Anti-seepage and reinforcing paste slurry capable of resisting water flow erosion

A plaster slurry and cement technology, which is applied in the field of geotechnical engineering foundation treatment grouting, can solve the problems of expensive modifier, short slurry gel time, and large amount of modifier added, so as to achieve water retention and water resistance dispersion. Improve the ability, improve the effect of anti-scour and filling and plugging, and enhance the effect of anti-water erosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

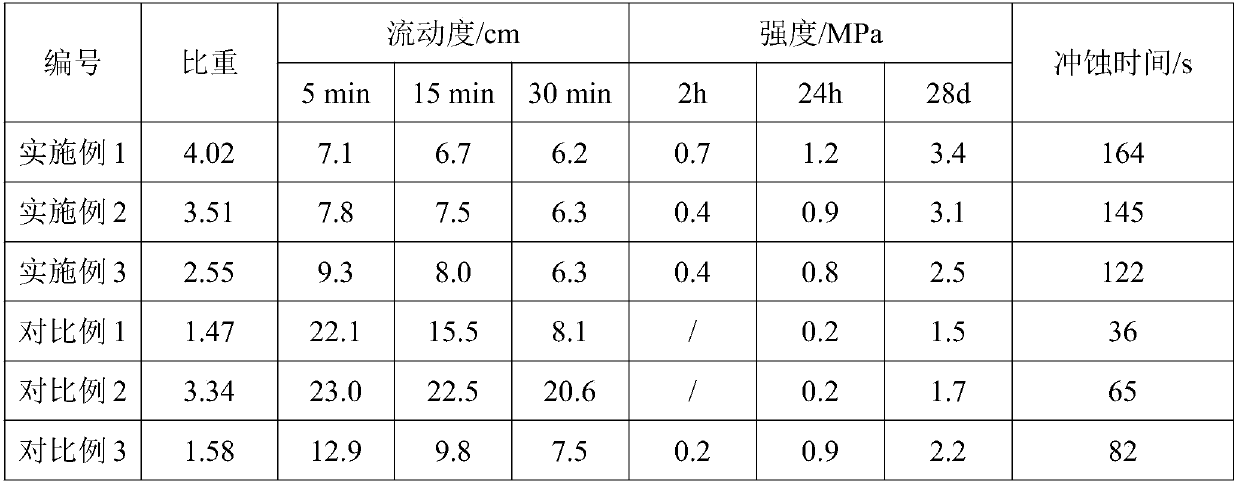

Embodiment 1

[0026] The invention relates to an anti-seepage and reinforcement slurry against water flow erosion, which comprises clay powder, cement, thickener, weighting agent, tackifier and water. Wherein, the mass ratio of the added amount of clay powder to cement is 0.5:1. The thickener is a water-absorbing resin, and the mass ratio of the added amount of the water-absorbing resin to water is 0.005:1. The weighting agent is made by mixing barite powder, iron ore powder and steel sand at a mass ratio of 1:1:2, and the mass ratio of the weighting agent to cement is 3.5:1. The tackifier is vegetable glue, wherein the vegetable glue is made by mixing xanthan gum and konjac fine powder at a mass ratio of 2.3:1, and the mass ratio of the amount of tackifier to cement is 0.002:1. The total mass ratio of the amount of water added to cement, clay and weighting agent is 0.4:1.

Embodiment 2

[0030] The invention relates to an anti-seepage and reinforcement slurry against water flow erosion, which comprises clay powder, cement, thickener, weighting agent, tackifier and water. Wherein, the mass ratio of the added amount of clay powder to cement is 0.5:1. The thickener is a water-absorbing resin, and the mass ratio of the added amount of the water-absorbing resin to water is 0.005:1. The weighting agent is made by mixing barite powder, iron ore powder and steel sand at a mass ratio of 1:1:1, and the mass ratio of the weighting agent to cement is 3:1. The tackifier is vegetable glue, wherein, the vegetable glue is mixed with xanthan gum and konjac fine powder at a mass ratio of 2.3:1, and the mass ratio of the amount of tackifier to cement is 0.001:1. The total mass ratio of the amount of water added to cement, clay and weighting agent is 0.4:1.

Embodiment 3

[0034] The invention relates to an anti-seepage and reinforcement slurry against water flow erosion, which comprises clay powder, cement, thickener, weighting agent, tackifier and water. Wherein, the mass ratio of the added amount of clay powder to cement is 1:1. The thickener is a water-absorbing resin, and the mass ratio of the added amount of the water-absorbing resin to water is 0.01:1. The weighting agent is made by mixing barite powder, iron ore powder and steel sand at a mass ratio of 1:1:1, and the mass ratio of the weighting agent to cement is 1.5:1. The tackifier is vegetable glue, wherein, the vegetable glue is mixed with xanthan gum and konjac fine powder at a mass ratio of 2.3:1, and the mass ratio of the amount of tackifier to cement is 0.001:1. The total mass ratio of the amount of water added to cement, clay and weighting agent is 0.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com