Solid mixture multilayer vibration physics screening machine

A multi-layer vibration and mixture technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of high cost, high labor intensity, low efficiency, etc., and achieve the goal of increasing operating cost, low labor intensity and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

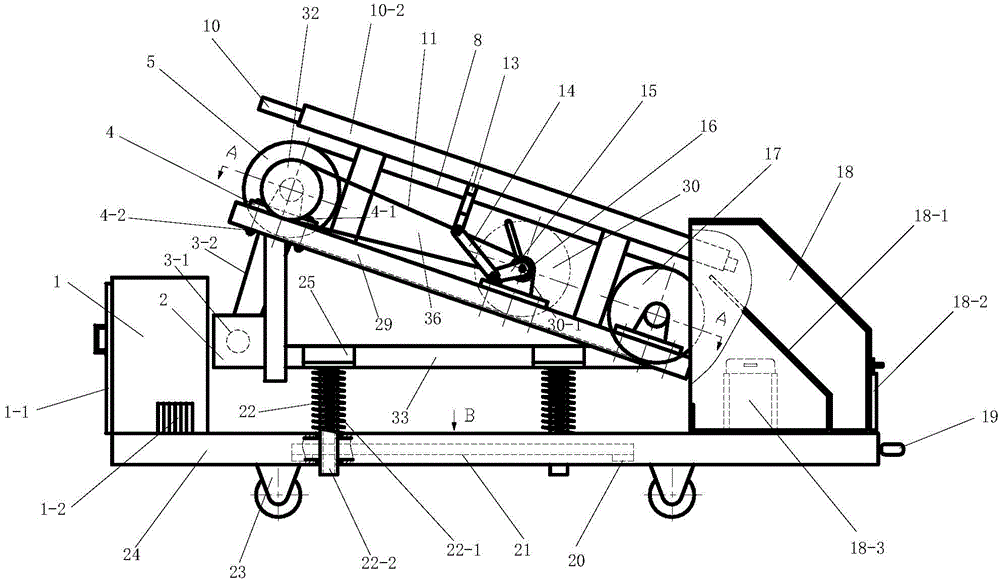

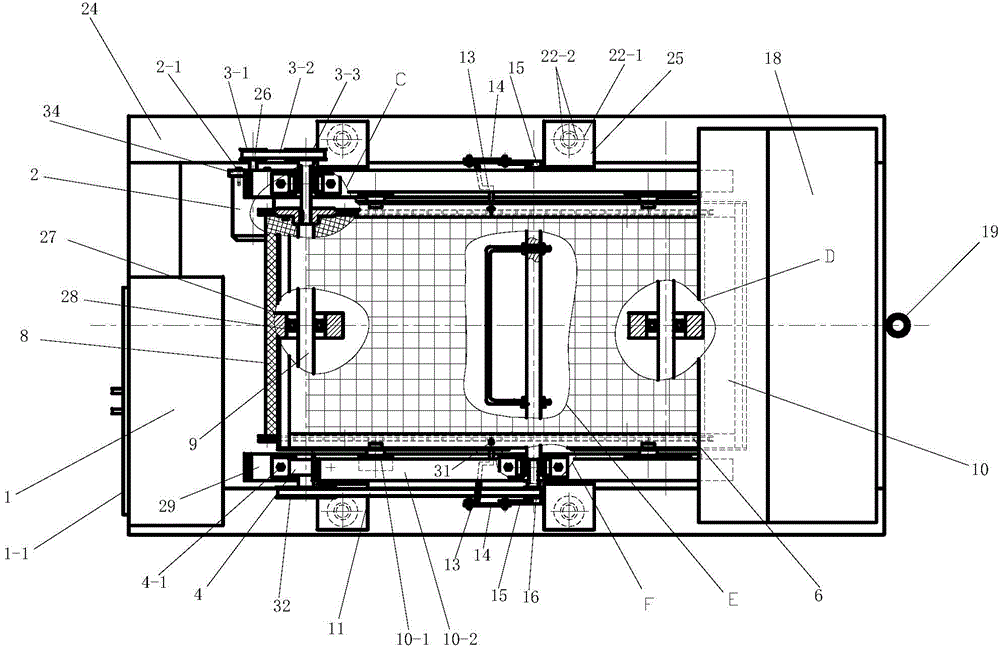

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] see Figure 1 to Figure 7 , the present invention comprises sliding screen 10, double-deck rotary screening device 36, vibrating screen that is rotating screen 8, knocking mechanism 30, damping mechanism 22, receiving box 18, frame 29 and vehicle frame 24,

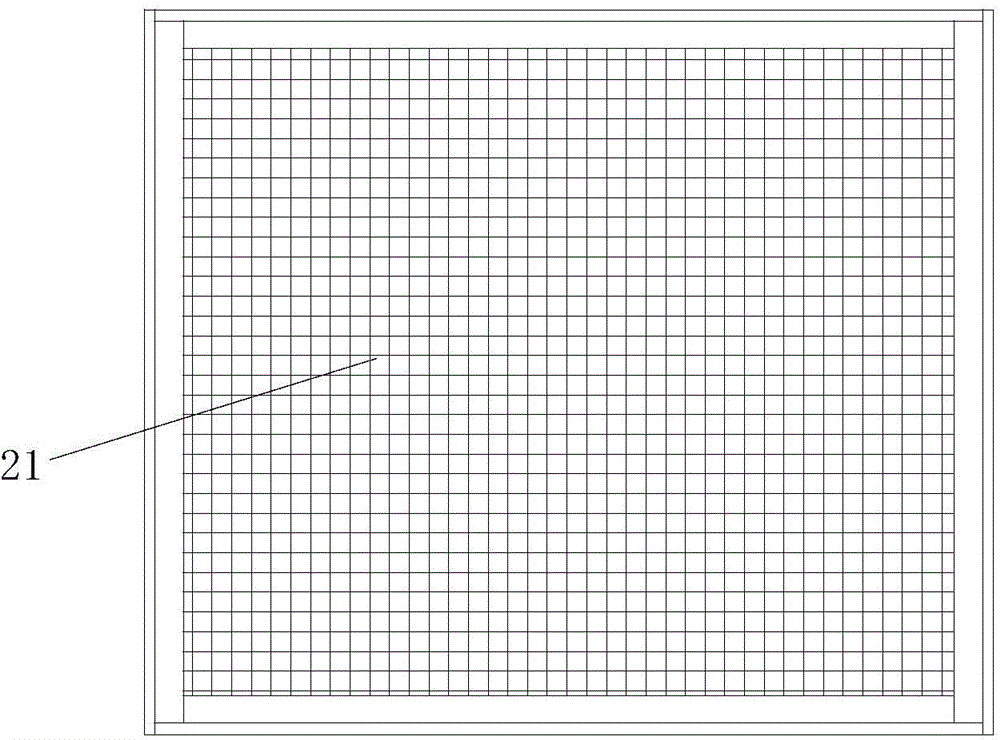

[0032] The sliding screen 10 is placed obliquely on the bearing guide rail 10-2 through the rolling bearings 10-1 installed on both sides, and its inclination angle is about 30°. Sliding screen cloth 10 is connected and fixed with the upper end of sliding screen cloth fixed arm 13, and a sliding screen cloth fixed arm 13 is respectively installed on the left and right sides, and the lower end of sliding screen cloth fixed arm 13 then links to each other with an end of connecting rod 14, and is The rotating bearing guide rail 10-2 makes inclined up and down reciprocating translational motion, the function i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com