Vibrating screen

A technology of sieve screen and screen frame, which is applied in the field of high-efficiency vibrating sieve screen, can solve the problems of high plugging rate, large sieving particle size control error, poor screening accuracy, etc., and achieve low plugging rate , saving energy consumption, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

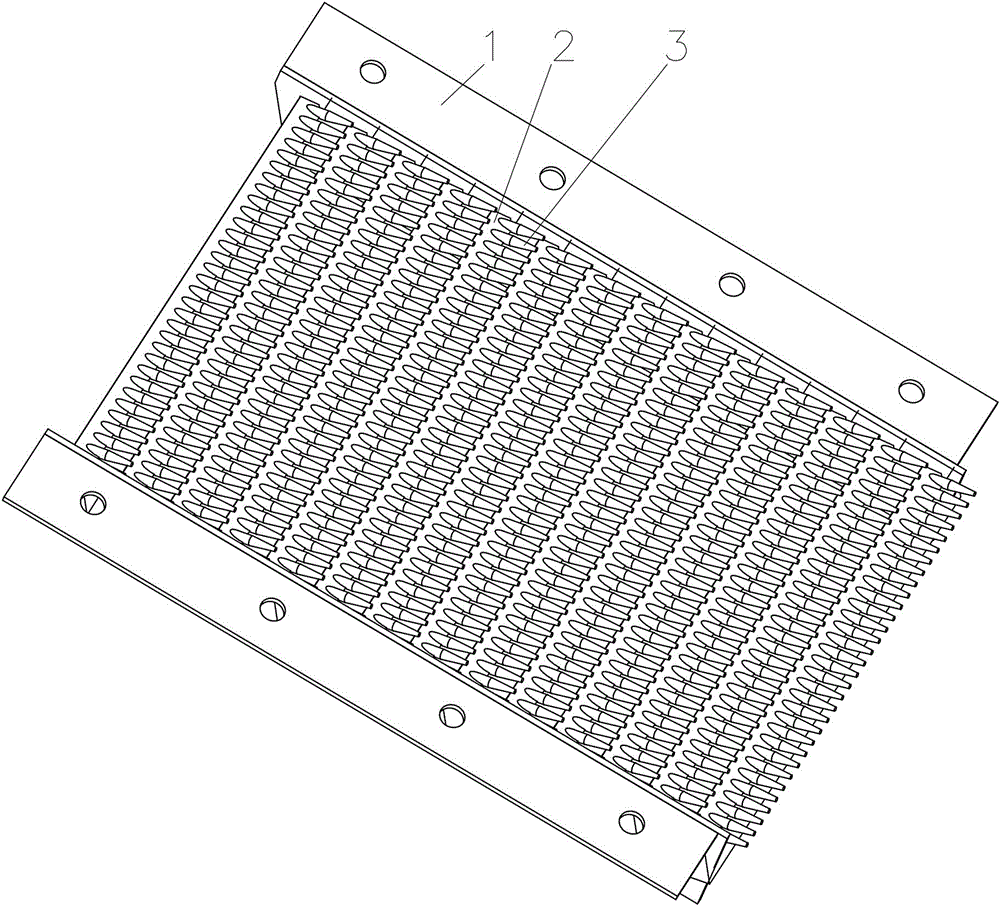

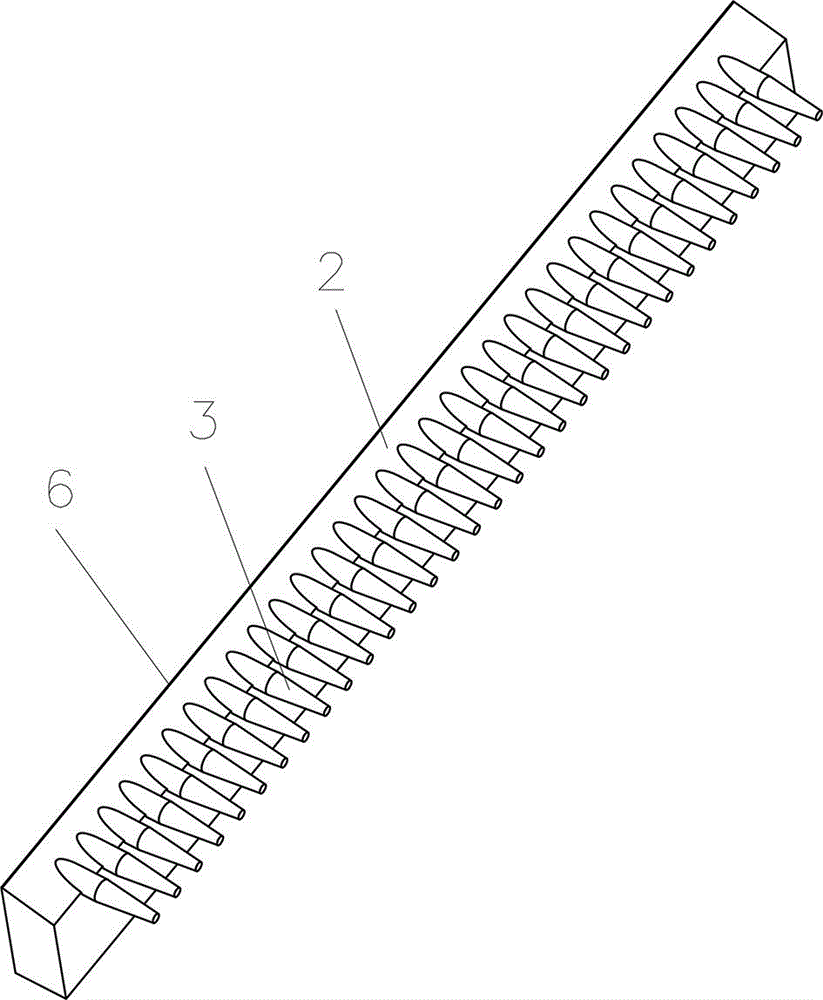

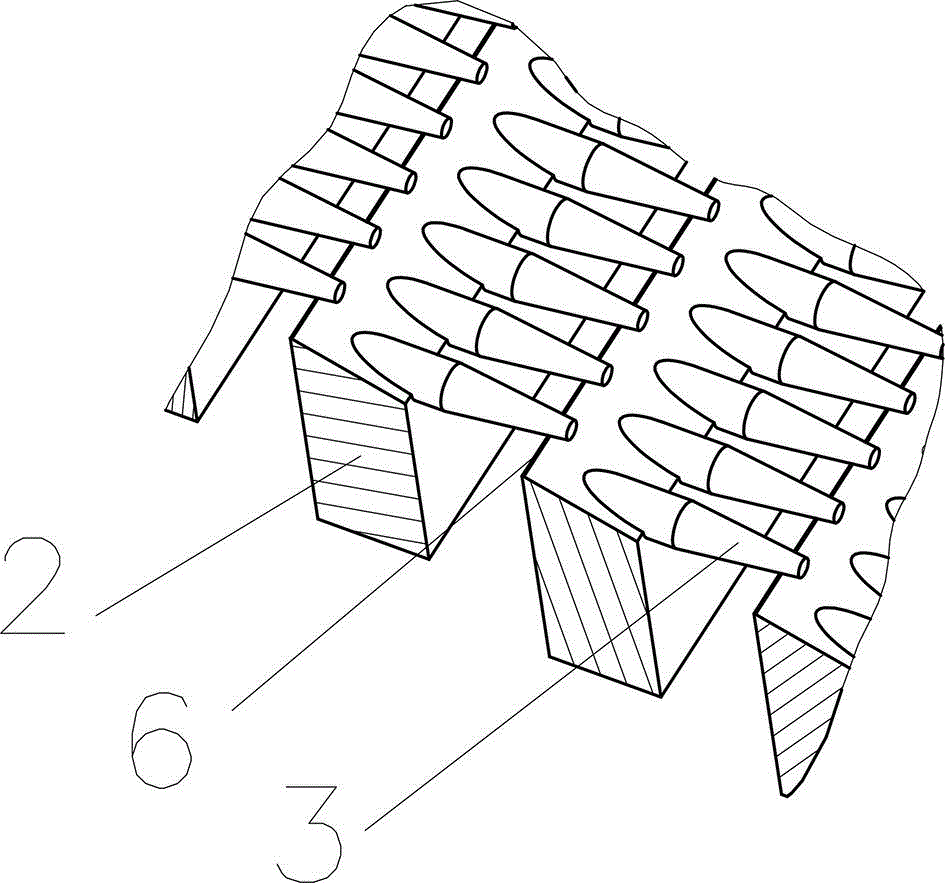

[0034] The application will be further described below in conjunction with the accompanying drawings.

[0035] A vibrating screen has a screen frame 1 on both sides, and bolt holes are arranged on the screen frame 1 . The ends of several sieve teeth 3 are evenly distributed in the same direction and fixed on the beam 2 side by side. constitute a sieve unit. The rear part of the sieve tooth 3 is consolidated with the beam 2, and the end part is suspended. The sieve tooth 3 is integrally made of alloy steel, which has high strength and toughness. The front portion of the sieve teeth 3 is a conical surface with a cone angle of 18°. The cylindrical surface in the middle of the sieve teeth 3 is connected with the cone surface, and there is a cylindrical surface with a slightly larger diameter than the cylindrical surface at the tail. On the crossbeam 2 there are mesh hole 21 and steps 27 uniformly distributed parallel to the diameter of the tail of the mesh 3 and the raised ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com