Patents

Literature

38results about How to "Improve delivery function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

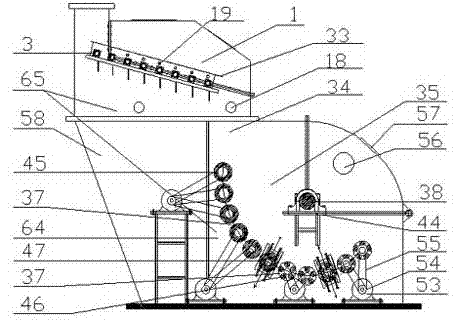

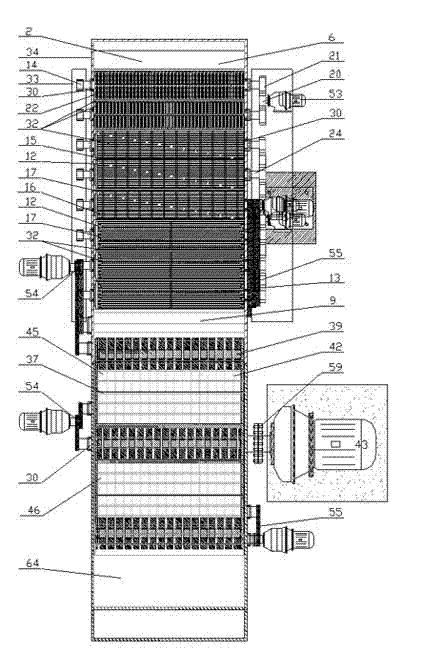

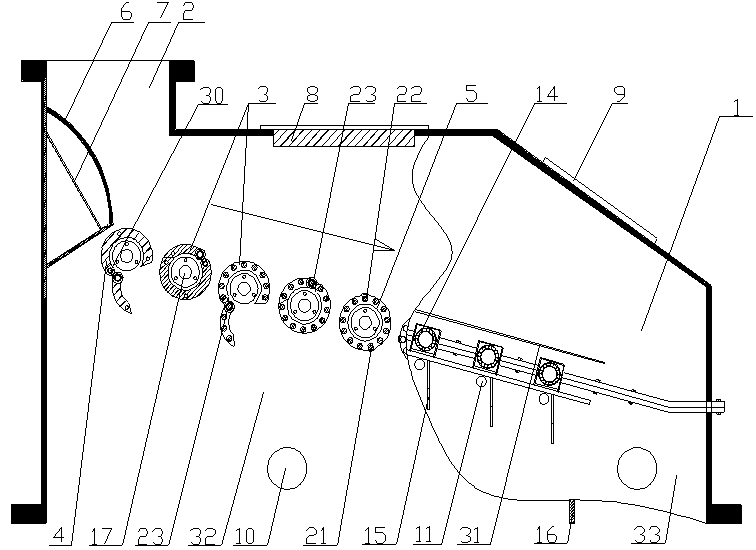

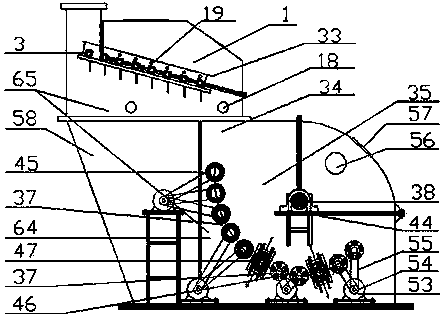

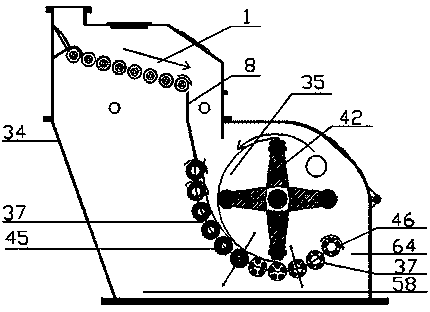

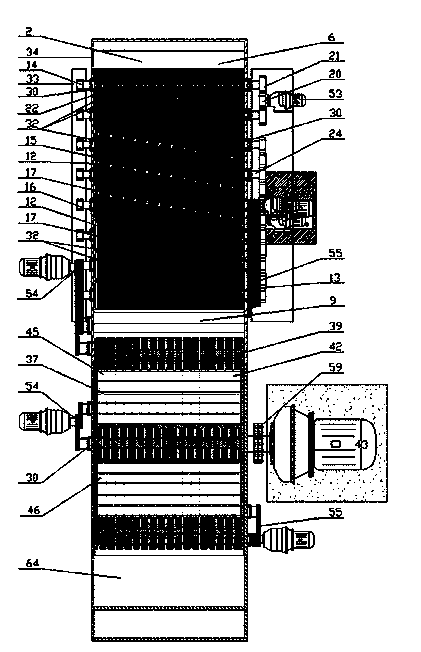

Sieving and crushing integrated machine

ActiveCN102896019AStrong impact resistanceReduces impact and wearSievingScreeningSystem structureProcess engineering

