External cylindrical vibrating screen for screening ore pulp material

A technology of material sieve and vibrating screen, which is applied in the direction of sieving, solid separation, grid, etc., can solve the problems of low sieving rate, short service life, low classification efficiency, etc., to improve the sieving rate and classification efficiency, extend the The effect of long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

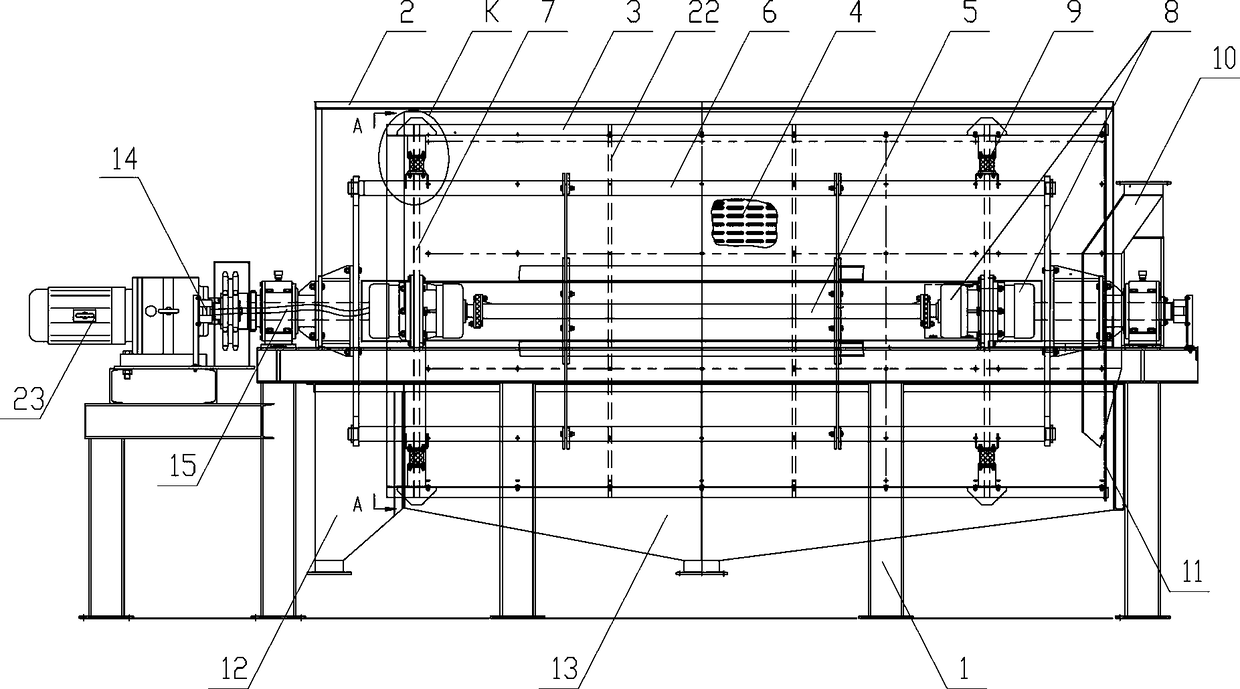

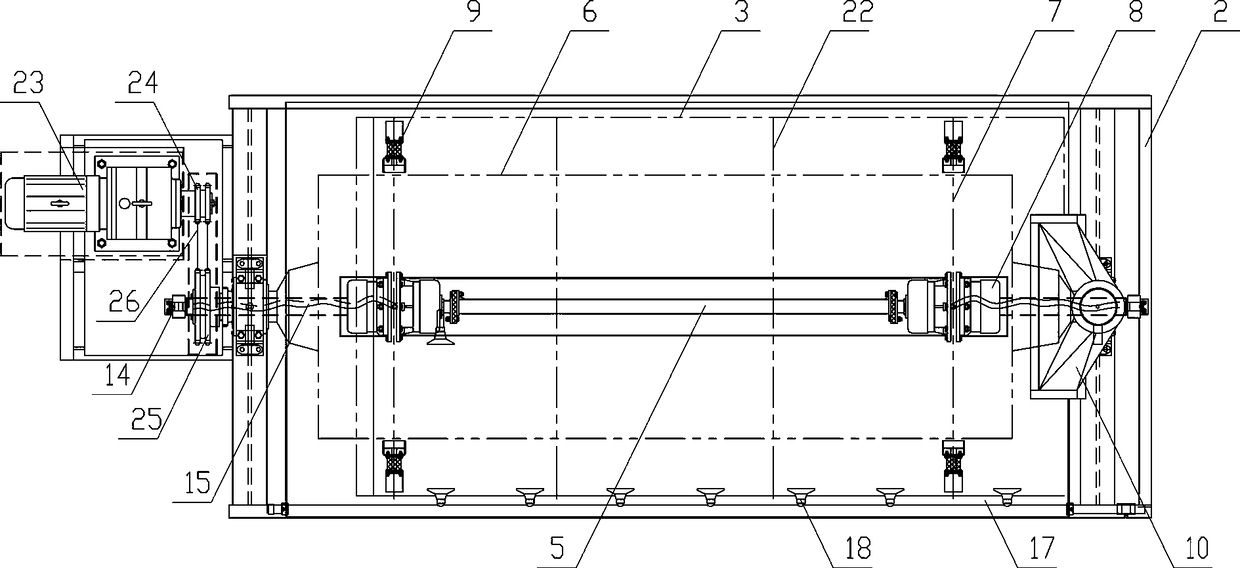

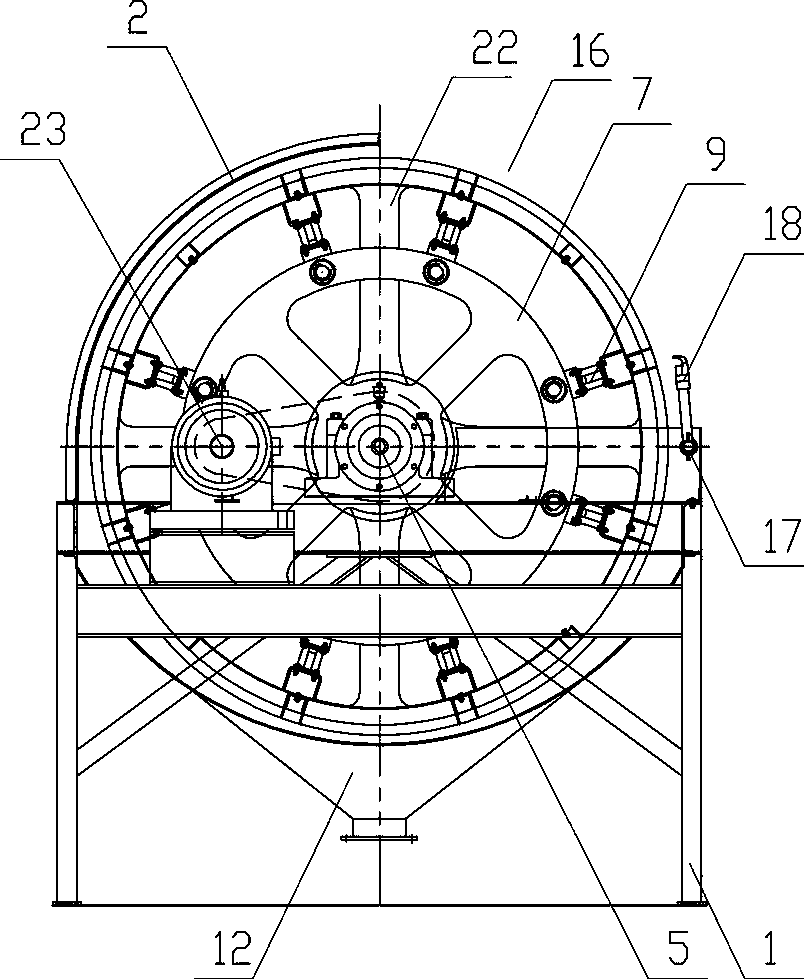

[0018] see Figure 1-5 , the present embodiment provides an external cylindrical vibrating screen for screening pulp materials, including a frame 1, a screen box 2 and a screen cylinder 3 built in the screen box 2, and the outer wall of the screen cylinder 3 is mounted There is a screen 4, and a coaxially arranged main shaft 5 is arranged inside the screen cylinder 3, and one end of the main shaft 5 protrudes from the screen box 2 and is connected with the driving mechanism; a coaxially arranged squirrel-cage transmission cylinder is arranged on the inner side of the screen cylinder 3 6. Two vibrating discs 7 coaxially arranged at both ends of the transmission cylinder 6 are installed, and the left and right sides of each vibrating disc 7 are equipped with vibrating motors 8 arranged coaxially, wherein the vibrating motors 8 adopt High-frequency low-amplitude wall-mounted vibration motor with fully sealed structure, the output shaft of the vibration motor 8 is coaxially connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com