Porous membrane and lithium ion battery

A technology of lithium-ion batteries and porous membranes, which is applied in the direction of secondary batteries, battery electrodes, battery components, etc., can solve the problems of lithium-ion battery cycle capacity reduction and impact on service life, and achieve excellent rate performance and cycle performance. The effect of reducing the probability of hole plugging and improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

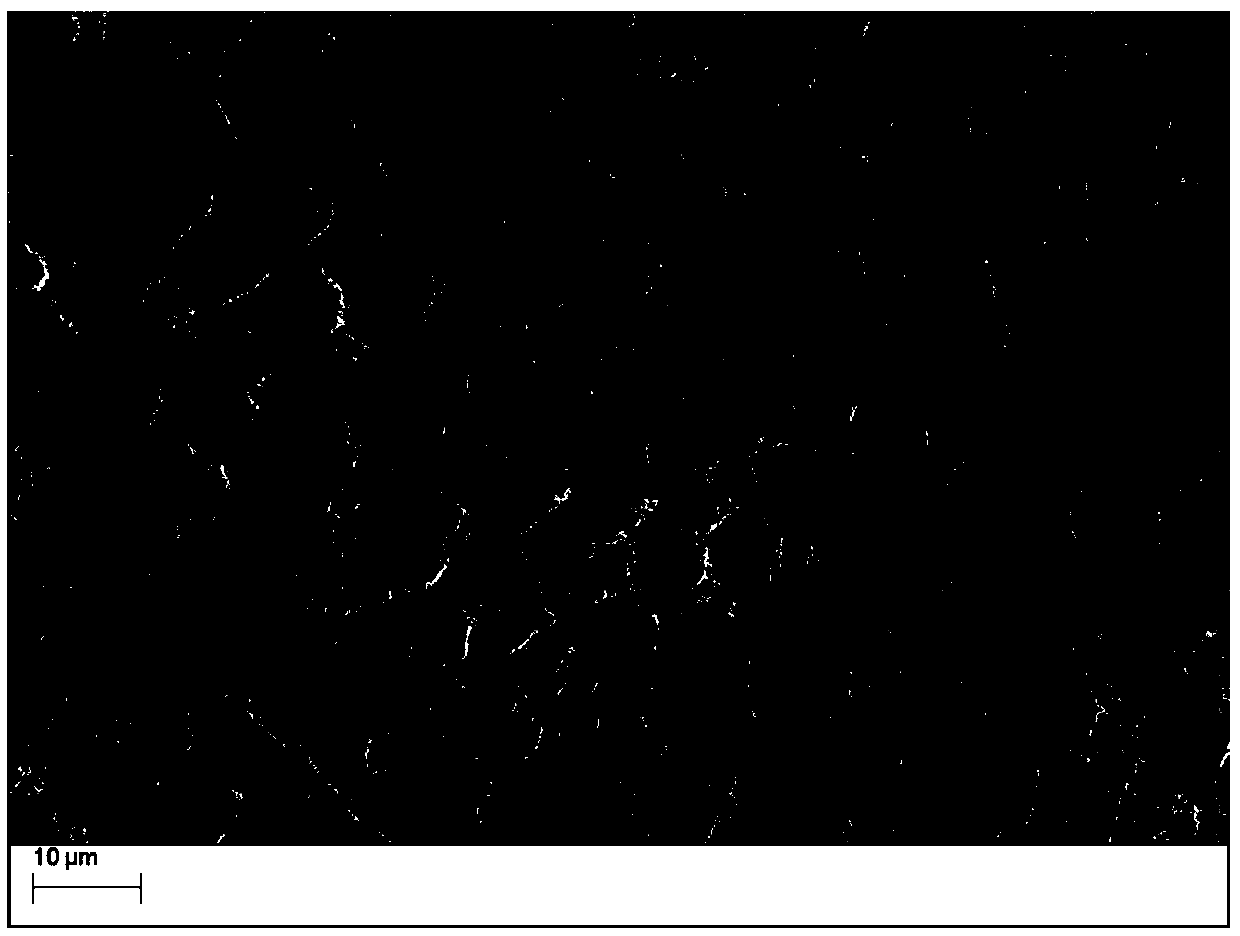

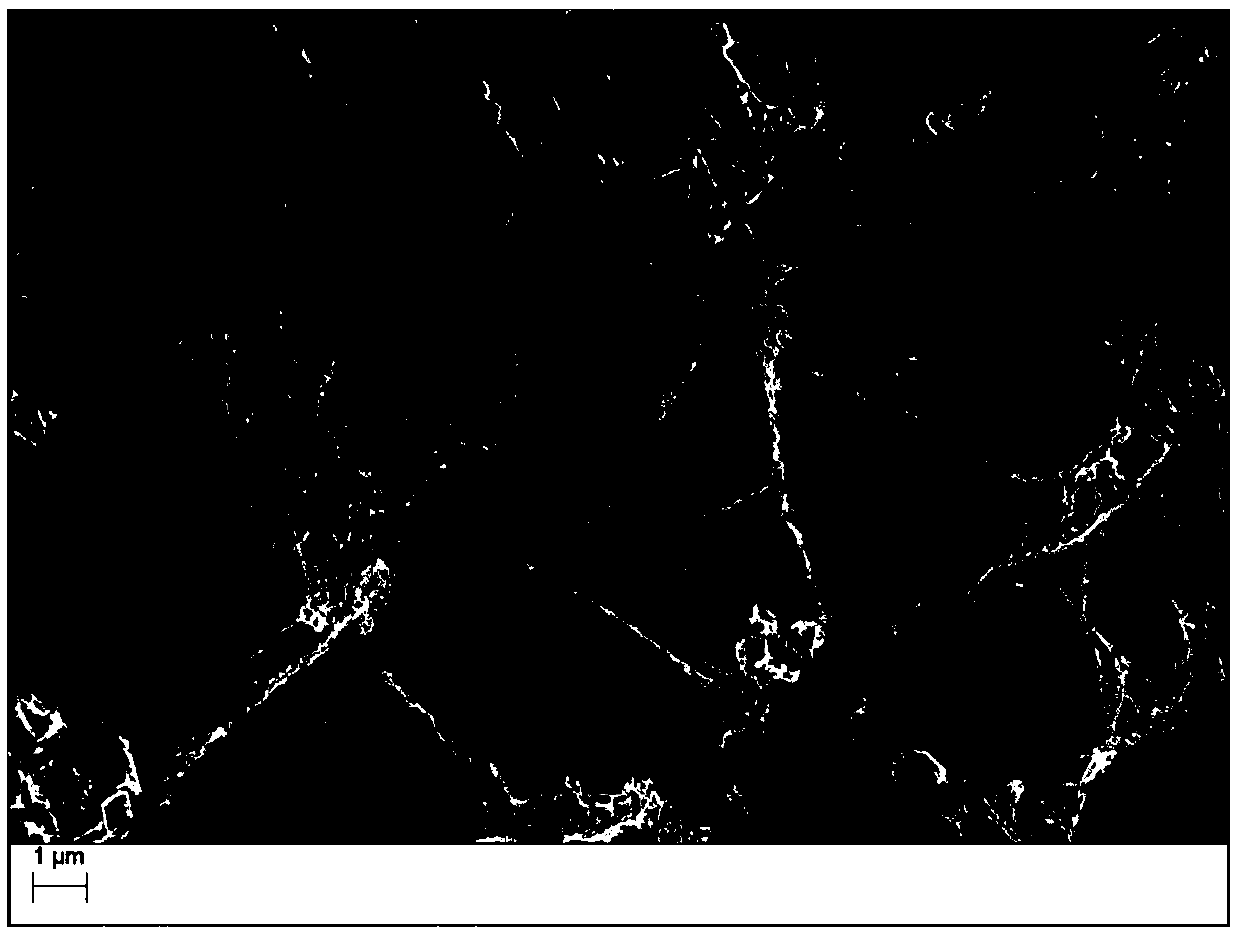

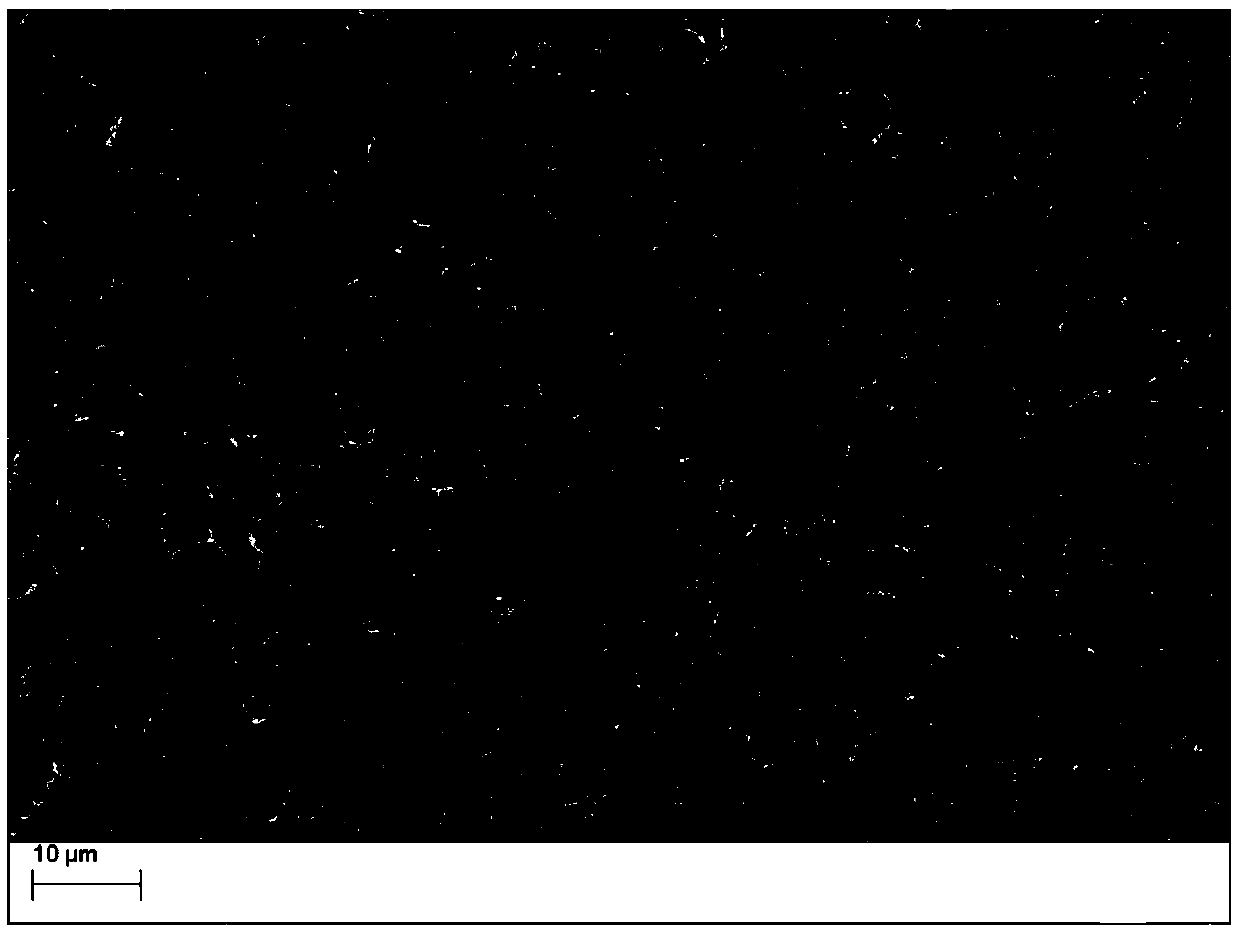

[0032] According to the second aspect of the present application, there is provided a method for preparing a porous film, which is used to prepare the porous film described in the first aspect of the present application, comprising the steps of: (1) mixing the inorganic particles with a binder, and then adding the second A solvent and uniformly stirred to obtain a coating liquid, wherein the binder is