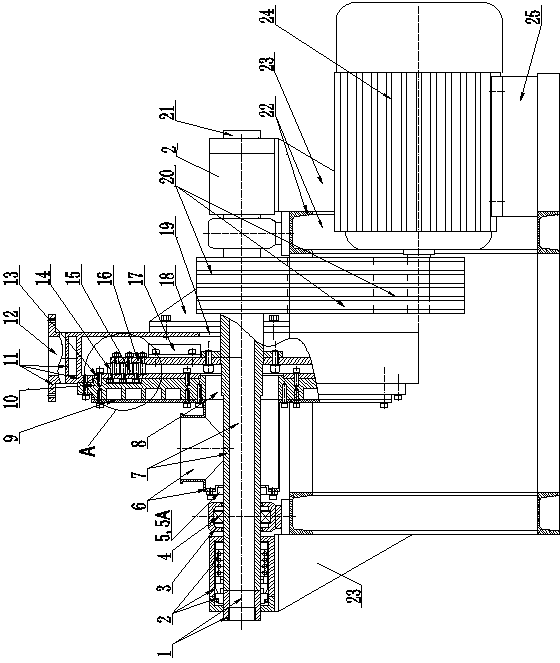

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

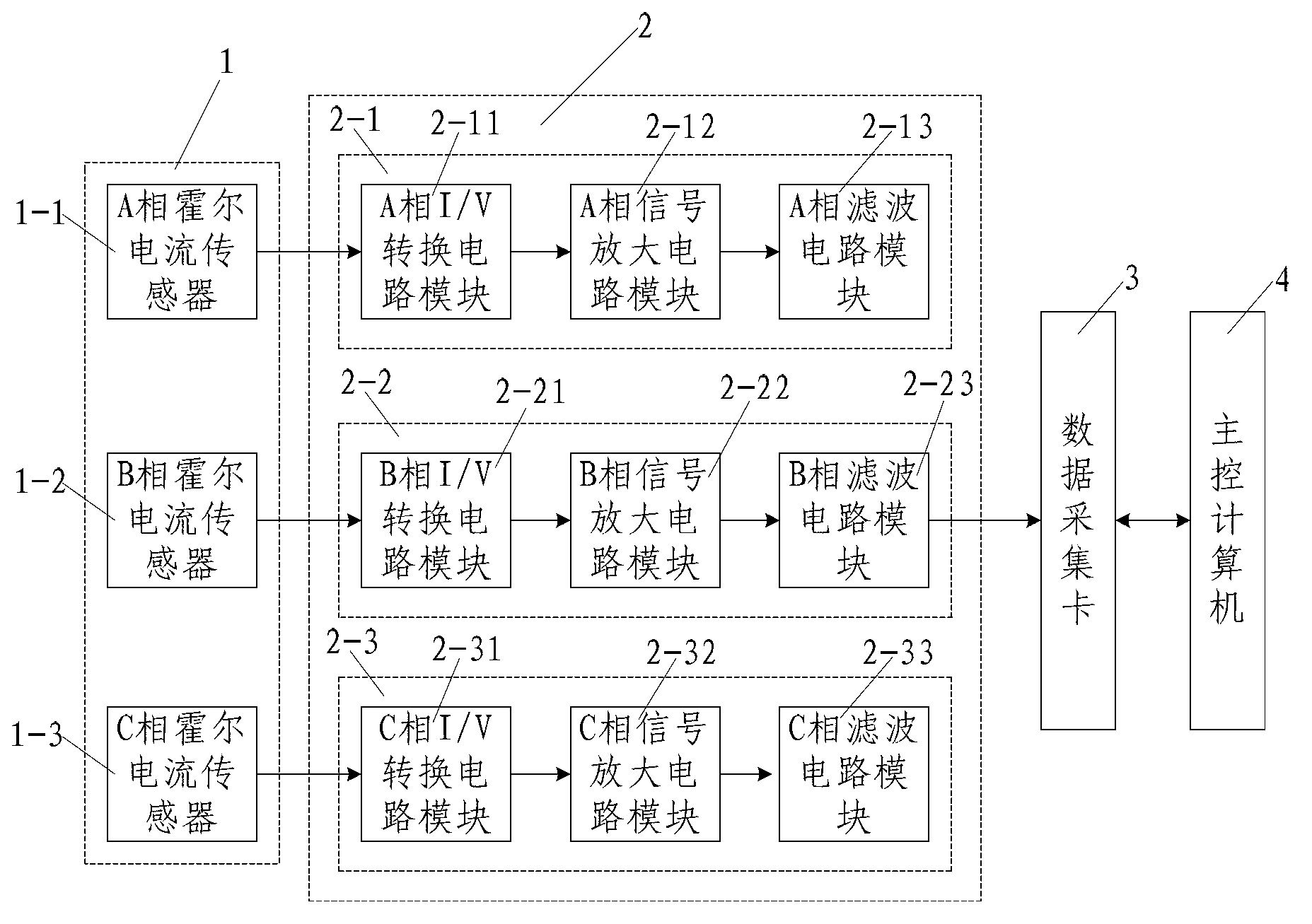

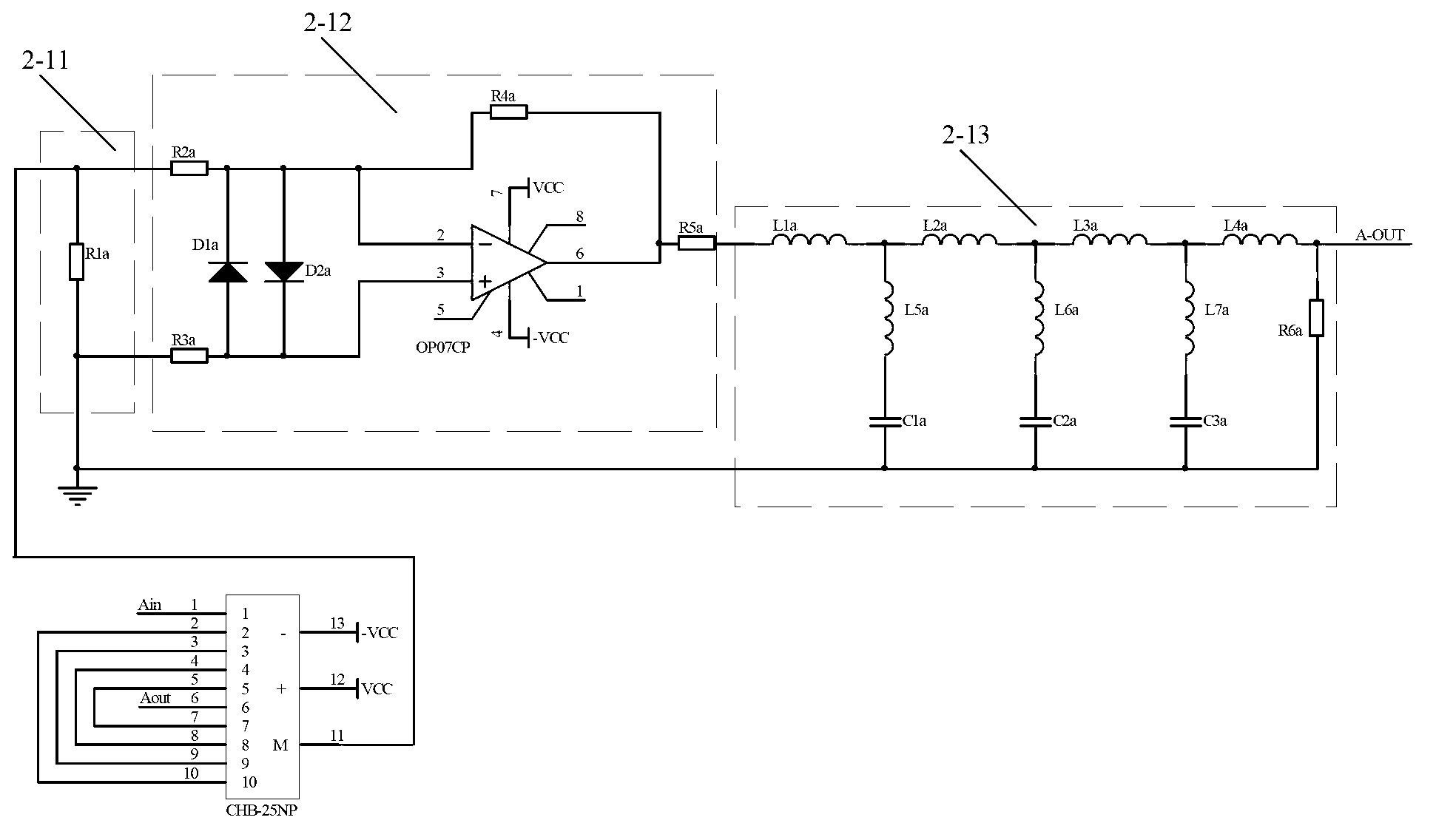

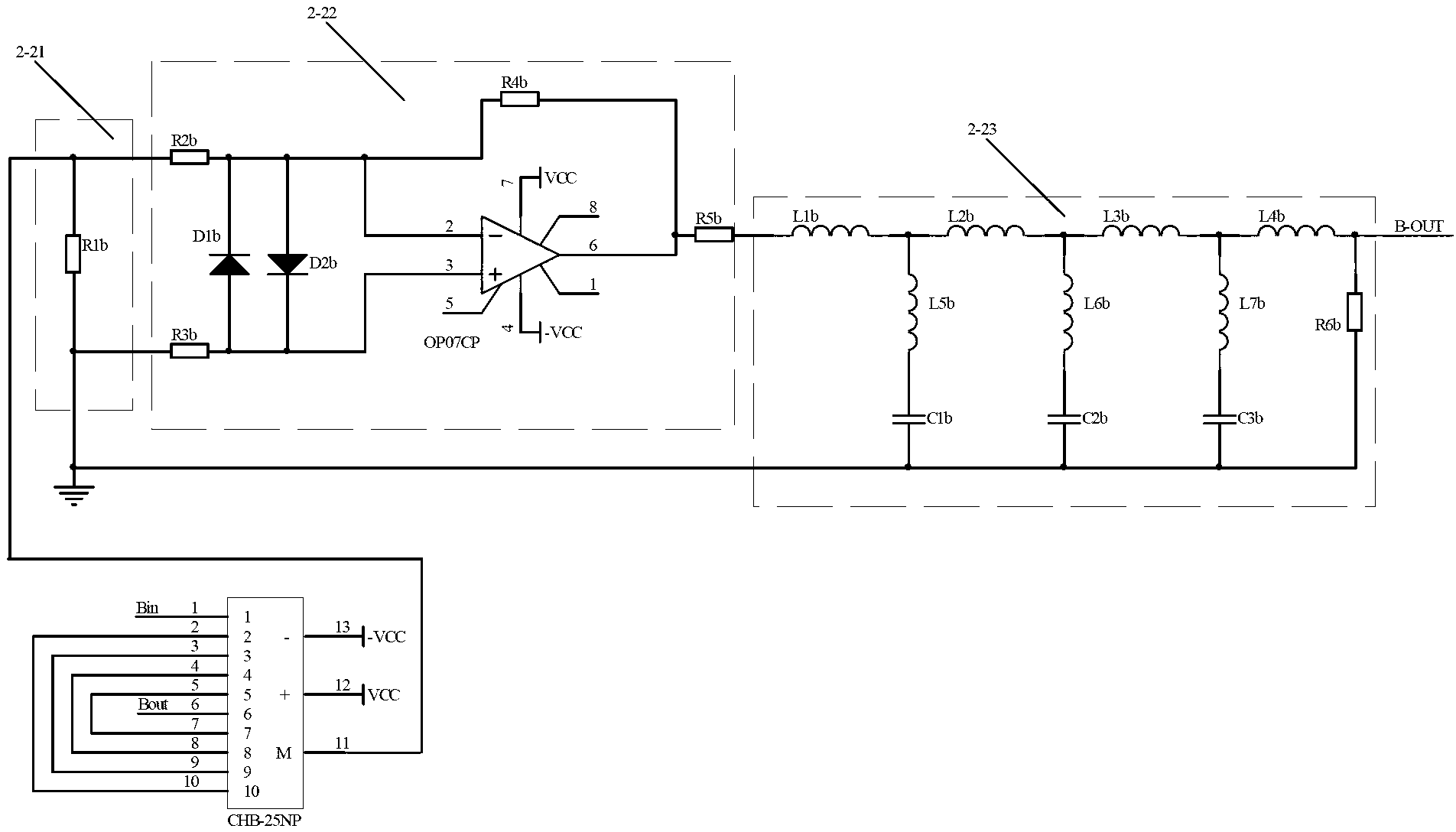

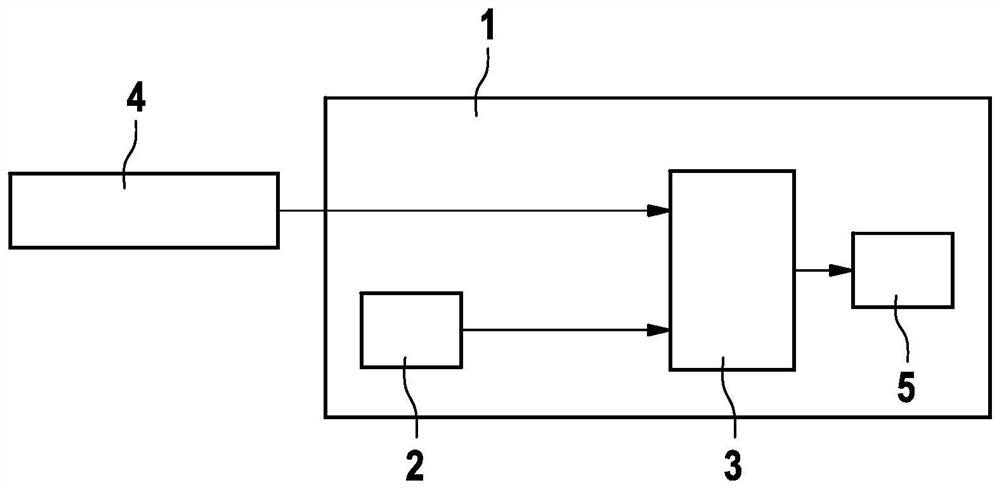

System and method for recognizing power cable fault based on fractal and wavelet transform

InactiveCN103323748ASimple structureNovel and reasonable designFault locationPhase filterData acquisition

The invention discloses a system and method for recognizing a power cable fault based on fractal and wavelet transform. The system comprises a current detection circuit module, a signal modulation circuit module, a data collecting card and a master control computer which are connected in sequence, wherein the current detection circuit module comprises an A-phase hall current sensor, a B-phase hall current sensor and a C-phase hall current sensor, and the signal modulation circuit module comprises an A-phase I / V switching circuit module, a B-phase I / V switching circuit module, a C-phase I / V switching circuit module, an A-phase signal amplifying circuit module, a B-phase signal amplifying circuit module, a C-phase signal amplifying circuit module, an A-phase filter circuit module, a B-phase filter circuit module and a C-phase filter circuit module. The method comprises the following steps that signals are detected in real time and uploaded synchronously; the signals are collected and saved; the cable fault is recognized. The system and method for recognizing the power cable fault based on the fractal and the wavelet transform has the advantages of being novel and reasonable in design, high in detection precision, stability and reliability due to the fact that the hall current sensors are adopted to detect the cable current, capable of easily, rapidly, accurately and effectively recognizing the type of cable short fault by means of the combination of the fractal method and the wavelet transform method, strong in practicability, good in using effect and convenient to popularize and use.

