Method and device for controlling stope debris flow in caving mining method

A caving mining and debris flow technology, applied in safety devices, surface mining, mining equipment and other directions, can solve the problems of caving stope debris flow control problems such as urgency, low efficiency and high cost, treating symptoms rather than root causes, and achieving improved efficiency and resource recovery. efficiency, low cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

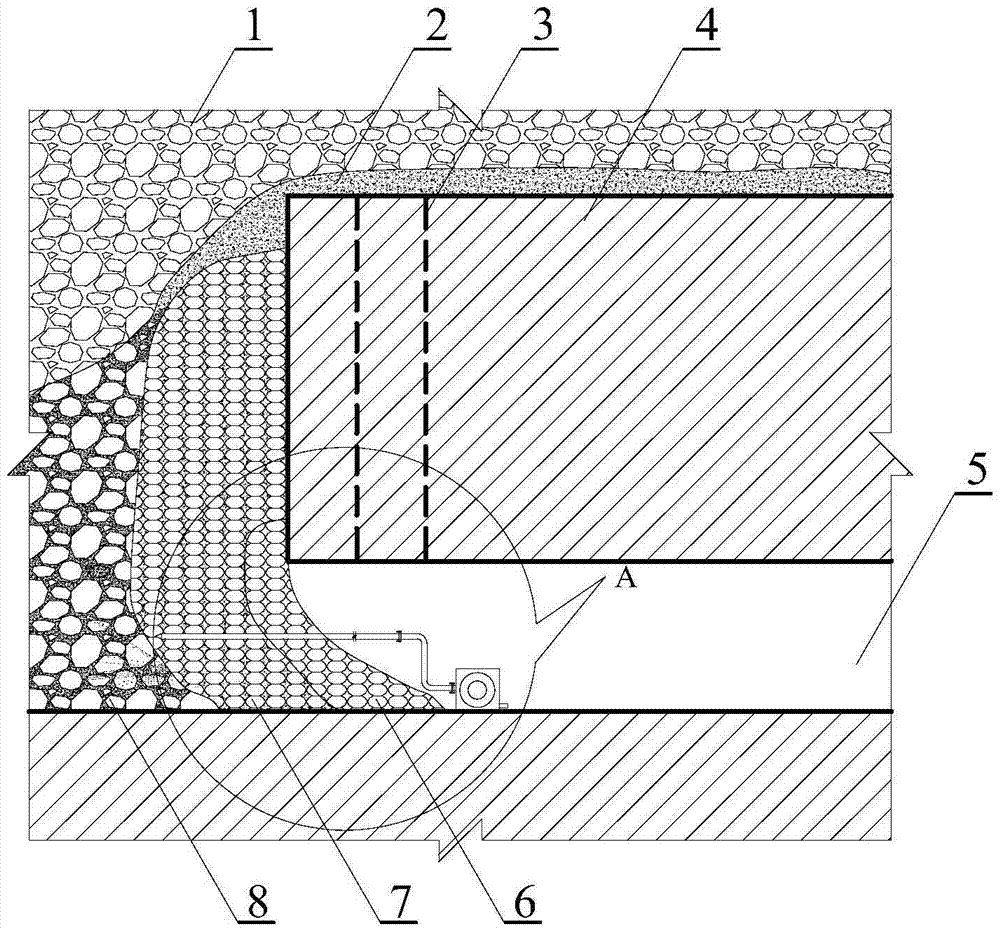

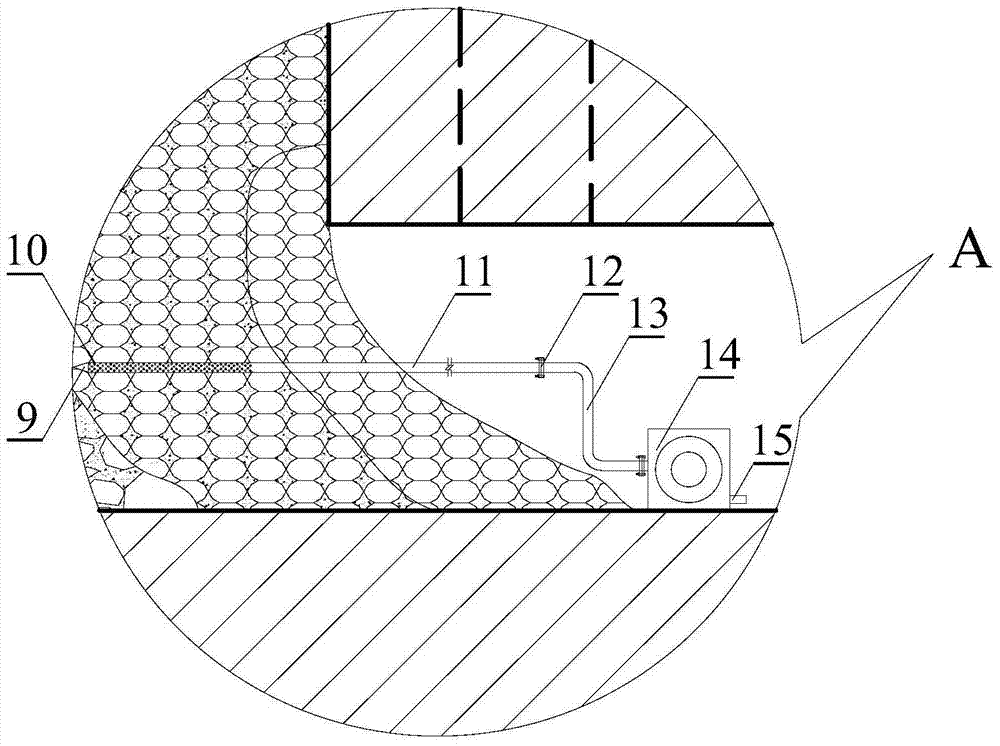

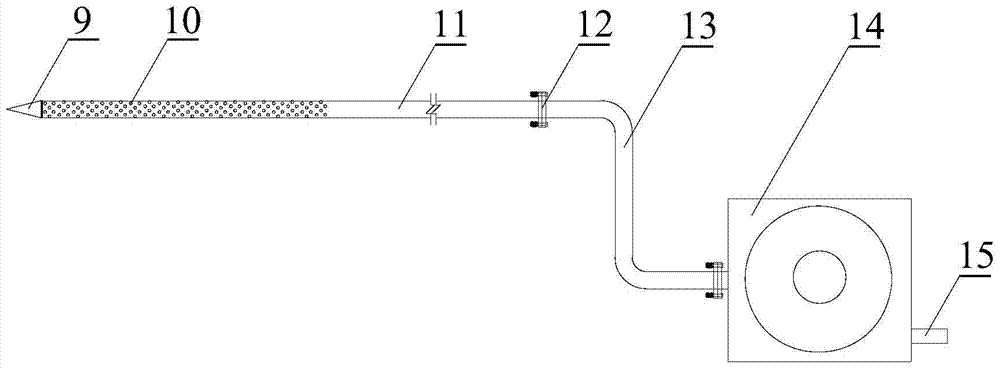

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] see figure 1 , figure 2 , image 3 and Figure 4 The mud pump 14 is provided with a drain port 15, and the inlet end of the mud pump 14 is connected with a water filter steel pipe 11 through a rigid flange 12. water hole 10. The main body of the water filter steel pipe 11 is a seamless steel pipe with an outer diameter of Φ100-150mm, a wall thickness of δ5mm-8mm, and a length of 6-8m. flange12.

[0030] The length of cone 9 is 2 times of the diameter of water filter steel pipe 11, and diameter is identical with water filter steel pipe 11 diameters.

[0031] The front end 1m-2m of the water-filtering steel pipe 11 is drilled with a drill to drill some of the above-mentioned water-filtering holes 10 with a diameter of Φ10mm-20mm. The several water-filtering holes 10 are arranged in a quincunx shape, and the area of the several wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com