A construction waste removal and classification auger and a complete set of construction waste treatment equipment

A construction waste, complete set of treatment technology, applied in construction waste recycling, solid waste removal, recycling technology and other directions, can solve the problems of poor use effect, single function of the auger, and achieve high production efficiency, high degree of intelligence, Use easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

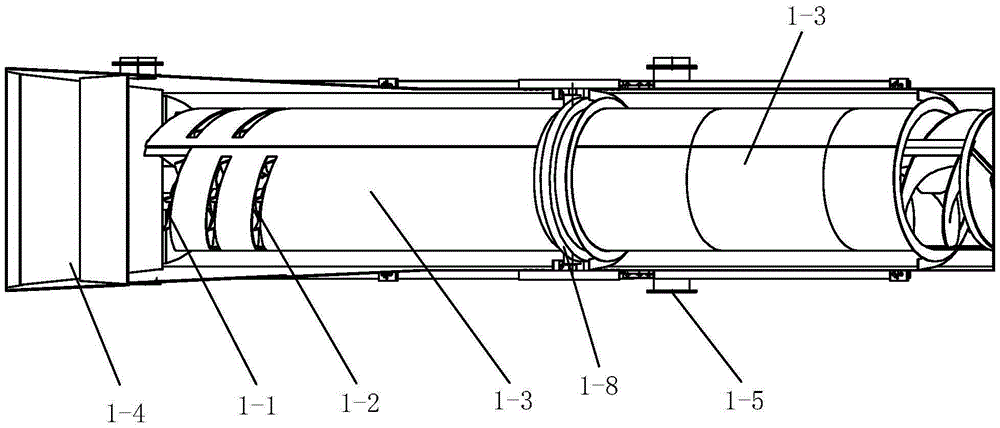

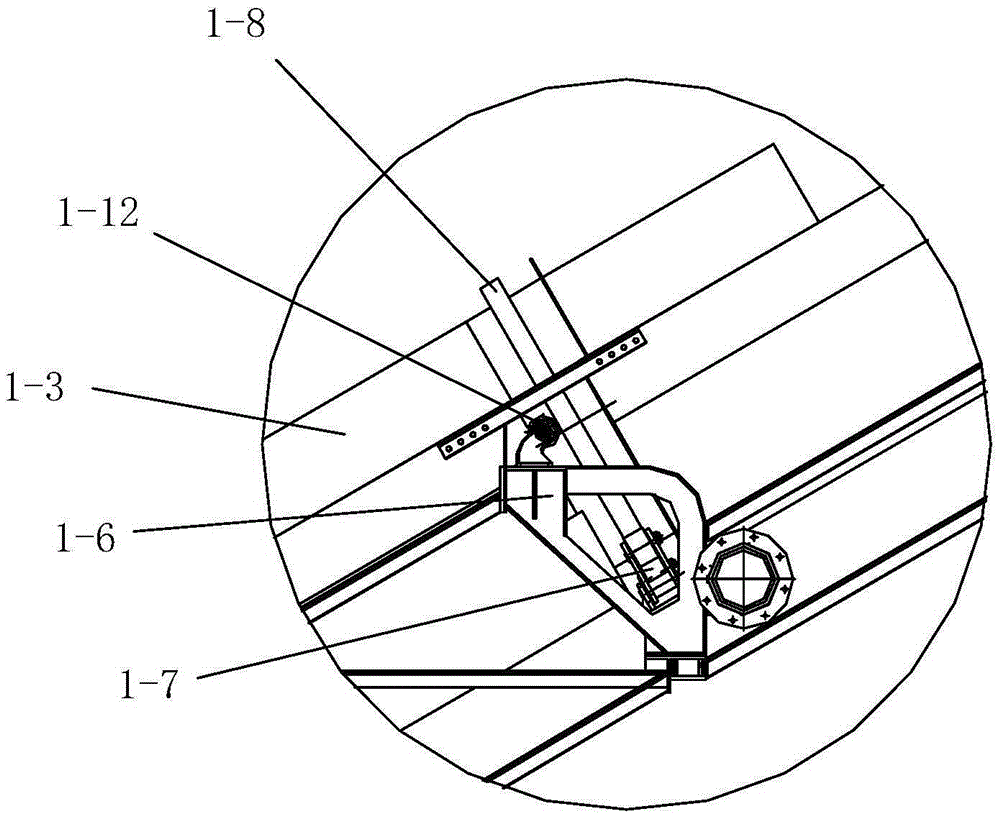

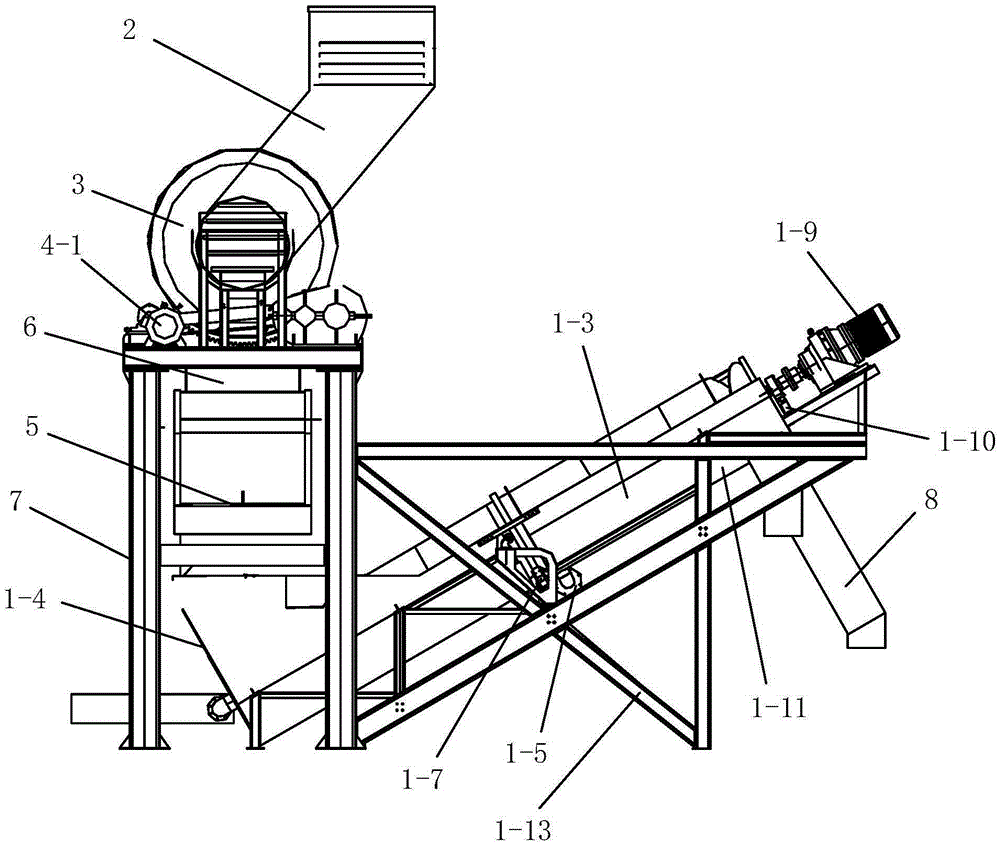

[0044] Such as figure 1 , figure 2 The construction waste removal and grading auger shown includes a screen cylinder 1-3, a screw conveying mechanism 1-2 installed in the screen cylinder 1-3, and a construction waste that needs to be processed before entering the screen cylinder 1-3. Washing tank 1-4, one end of the screen cylinder 1-3 is the feed end and the other end is the discharge end, the feed end is located in the water wash tank 1-4, and the discharge end is set outside There is an electric driving mechanism that drives the screw feeding mechanism 1-2 to continuously rotate, and the screw feeding mechanism 1-2 is connected to the electric driving mechanism through a transmission mechanism. The screw conveying mechanism 1-2 and the screen drum 1-3 are arranged coaxially.

[0045] In this embodiment, the construction waste removal and grading auger of the present invention also includes an auger support 1-13 for supporting the sieve cylinder 1-3, and the auger support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com