Patents

Literature

54results about How to "Increase sieving rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

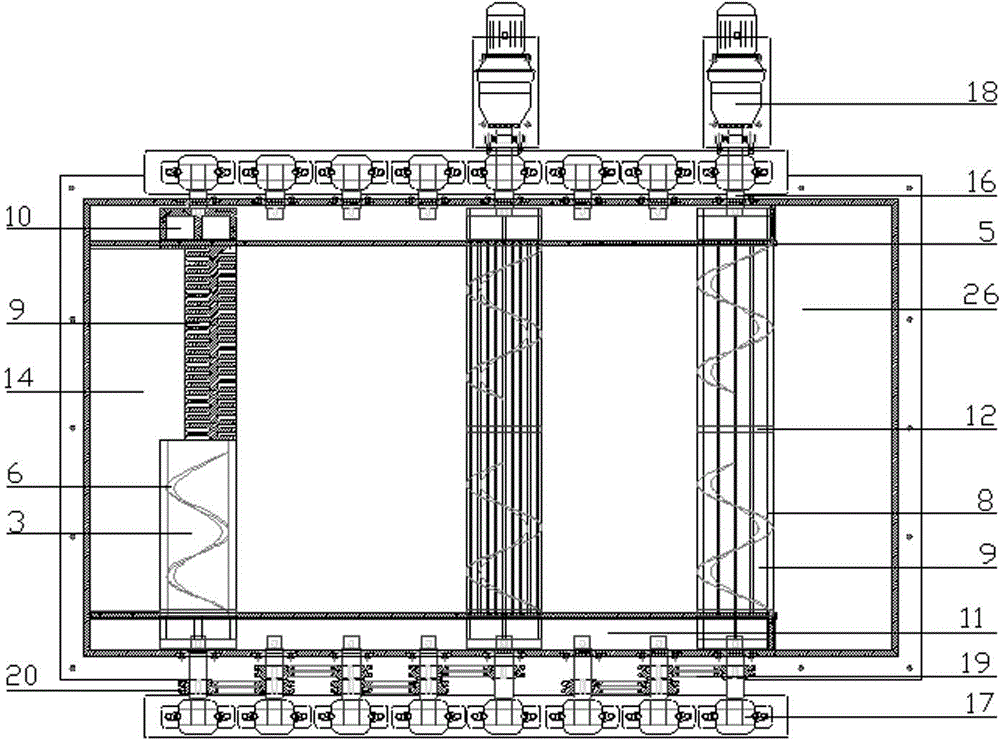

Sieving and crushing integrated machine

ActiveCN102896019AStrong impact resistanceReduces impact and wearSievingScreeningSystem structureProcess engineering

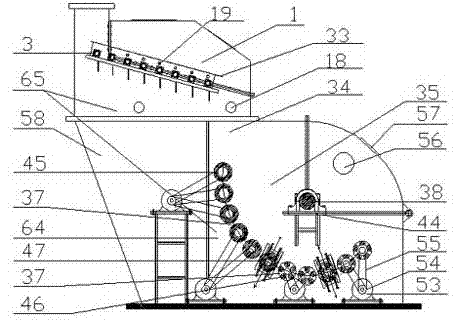

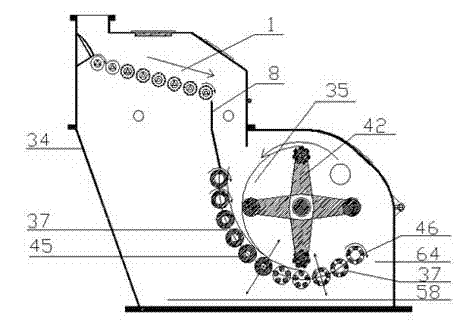

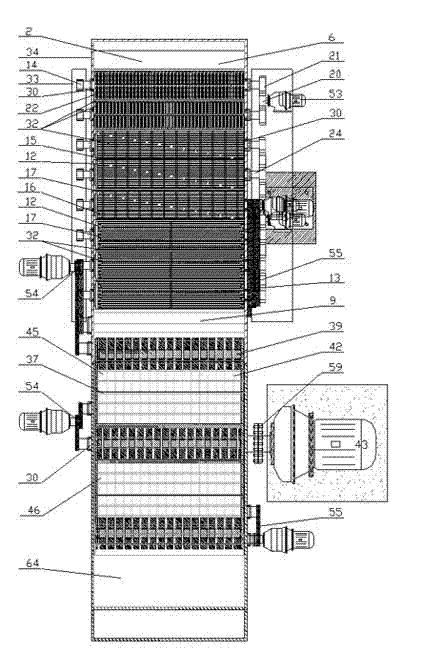

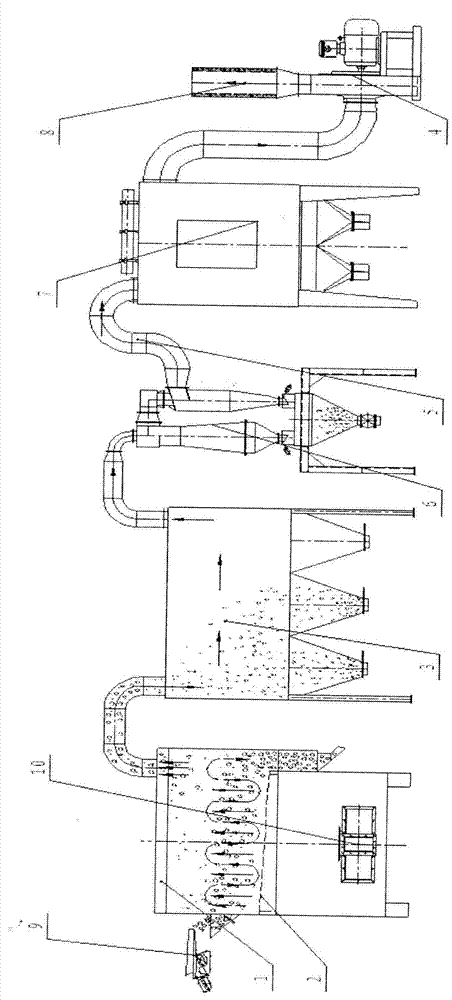

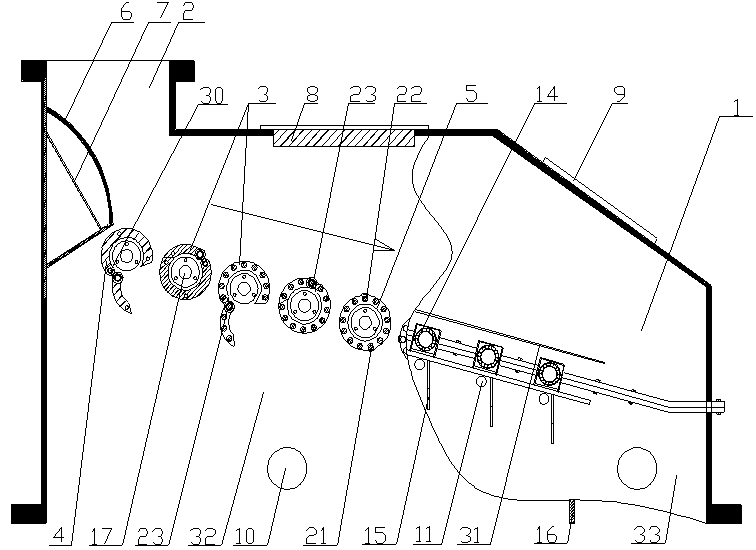

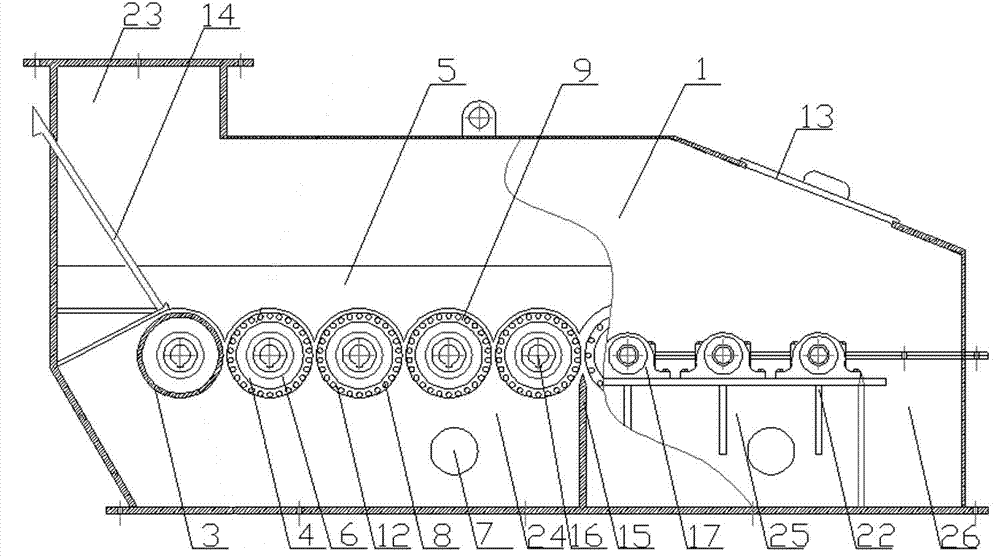

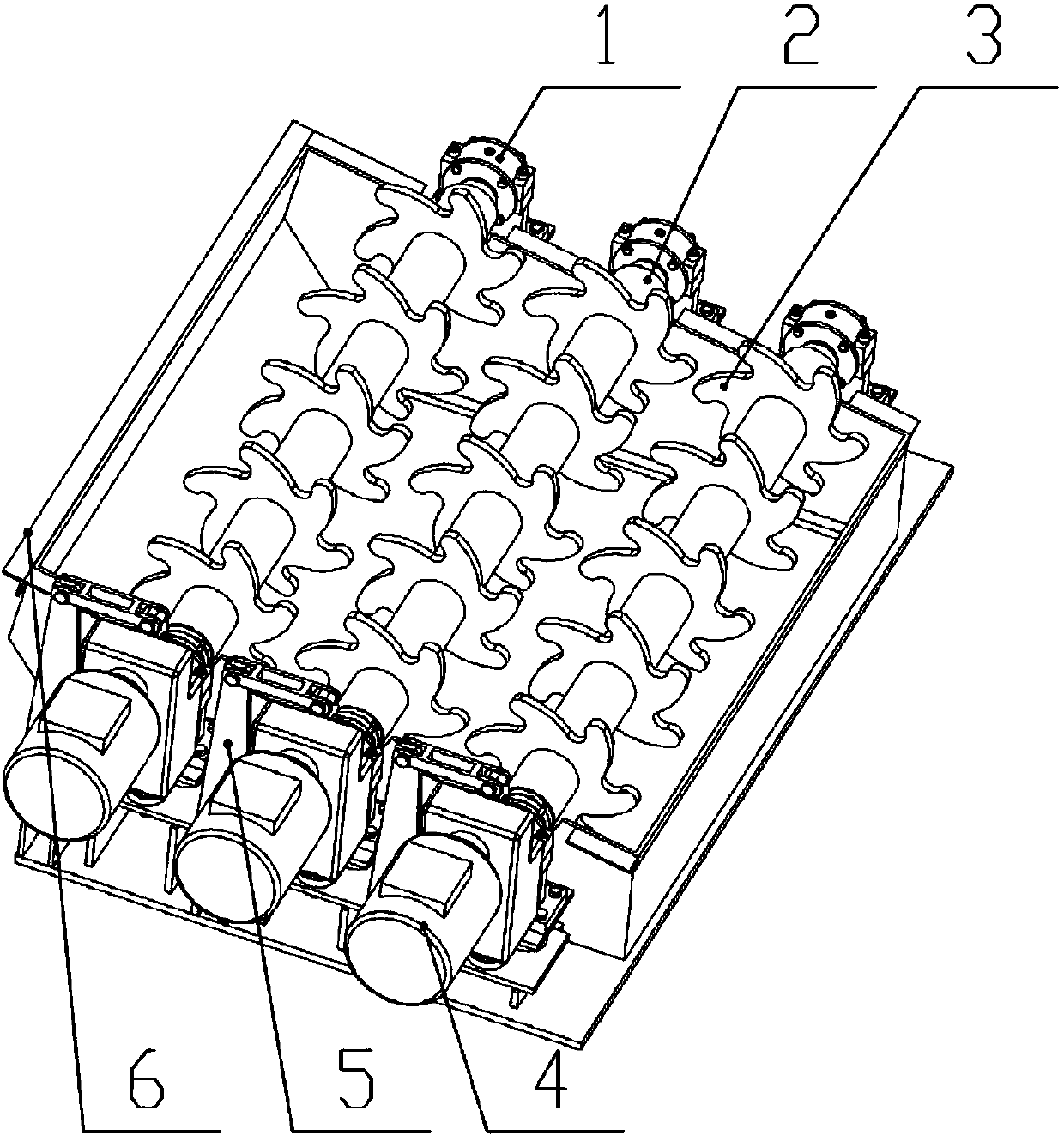

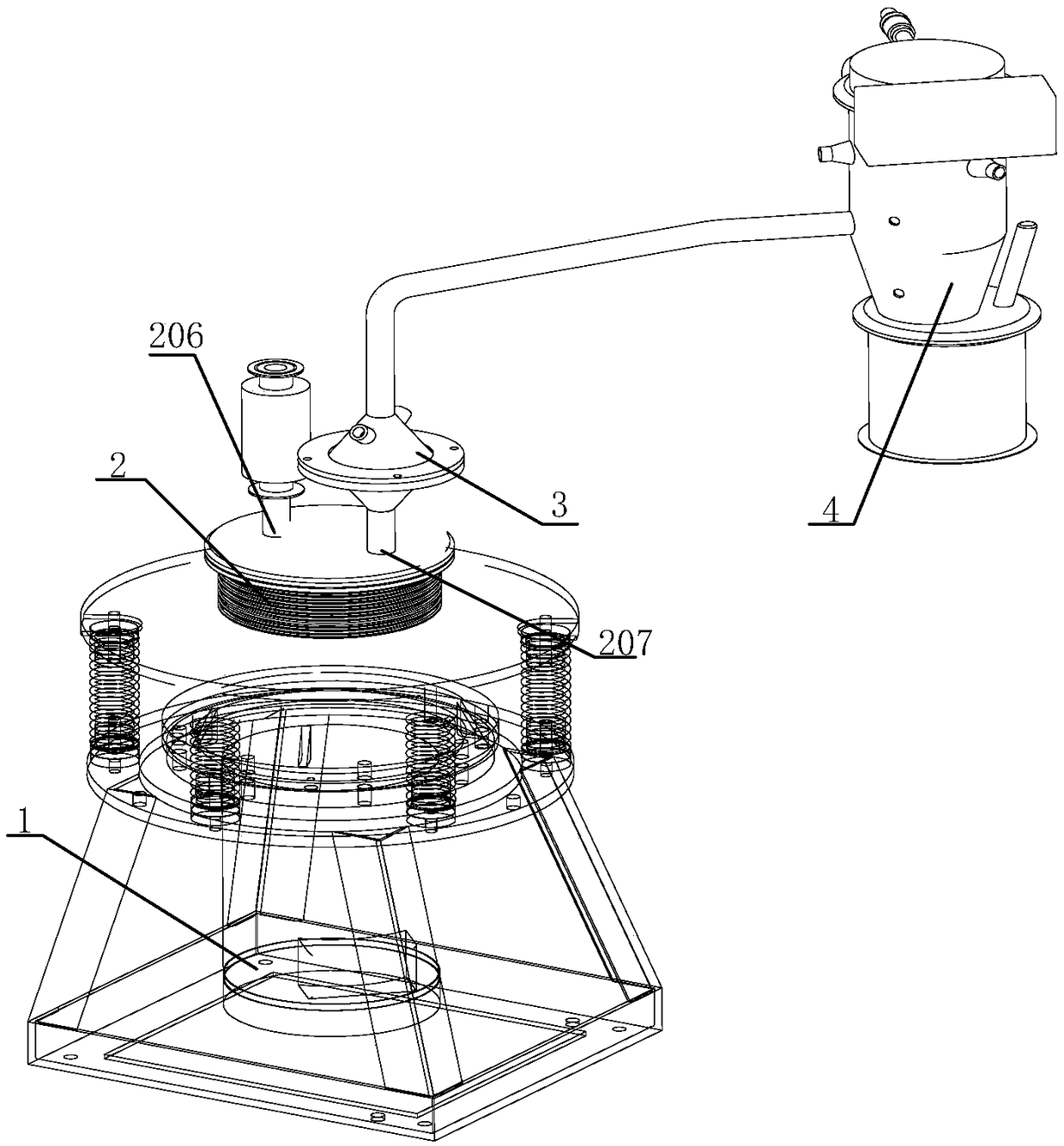

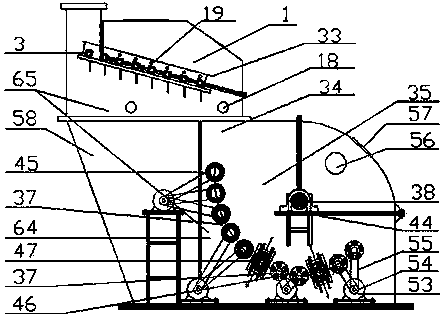

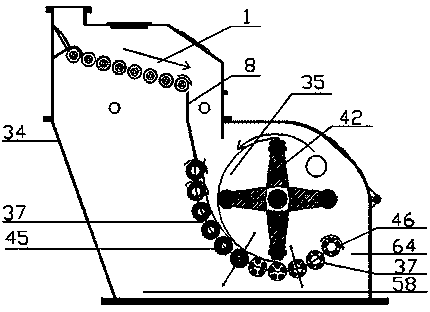

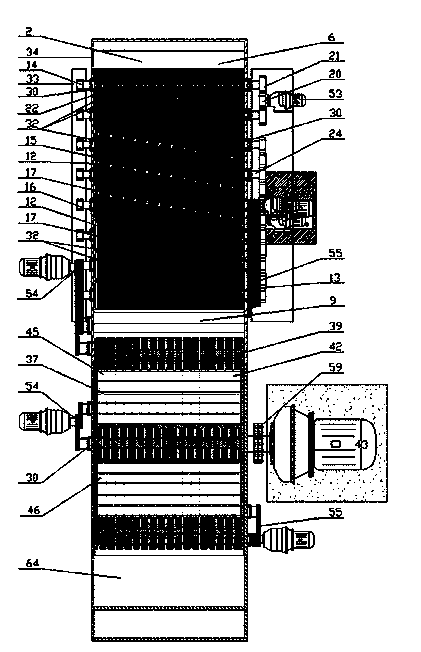

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Solid mixture multilayer vibration physics screening machine

InactiveCN104028452ASimple structureReasonable designSievingScreeningVehicle frameReciprocating motion

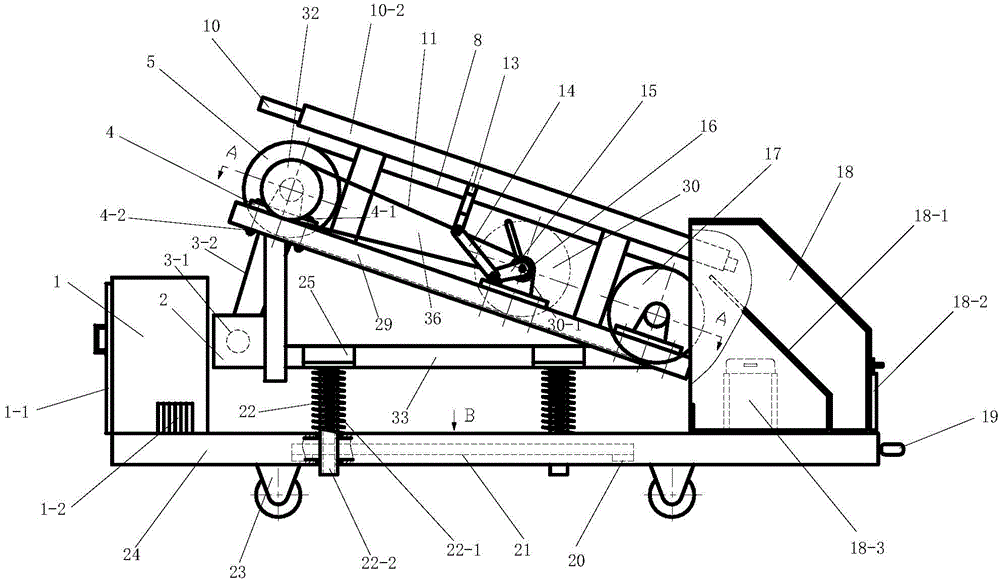

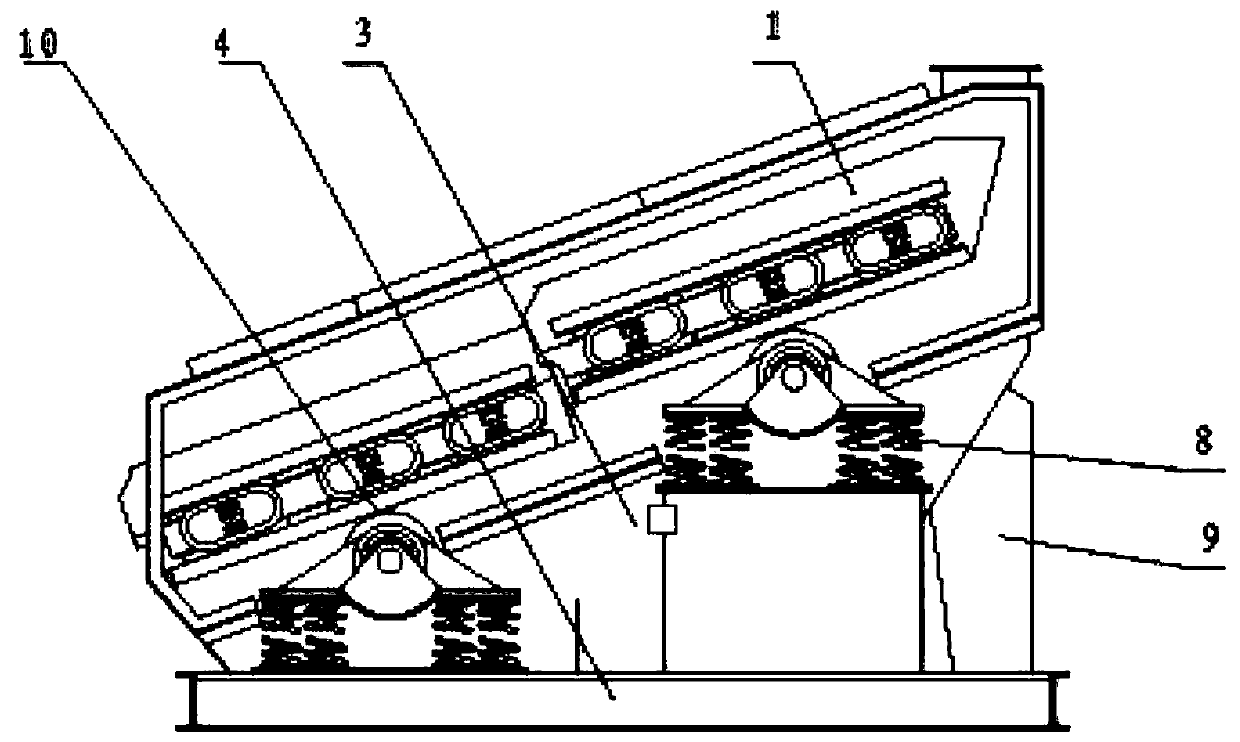

The invention discloses a solid mixture multilayer vibration physics screening machine. The solid mixture multilayer vibration physics screening machine comprises sliding screen nets installed on a car frame and a machine frame and a double layer circling screening device, wherein the double layer circling screening device is obliquely installed on a sliding guide rail of the machine frame and can perform straight reciprocating motion along the sliding guide rail of the machine frame, a beating mechanism is located between two layers of screen nets of the double layer circling screening device, a beating rod on a rotation shaft of the beating mechanism performs auxiliary beat on a vibrating screen net so as to achieve efficient and rapid penetration screening, the car frame is located at the bottom of the solid mixture multilayer vibration physics screening machine, the machine frame is installed on the car frame on the lower portion of the solid mixture multilayer vibration physics screening machine through a shock absorption mechanism, a material receiving disc is located below the double layer circling screening device and installed on the car frame, a material receiving box is installed and fixed on a portion of the car frame, located in front of the solid mixture multilayer vibration physics screening machine, the material receiving box is divided into storage compartments of different grain diameters of materials through material guide dummy plates, and the different storage compartments are respectively provided with different unloading doors. The solid mixture multilayer vibration physics screening machine can effectively screen solid mixture materials, achieves physics screening on the solid mixture materials according to the different grain diameters, and is high in efficiency, low in labor intensity, low in cost, and wide in application range.

