Device for soft soil foundation shield tunnel construction and using method

A technology for shield tunnels and soft soil foundations, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of shield water seepage, time-consuming, difficulty in grasping accuracy, etc., to reduce labor intensity and screening efficiency. The effect of improving and enhancing installation efficiency and construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

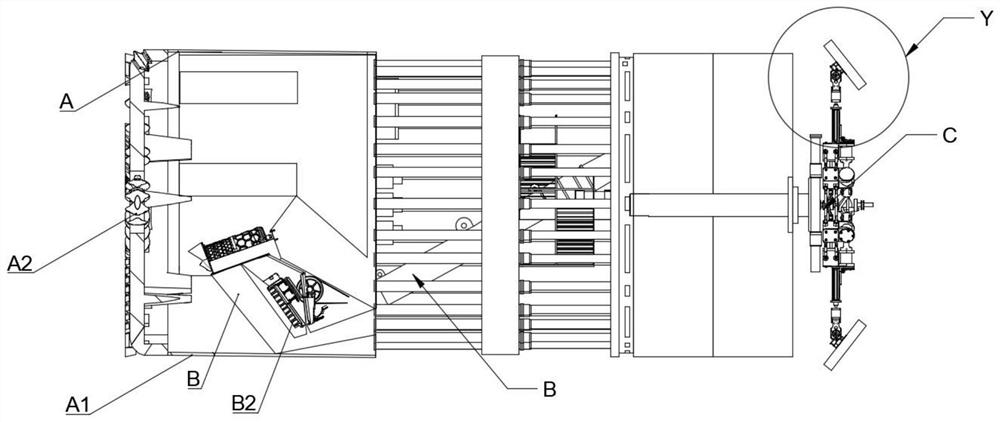

[0078] Such as Figures 1 to 7 As shown, a soft ground shield tunnel construction device includes a shield body A, a cleaning system B and a segment D assembling system C;

[0079] The cleaning system B is set inside the shield body A, and the segment D assembly system C is connected to the tail of the shield body A;

