Regeneration impregnation liquid and regeneration technology for vanadium-titanium corrugated plate type denitrification catalyst

A denitration catalyst and corrugated plate technology are applied in the field of regeneration dipping solution and regeneration process of vanadium-titanium series corrugated plate denitration catalysts, which can solve the problems of untargeted regeneration of corrugated plate catalysts and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Select a deactivated vanadium-titanium series corrugated plate catalyst that has been used for two years in a power plant. The activity of the fresh catalyst is 93%, and the denitrification activity of the deactivated catalyst is reduced to 41%. The pore clogging rate of the above-mentioned corrugated plate catalyst reaches 31%. The size of the catalyst monomer is 46cm×23cm×60cm (length×width×height), and a section of the catalyst with the size of 15cm×15cm×30cm is cut off for simulated regeneration experiment.

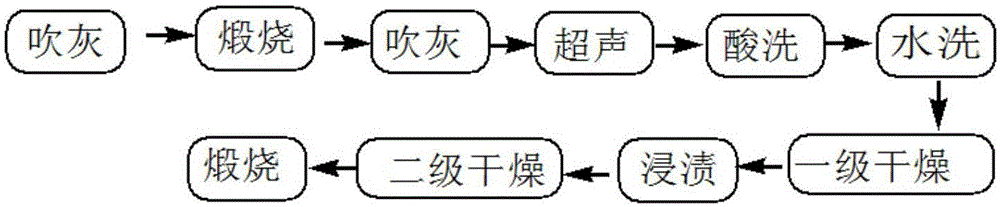

[0049]The catalyst was purged with 0.2MPa compressed air for 1h; the purged catalyst module was calcined in a muffle furnace at a heating rate of 10°C / min, and calcined at 450°C for 2h; the calcined catalyst module was compressed with 0.2MPa Air was purged for 30 minutes; the catalyst module after secondary dedusting was ultrasonically cleaned for 20 minutes at an ultrasonic frequency of 15kHZ; The catalyst module was washed in the water washing tank for 30 mi...

Embodiment 2

[0053] Select a deactivated vanadium-titanium series corrugated plate catalyst that has been used for two years in a power plant. The activity of the fresh catalyst is 93%, and the denitrification activity of the deactivated catalyst is reduced to 41%. The pore clogging rate of the above-mentioned corrugated plate catalyst reaches 31%. The size of the catalyst monomer is 46cm×23cm×60cm (length×width×height), and a section of the catalyst with the size of 15cm×15cm×30cm is cut off for simulated regeneration experiment.

[0054] The catalyst was purged with 0.5MPa compressed air for 40min; the purged catalyst module was calcined in a muffle furnace at a heating rate of 10°C / min, and calcined at 500°C for 2h; the calcined catalyst module was fired with 1MPa compressed air Purge for 10 minutes; ultrasonically clean the catalyst module after secondary dust removal for 30 minutes, and the ultrasonic frequency is 20kHZ; then clean the catalyst module after ultrasonic treatment for 30...

Embodiment 3

[0058] Select a deactivated vanadium-titanium series corrugated plate catalyst that has been used for two years in a power plant. The activity of the fresh catalyst is 93%, and the denitrification activity of the deactivated catalyst is reduced to 41%. The pore clogging rate of the above-mentioned corrugated plate catalyst reaches 31%. The size of the catalyst monomer is 46cm×23cm×60cm (length×width×height), and a section of the catalyst with the size of 15cm×15cm×30cm is cut off for simulated regeneration experiment.

[0059] Blow the catalyst with 1MPa compressed air for 30min; calcinate the purged catalyst module in a muffle furnace at a heating rate of 10°C / min, and calcine at 550°C for 2h; blow the calcined catalyst module with 1MPa compressed air Sweep for 20 minutes; ultrasonically clean the catalyst module after secondary dust removal for 40 minutes, and the ultrasonic frequency is 32kHZ; then clean the catalyst module after ultrasonic treatment in a pickling pool fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com