Owner:CHANGAN UNIV

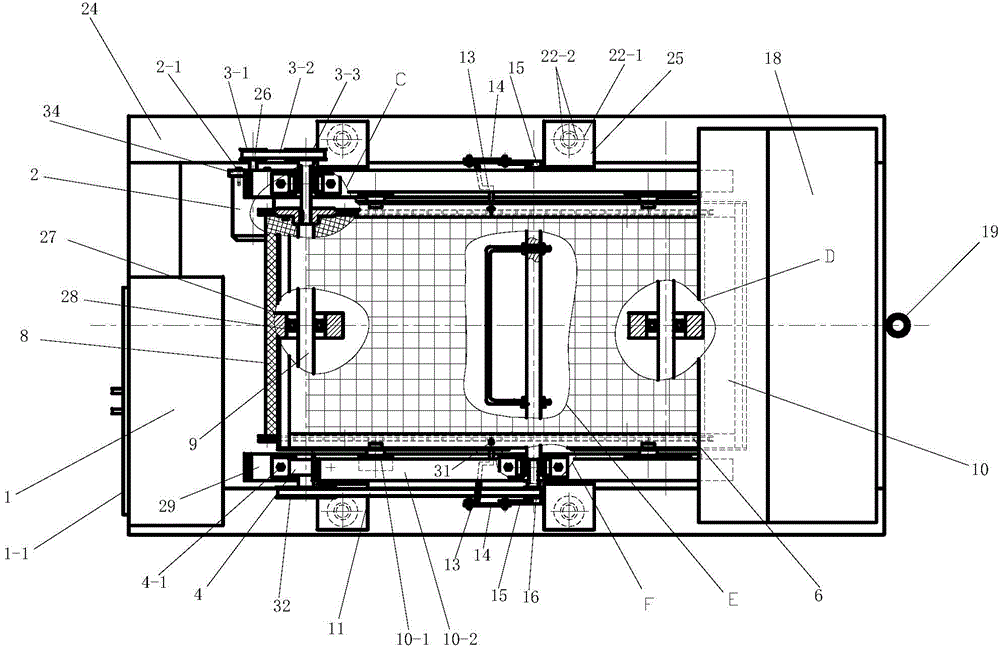

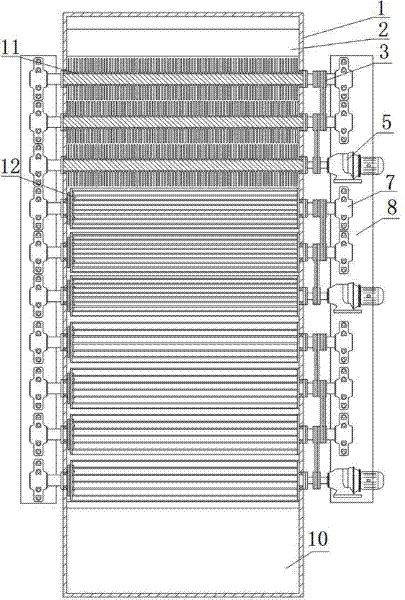

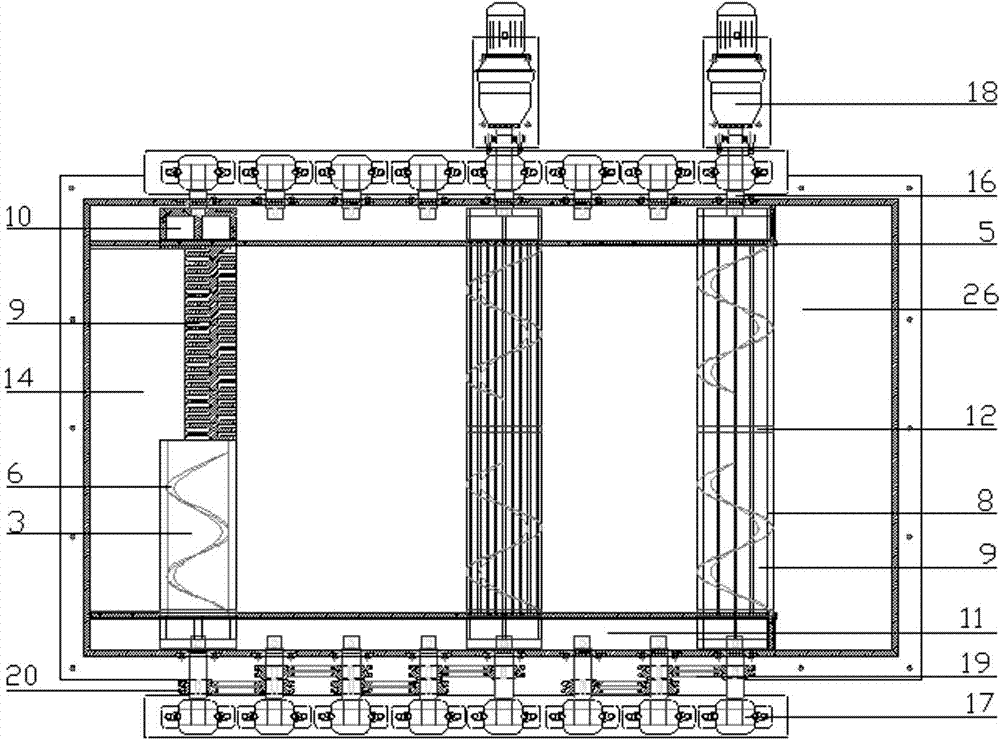

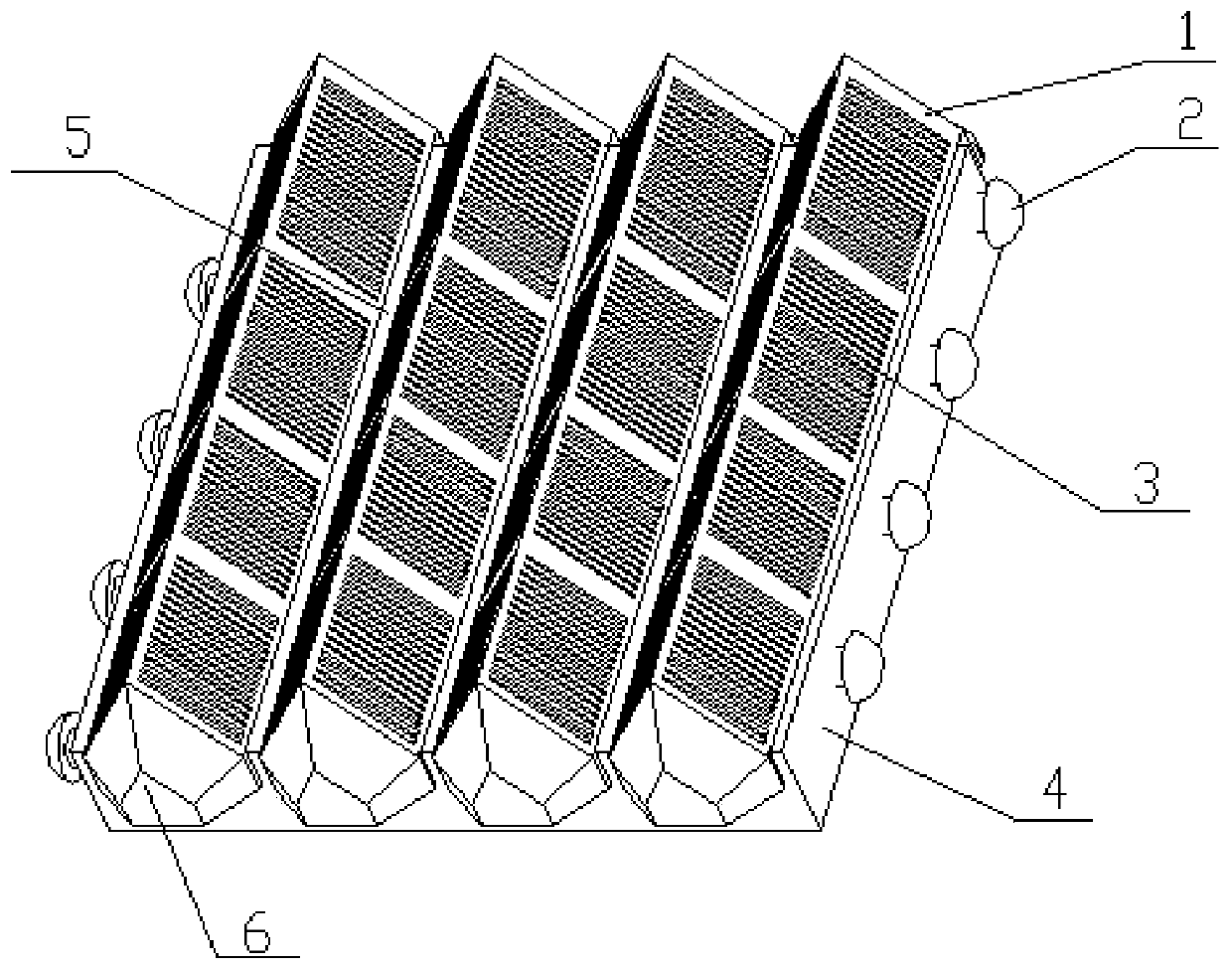

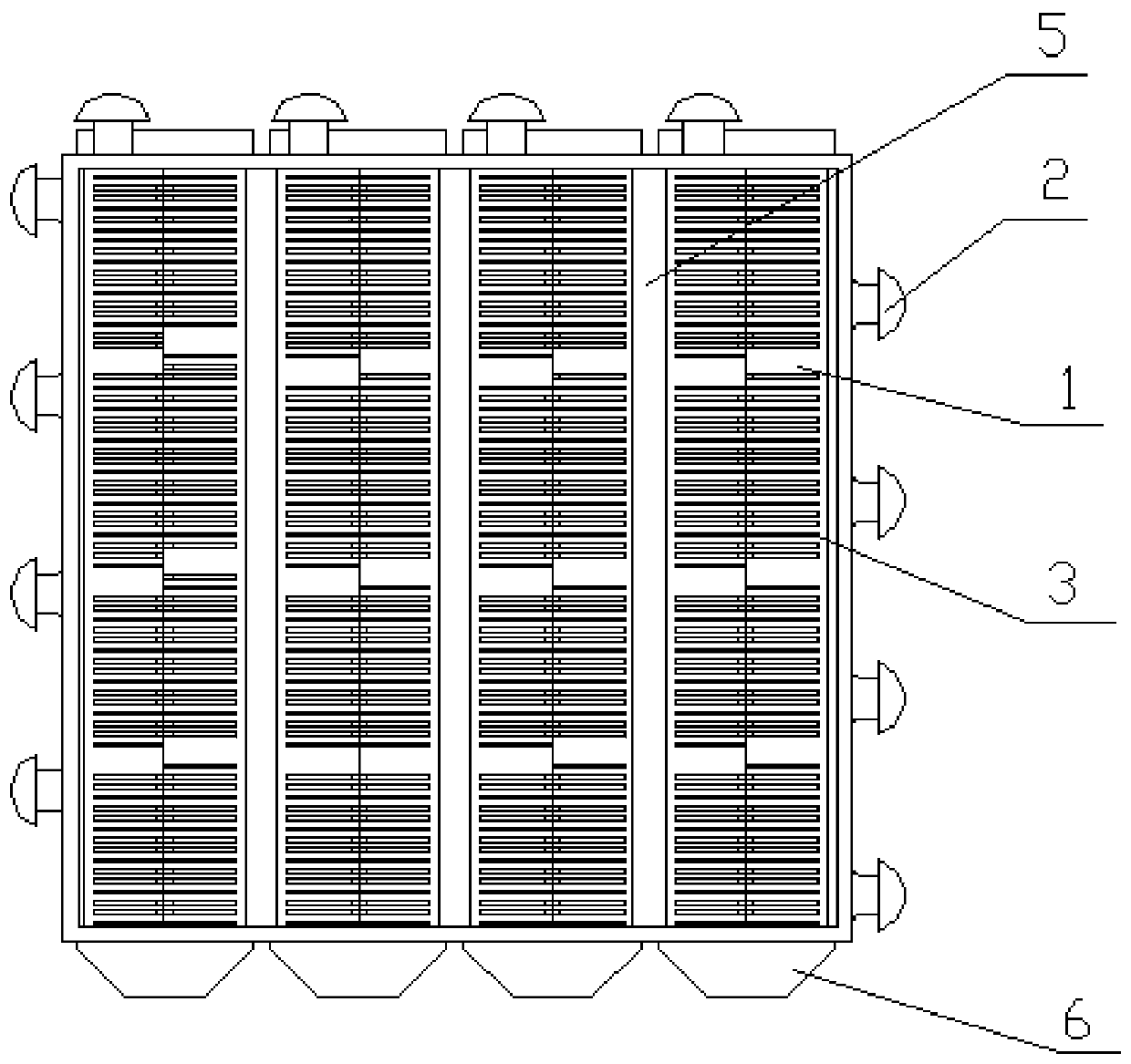

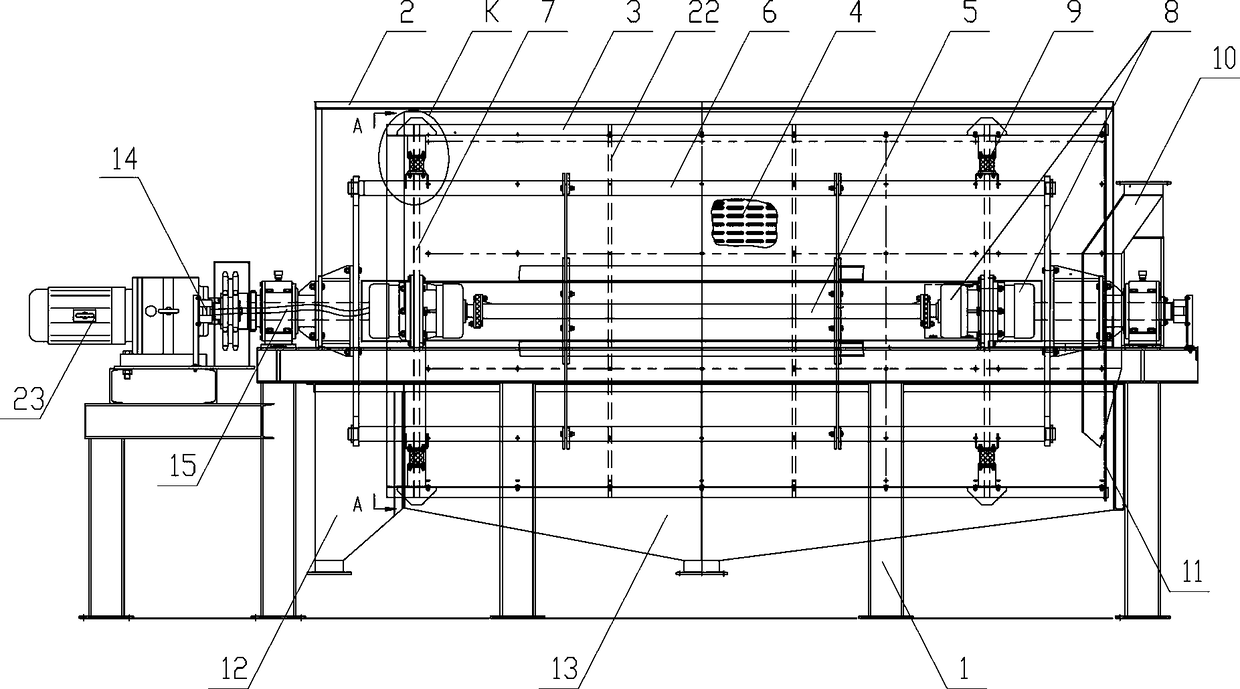

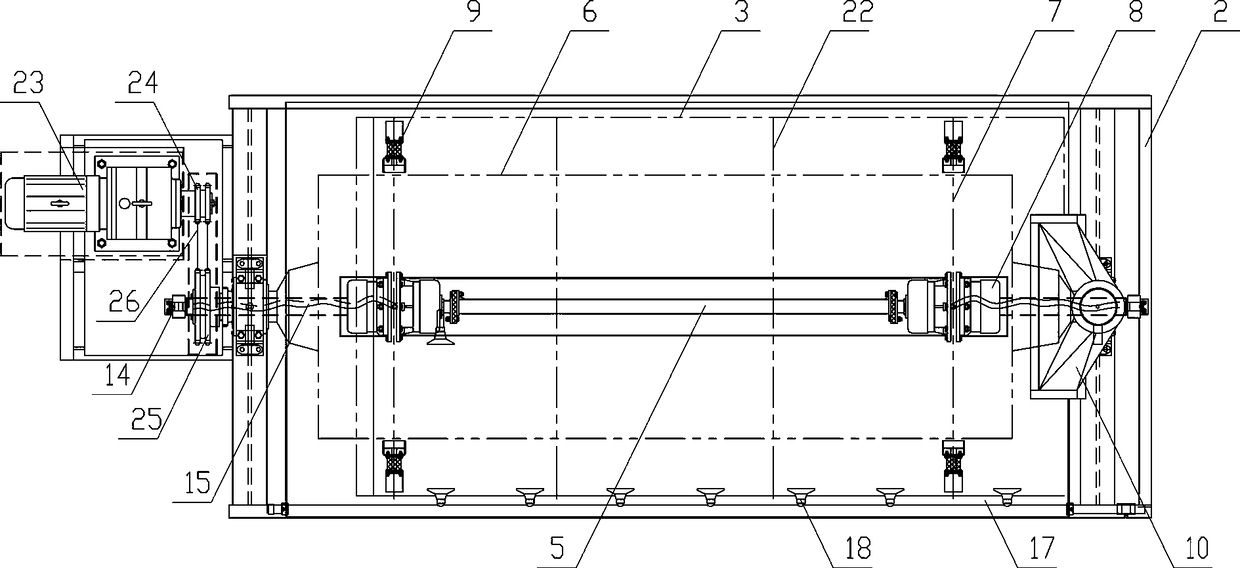

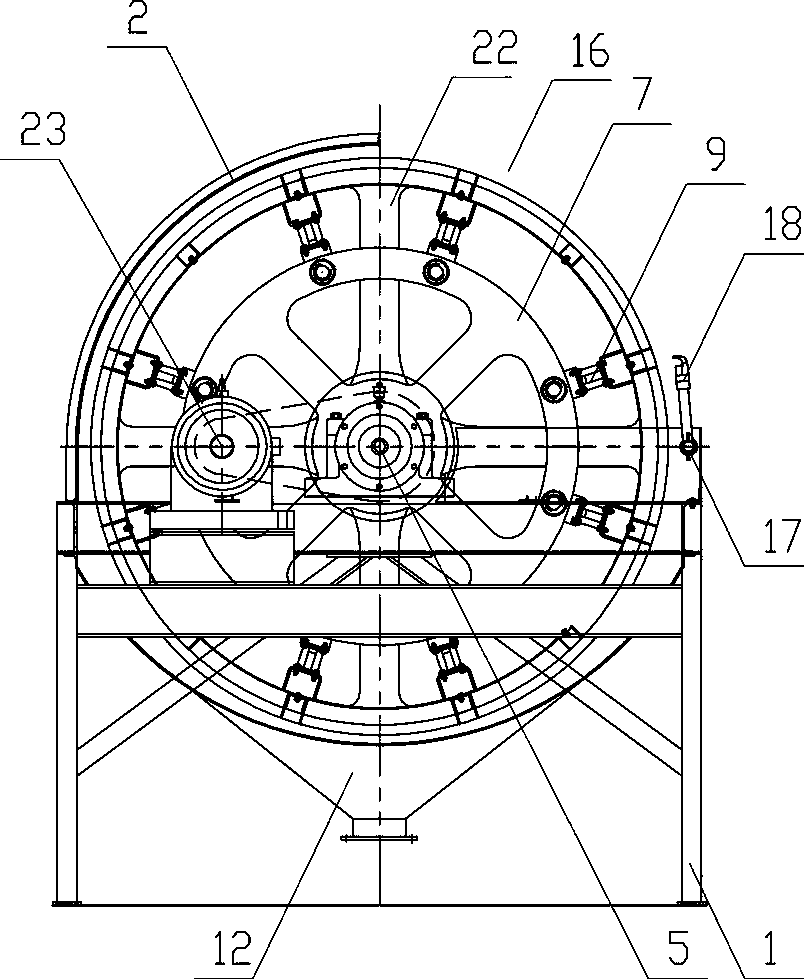

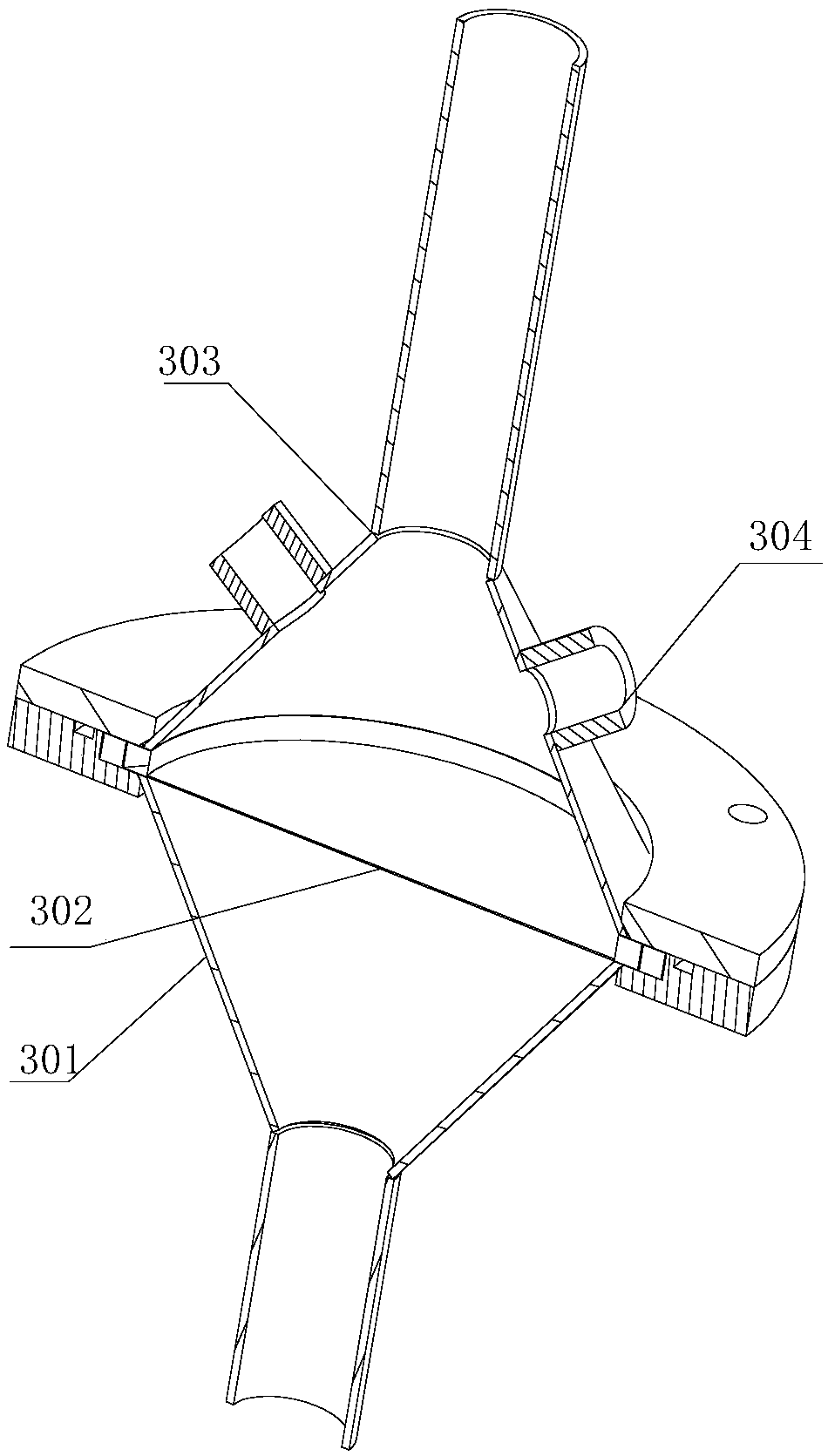

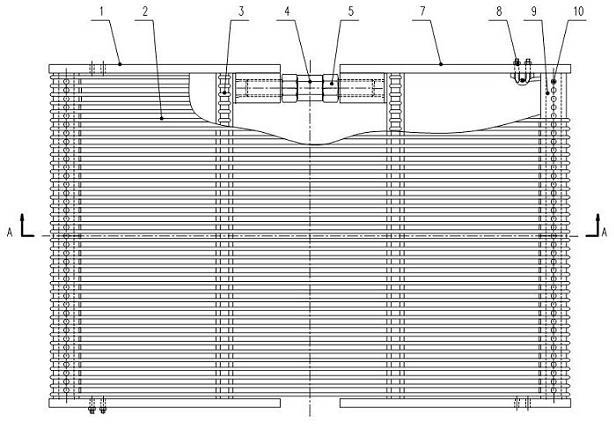

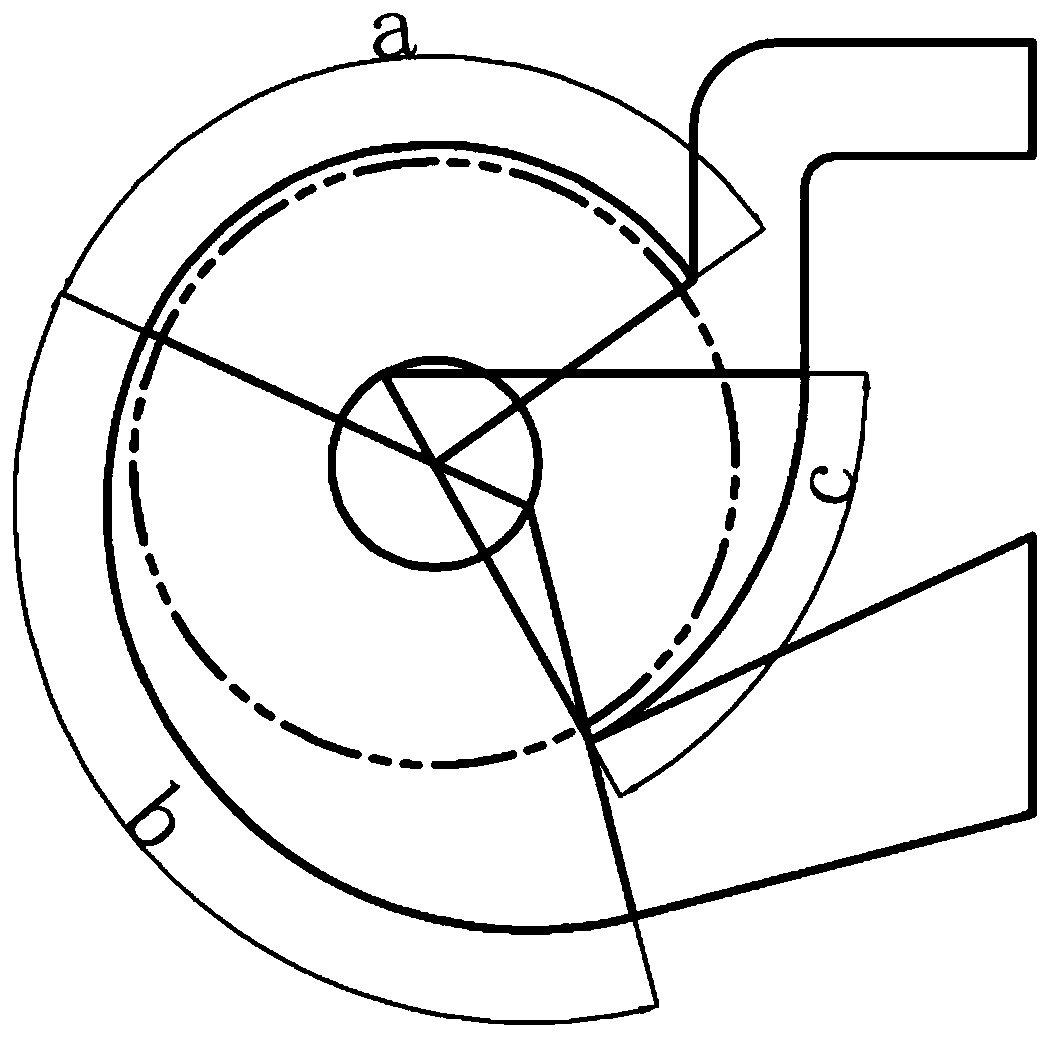

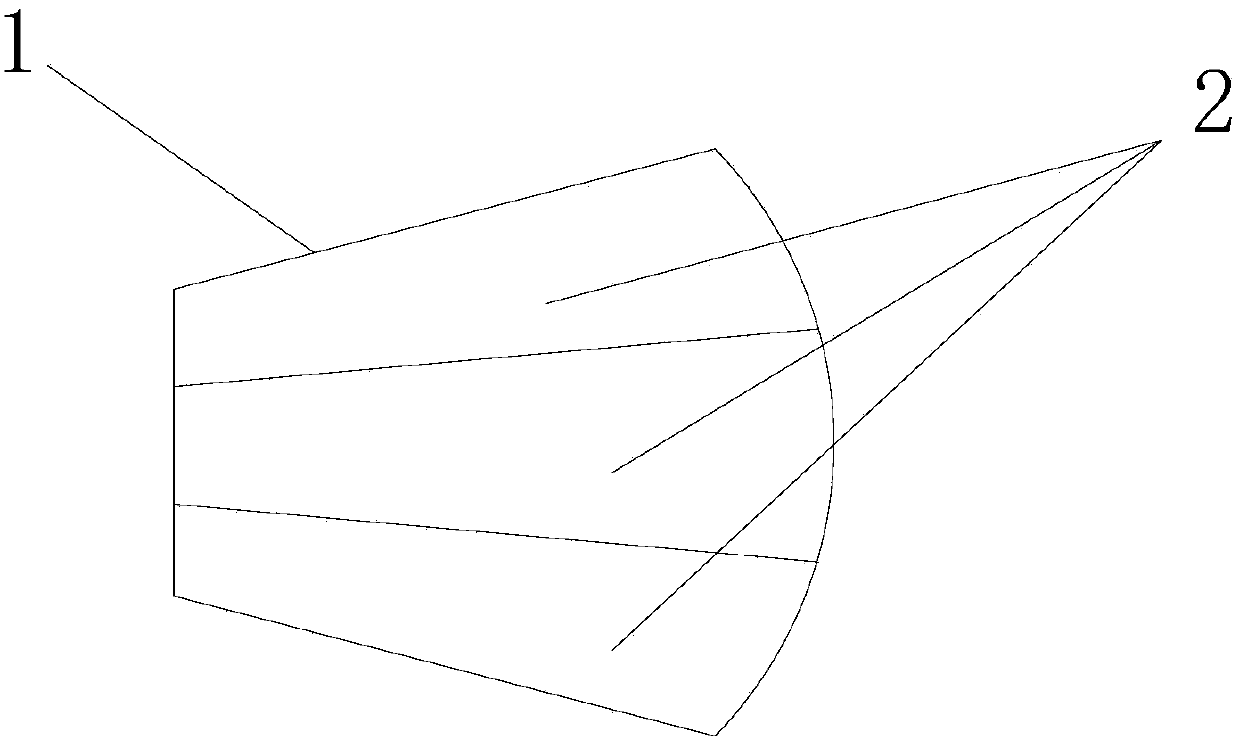

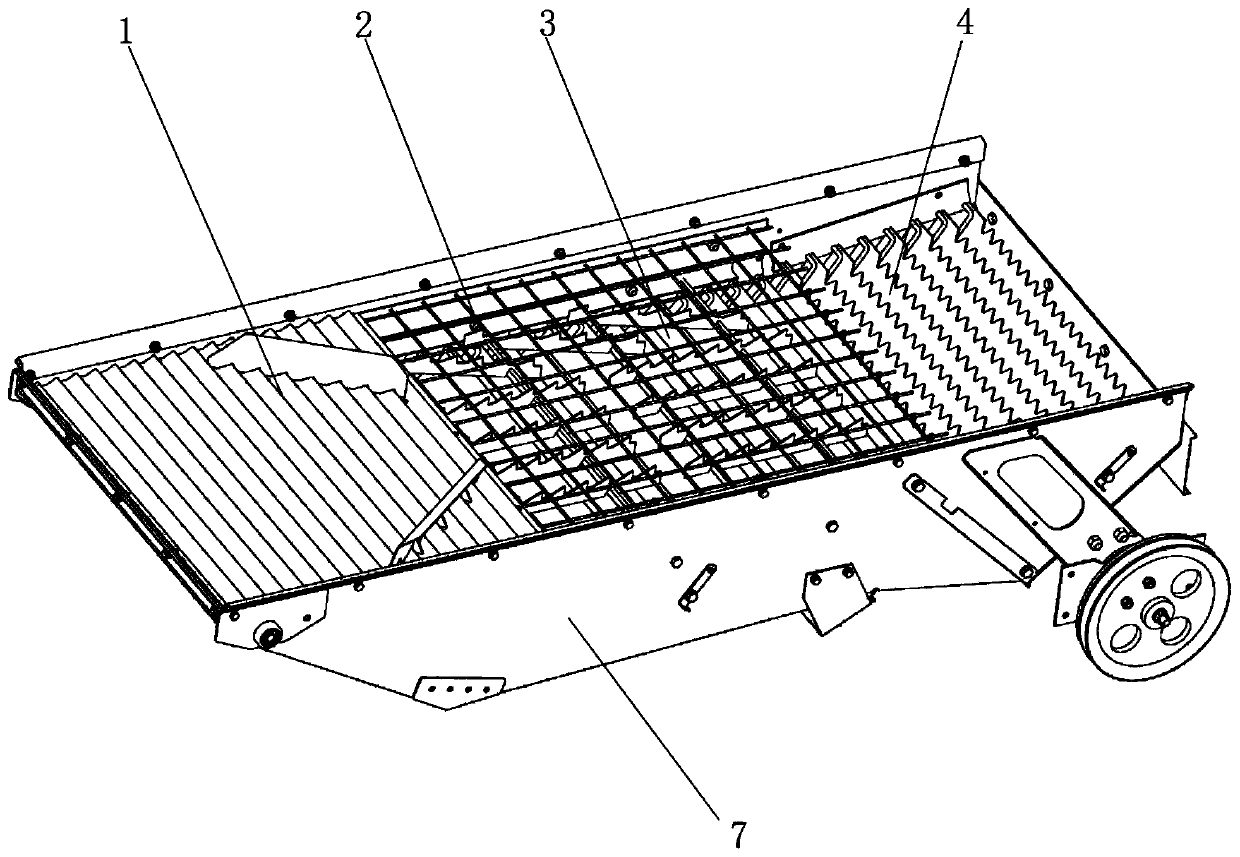

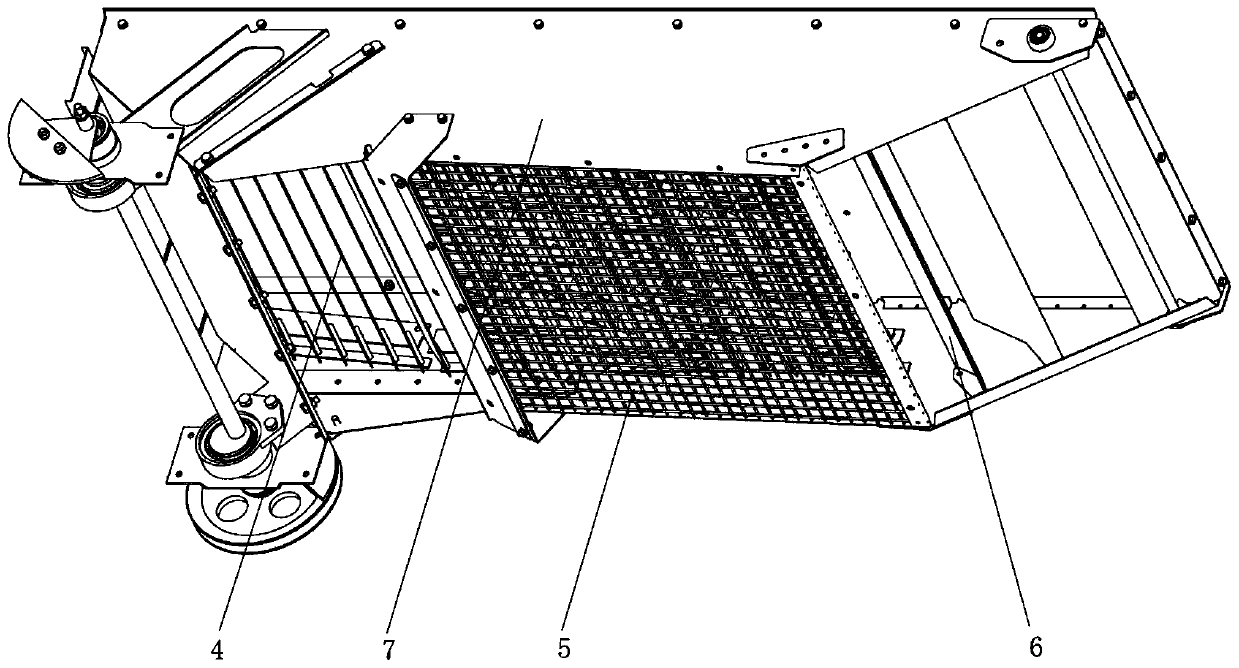

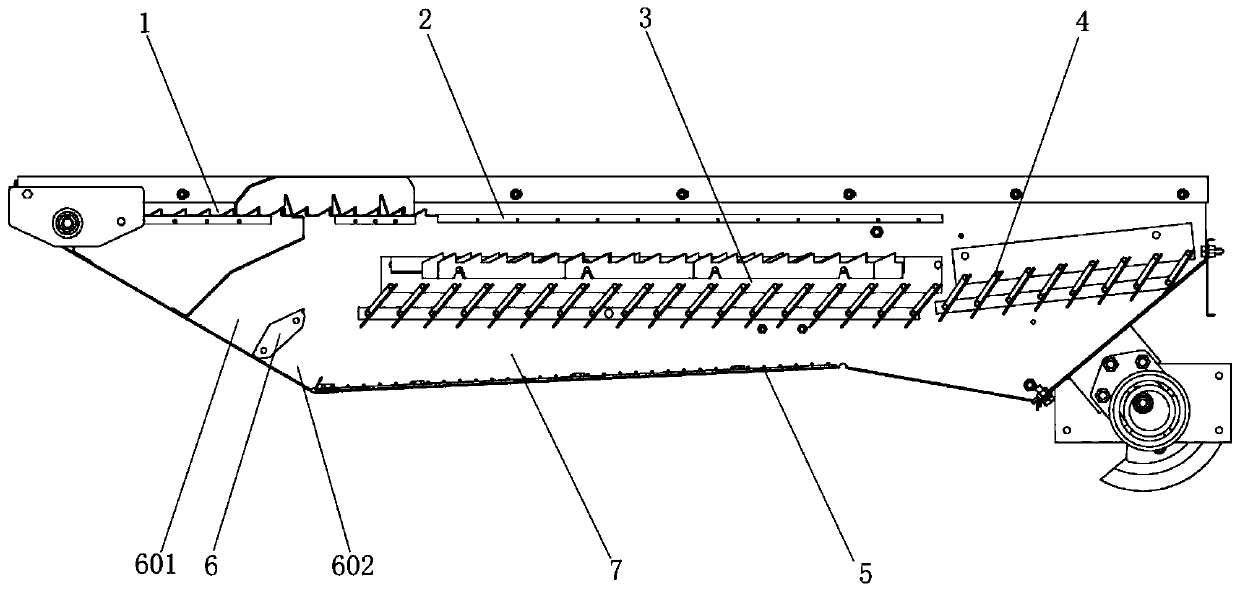

Material distributing screening machine

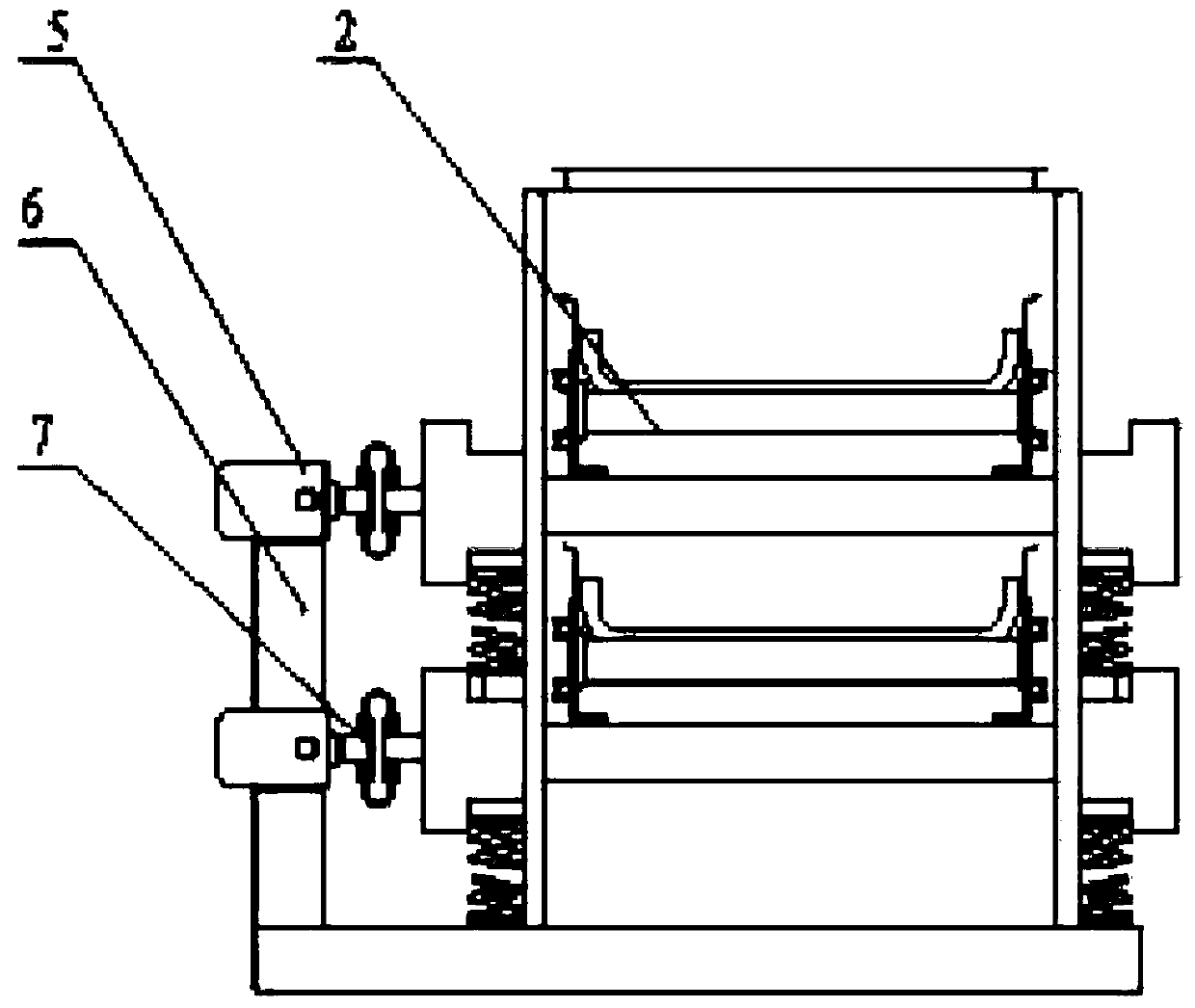

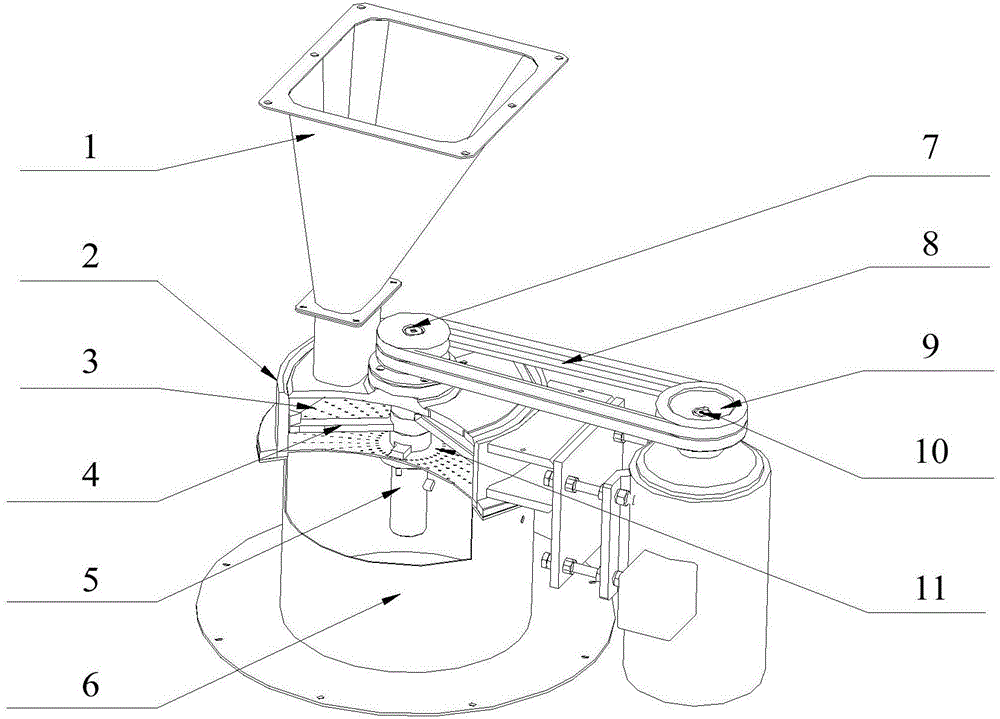

The invention discloses a material distributing screening machine, comprising a machine case (1), a forced fabric plate (2), a driving device (3), a filtering roller (4), a reducer motor (5) and an iron removing device (24), wherein the machine case (1) is provided with a feeding hole (6) and a plurality of discharging holes (10), the filtering roller (4) comprises a flange disk type roller (11) and a filtering rope type roller (12), the filtering roller (4) is provided with the driving device (3), the reducer motor (5) drives the filtering roller (4) to rotate by virtue of the driving device (3), and material enters from the feeding hole (6), is screened by the filtering roller (4) and is discharged by the discharging hole (10). The invention has the beneficial effects that: more than two materials in different grain sizes can be screened by setting different interstitial screen cuts, the working condition requirement for screening more than two materials can be met, screening efficiency is high, bulk material impact resistance is high, material is distributed more uniformly, no blockage is caused, and an iron piece contained in the material can be removed.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