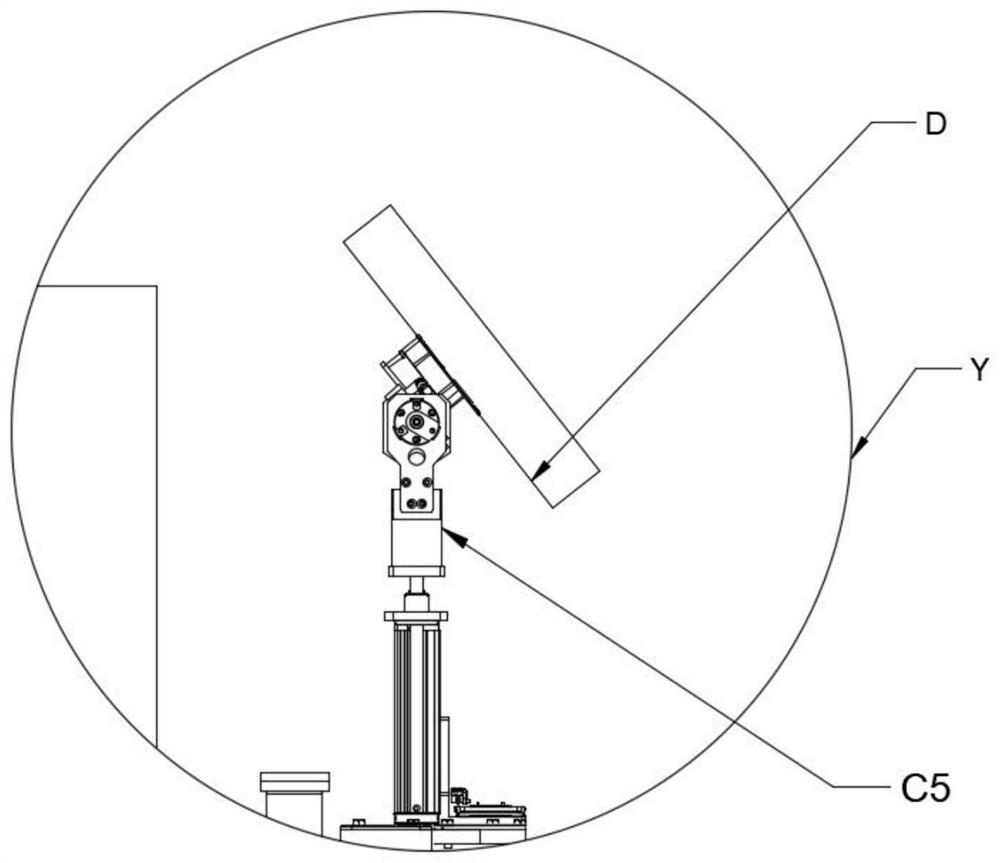

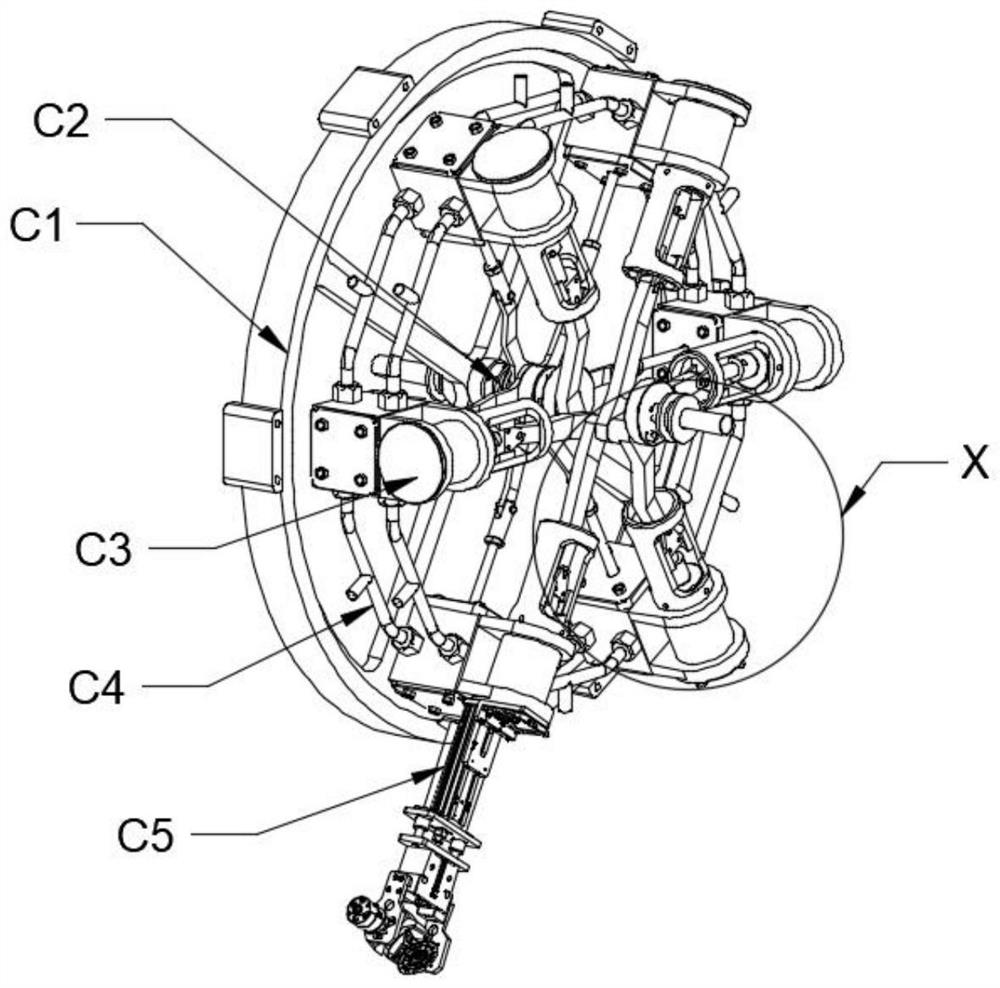

[0080] The segment D assembly system C is connected to the tail of the shield body A through the installation plate C1, and the segment D assembly system C includes a pushing part C3 and a clamping part C5, the pushing part C3 is fixedly connected to the mounting plate C1, and the clamping part C5 is connected to the The free movable end of the pushing part C3 is connected, and the clamping part C5 clamps the segments D for splicing.

[0081] There are multiple pushing parts C3 and clamping parts C5, and the number of pushing parts C3 and clamping parts C5 is equal, and the multiple pushing parts C3 are distributed on the mounting plate C1 at uniform intervals,...

Embodiment 2

[0094] Such as Figure 1-10 As shown, a soft ground shield tunnel construction device includes a shield body A, a cleaning system B and a segment D assembling system C;

[0095] The cleaning system B is set inside the shield body A, and the segment D assembly system C is connected to the tail of the shield body A;

[0096] The segment D assembly system C is connected to the tail of the shield body A through the installation plate C1, and the segment D assembly system C includes a pushing part C3 and a clamping part C5, the pushing part C3 is fixedly connected to the mounting plate C1, and the clamping part C5 is connected to the The free movable end of the pushing part C3 is connected, and the clamping part C5 clamps the segments D for splicing.

[0097] There are multiple pushing parts C3 and clamping parts C5, and the number of pushing parts C3 and clamping parts C5 is equal, and the multiple pushing parts C3 are distributed on the mounting plate C1 at uniform intervals, an...

Embodiment 3

[0113] Such as Figure 1-14 As shown, a soft ground shield tunnel construction device includes a shield body A, a cleaning system B and a segment D assembling system C;

[0114] The cleaning system B is set inside the shield body A, and the segment D assembly system C is connected to the tail of the shield body A;

[0115] The segment D assembly system C is connected to the tail of the shield body A through the installation plate C1, and the segment D assembly system C includes a pushing part C3 and a clamping part C5, the pushing part C3 is fixedly connected to the mounting plate C1, and the clamping part C5 is connected to the The free movable end of the pushing part C3 is connected, and the clamping part C5 clamps the segments D for splicing.

[0116] There are multiple pushing parts C3 and clamping parts C5, and the number of pushing parts C3 and clamping parts C5 is equal, and the multiple pushing parts C3 are distributed on the mounting plate C1 at uniform intervals, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com