dissolved in the first solvent; (2) the coating liquid is evenly coated on at least one surface of the substrate to form a wet film; (3) the The matrix of the wet film is immersed in the coagulation liquid for phase inversion, wherein the coagulation liquid includes the second solvent and the third solvent, and the second solvent and the third solvent are mutually soluble; (4) after the phase inversion is completed, dry treatment is performed to obtain the surface with The substrate of a porous membrane, wherein the average wall thickness between adjacent pores in the porous membr...

Embodiment 1

[0072] (1) Preparation of negative electrode sheet

[0073] Negative electrode active material artificial graphite, binder styrene-butadiene rubber, conductive agent conductive carbon black (Super P) are mixed with deionized water at a mass ratio of 92:3:5 to make negative electrode slurry, and then the negative electrode slurry is evenly coated Cover the positive and negative sides of the copper foil of the negative electrode current collector, and then dry it at 85°C to form a negative electrode active material layer, and then perform cold pressing, slitting, cutting, and welding the negative electrode lugs to obtain the negative electrode sheet.

[0074] (2) Preparation of positive pole piece

[0075] The positive electrode active material lithium cobalt oxide (LiCoO 2 ), the binder polyvinylidene fluoride (PVDF), and the conductive agent conductive carbon black (Super P) are dissolved in the solvent N-methylpyrrolidone (NMP) at a mass ratio of 97:1.5:1.5, and stirred even...

Embodiment 2

[0083] In this embodiment, the preparation methods of the negative pole piece, the positive pole piece, the electrolyte solution, and the lithium-ion battery are the same as the corresponding preparation methods described in Example 1. The preparation method of the isolation film is the same as that described in Example 1, except that the solid content of the coating liquid is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com