Decomposing tank scab cleaning and recovery method and system thereof

A recovery method and technology of a recovery system, applied in the field of decomposing tank scab cleaning recovery method and its system, can solve the problems of high cost, steam consumption, low recovery rate, etc., to improve production efficiency, avoid equipment maintenance, and improve screening rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

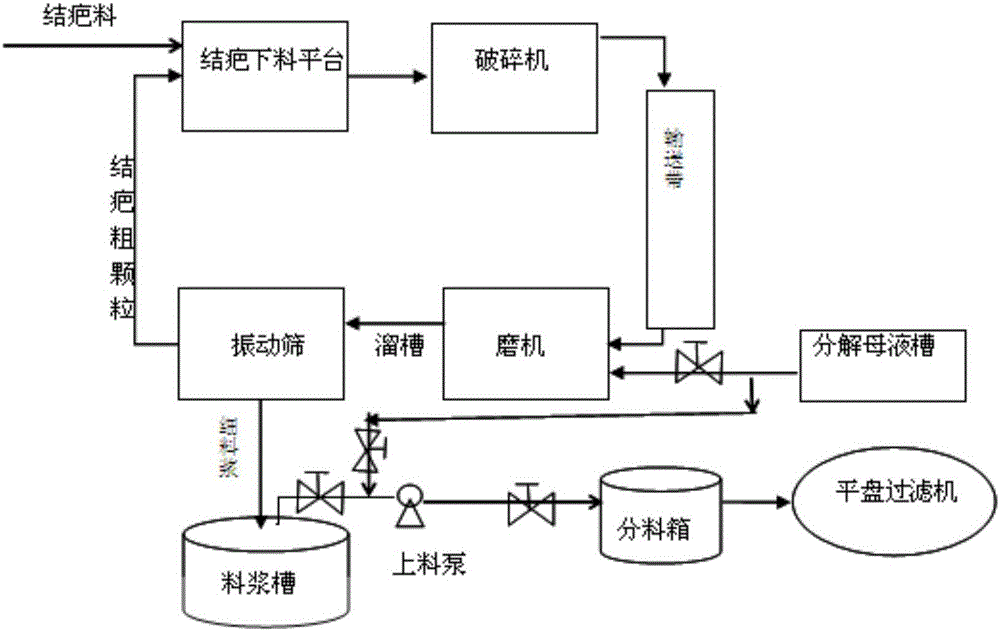

[0032] A method for cleaning and recovering scars in a decomposition tank includes the following steps:

[0033] (1) Manual removal of scars: The scars on the decomposition tank are manually cleaned, and the cleared scars are transported to the crushing site; the method of manually cleaning the scars on the decomposition tank is to first open the manhole and open the manhole scar, then Use the decomposition mother liquor to flush the unscarred deposits in the decomposition tank out of the manhole, then pull the scars on the decomposition tank wall manually to clear the manhole, and finally use a pneumatic pick to clean the scarred out manhole at the bottom of the decomposition tank;

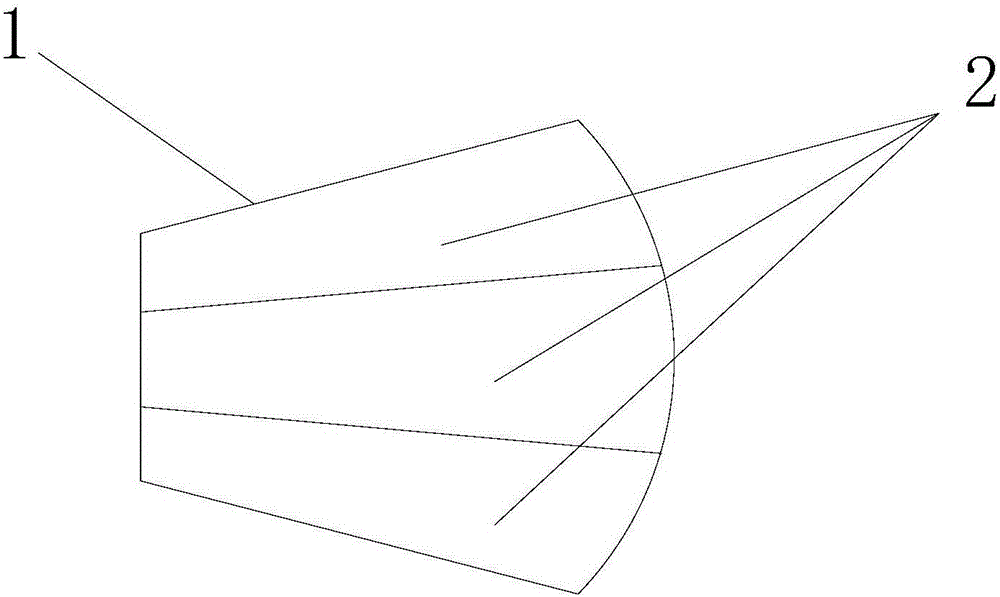

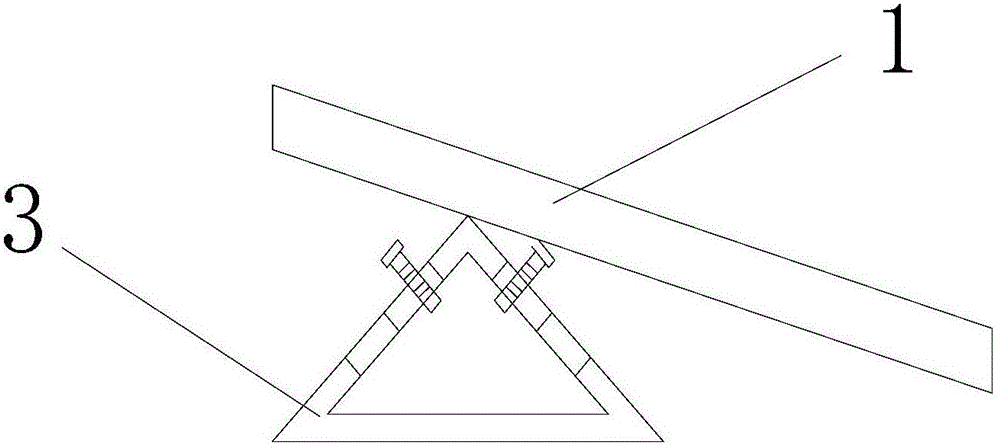

[0034] (2) Scar recovery treatment: use a crusher to crush the scars on the scraping platform to obtain scars with a particle size of ≤250mm. The crushed scars are sent to the ball mill through the conveyor belt and pumped into the ball mill The decomposing mother liquor is ball milled, and the volume...

Embodiment 2

[0039] The recovery method and recovery system are the same as the recovery system of Example 1, and the inventive concept is the same. The difference is: the volume ratio of scarring to decomposition mother liquor is 1:3, and the decomposition mother liquor is introduced at the inlet of the feeding pump to adjust the solidity of the slurry. The content ratio is 700g / l, and the fan-shaped chute is divided into 5 fan-shaped guide grooves by the partition; the feeding pump and the hydraulic pump are gear pumps and the flow rate is 35m 3 / h, the output pressure is 0.8Mpa; the distance between the control valve and the feeding pump is 3m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com