Novel mining vibrating screen

A vibrating screen, mining technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problem that the linear vibrating screen can not be well adapted, the jamming screen paste is not as good as the circular vibrating screen, etc., to improve the screen penetration. high efficiency, simple structure and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

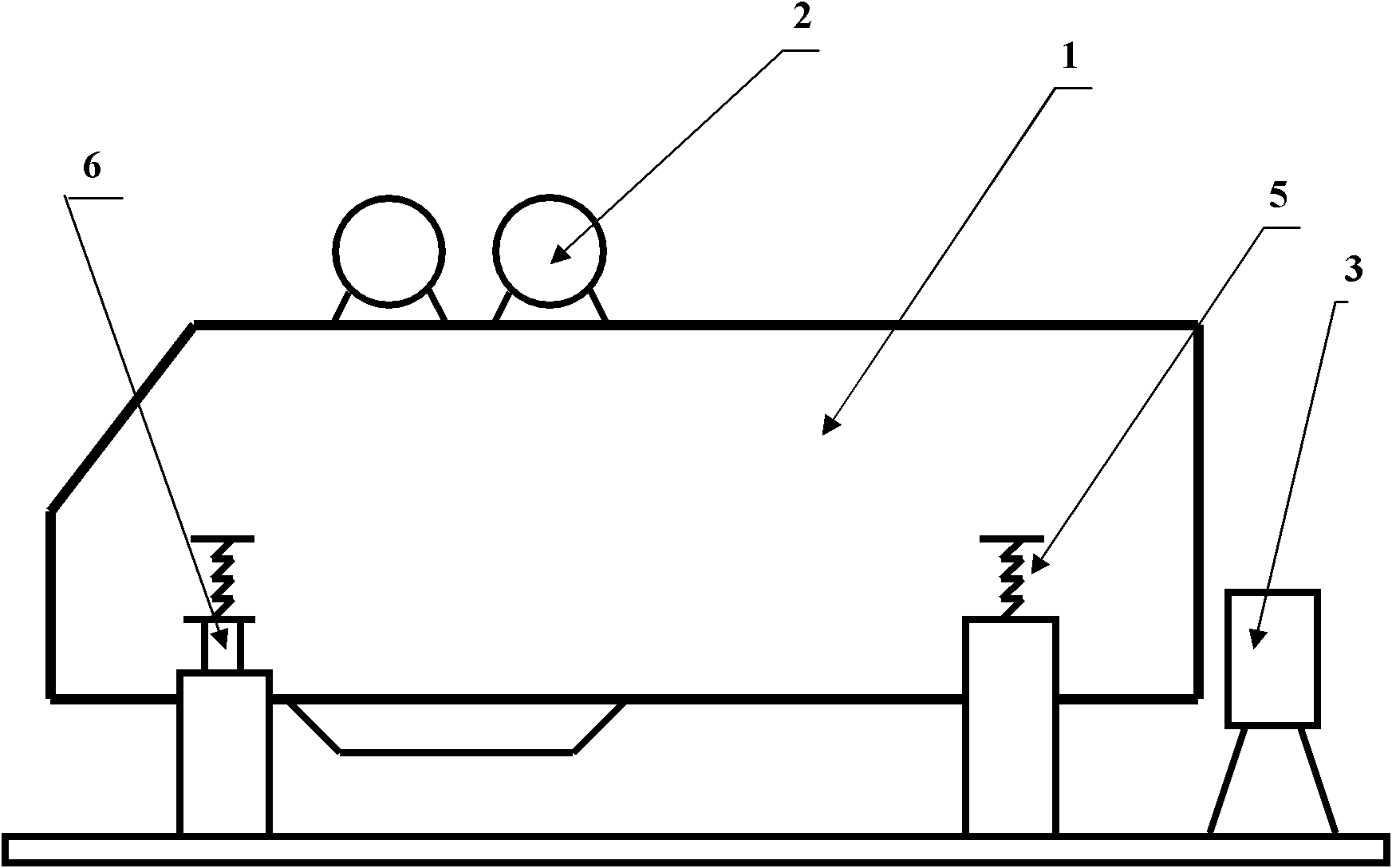

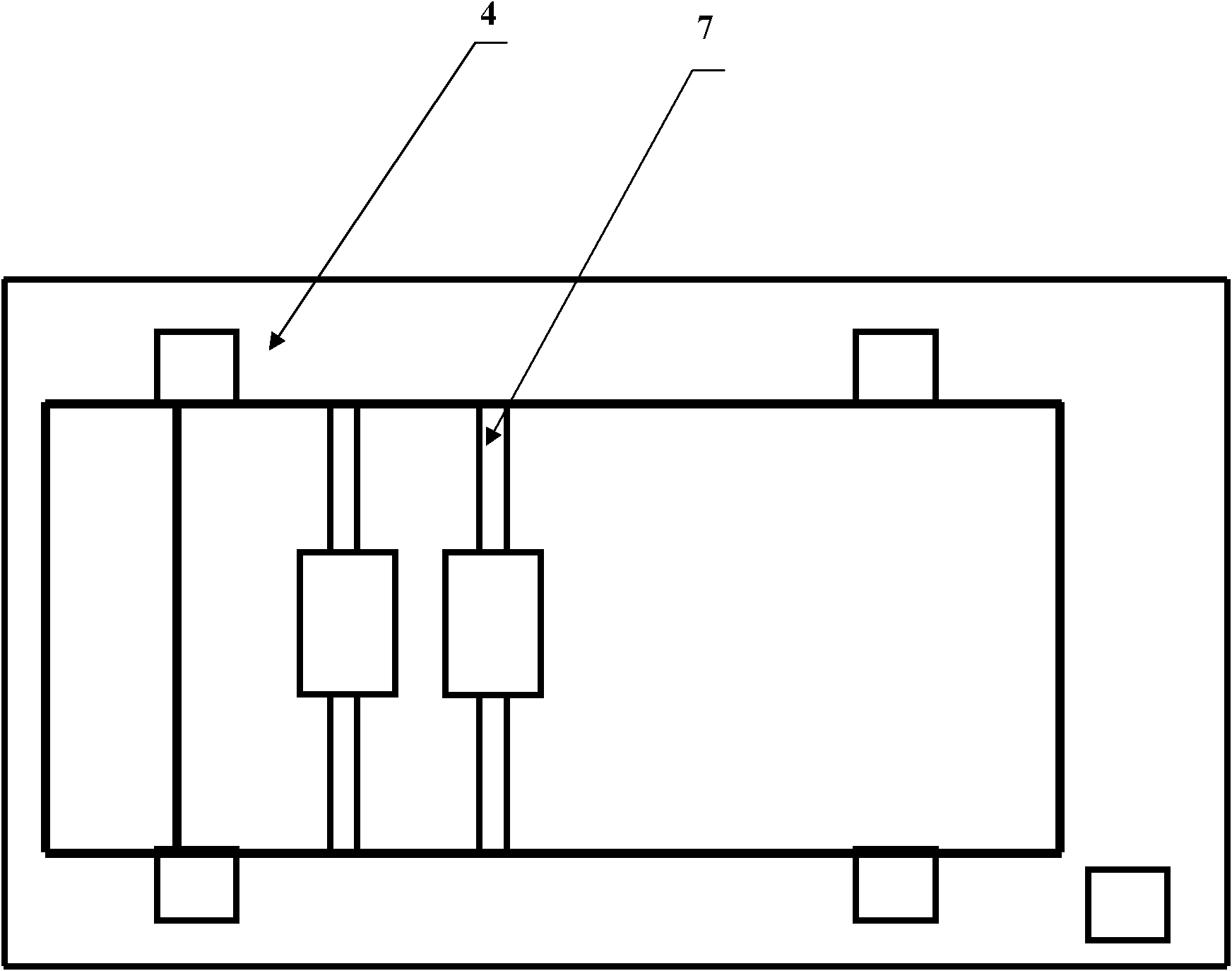

[0022] Embodiment 1: The novel mining vibrating screen of the first structure

[0023] The vibrating screen adopts the structure of two excitation motors. like figure 1 and figure 2 As shown: there is a vibrating screen box 1, which is supported on the base 4 of the vibrating screen by four rubber damping springs 5 with variable stiffness. The center of mass of the box 1 ensures the stability of the vibrating screen box 1 during startup and operation. The vibrator 2 composed of two vibrating motors is installed on the vibrating screen box 1 through the support shaft 7. The vibrator is based on the force center theory of the inertial vibrating screen and the non-equal mass diameter product following self-synchronization and synchronous state stability theory. Work to realize the translational elliptical mode shape motion of the single-mass biaxial self-synchronized translational elliptical vibrating screen. The automatic control electrical appliance switch box 3 is insta...

