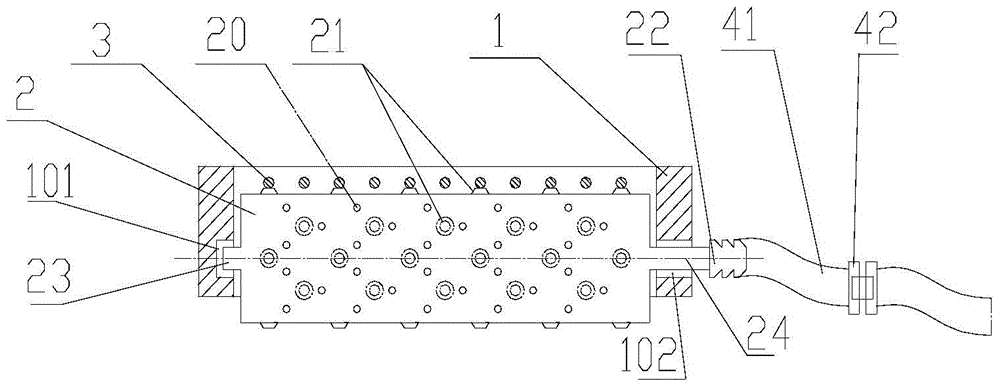

[0020] like figure 1 and figure 2 As shown, the preferred embodiment of the screen plate of the vibrating screen includes a screen bar 3 , a side plate 1 for installing the screen bar 3 and a rapping bar 2 . The screen bar 3 is movably mounted on the upper part of the side plate 1 . The mounting member of the rapping rod 2 is mounted on the side plate 1 and is located below the screen bar 3 . In application, when the rapping bar 2 vibrates with the sieve plate, it can vibrate with a large amplitude, thereby hitting the sieve bar 3 . It can be seen that the distance between the rapping bar 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com