Gravel production process capable of suppressing dust and preventing sand flying under strong wind condition

A production process and conditional technology, applied in the field of artificial sand making, can solve the problems of reduced screening rate, imperceptible, waste of energy, etc., and achieve the effect of reducing the probability of hole plugging, ensuring production efficiency, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

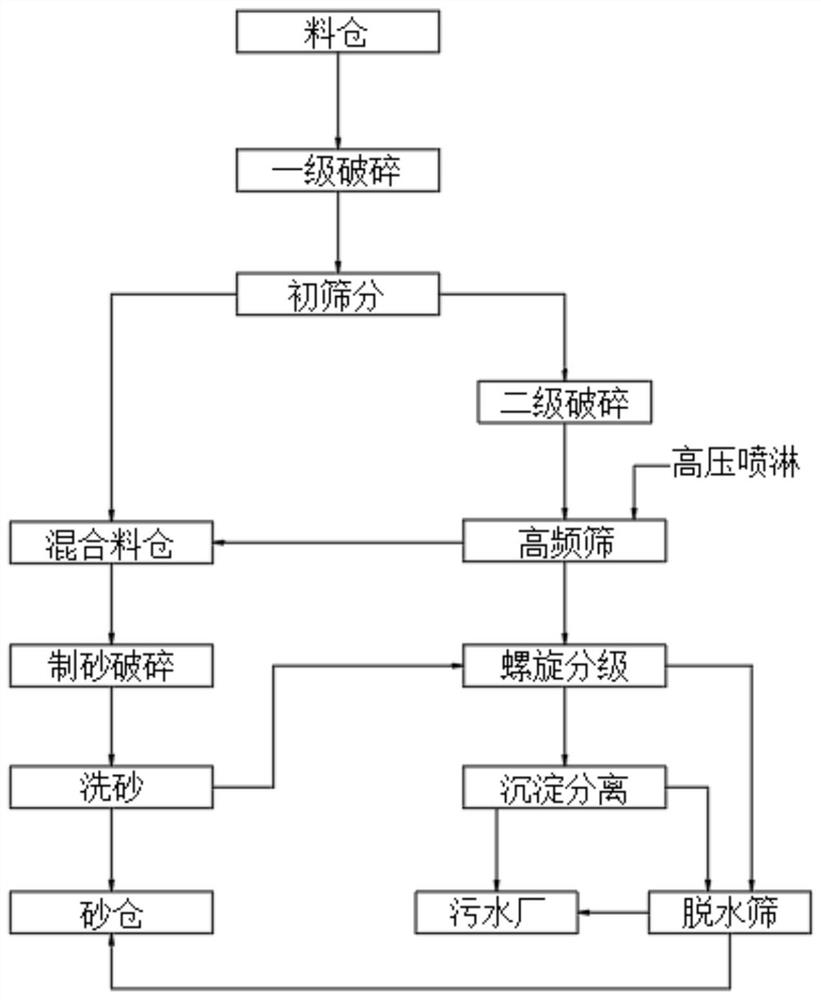

[0022] The invention provides a sandstone production process for dust suppression and flying sand prevention under strong wind conditions, comprising the following steps:

[0023] Step 1. Primary crushing. Raw materials with a particle size of 40mm to 120mm enter the crusher, and after crushing, carry out primary screening, small stones enter the mixing bin, and large stones enter the secondary crushing;

[0024] Step 2. Wet screening. The secondary crushed material is sent to the high-frequency screen with a belt conveyor. At the same time, the outlet of the belt conveyor is sprayed with a high-pressure spray pipe to adjust the flow of spray water so that the water content of the feed is 15. % to 25%, three sieve plates are arranged in sequence from top to bottom on the working surface of the high-frequency sieve. After the stone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com