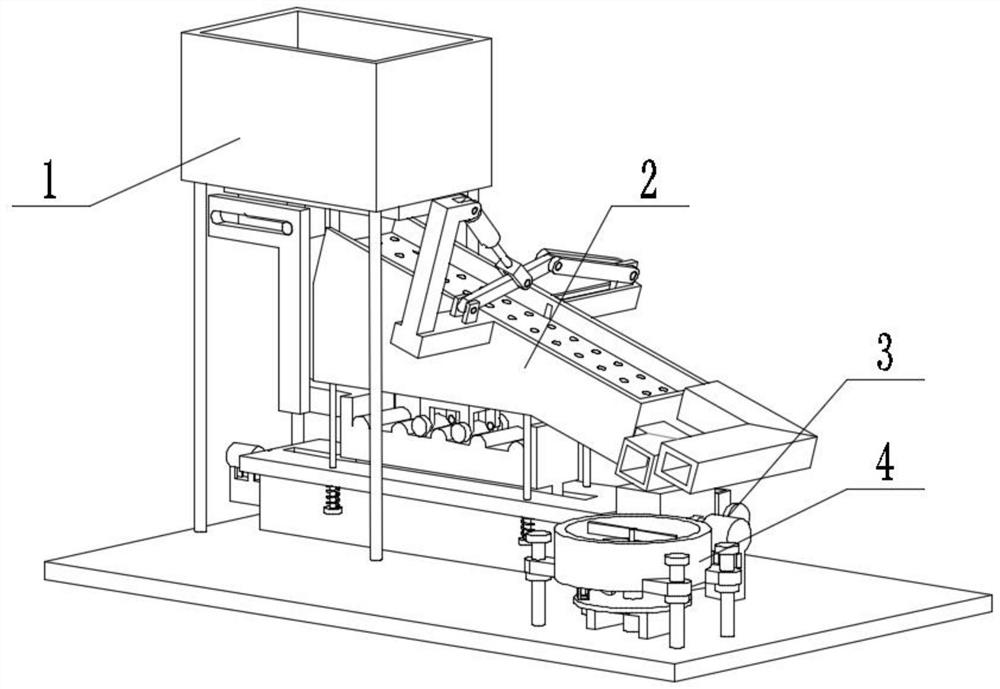

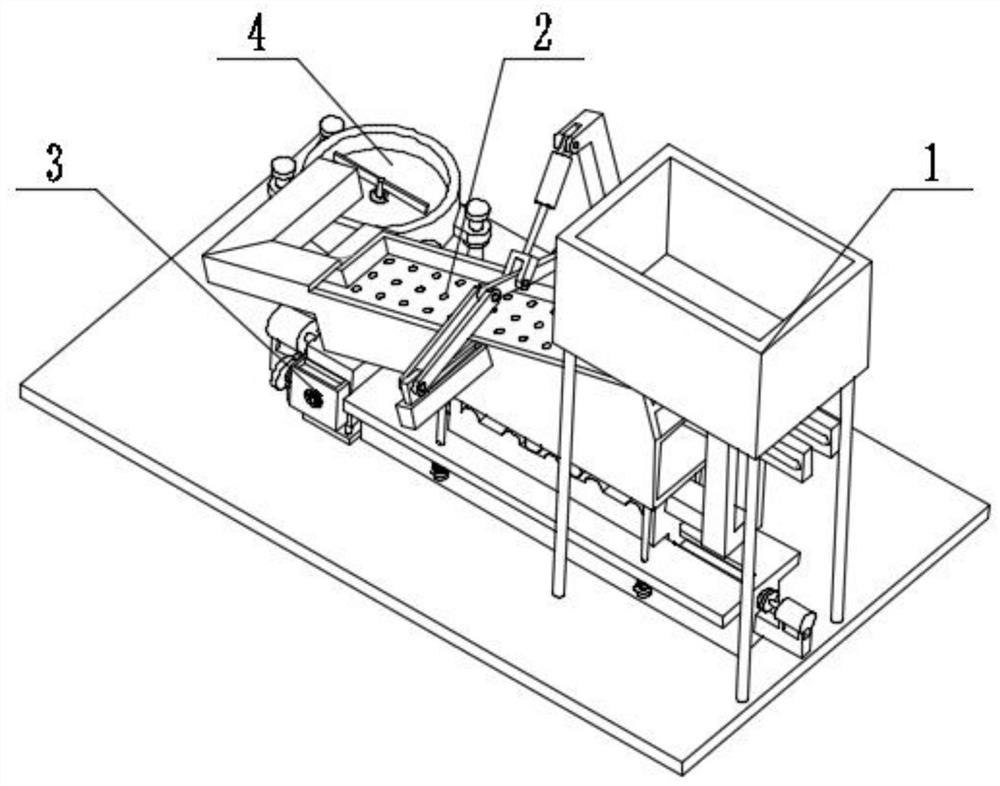

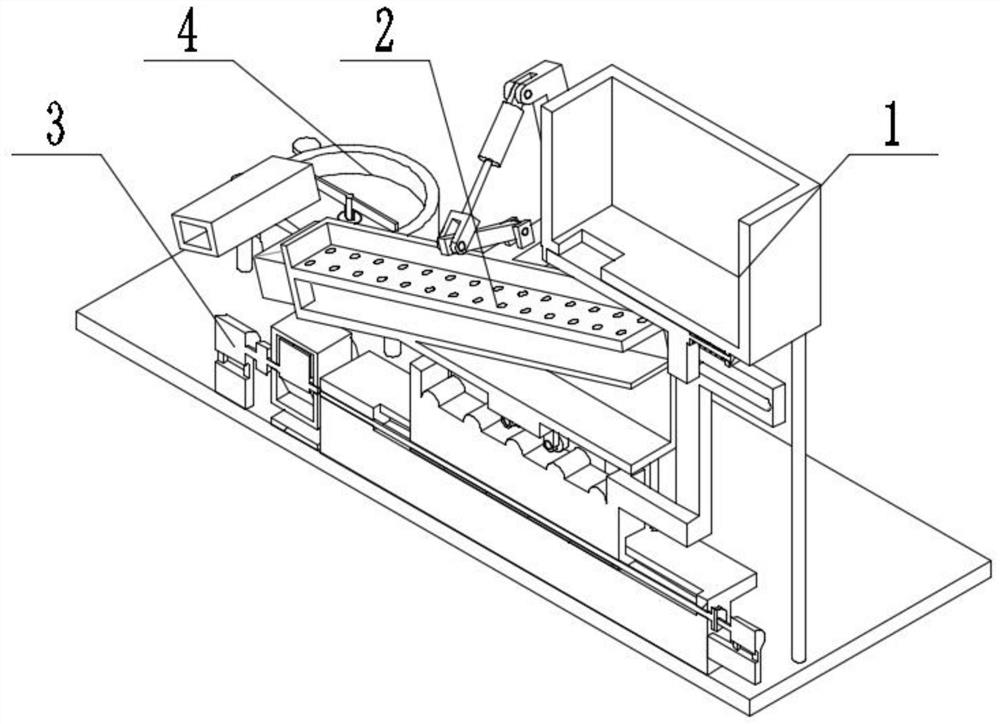

Fruit grading treatment equipment

ActiveCN111644372AVery high screening efficiency and screening rateImprove screening efficiencySievingScreeningEngineeringDust control

The invention relates to grading equipment, in particular to fruit grading treatment equipment. The fruit grading treatment equipment comprises a feeding box mechanism, a screening mechanism, a dust removing mechanism and a cleaning mechanism, wherein the equipment can discharge materials intermittently, carry out screening, improve screening efficiency and screening rate and clean fruits, and thefeeding box mechanism is connected with the screening mechanism, connected with the dust removing mechanism, and connected with the cleaning mechanism.

Owner:张晓锋

Method and special apparatus for improving surface purity and surface cleanliness of silicon carbide particles

The invention discloses a method and special apparatus for improving surface purity and surface cleanliness of silicon carbide particles. The method is characterized in that cleaning and dust removal are conducted on the surface of silicon carbide through a physical method, namely, silicon carbide particle materials are pushed by strong airflow to rotate at a high speed and to be thrown up, the silicon carbide particle materials are processed through repeated collision and friction, the silicon carbide particle materials can be separated from suspension dust among the silicon carbide particle materials and surface adhesion dust, and finally the requirement for improving the surface purity and the surface cleanliness of the silicon carbide particle materials is met. According to the method, the surface purity and the surface cleanliness of the silicon carbide particle materials are improved through the physical method instead of a chemical method, the suspension dust among the crushed silicon carbide particle materials and the particle surface adhesion dust can be effectively removed, the production cost is reduced to a great extent, production efficiency of the back end working procedure is improved, zero emission of pollutants is basically achieved in the whole production process, and the foundation is laid for large-scale industrial production and realization of automatic control in the production process.

Owner:ZHENGZHOU JINYE TECH DEV

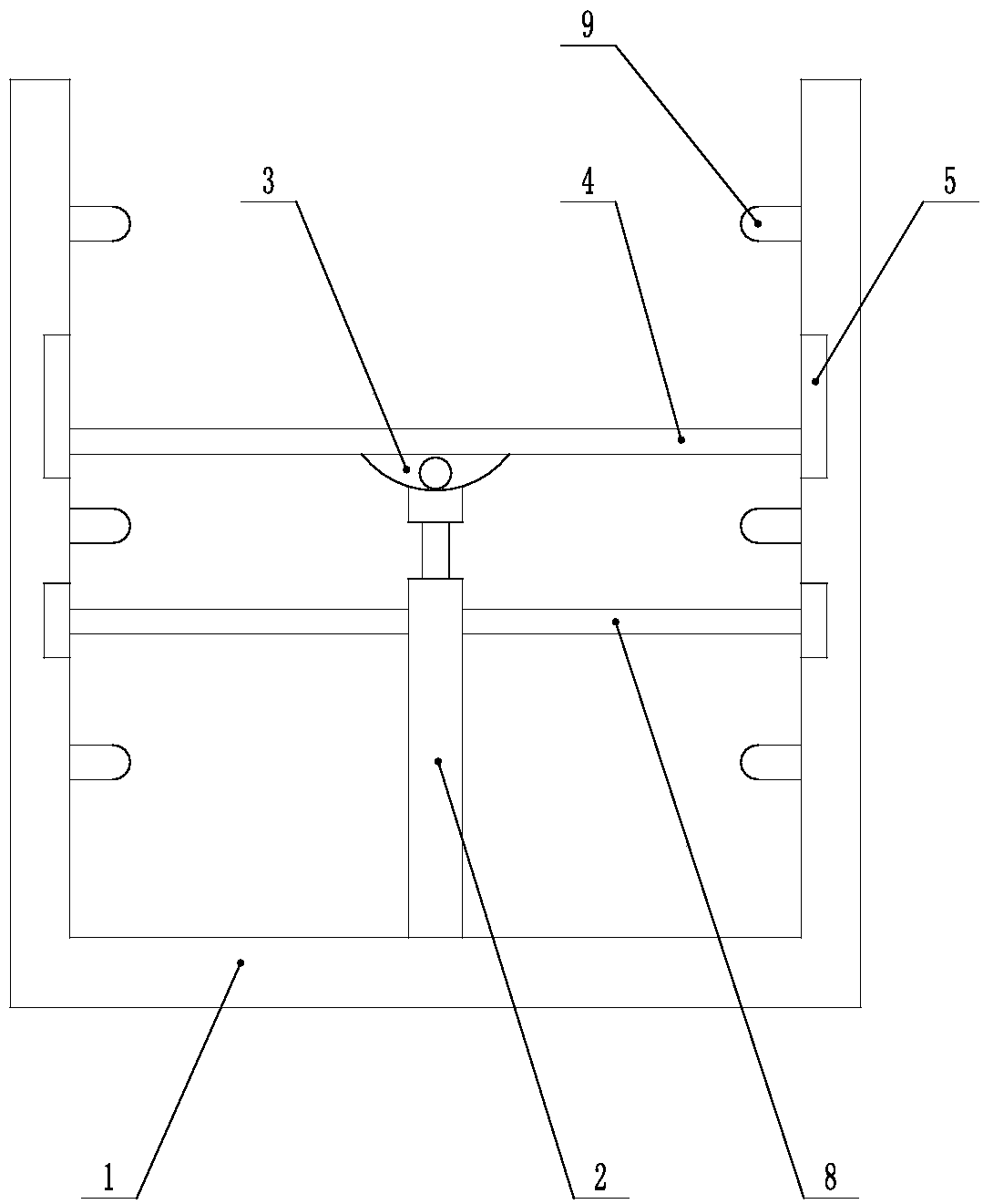

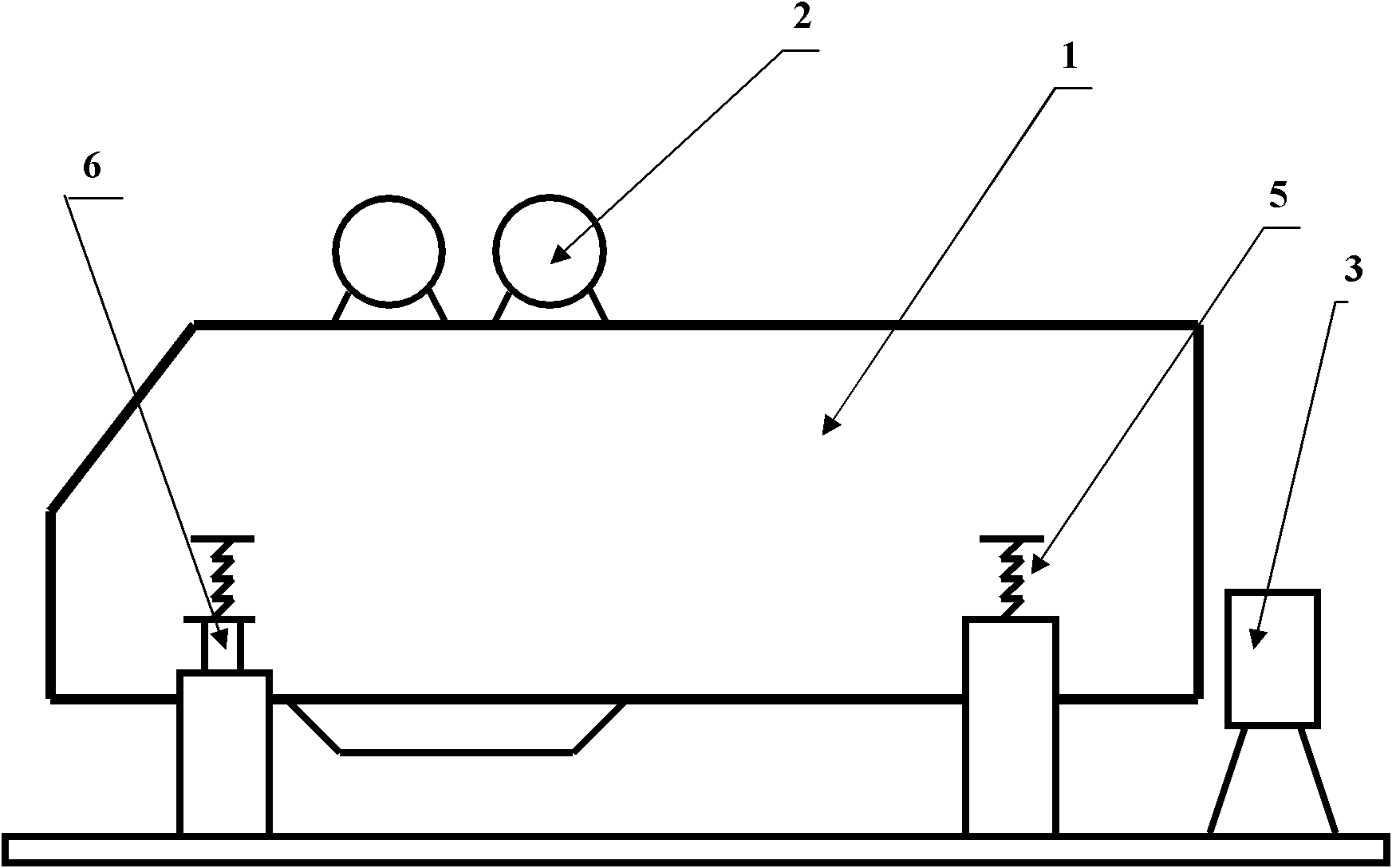

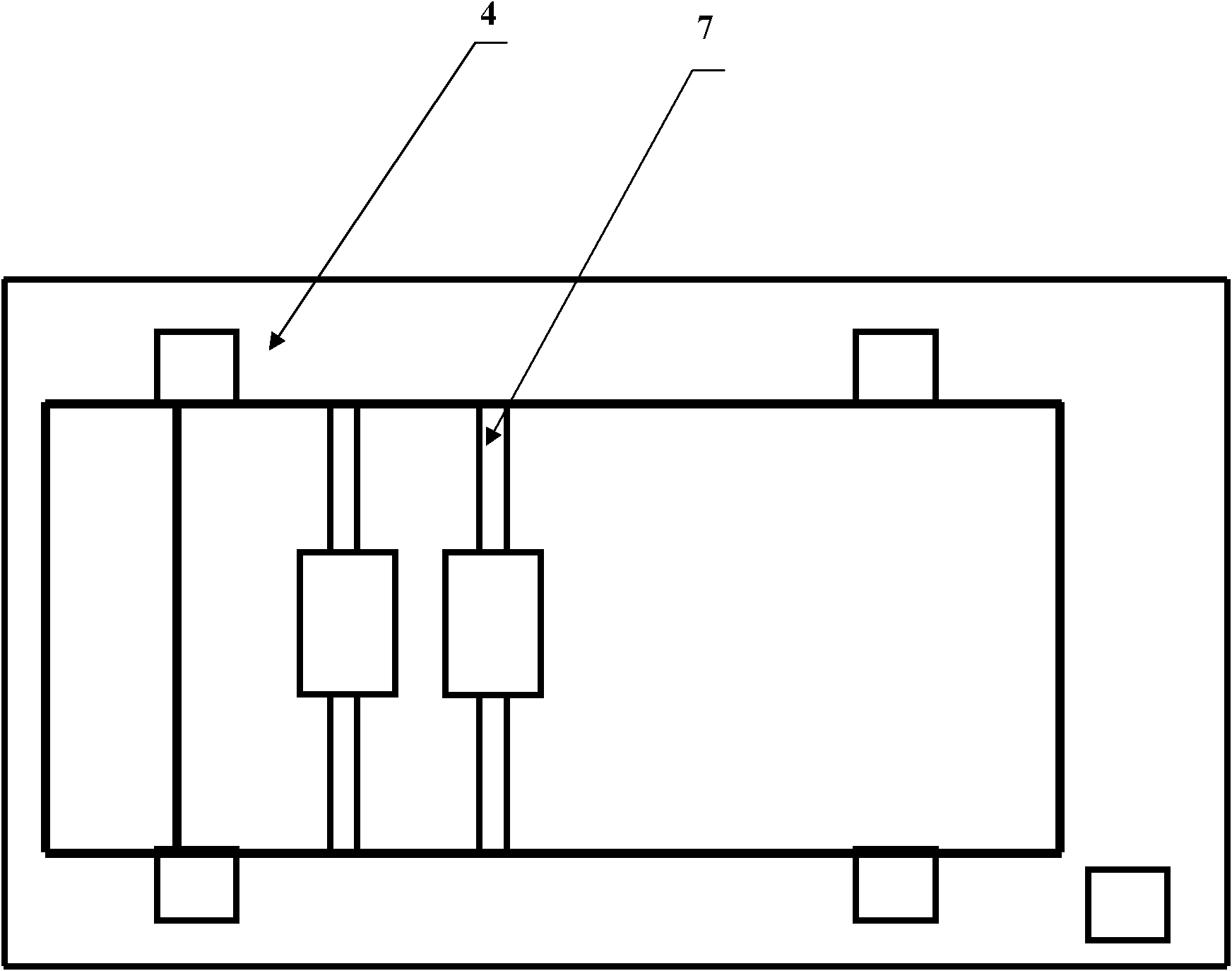

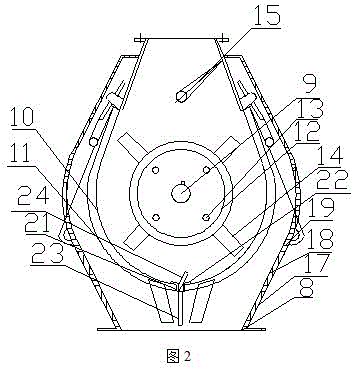

Complex frequency flip-flow screen and using method thereof

PendingCN110813723AParticipating weight reductionReduce weightSievingScreeningElectric machineryEngineering

The invention discloses a complex frequency flip-flow screen and a using method thereof. The flip-flow screen comprises a screen box, a screen core, a feeding hopper, a bottom support, a motor, a motor support and an end transmission device, the screen box is obliquely installed on the top of the bottom support, the feeding hopper is connected with the bottom of the screen box, and the motor support is connected to the portion, behind the screen box, on the top of the bottom support. The motor is installed on the top of the motor support, the end transmission device is connected with an outputshaft of the motor, and the end, away from the motor, of the end transmission device is connected with the screen core. The screen core is arranged in the screen box. The complex frequency flip-flowscreen makes complex frequency screening, flip-flow screening, a complex frequency screen structure and a flip-flow screen structure combined into a whole, the vibration mass of equipment is reduced,secondary vibration of a screen plate is also achieved, and a screening module is independent, so that the complex frequency flip-flow screen is smaller in size, lower in weight, higher in screening rate and good in static sealing and environmental protection performance, and the service life of the whole equipment can be prolonged through application of a spring part and a leaf spring.