Embodiment 2

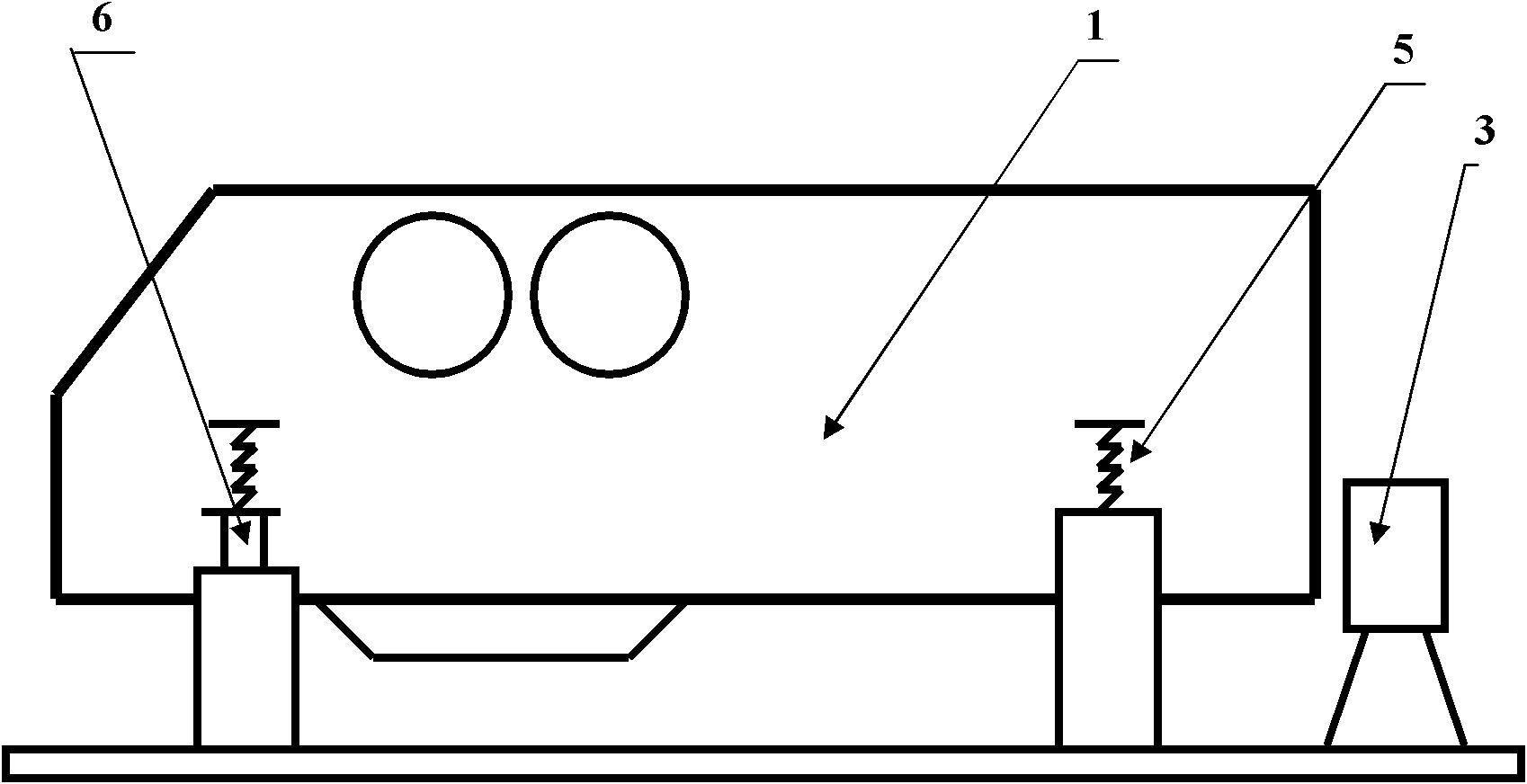

[0024] Embodiment 2: the novel mining vibrating screen of the second structure

[0025] The vibrating screen adopts the structure of four excitation motors. like image 3 and Figure 4 As shown: there is a vibrating screen box 1, which is supported on the base 4 of the vibrating screen by four rubber damping springs 5 with variable stiffness. The center of mass of the box 1 ensures the stability of the vibrating screen box 1 during startup and operation. The vibrator 2 composed of four side plate vibrating motors is directly installed on the side plate of the vibrating screen box 1, and the four side plate vibrating motors are connected in pairs by the connecting shaft 7. Center theory and non-equal mass-diameter product following self-synchronization and synchronization state stability theory work to realize the translational elliptical mode shape motion of single-mass multi-axis self-synchronized translational elliptical vibrating screen. The automatic control electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com