High-efficiency muffling hammer slice crusher

A sound-absorbing hammer and pulverizer technology, which is applied in the field of mechanical equipment, can solve problems such as material screening, physical and mental impact of workers, and noise annoyance that have not been fundamentally solved, so as to reduce noise pollution, improve crushing efficiency, and reduce working noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

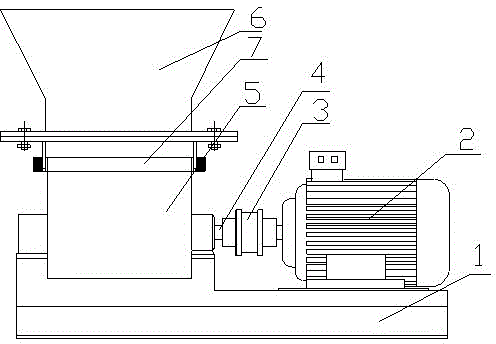

[0021] Please refer to the figure, a high-efficiency sound-absorbing hammer mill, including a base 1, a motor 2, a coupling 3, a rotor 4, a crushing chamber 5 and a feed bin 6, and the motor 2 and the crushing chamber 5 are installed in the On the base 1, the motor 2 is connected with the rotor 4 through the coupling 3, and the other end of the rotor 4 extends into the crushing chamber 5, and the outlet of the feeding bin 6 is connected with the inlet of the crushing chamber 5 through a soft connection 7, because the soft The connection 7 has the function of buffering and absorbing the vibration amplitude, which can effectively buffer and absorb the vibration and noise generated when the pulverizer is working, so as to achieve the purpose of reducing the noise of the whole machine.

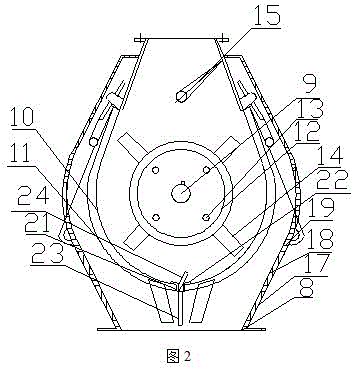

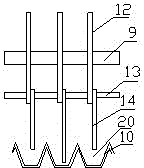

[0022] The crushing chamber 5 includes a casing 8, a rotor shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com