Owner:HENAN WINNER VIBRATING EQUIP

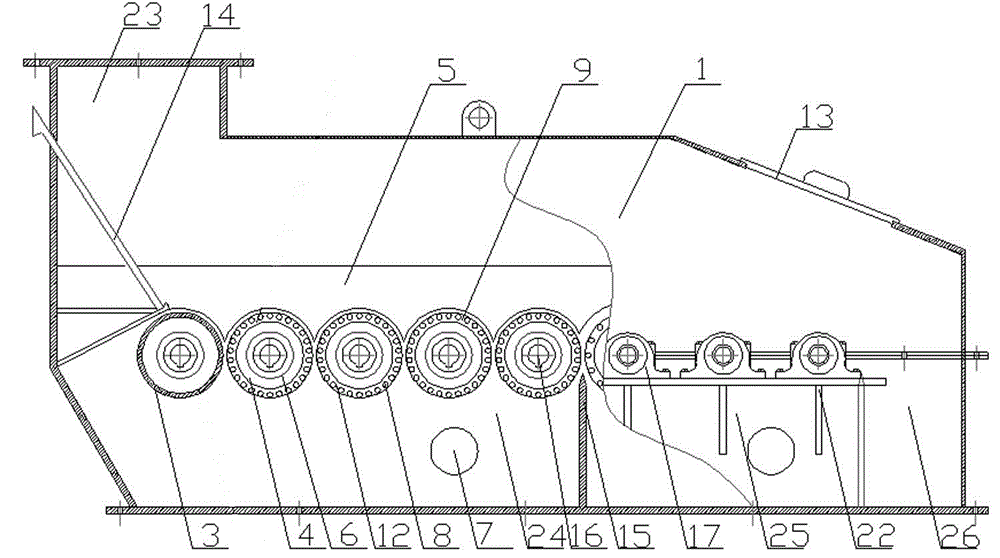

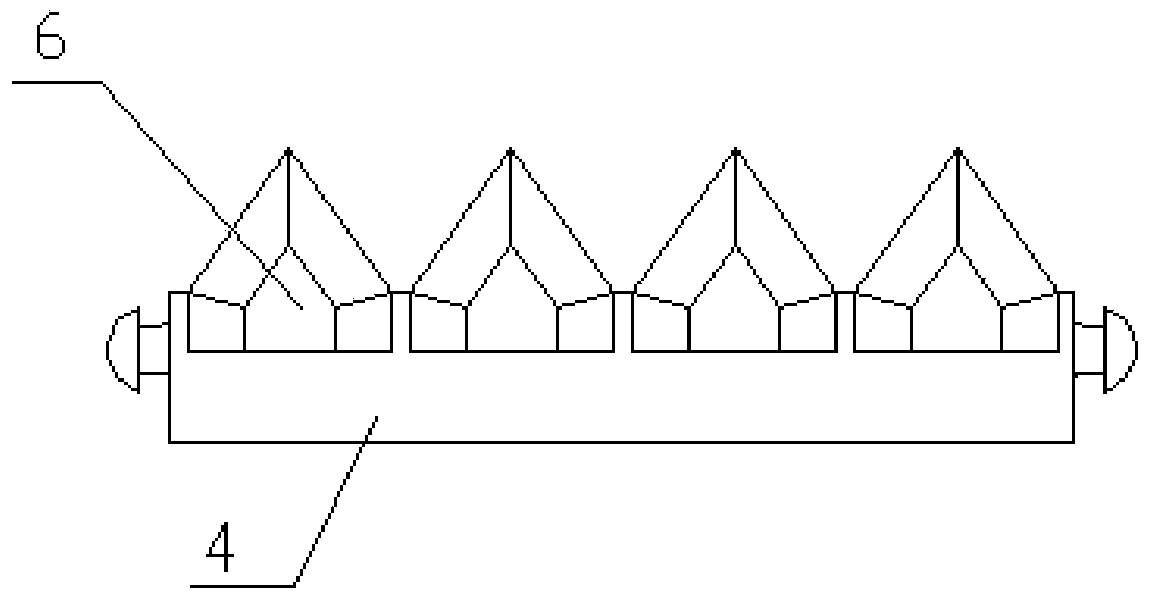

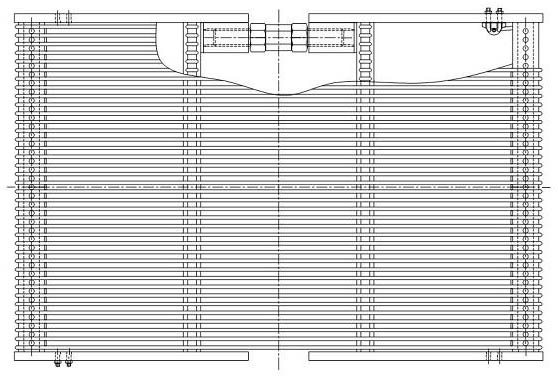

Filtering sieve shaft of sieving machine

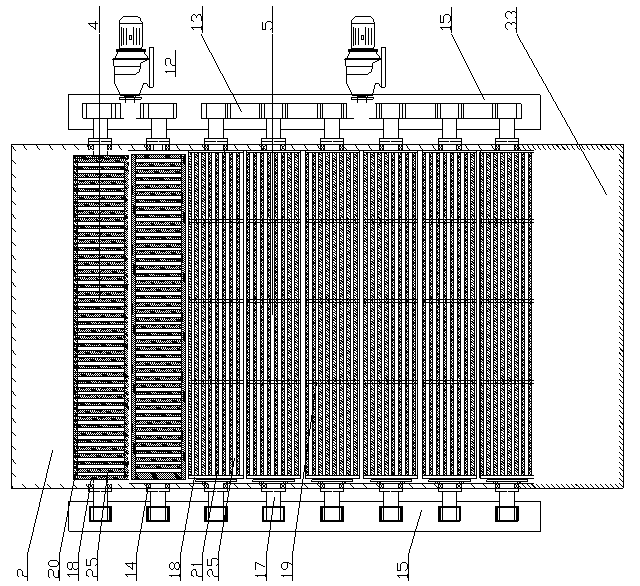

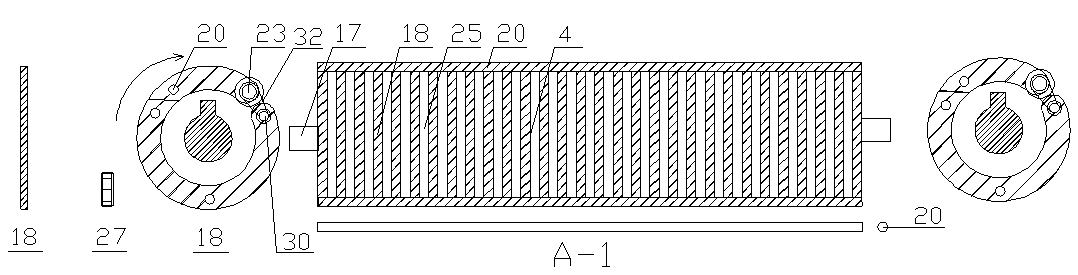

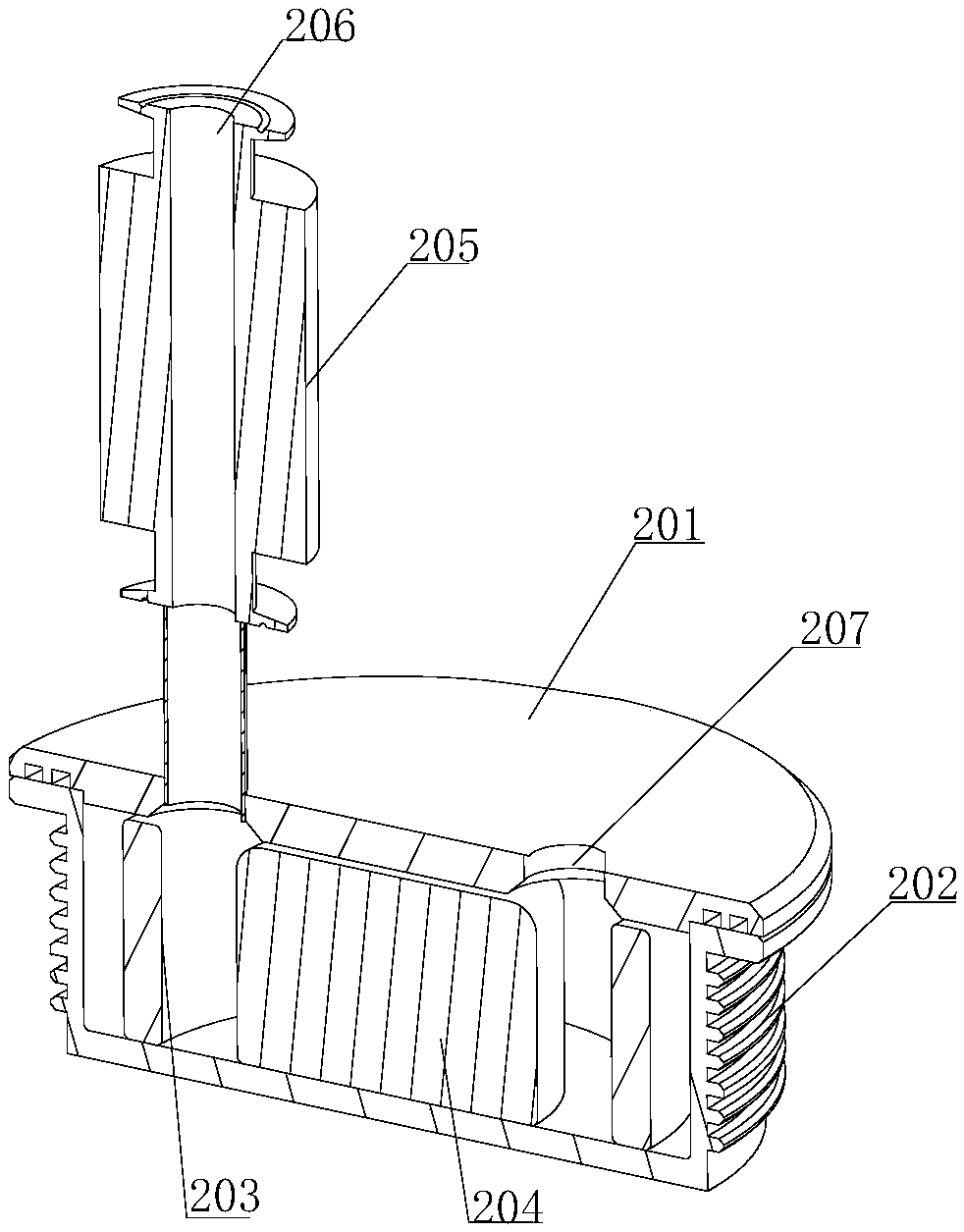

ActiveCN102989657ATo achieve the function of forced deliveryRealization without material blockingSievingScreeningEngineeringMaterial distribution

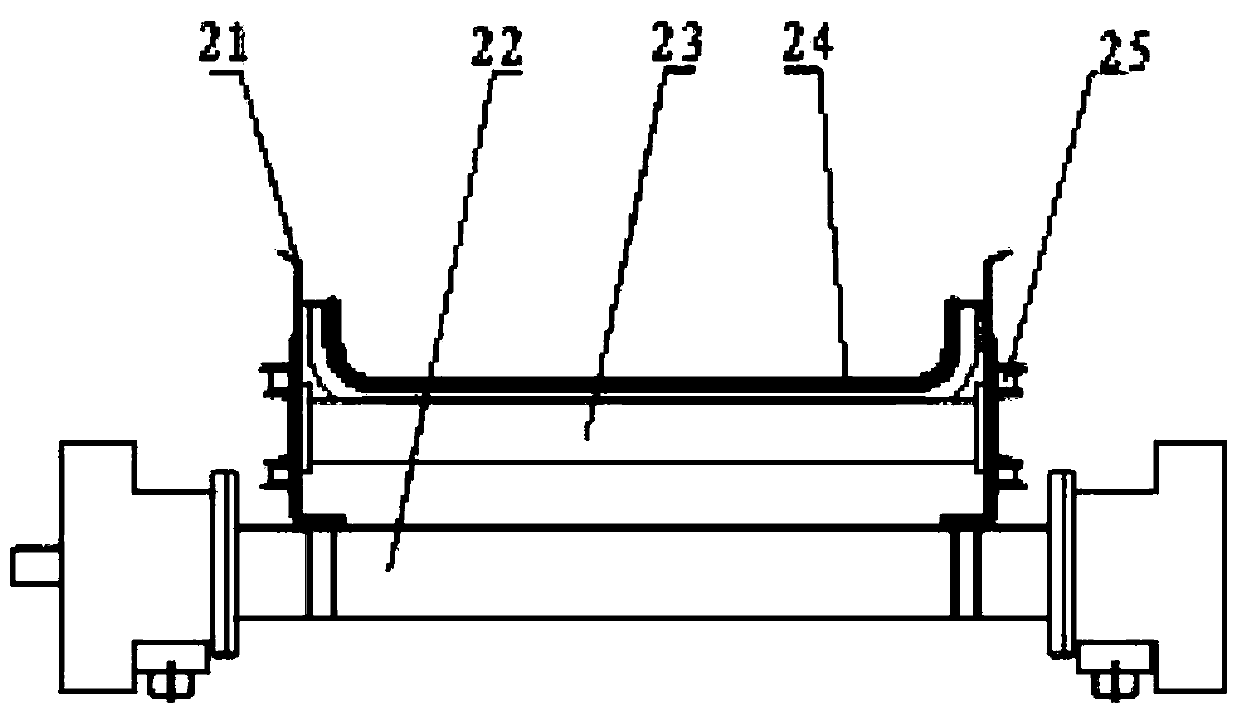

The invention discloses a filtering sieve shaft of a sieving machine. The filtering sieve shaft comprises a sieving face composed of a movable flange plate type sieve shaft (4), a movable sieving strip type sieve shaft (5) and a spring type sieve shaft (24). The filtering sieve shaft has the advantages of guaranteeing sieving granular size and solving the problem that materials are not blocked in the hollow filtering sieve shaft. The filtering sieve shaft has the advantages of being good in anti-impact capacity, efficient in sieving, capable of guaranteeing granular size, free of material blocking, capable of removing iron, even in material distribution, capable of meeting requirements of more than two discharging granular sizes, convenient to overhaul, favorable for replacing parts and the like and is major breakthrough in the field of the sieving machine.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

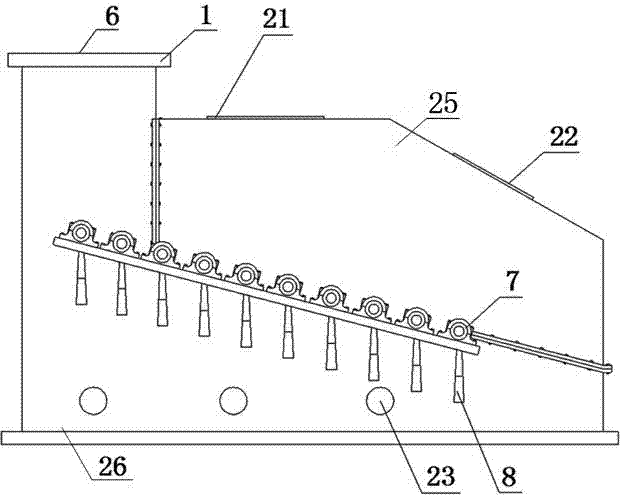

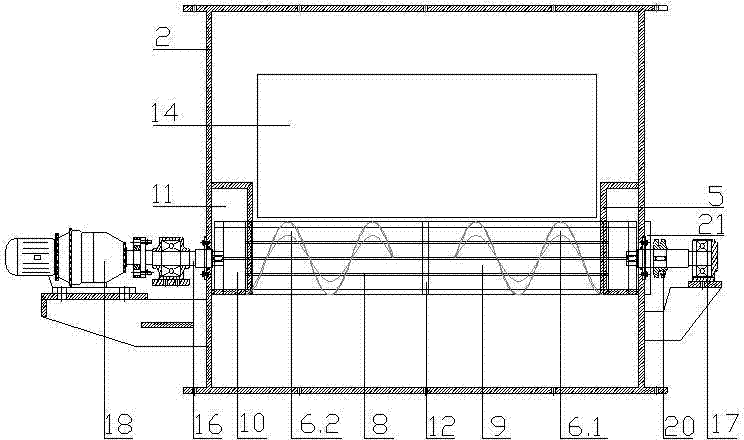

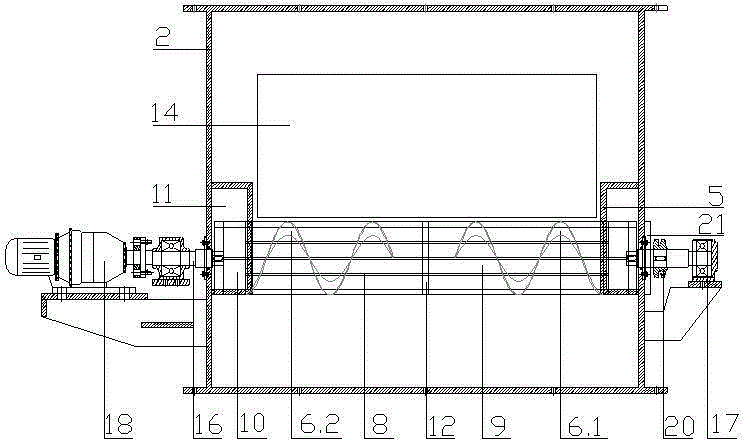

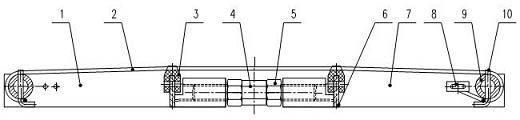

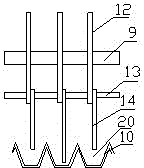

Coal classifying screen

The invention discloses a coal classifying screen. A distribution plate (14) is arranged below a feeding port (23) in an inclined mode. The two ends of a roller screen shaft (3) are installed on the two sides of a case (2) through bearing pedestals (17) respectively, and the two ends of each screen bar screen shaft (4) are installed on the two sides of the case (2) through bearing pedestals (17) respectively. Spiral guide parts (6) are arranged in the roller screen shaft (3) and the screen bar screen shafts (4) respectively and composed of forward spiral guide parts (6.1) and backward spiral guide parts (6.2), the forward spiral guide parts (6.1) are fixedly installed on one side inside the roller screen shaft (3) and one sides inside the screen bar screen shafts (4) respectively, and the backward spiral guide parts (6.2) are fixedly installed on the other side inside the roller screen shaft (3) and the other sides inside the screen bar screen shafts (4) respectively. Anti-blocking holes (10) are formed in the two ends of the roller screen shaft (3) respectively, and anti-blocking holes (10) are formed in the two ends of each screen bar screen shaft (4) respectively. The coal classifying screen is uniform in distribution and high in impact resistance, a screen surface and the screen shafts are not blocked, the requirement for two or more particle sizes of discharged materials is met, and spare parts are convenient to maintain and replace.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

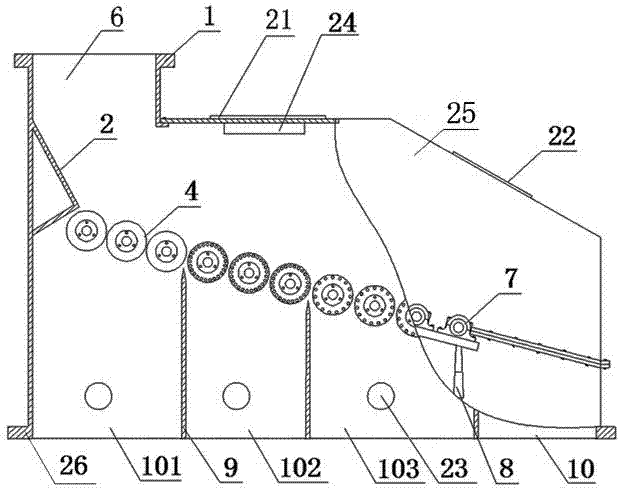

Classifying screen for coal

The invention discloses a classifying screen for coal. A material distribution plate (14) is obliquely arranged below a feed port (23), the two ends of a rotary screen sieve shaft (3) and the two ends of a grating sieve shaft (4) are installed on the two sides of a case (2) through bearing pedestals (17) respectively; guide spirals (6) are arranged inside the rotary screen sieve shaft (3) and the grating sieve shaft (4); the guide spirals (6) comprise the forward guide spiral (6.1) and the backward guide spiral (6.2), the forward guide spiral (6.1) is fixedly installed in one side of the rotary screen sieve shaft (3) or the grating sieve shaft (4), and the backward guide spiral (6.2) is fixedly installed in the other side of the rotary screen sieve shaft (3) or the grating sieve shaft (4). The two ends of the rotary screen sieve shaft (3) and the two ends of the grating sieve shaft (4) are provided with anti-blocking holes (10) respectively. The classifying screen for the coal has the advantages of being even in material distribution, high in shock resistance, capable of meeting requirements of two or more discharge particle sizes, and convenient to overhaul and replace, and blockage does not exist inside sieving faces or the sieve shafts.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Pre-grading device and vibration screening machine with same

The invention discloses a pre-grading device and a vibration screening machine with the same and relates to the field of gravel screening machines. The pre-grading device comprises an air blower, a main grading cavity, a feeding channel and a plurality of discharging channels. The main grading cavity is provided with an air inlet, a feeding opening and a plurality of discharging openings, and an air outlet of the air blower is connected with the air inlet; the feeding opening is formed in the upper portion of the main grading cavity and connected with the feeding channel, and all the discharging openings are formed in the lower portion of the main grading cavity and are connected with the discharging channels in a one-to-one corresponding mode; and all the discharging openings are formed in an arrayed mode in the direction opposite to the air inlet along the air inlet, and the feeding opening corresponds to the discharging opening closest to the air inlet or is closer to the air inletthan the discharging opening. The vibration screening machine comprises a screen cloth device with a plurality of layers of screen clothes being vertical arranged at intervals and further comprises avibrating mechanism and the pre-grading device which are connected with the screen cloth device; the pre-grading device is arranged above the front section of the screen cloth device, and the front ends of all layers of the screen cloths, except the screen cloth of the bottommost layer, of the screen cloth device are each provided with a lower layer falling opening; and the discharging openings ofall the discharging channels correspond to all the screen clothes from top to bottom in one-to-one and layer-by-layer modes in the direction opposite to the air inlet along the air inlet, and the layer number of the screen clothes of the screen cloth device is matched with the number of the discharging channels.

