Material distributing screening machine

A screening machine and fabric distribution technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor impact resistance of bulk materials, inability to remove materials, uneven distribution, etc., and achieve easy maintenance, high screening rate, even cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

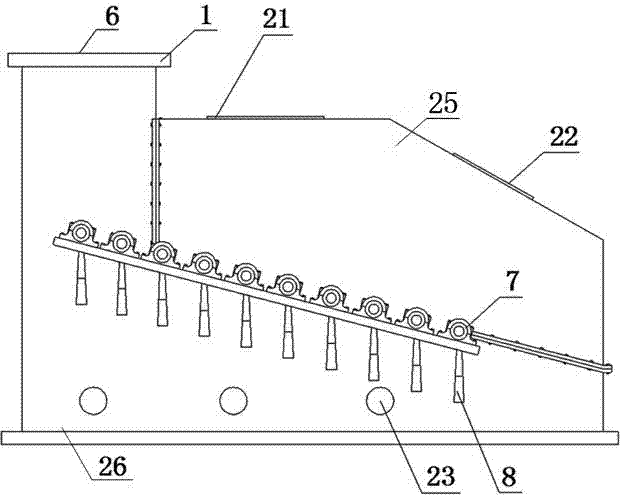

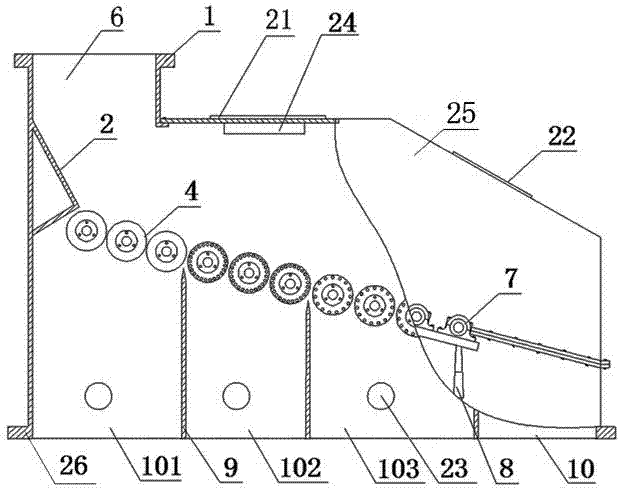

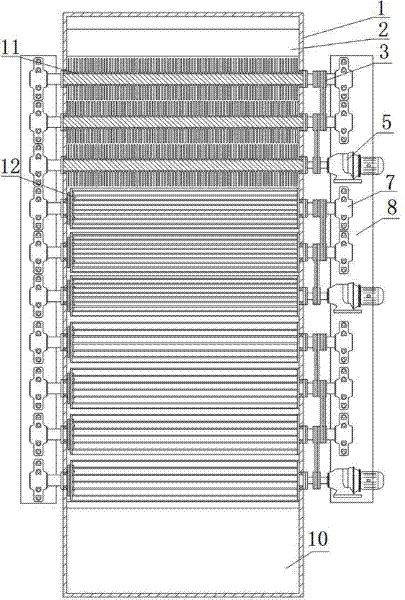

[0047] Example 1: Combining figure 1 , Figure 9 , Figure 10 , Figure 4 , Figure 5 Describe this embodiment, the material distribution screening machine, it comprises casing 1, forced distribution plate 2, transmission device 3, filter drum 4, deceleration motor 5, the top of casing 1 is provided with feeding port 6, and forced distribution plate 2 is located at On the casing 1 below the feed inlet 6, the forced distribution plate 2 is installed on the flange plate drum 11, and is located in the material falling channel. The angle between the forced distribution plate 2 and the falling channel is less than 90°. It is made of wear-resistant and impact-resistant material, and the wear-resistant material of the forced cloth plate can be replaced. There are 14 filter drums 4 installed in the casing 1, and the two ends of each filter drum 4 are installed on the bearing housing 7, and the bearing housing 7 is fixed on the support frame 8 on both sides of the outer casing 1, a...

Embodiment 2

[0052] Example 2: Combining figure 1 , figure 2 , Figure 11 , Figure 4 , Figure 5 Describe this embodiment, the material distribution screening machine, it comprises casing 1, forced distribution plate 2, transmission device 3, filter drum 4, deceleration motor 5, the top of casing 1 is provided with feeding port 6, and forced distribution plate 2 is located at On the casing 1 below the feed inlet 6, the forced distribution plate 2 is installed on the flange plate drum 11, and is located in the material falling channel. The angle between the forced distribution plate 2 and the falling channel is less than 90°. It is made of wear-resistant and impact-resistant material, and the wear-resistant material of the forced cloth plate can be replaced. There are 20 filter drums 4 installed in the casing 1, and the two ends of each filter drum 4 are installed on the bearing housing 7, and the bearing housing 7 is fixed on the support frame 8 on both sides of the outer casing 1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com