Coal classifying screen

A grading sieve and sieve shaft technology, applied in the direction of filter screen, solid separation, grid, etc., can solve problems such as insufficient output, material blocking on the screen surface, and material blocking in the sieve shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

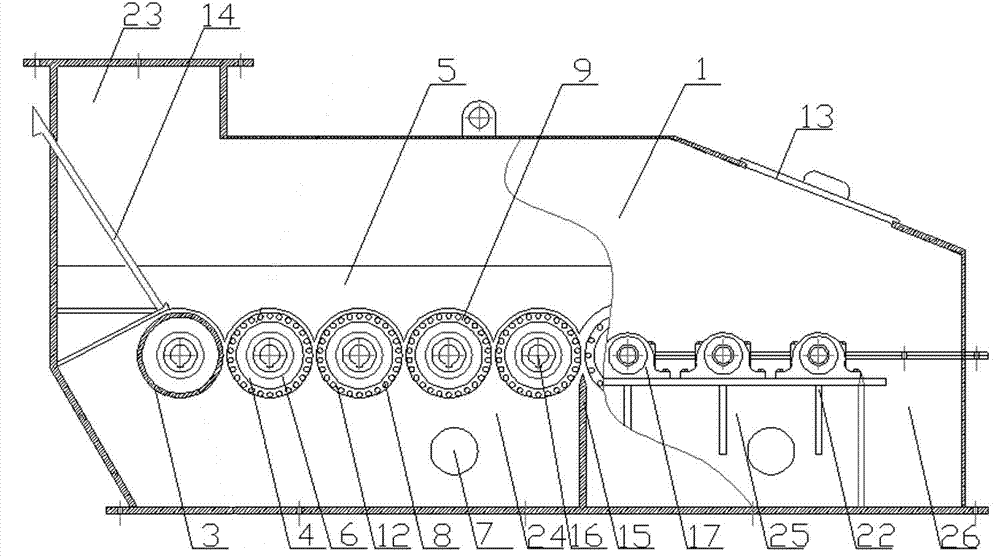

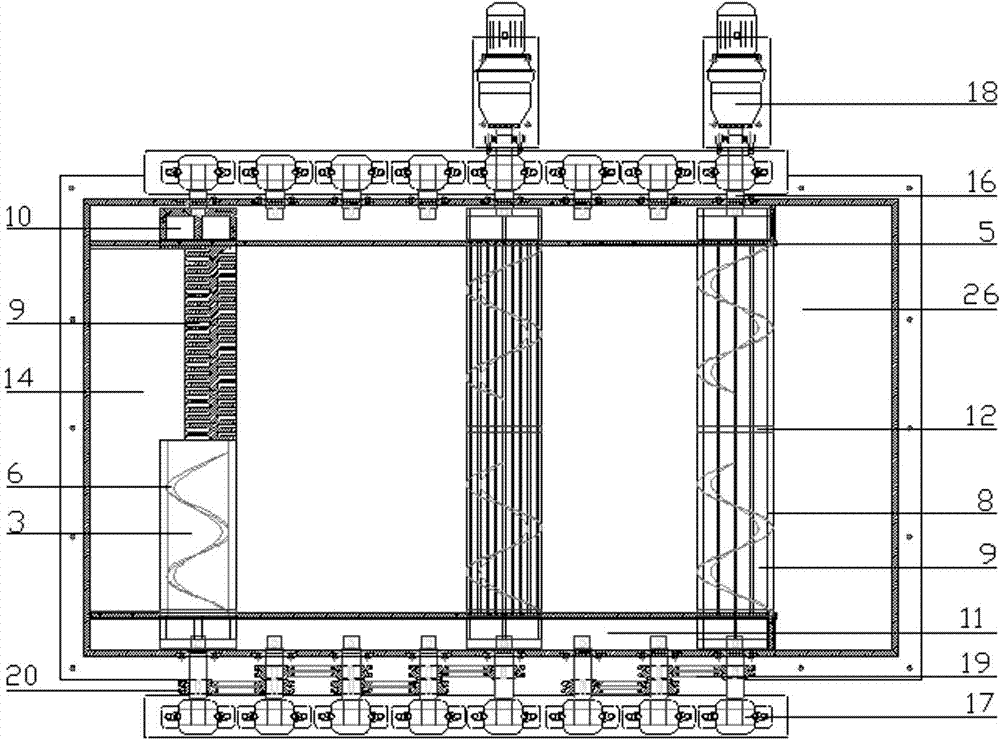

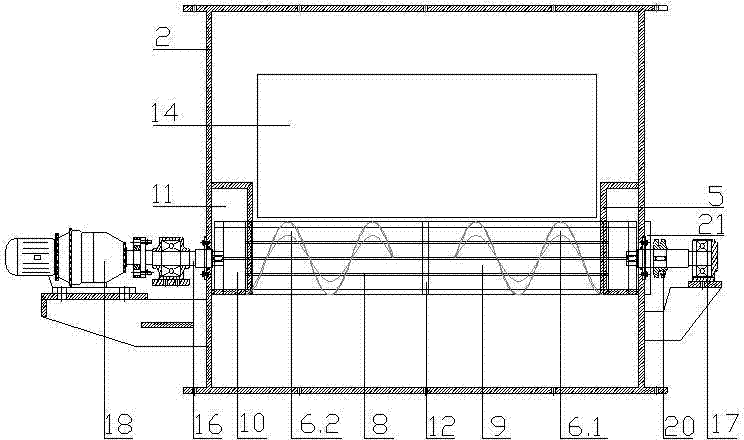

[0046]Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0047] Such as figure 1 , figure 2 , image 3 As shown, a grading screen 1 for coal includes a casing 2, a trommel shaft 3, a screen bar shaft 4, a tooth-shaped partition plate 5, a material guide screw 6, a particle size observation hole 7, a screen bar 8, and a screen slot 9. Anti-blocking hole 10, feeding channel 11, flange plate 12, screen surface observation hole 13, pull-out distribution plate 14, distribution plate 15, detachable transmission shaft 16, bearing seat 17, gear motor 18, chain 19. Sprocket 20, sealing device 21, support frame 22, material inlet 23, first qualified particle size discharge port 24, second qualified particle size discharge port 25, unqualified particle size discharge port 26.

[0048] The grading screen for coal is mainly composed of a pull-out distributing plate 14, two tooth-shaped partition plates 5, a trommel shaft 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com