Owner:FUJIAN NONNON TECH

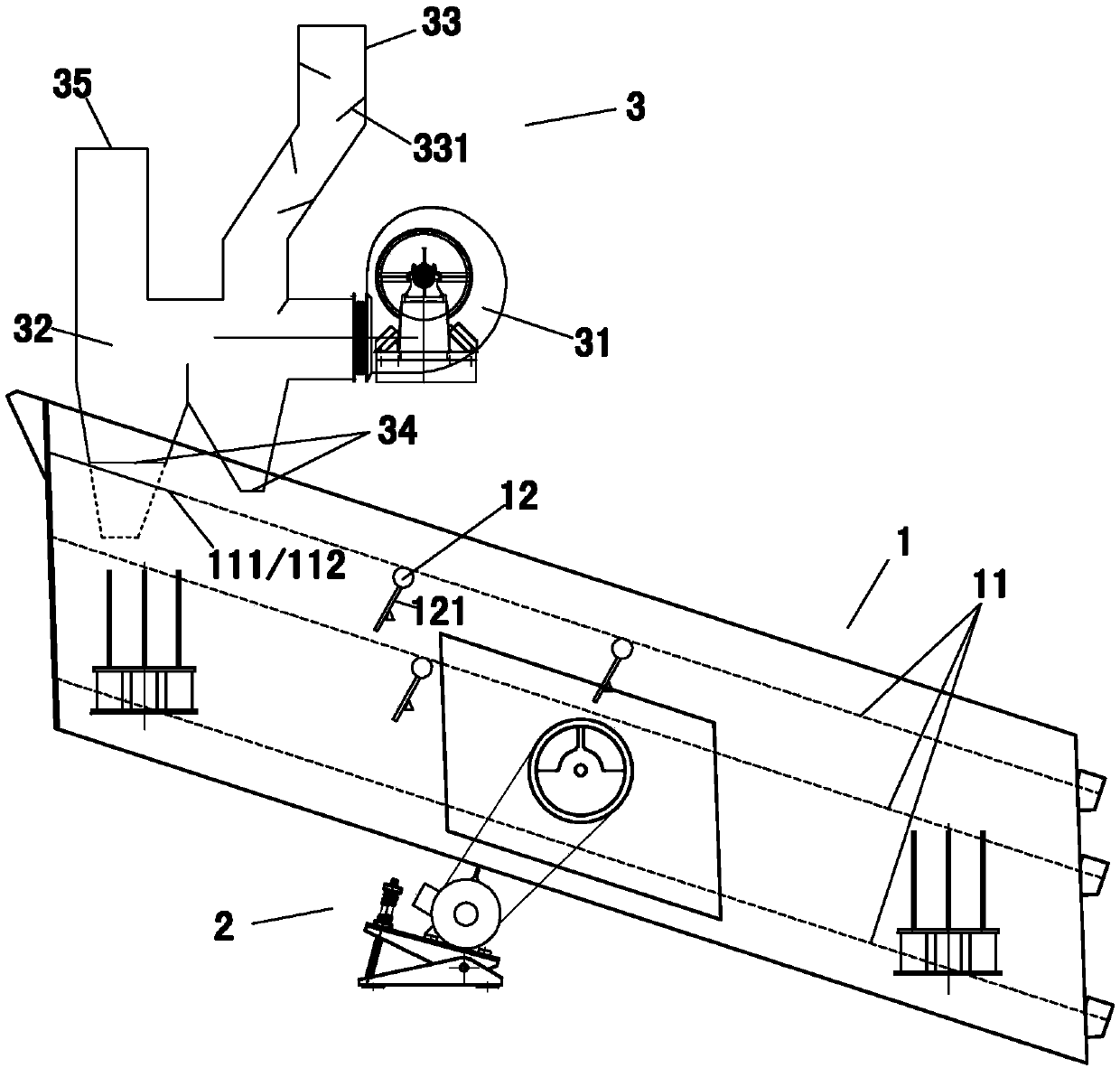

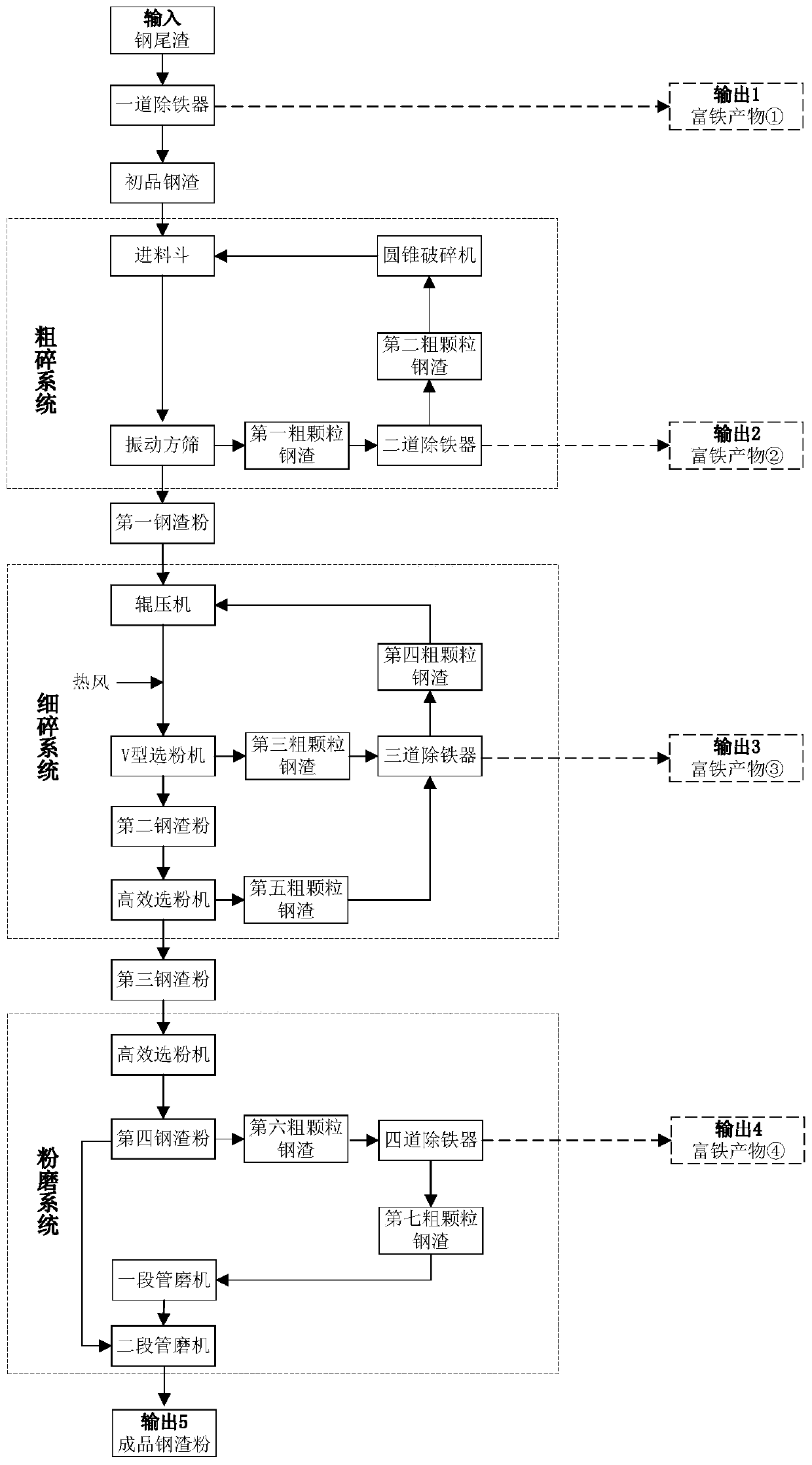

Steel slag real-time circular iron removal and grinding method

ActiveCN110788114AReduce lossImprove grinding efficiencySievingTransportation and packagingIron powderSlag

The invention discloses a steel slag real-time circular iron removal and grinding method, which belongs to the technical field of steel slag comprehensive utilization, and includes the following steps: feeding and iron removal, coarse crushing and iron removal, fine crushing and iron removal, and grinding and iron removal, and finally the ground steel slag with the specific surface area of 400 m2 / kg-500m2 / kg, and the metallic iron content smaller than or equal to 0.3%. Through utilizing the steel slag real-time circular iron removal and grinding method provided by the invention, the steel slagreal-time circular iron removal is combined with the 'more crushing and less grinding' and the 'segmented grinding' technologies for steel slags, so that not only the metallic iron in the steel slagsis fully recovered, but also the grinding efficiency in the steel slags is further improved, the energy consumption is reduced, and steel slag micro powder is obtained.

Owner:QIANAN WEISHENG SOLID WASTE ENVIRONMENTAL PROTECTION IND CO LTD +1

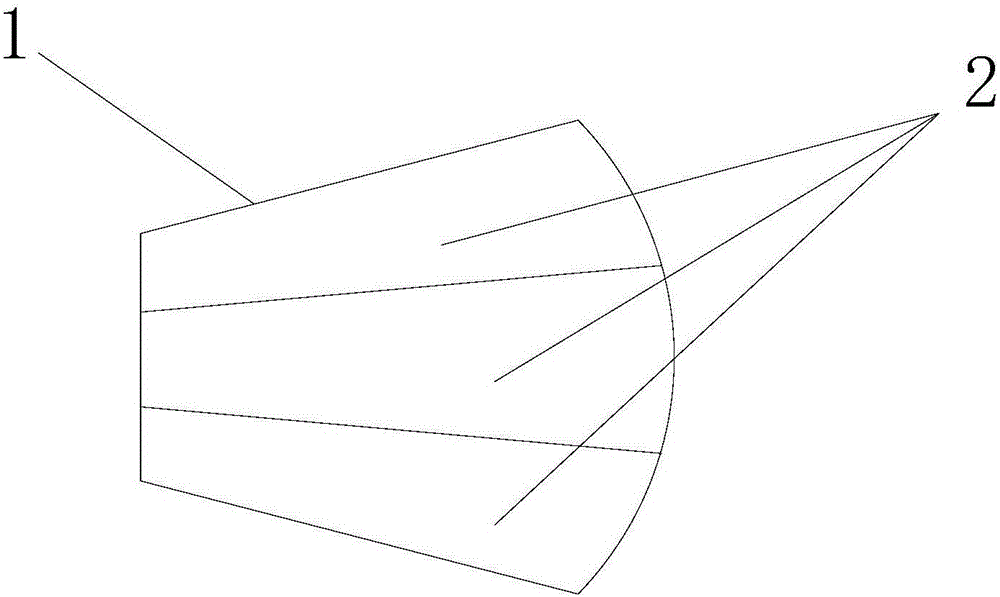

Wave-shaped sieve plate and production processes thereof

PendingCN110116090AMultiple contact opportunitiesIncrease sieving rateSievingScreeningWave shapePulp and paper industry

The invention provides a wave-shaped sieve plate which comprises a sieve plate mounting seat and a plurality of sieve plate modules; each sieve plate module is fixed on the sieve plate mounting seat and comprises a base and a plurality of sieve plate units; each base and the plurality of sieve plate units are integrally formed; the plurality of sieve plate units are arranged at the upper end of each base side by side; each sieve plate unit is of a long triangular body structure with an upward tip; sieve holes with same number and shape are uniformly distributed on the two sides of the tips; and a flow guide channel is formed between every two adjacent sieve plate units. The invention also provides two production processes, namely a casting process and an injection molding process. Comparedwith a sieve plate with a similar size, for the wave-shaped sieve plate, the aperture ratio of the sieve plate is multiplied by a wave-shaped sieve surface, so that the production efficiency of sieving machinery, particularly the efficiency of a dehydration sieving machine, is greatly improved; and the special tip structure of each module vibrates along with the sieving machine to exert the effect of loosening a material bed layer from the bottom, so that adjustment of the bed layer structure and material advancing are assisted to a certain extent, and the probability of hole blocking and thelabor cost for cleaning and maintaining are reduced.

Owner:莫图泰克筛分系统(天津)有限公司

Screening equipment capable of keeping fertilizers dry

The invention discloses screening equipment capable of keeping fertilizers dry. The screening equipment comprises a cylinder; a rotating shaft is arranged in the cylinder; a mounting plate is arrangedat the top of the rotating shaft, and is hinged with a first filter screen; mounting grooves are formed in two sides of the inner wall of the cylinder; connecting shafts are arranged in the mountinggrooves; the two ends of the first filter screen are connected with two connecting shafts; the first filter screen and the connecting shafts are connected through elastic elements; a second filter screen is arranged under the first filter screen, is connected with the rotating shaft, and can be rotated along with the rotating shaft; and multiple drying devices are arranged in the cylinder. Throughcombined effects of the first filter screen and the second filter screen, the screening rate of the fertilizers can be increased; and through the drying devices, the fertilizers are kept dry, and areprevented from bonding on the filter screens to block the filter screens.

Owner:蒙城县贵智生态农业科技有限公司

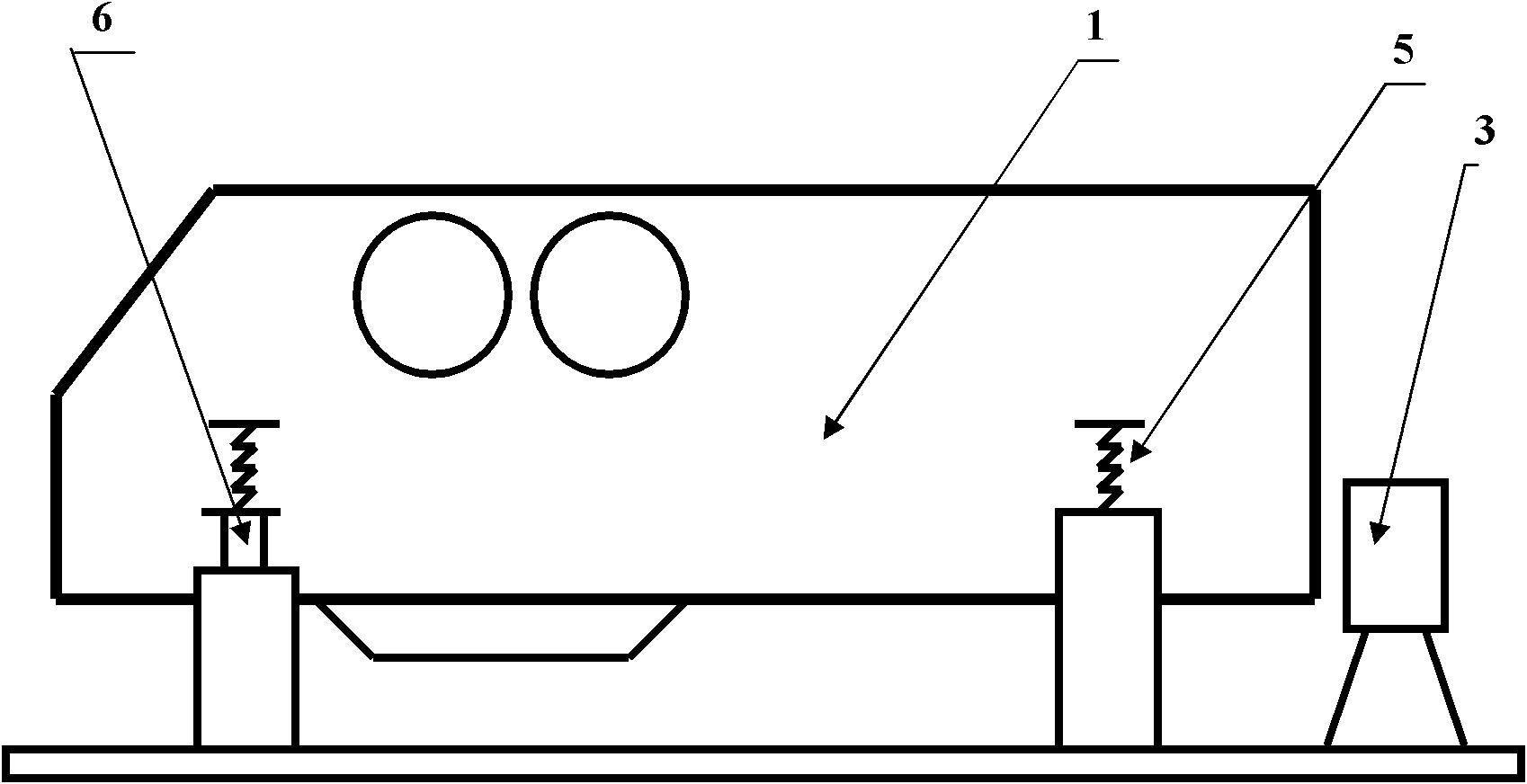

Novel mining vibrating screen

InactiveCN101844132ARealize automatic round circulationDoes not affect normal workSievingScreeningAutomatic controlVibration exciter

The invention provides a novel mining vibrating screen, which is mainly formed by a vibrating screen box (1), a vibration exciter (2) formed by two or four exciting motors, an automatic control appliance switchbox (3) and a vibrating screen base (4), wherein the vibrating screen box (1) is supported on the base (4) by four damping springs with unequal rigidities; the vibration exciter (2) is installed on the vibrating screen box (1) through a supporting shaft or a connecting shaft; the automatic control appliance switchbox (3) is installed on the base (4); and a jack mechanism (6) used for adjusting the inclination of the vibrating screen box (1) is installed on a frame at the front end of the vibrating screen box (1). The invention has the advantages of energy saving, high efficiency, simple structure, convenient manufacturing, low cost, high popularization value and the like.

Owner:钟祥新宇机电制造股份有限公司 +1

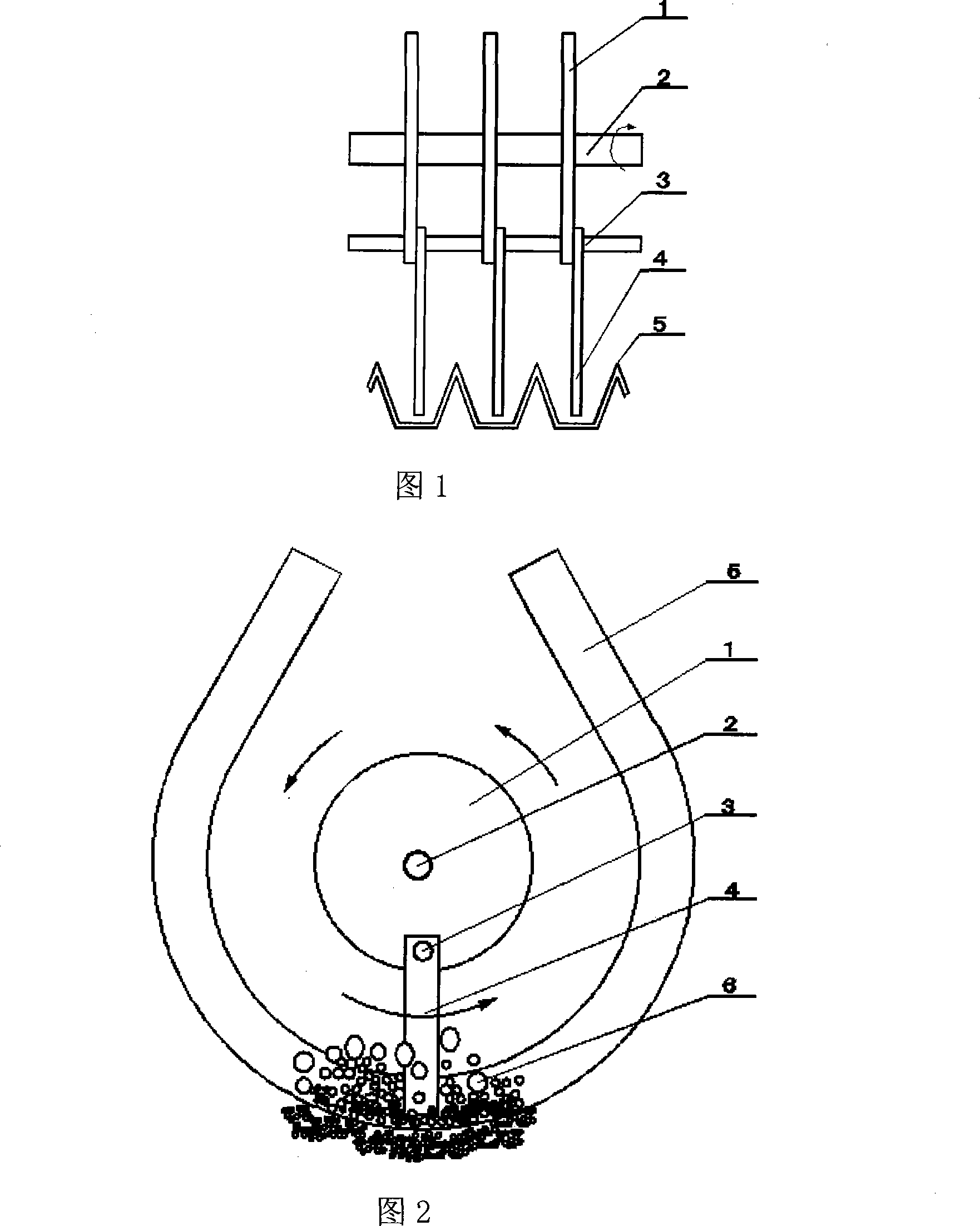

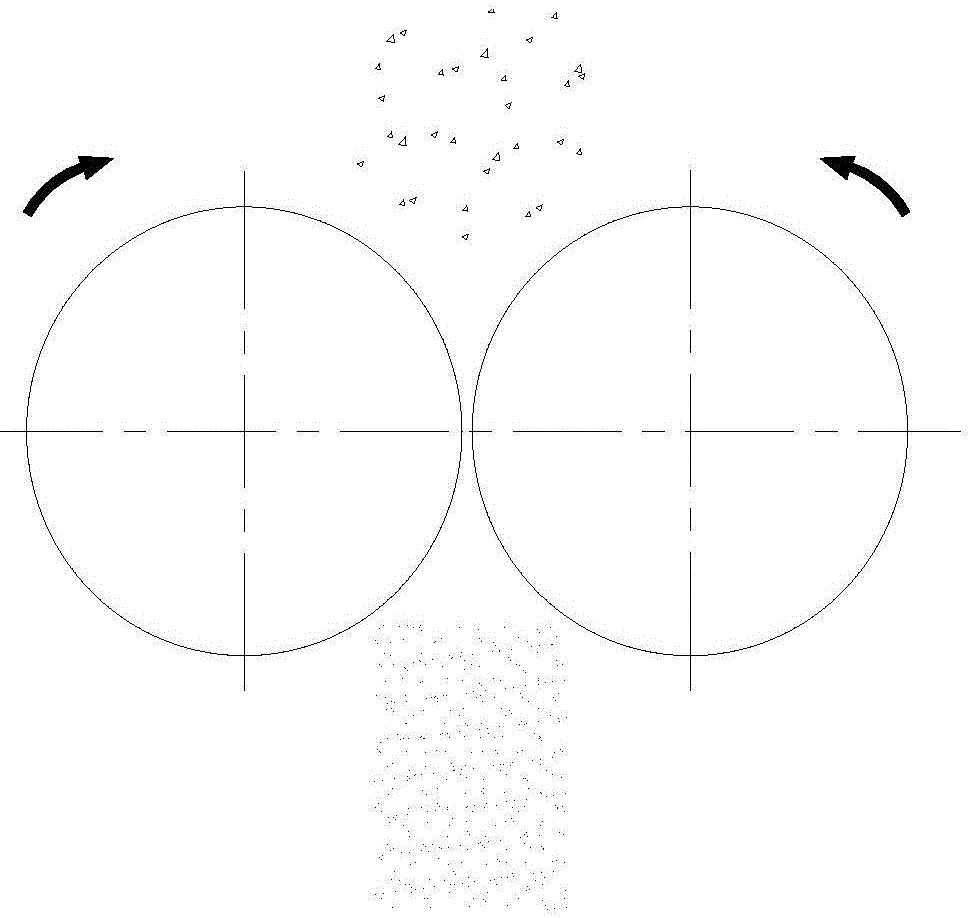

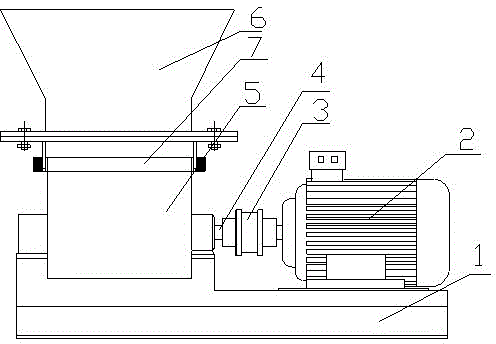

Method for improving crush efficiency factor of hammer piece disintegrating machine

InactiveCN101219404AIncrease resistanceImprove product sieving rateGrain treatmentsPulverizerEngineering

The invention pertains to feedstuff processing technological field of agricultural engineering, relating to a method to improve the grinding efficiency of a hammer grinder for the processing of fine powder of feedstuff materials. The sieving areas of sieve plates of the hammer grinder are combined with altering of hammer parameters; To-be-ground materials enter into a grinding chamber and automatically come into troughs of the sieve plates, the high speed rotating hammers move in the troughs, and the to-be-ground materials are forcedly hit by the high speed rotating hammers; the whole sieve plates consists of a plurality of troughs, while the number and shape-structure parameters of the troughs of the sieve plates should be matched and consistent with the arrangement of the hammers. Moreover, since the altering of the structure of the sieve plates, the resistance of material circulation is increased, both factors comprehensively and dramatically enhance the hitting efficiency of the hammers, which can not only solve the problem that ordinary horizontal hammer grinder used for fine grinding of feedstuff materials, but also greatly enhance the grinding efficiency by 20 to 30 percent.

