Honeycombed catalyst and preparation method and application thereof

A technology of honeycomb catalyst and SCR catalyst, which is applied in the field of honeycomb catalyst and its preparation, which can solve the problems of poor dispersion effect and achieve the effects of low shedding rate, excellent resistance to sulfur poisoning, and high loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

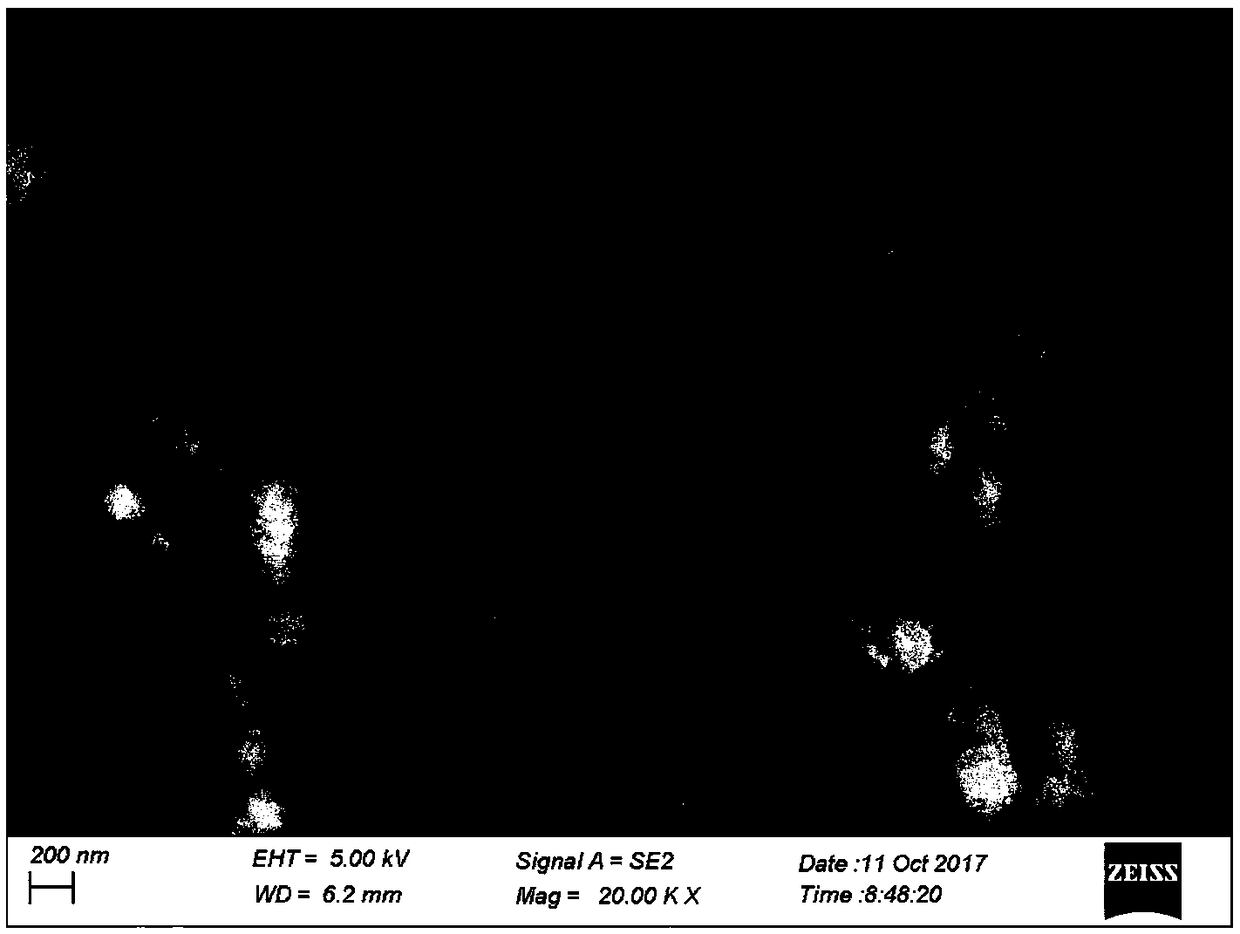

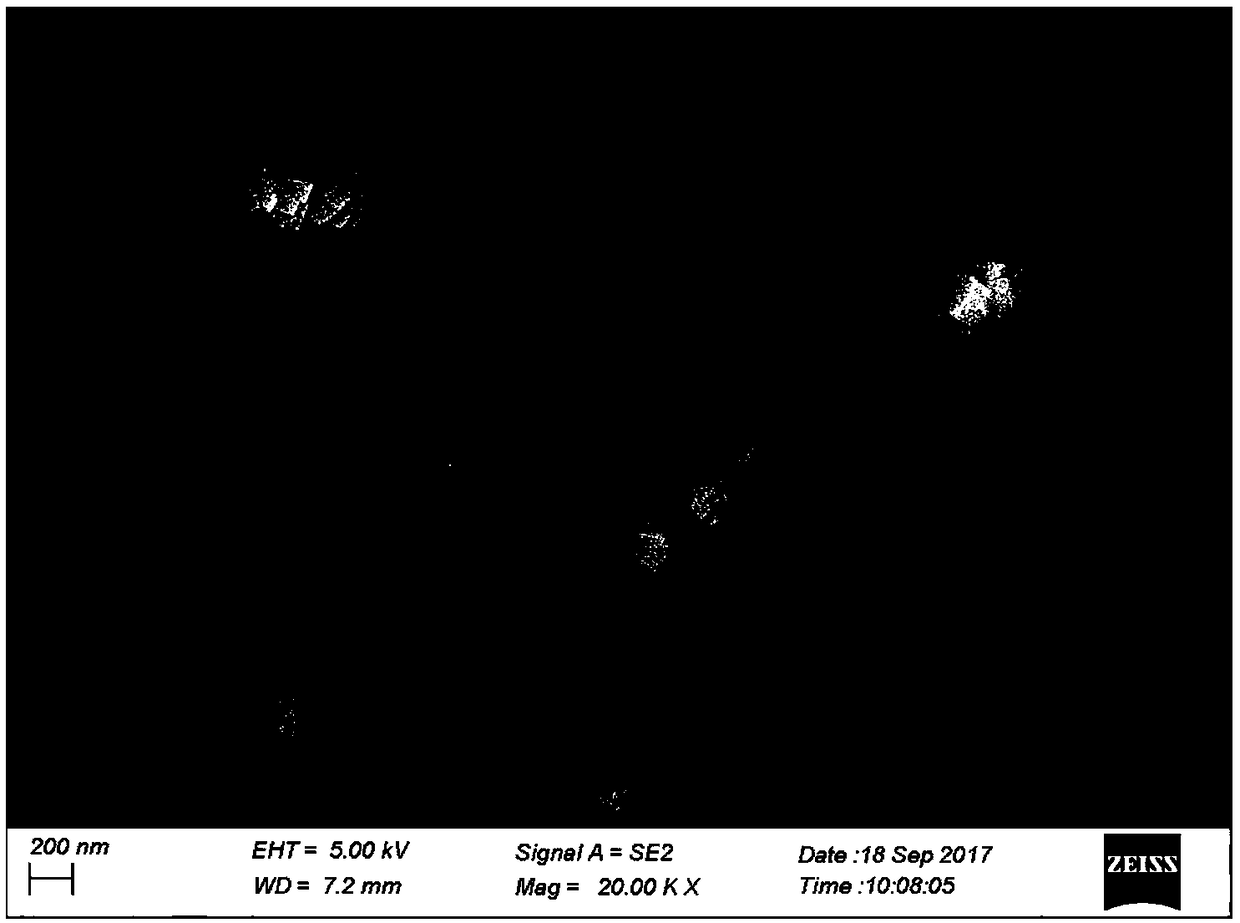

Image

Examples

preparation example Construction

[0039]

[0040] The preparation method of the honeycomb catalyst of the present invention includes the following steps: (A') electromagnetic oscillation dispersion treatment step of SCR catalyst slurry; (A) honeycomb ceramic treatment step; (B) coating the SCR catalyst slurry after electromagnetic oscillation dispersion treatment The step of covering the honeycomb ceramic; (C) the drying and firing step.

[0041] In step (A'), the frequency of the electromagnetic oscillation is 40 to 200 kHz, preferably 80 to 180 kHz. The dispersion treatment time is 0.5-10 min, preferably 1.5-8 min, preferably 2.5-6 min. Through electromagnetic shock dispersion treatment, the secondary aggregation of high-viscosity SCR catalyst slurry can be avoided, and there is no material-in-water phenomenon. By adopting the above dispersion conditions, the components in the catalyst slurry can be uniformly dispersed, thereby increasing the loading capacity of the slurry, reducing the shedding rate, and redu...

preparation example 1

[0085] Preparation Example 1-Preparation of Cerium Glutamate

[0086] Add 1.335g of glutamic acid to 25mL of H 2 In O, heat to 65°C and stir evenly, add 2.67g of cerium carbonate and stir for 2h.

preparation example 2

[0087] Preparation Example 2-Preparation of Cerium Gluconate

[0088] Add 1.98g glucose and 2.67g cerium carbonate to 25mL of H 2 In O, heat to 60°C, stir and react for 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com