Ball inserting device for concrete pumps

A technology of ball loading and concrete pumping, which is applied in construction, building structure, and building material processing, etc., can solve problems such as difficulty in loading balls, cleaning ball blocked pipes, waste of resources and manpower, etc., to shorten the time for cleaning pipes, reduce The effect of extra waste and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

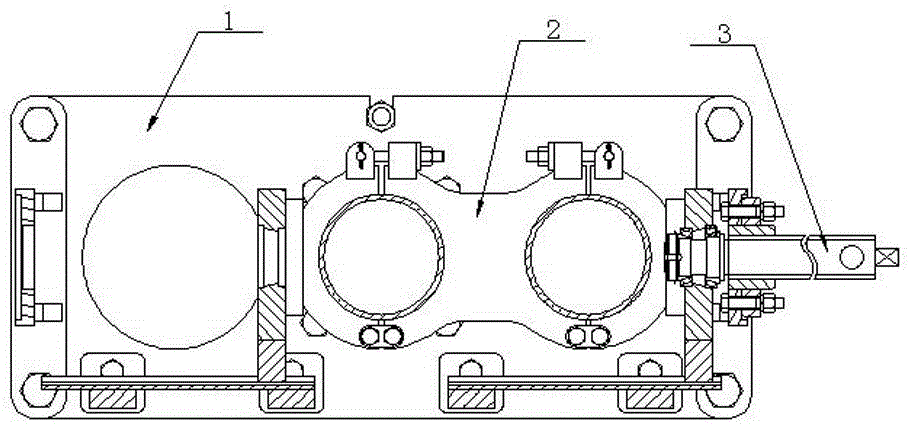

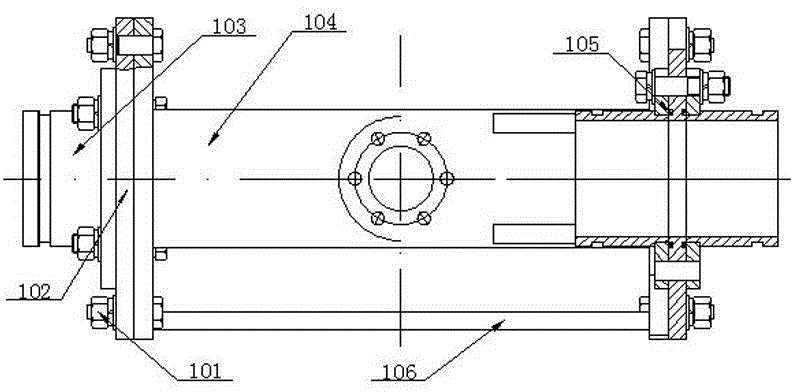

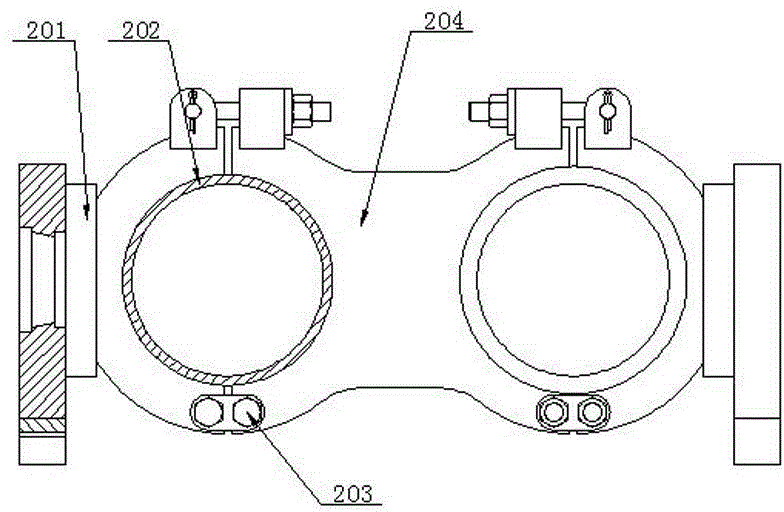

[0020] see Figure 1-Figure 4 , the specific embodiment adopts the following technical scheme: it includes a housing 1, a spool 2, and a power transmission device 3, the spool 2 is installed in the housing 1, the power transmission device 3 is connected to the spool 2, and the housing 1 is composed of fasteners 101, valve plate 102, connecting standard pipe 103, butt support plate 104, sealing ring 105, and transverse shelf 106; the lower end of the housing 1 is provided with a transverse shelf 106, and the valve plate 102 passes through the fastener 101 is connected with the docking support plate 104 and the connection standard pipe 103, and the sealing ring 105 is arranged on the valve plate 102; the valve core 2 is composed of a hoop 201, a valve core pipe 202, a connector 203, and a valve core connecting plate 204; The spool connecting plate 204 is provided with a spool pipe 202, one side of the spool pipe 202 is provided with a connector 203, both ends of the spool connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com