Owner:CHINA AGRI UNIV

Large block removing device for bucket wheel machine

InactiveCN103848233ANot to be scratchedMeet the needs of industrial developmentCleaningLoading/unloadingImpellerDrive shaft

The invention relates to a large block removing device for a bucket wheel machine. The large block removing device for the bucket wheel machine comprises a bearing support seat assembly, a driving shaft assembly, impellers, a driving device assembly, a plurality of floating moment arms, an outer casing, an elastic automatic sweeping device, a plurality of elastic buffer seat body and an electric control cabinet. The impellers adopted by the large block removing device are arranged on driving shafts in a spiral curve shape, so the driving shafts rotate at a high speed, large blocks can be favorably discharged out, and the sieve passing rate is increased. The elastic automatic sweeping device of the large block removing device can be used for clearing sundries pasted on the impellers in time. When the large blocks are clamped between the adjacent driving shafts, the elastic buffer seat body and the floating moment arms can generate certain displacement, the force balance is damaged, and the clamping is eliminated. The large block removing device adopts the electric control cabinet, and can realize the remote on-site control conversion.

Owner:洛阳广盈机械设备有限公司

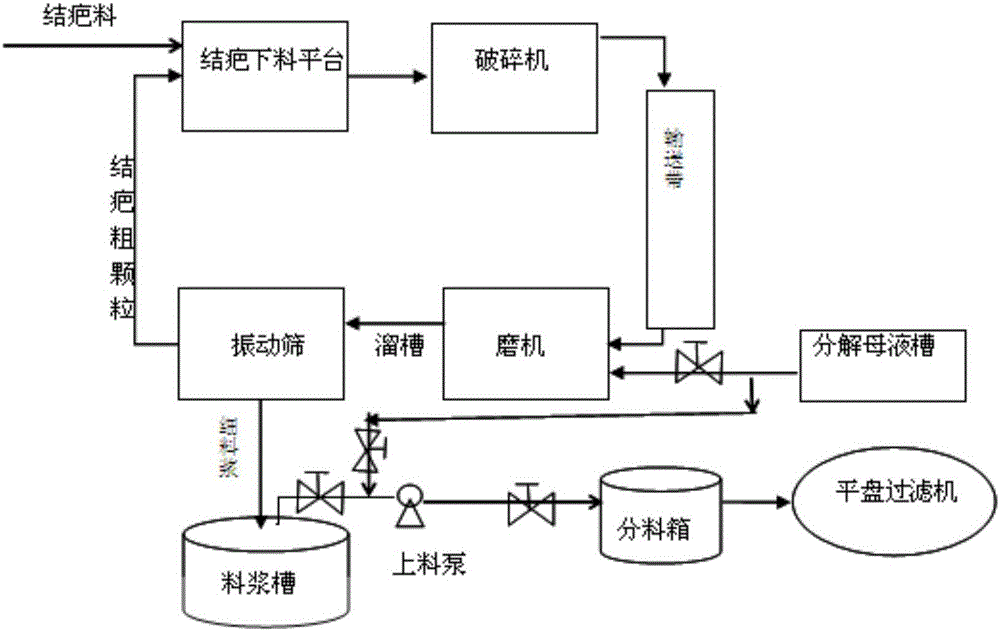

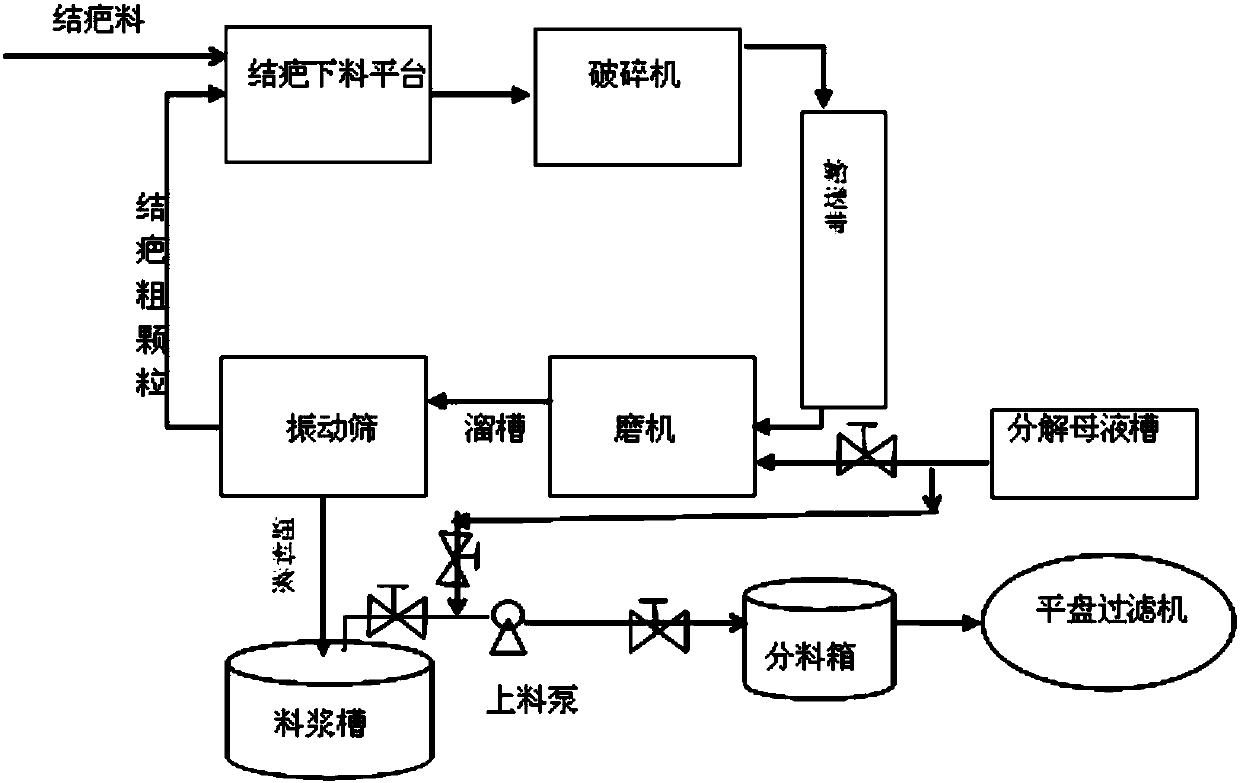

Decomposing tank scab cleaning and recovery method and system thereof

ActiveCN106076578AIncrease sieving rateAvoid equipment repairsSolid waste disposalGrain treatmentsMother liquorAgricultural engineering

The invention discloses a decomposing tank scab cleaning and recovery method and a system thereof. The decomposing tank scab cleaning and recovery method comprises the following steps of (1) cleaning scabs manually, and (2) recovering and treating the scabs. The system comprises a scab discharging platform, a crusher, a ball mill, a vibrating screen, a slurry tank, a decomposing mother liquor tank, a distributing box and a flat plate filter, wherein the scab discharging platform is connected with the crusher through a conveying belt; the crusher is connected with the ball mill through the conveying belt; the ball mill is connected with the vibrating screen through a chute; the vibrating screen is connected with the scab discharging platform through the conveying belt; the slurry tank is arranged at the bottom of the vibrating screen, and is connected with the distributing box through a connecting pipeline; a charging pump is arranged on the connecting pipeline; the distributing box is connected with the flat plate filter; the decomposing mother liquor tank is connected with inlets of the ball mill and the charging pump through the hydraulic pipelines respectively; and hydraulic pumps are arranged on the hydraulic pipelines. The decomposing tank scab cleaning and recovery method and the system are reasonable in design, low in cost, and high in recovery rate, and have popularization values.

Owner:广西田东锦鑫化工有限公司

External cylindrical vibrating screen for screening ore pulp material

InactiveCN109351590AIncrease sieving rateImprove classification efficiencySievingScreeningSlurryVibration motor

The invention discloses an external cylindrical vibrating screen for screening an ore pulp material. The external cylindrical vibrating screen comprises a rack, a screen box, a screen drum and a screen mesh, wherein a main shaft is arranged in the screen drum, and one end of the main shaft extends out of the screen box and is connected to a driving mechanism; a transmission drum is coaxially arranged at the inner side of the screen drum; a vibration disc is arranged along the central axis of the transmission drum; vibration motors are arranged at the left side and right side of the vibration disc; output shafts of the vibration motors are coaxially connected to the main shaft; the vibration disc is connected to the screen drum through spring supporting parts which are arranged in a radialdirection; a feed hopper is arranged on the rack; an annular stop opening is formed at the port of the feeding end of the screen drum; and an oversize collecting hopper and a sieve residue collectinghopper are arranged at the lower side of the rack. The external cylindrical vibrating screen solves the problem that the pulp material stagnates and stick on the screen mesh of the high-speed rotatingcylindrical vibrating screen by carrying out the high-frequency shock excitation on the screen mesh of the cylindrical vibrating screen in the rotating process, thus, the sieving rate and classification efficiency of the cylindrical vibrating screen are effectively improved, and the service life of the cylindrical vibrating screen is prolonged.

Owner:HUBEI XINYING ENVIRONMENTAL TECH

Grinding type pulverizer

The invention discloses a grinding type pulverizer which comprises a grinding device, a drive device and a screen assembly. The grinding type pulverizer is additionally provided with the screen assembly, the screen assembly comprises a base communicating with a discharge outlet, an upper cover matched with the base and a screen arranged between the base and the upper cover, and the upper cover communicates with a vacuum suction device through a pipeline. Vacuumizing operation is carried out on a cavity through the vacuum suction device, negative pressure is formed in the cavity, samples in thegrinding device are sucked, the samples enter the base at first and then pass through the screen, the samples meeting the screening requirement pass through the screen to enter the upper cover and are pumped away by the vacuum suction device, the samples not meeting the screening requirement are left on the base and enter the grinding device again for grinding till meeting the screening requirement, and afterwards the samples pass through the screen and are pumped away by the vacuum suction device. By means of the grinding type pulverizer provided by the invention, the samples entering the vacuum suction device can completely meet the screening requirement, and the sample screening rate is effectively increased.

Owner:长沙开元仪器有限公司

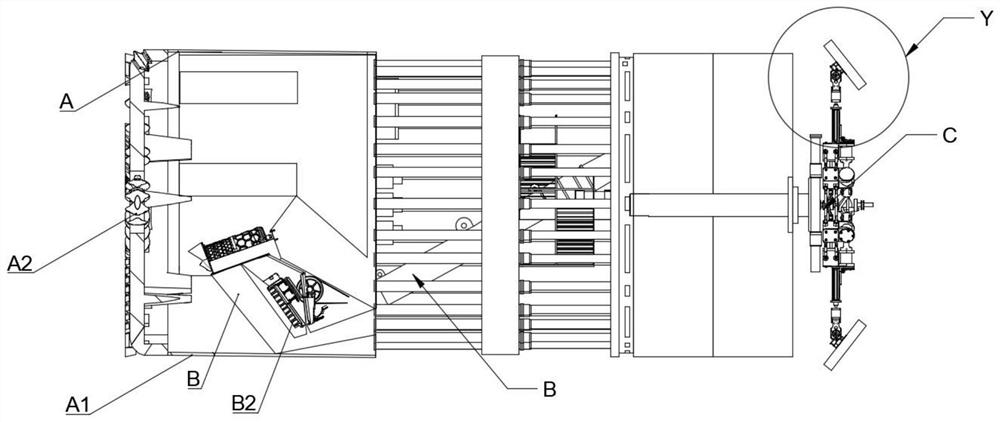

Sieving and crushing integrated machine

ActiveCN102896019BReasonable layoutReduce power consumptionSievingScreeningEngineeringSystem structure

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

Breaking equipment and breaking device thereof

The invention discloses breaking equipment and a breaking device of the breaking equipment. The breaking device comprises a breaking cavity (2), a sieve plate (3) fixed to the bottom of the breaking cavity (2), a main shaft (7) stretching into the breaking cavity (2), a driving device (10) driving the main shaft (7) to rotate, and a blade hammer head (4) connected with the main shaft (7). The main shaft (7) is rotatably connected with the wall of the breaking cavity (2), a gap exists between the blade hammer head (4) and the breaking cavity (2), and sieve holes (11) are formed in the sieve plate (3). The breaking device improves the sieving rate of materials in the breaking process.

Owner:CHANGSHA KAIYUAN INSTR

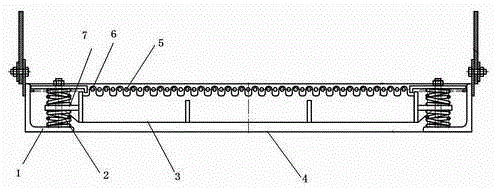

Tensionable linear sieve

The invention discloses a tensioning type linear sieve plate belonging to the field of vibratory screening machinery and overcoming the defects of low aperture ratio, poorer elasticity, easiness in pore blockage and the like of the traditional sieve plate. A sieve plate frame comprises a left sieve plate frame and a right sieve plate frame which are fastened together through a tensioning connecting device; two ends of the sieve plate frame are provided with grating fixing beams; the middle of the sieve plate frame is provided with a grating supporting beam, and a supporting positioning strip is arranged on the grating supporting beam; and a grating is a linear grating, one end of the linear grating is locked through a locking member and sequentially fixed on the grating fixing beam at twoends of the sieve plate frame in a reciprocating manner, the middle of the linear grating is arranged on the supporting positioning strip on the grating supporting beam, and the other end of the linear grating is locked through the locking member. The sieve plate disclosed by the invention has the characteristics of high aperture ratio, good elasticity, high sieve-penetrating ratio, difficulty inpore blockage and convenience for tensioning, replacing and maintaining, and is especially suitable for sieving wet and sticky fine particular materials.

Owner:鞍山鞍重矿山机械有限公司

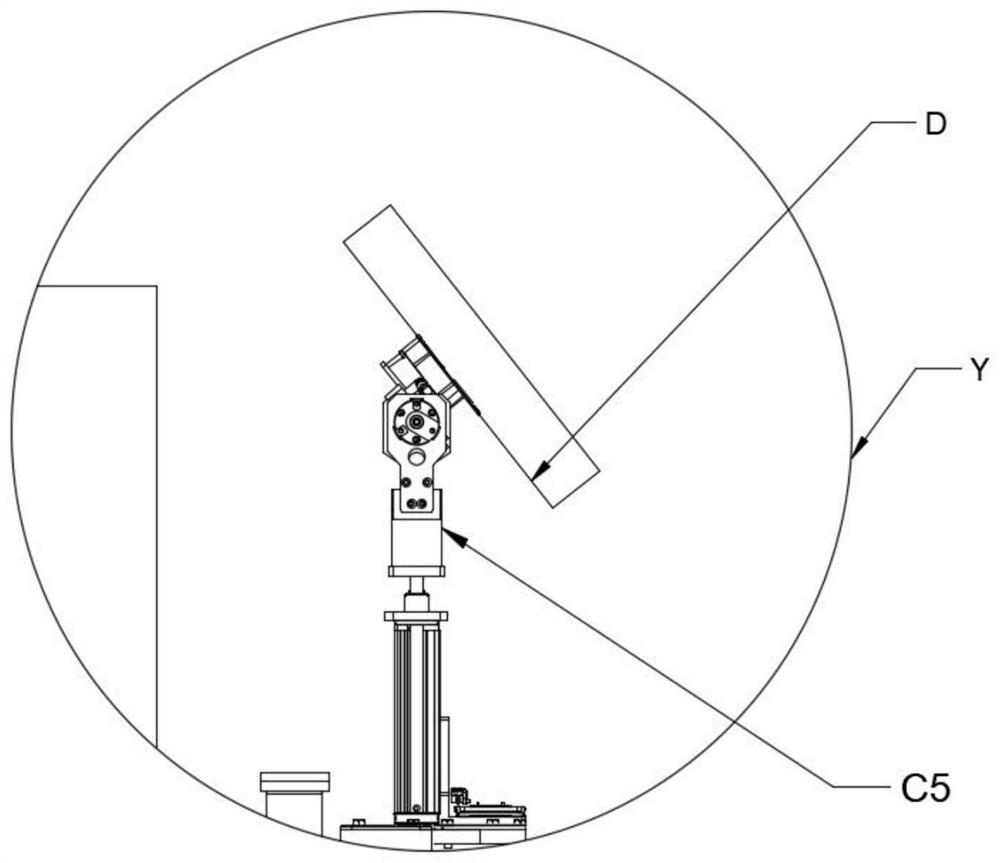

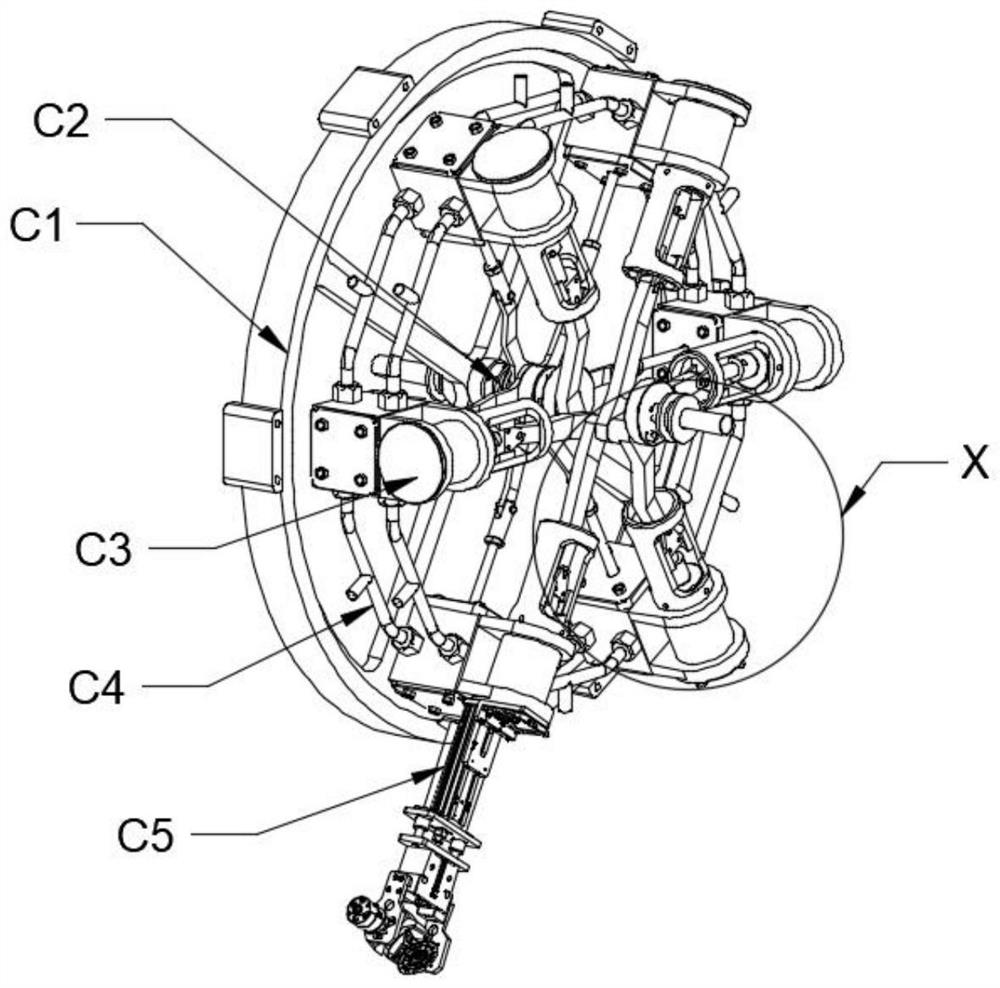

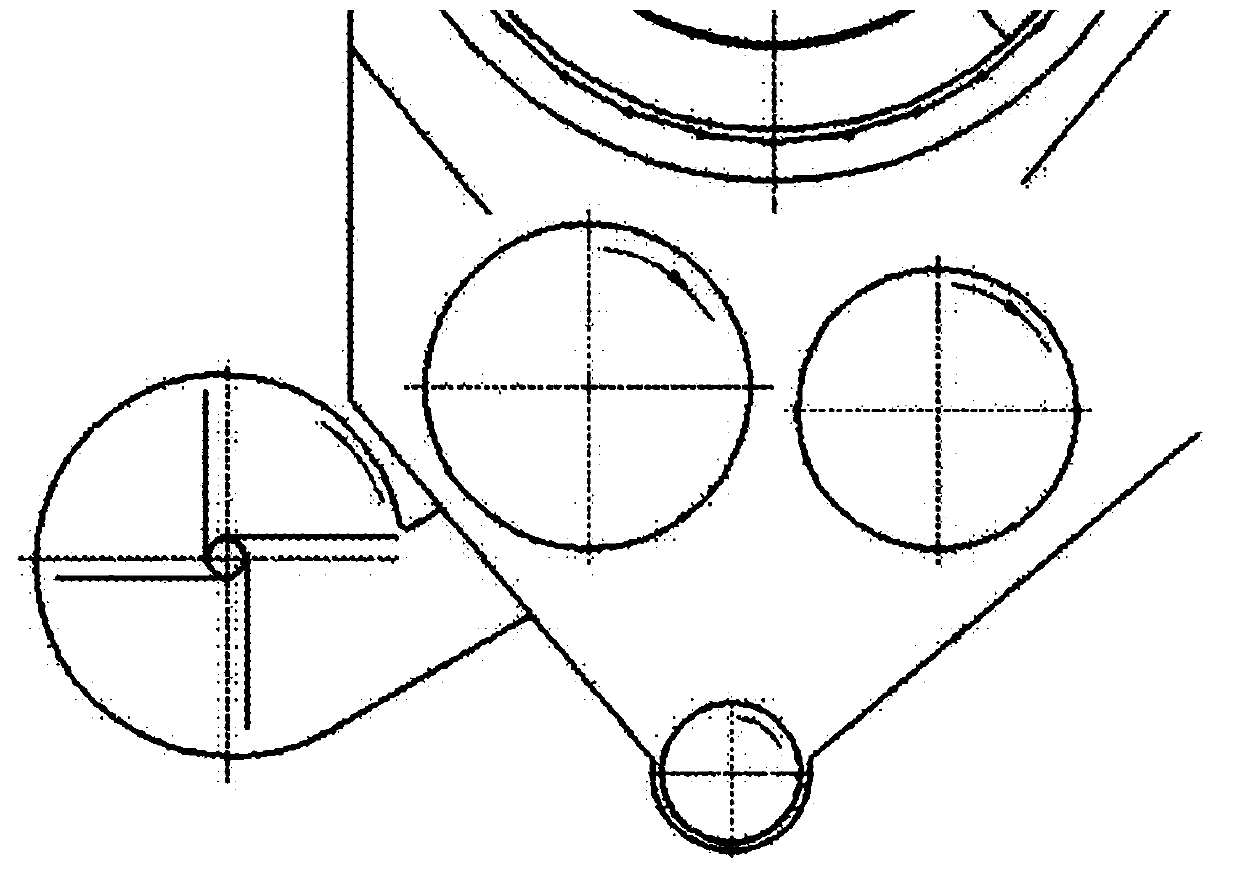

Device for soft soil foundation shield tunnel construction and using method

InactiveCN112576262AHigh degree of automationSave human effortTunnelsLine tubingArchitectural engineering

The invention relates to the technical field of tunnel construction, in particular to a device for soft soil foundation shield tunnel construction. The device for soft soil foundation shield tunnel construction comprises a shield body, a cleaning system and a segment assembling system, wherein the cleaning system is arranged in the shield body, and the segment assembling system is connected with the tail of the shield body; the segment assembling system is connected with the tail of the shield body through a mounting disc and comprises a pushing part and a clamping part, the pushing part is fixedly connected with the mounting disc, the clamping part is connected with the free movable end of the pushing part, and the clamping part clamps segments for splicing and using. According to the device for soft soil foundation shield tunnel construction and an using method, the problems that in the specific using process in the prior art, an existing urban underground pipeline is very complex, large-diameter pipe pieces are not suitable for being installed in tunnels with complex and changeable lines, small-diameter pipe piece construction in the prior art consumes much time, and the accuracy is difficult to grasp are solved.

