Double-drum-sieve cleaning device and longitudinal axial flow ratoon rice combine harvester with the same

A cleaning device and double-cylinder technology, which is applied to harvesters, agricultural machinery and implements, threshing equipment, etc., can solve the problems of increasing the rated power of the cylinder screen and the low utilization rate of the fan, so as to improve the screening rate and increase the The effect of working and improving the cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

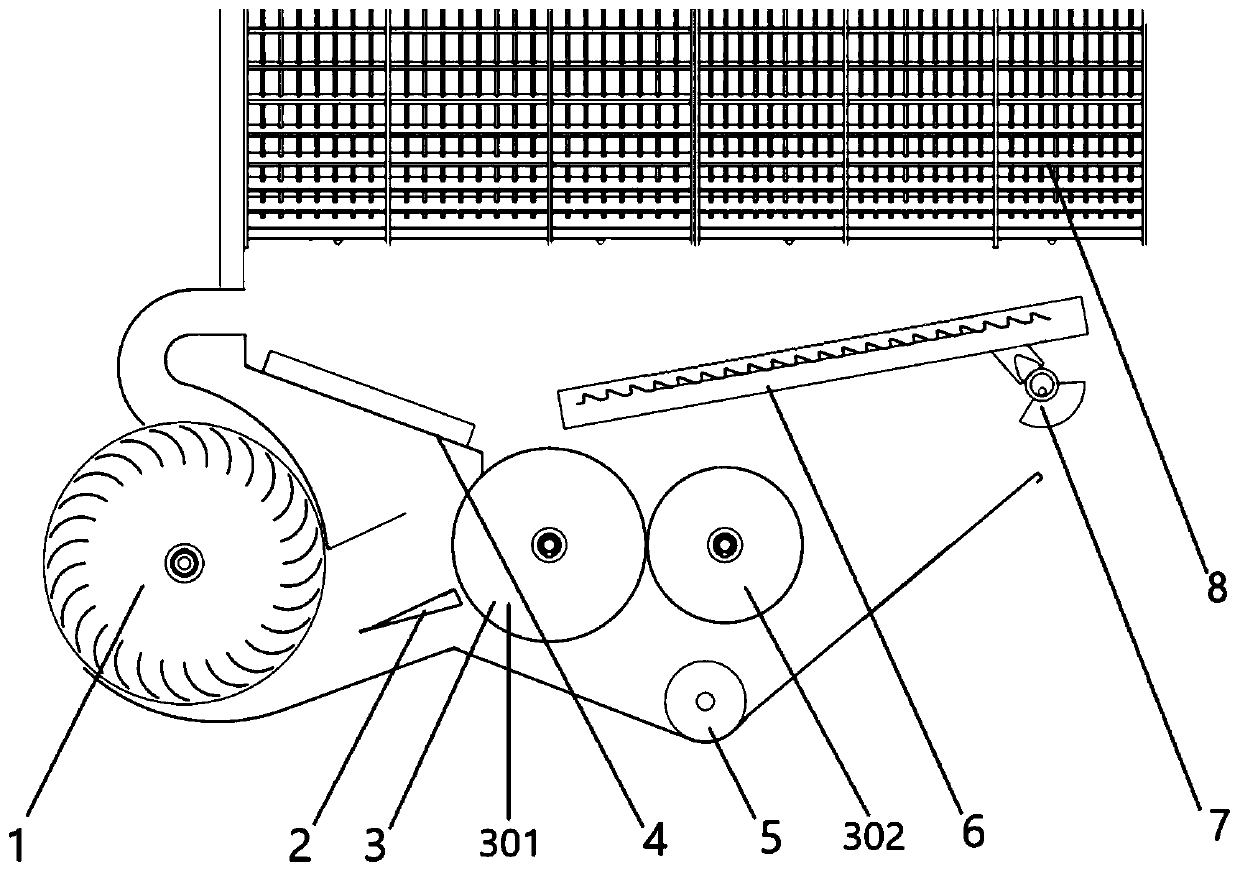

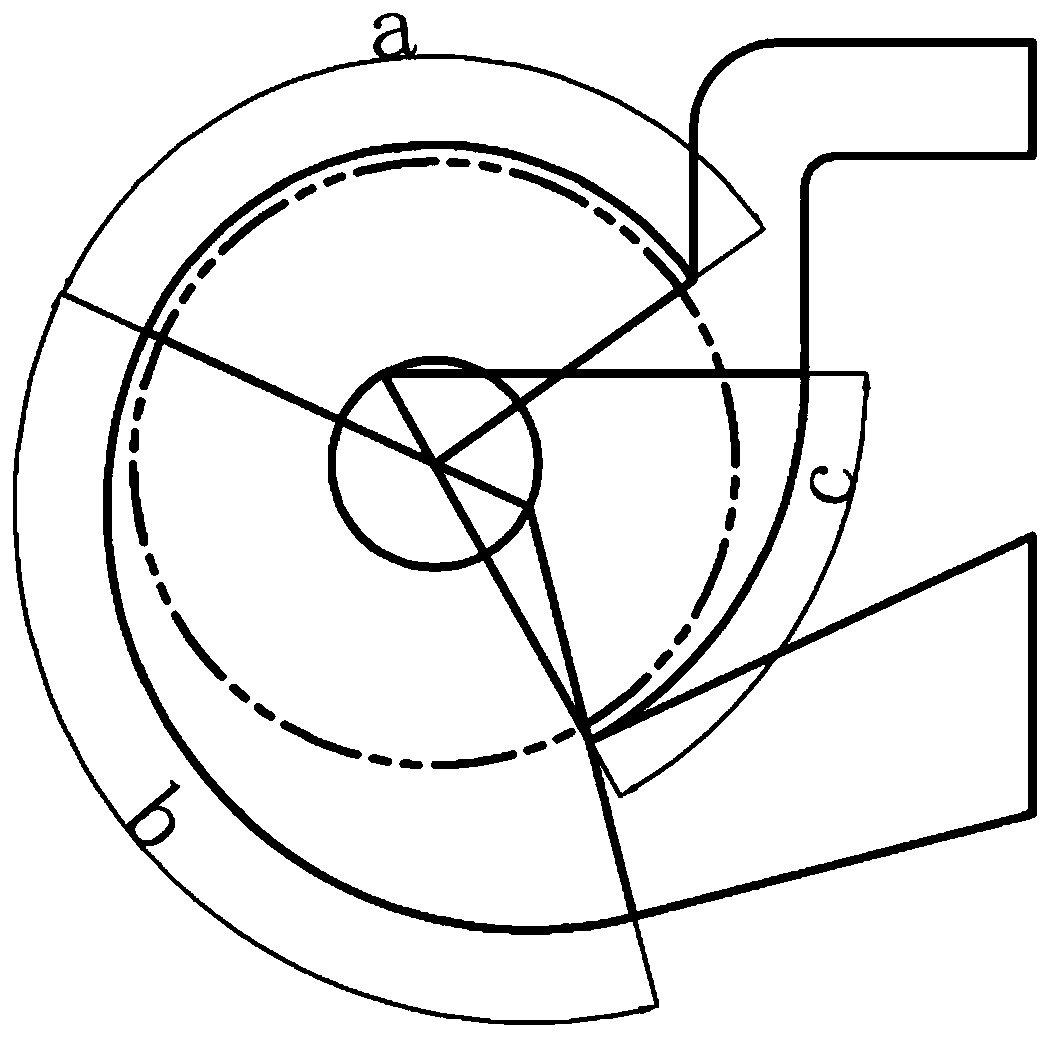

[0040] Such as figure 2As shown, the double cylinder sieve cleaning device of the present invention includes a longitudinal axial flow threshing device, a grain conveying auger 5, a double cylindrical sieve 3 and a double outlet cleaning fan 1, and the longitudinal axial flow threshing device is located in the double cylinder Above the drum sieve 3, the grain conveying auger 5 is located at the bottom of the double cylinder sieve 3; the longitudinal axial flow threshing device and the grain conveying auger 5 are existing structures and will not be described here. The lower air outlet of the double-export cleaning fan 1 is located in front of the double-cylinder screen 3, and is used to cooperate with the double-cylinder screen 3 to blow the large debris out of the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com