Owner:重庆贻晨兴工业设计有限责任公司

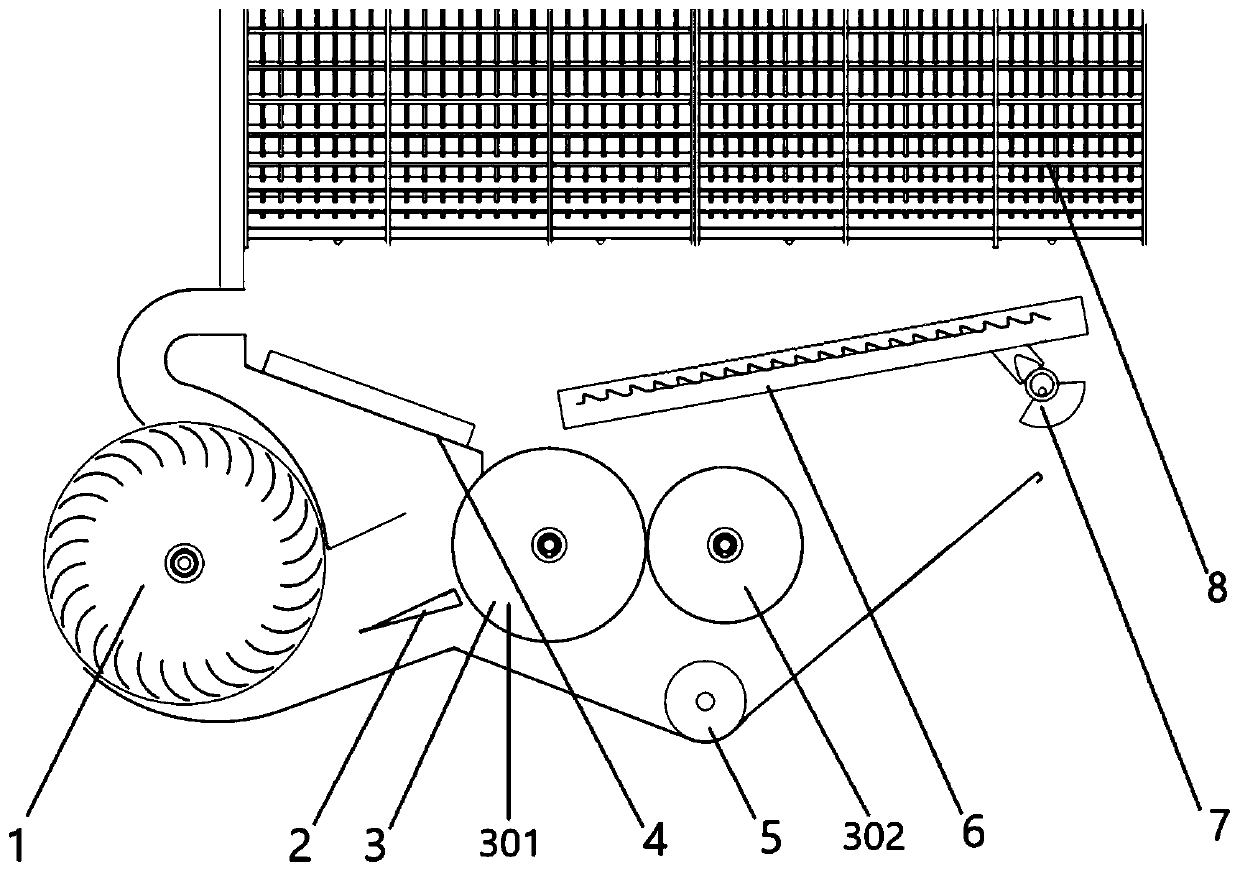

Double-drum-sieve cleaning device and longitudinal axial flow ratoon rice combine harvester with the same

The invention provides a double-drum-sieve cleaning device and a longitudinal axial flow ratoon rice combine harvester with the same. The double-drum-sieve cleaning device comprises double drum sievesand a double-outlet cleaning draught fan. A lower air outlet of the double-outlet cleaning draught fan is located in front of the double drum sieves and used for blowing large debris out of the machine in cooperation with the double drum sieves. An upper air outlet of the double-outlet cleaning draught fan is located above the double drum sieves and used for directly blowing light debris discharged by a threshing device out of the machine. A grain slide plate and a shaking plate divide a cleaning chamber into an upper cleaning area and a lower cleaning area, the upper cleaning area is used for directly blowing the light debris discharged by the threshing device out of the machine, and the lower cleaning area is used for blowing the large debris out of the machine. The limited longitudinalspace between the threshing device and a cleaning mechanism is sufficiently used for primary winnowing, the design power of the drum sieves can be reduced, and the light debris is directly blown outof the machine without being scattered by the drum sieves by reasonable use of the draught fan.

Owner:JIANGSU UNIV

Plant coloring agent and preparation method thereof

The invention discloses a plant coloring agent and a preparation method thereof. The plant coloring agent is composed of 1-3 parts of a compound thickening agent, 12-18 parts of a compound mordant and 0.5-2 parts of soybean meal. The compound thickening agent comprises sesbania gum, guar gum or carrageenan. The compound mordant is prepared from copperas, tannic acid and water. The weight ratio of the sesbania gum to the guar gum is 9: 1, and the weight ratio of the sesbania gum to the carrageenan is 7: 3. The weight ratio of the copperas to the tannic acid is 9: 1. The invention also provides the preparation method of the plant coloring agent. The plant coloring agent is relatively good in printing performance, clear in pattern outline edge after fabric dyeing, good in permeability and relatively high in color fastness.

Owner:BEIJING INST OF TECH ZHUHAI CAMPUS

High-efficiency muffling hammer slice crusher

The invention discloses a high-efficiency muffling hammer slice crusher. The high-efficiency muffling hammer slice crusher comprises a base, a motor, a shaft coupler, a rotor, a crushing chamber and a feeding cabin, wherein the motor is connected with the rotor by the shaft coupler; the outlet of the feeding cabin is flexibly connected with the inlet of the crushing chamber; the crushing chamber comprises a shell, a rotor shaft, a sieve plate, a sieve pressing frame, a rotary tray, a connecting pin, hammer slices, a first steering structure and a second steering structure, wherein the shell comprises a panel, an inner plate and muffling cotton; the second steering structure comprises a base supporting plate, a supporting plate and a steering plate. According to the high-efficiency muffling hammer slice crusher disclosed by the invention, the hammer slices are distributed radially in the sieve plate so that the internal annular flow layers of the crushing chamber are effectively damaged and the resistance of material ring flow is increased, and thus qualified small particles can be removed to the surface of the sieve plate in time and are discharged from the crusher by passing through sieve holes; the sieving rate of materials is increased, and the crushing efficiency is greatly improved; by adopting the flexible connection and the muffling cotton, the high-efficiency muffling hammer slice crusher disclosed by the invention has the advantages of greatly reducing the working noise of the overall crusher and alleviating the noise pollution of the surrounding environment.

Owner:曹波

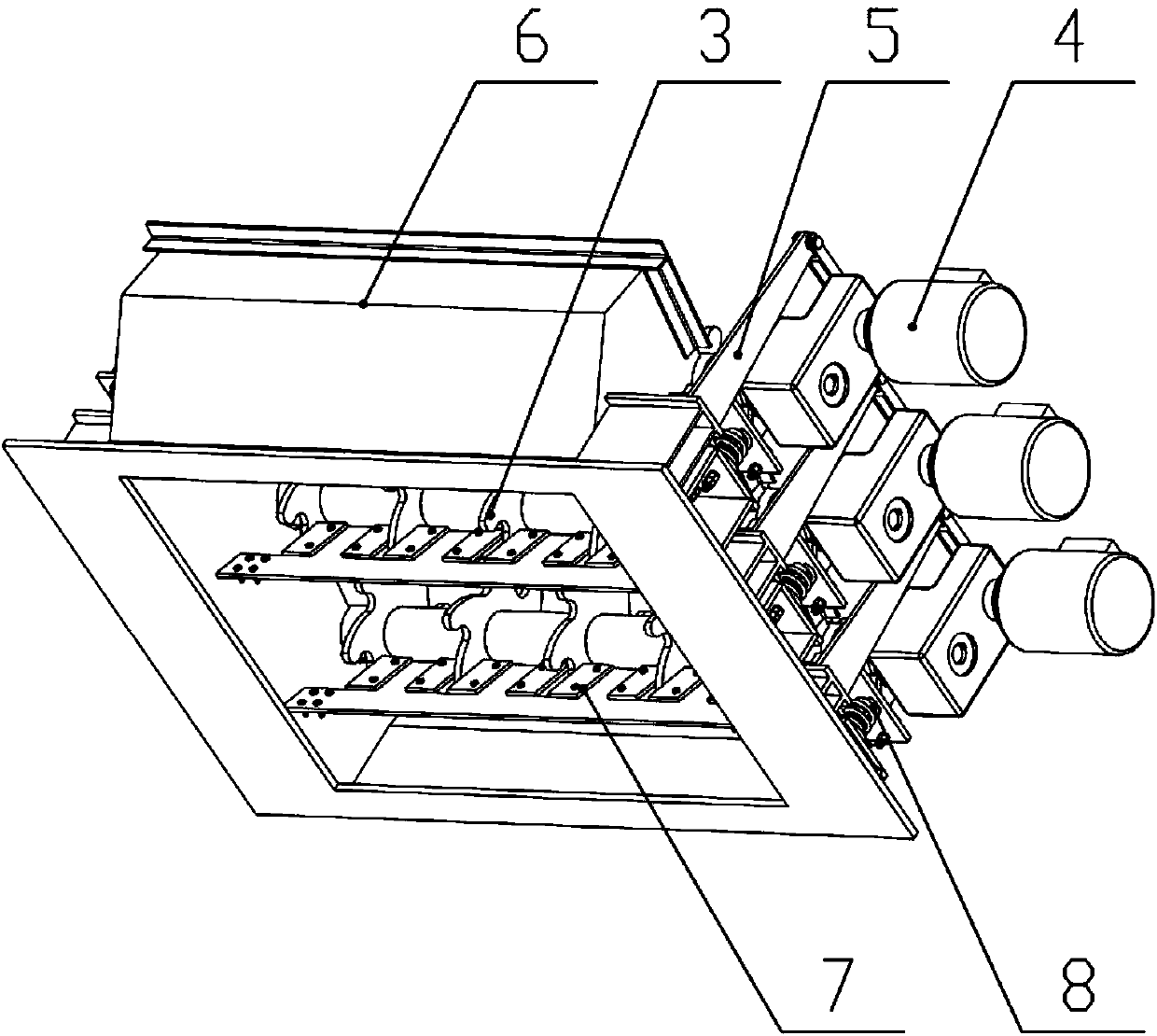

A method and system for cleaning and recovering scabs in decomposition tanks

ActiveCN106076578BGuaranteed GranularityAvoid cloggingSolid waste disposalGrain treatmentsAgricultural engineeringHydraulic pump

The invention discloses a decomposing tank scab cleaning and recovery method and a system thereof. The decomposing tank scab cleaning and recovery method comprises the following steps of (1) cleaning scabs manually, and (2) recovering and treating the scabs. The system comprises a scab discharging platform, a crusher, a ball mill, a vibrating screen, a slurry tank, a decomposing mother liquor tank, a distributing box and a flat plate filter, wherein the scab discharging platform is connected with the crusher through a conveying belt; the crusher is connected with the ball mill through the conveying belt; the ball mill is connected with the vibrating screen through a chute; the vibrating screen is connected with the scab discharging platform through the conveying belt; the slurry tank is arranged at the bottom of the vibrating screen, and is connected with the distributing box through a connecting pipeline; a charging pump is arranged on the connecting pipeline; the distributing box is connected with the flat plate filter; the decomposing mother liquor tank is connected with inlets of the ball mill and the charging pump through the hydraulic pipelines respectively; and hydraulic pumps are arranged on the hydraulic pipelines. The decomposing tank scab cleaning and recovery method and the system are reasonable in design, low in cost, and high in recovery rate, and have popularization values.

Owner:广西田东锦鑫化工有限公司

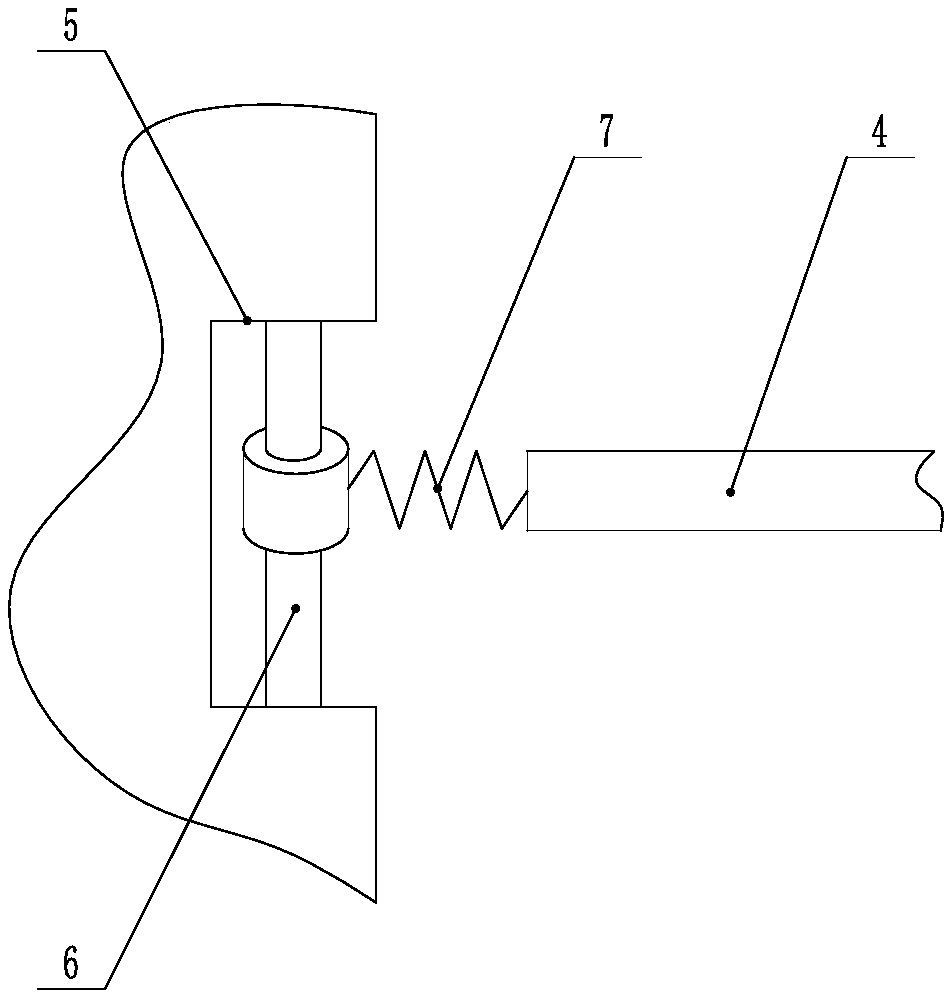

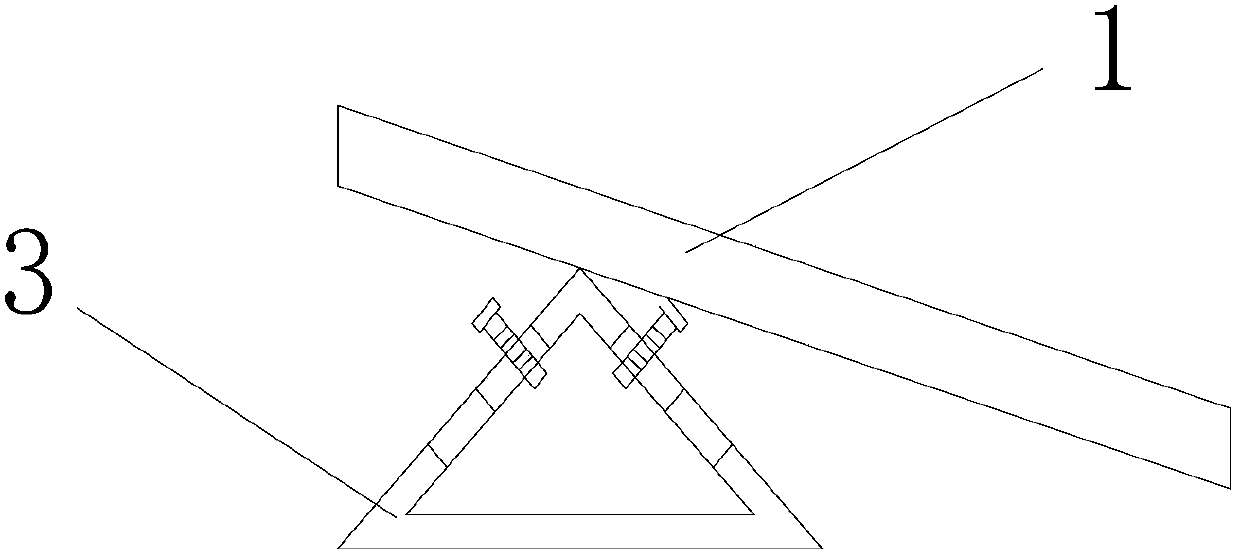

Spring type anti-blocking screen

InactiveCN105414008AIncrease sieving rateImprove screening efficiencySievingScreeningFixed frameEngineering

The invention discloses a spring type anti-blocking screen. According to the technical scheme, the spring type anti-blocking screen comprises a fixed frame and a spring, wherein the spring is arranged on the fixed frame, a fixedly connecting sleeve is arranged on the spring, the fixedly connecting sleeve is fixedly connected with a movable screen shoe, movable screen strip plates are arranged on the movable screen shoe, fixed screen strip plates are arranged at the upper part of the fixed screen shoe, movable screen strips of the movable screen strip plates are distributed between adjacent fixed screen strips of the fixed screen strip plates, the fixed screen strips and the movable screen strips are located on the same horizontal plane, and a slide carriage is arranged below the screen strips. The spring type anti-blocking screen is reasonable in structure, good in use effect, and capable of effectively promoting the screening percentage of a vibrating screen in screening clammy raw coal, coal slime, brown coal, coal gangue and other large materials, thus improving the overall screening efficiency of the vibrating screen.

Owner:HENAN WINNER VIBRATING EQUIP

Multi-layer sectional type ratooning rice grain cleaning screen

The invention provides a multi-layer sectional type ratooning rice grain cleaning screen. The multi-layer sectional type ratooning rice grain cleaning screen comprises a cleaning screen frame, a shaking plate, an upper-layer woven screen, a middle-layer louver screen, a tail fish scale screen and a lower-layer woven screen, wherein the shaking plate, the upper-layer woven screen, the middle-layerlouver screen, the tail fish scale screen and the lower-layer woven screen are installed on the cleaning screen frame. The front end of the upper-layer woven sieve is connected with the tail end of the shaking plate, the front end of the tail fish scale sieve is connected with the tail end of the middle-layer louver sieve, and the tail fish scale sieve is obliquely arranged upwards; the middle-layer louver screen comprises a screen piece, a plurality of first straw-shaking strip groups and a plurality of second straw-shaking strip groups, each first straw-shaking strip group comprises two first straw-shaking strips which are distributed in a splayed shape, each second straw-shaking strip group is arranged above the screen piece and comprises a plurality of second straw-shaking strips whichare parallel to one another, and the second straw-shaking strips are arranged in the front-to-back direction; according to the invention, the grain screening rate can be improved, and separated materials with high water content can be subjected to layered diffusion.

Owner:JIANGSU UNIV

Powdery high-activity calcium oxide and production process thereof

InactiveCN108502909AEfficient preparation methodThe method of preparation is of high qualityCeramicwareCalcium/strontium/barium oxides/hydroxidesCycloneDecomposition

The invention discloses powdery high-activity calcium oxide and a production process thereof, belonging to the technical field of the production of active lime. According to the adopted technical scheme, the production process comprises the steps of crushing limestone into small crushed materials with different sizes by virtue of a crushing machine, conveying produced coarse materials into a pulverizer by virtue of an electromagnetic vibration feeder, grinding the limestone into powder with the particle size of 0.1mm-3mm, storing the powdery limestone into a material bin, or directly conveyingthe powdery limestone into a multi-stage cyclone preheating cylinder for suspension type preheating decomposition, and conveying the powdery limestone into a rotary kiln for calcination, wherein a spiral distributor is further arranged in the rotary kiln and is used for uniformly distributing the materials in the rotary kiln, so that the 100% utilization of the limestone resource is realized, andthe large-scale production is realized. Advanced scientific instruments and techniques are applied to the whole production process of powdery high-activity calcium oxide, so that the production process of powdery high-activity calcium oxide is an efficient, high-quality and low-consumption modern calcium oxide production method which is accordant with environmental requirements and large-scale and automatic features.

Owner:郑小华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com