Owner:XIAN UNIV OF SCI & TECH

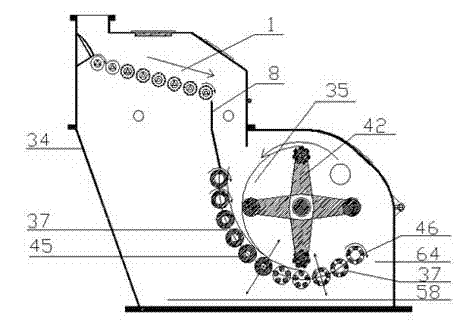

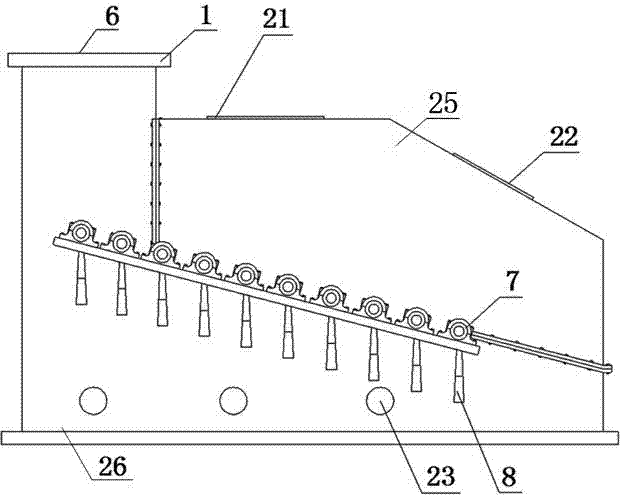

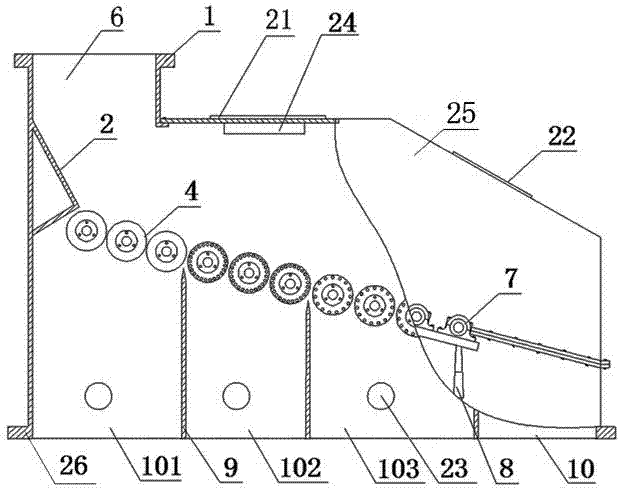

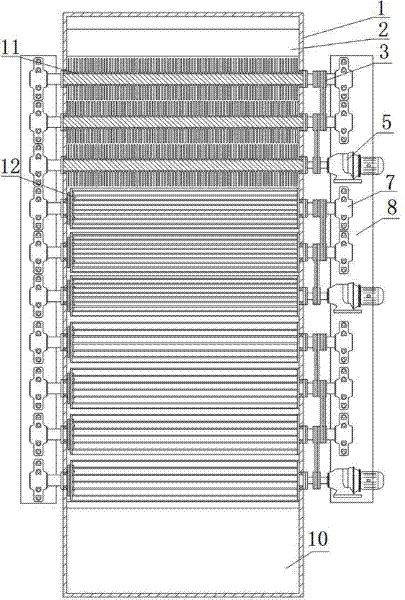

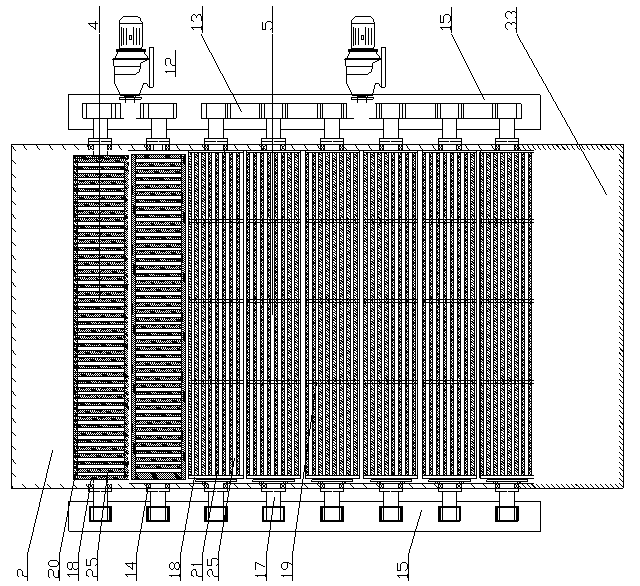

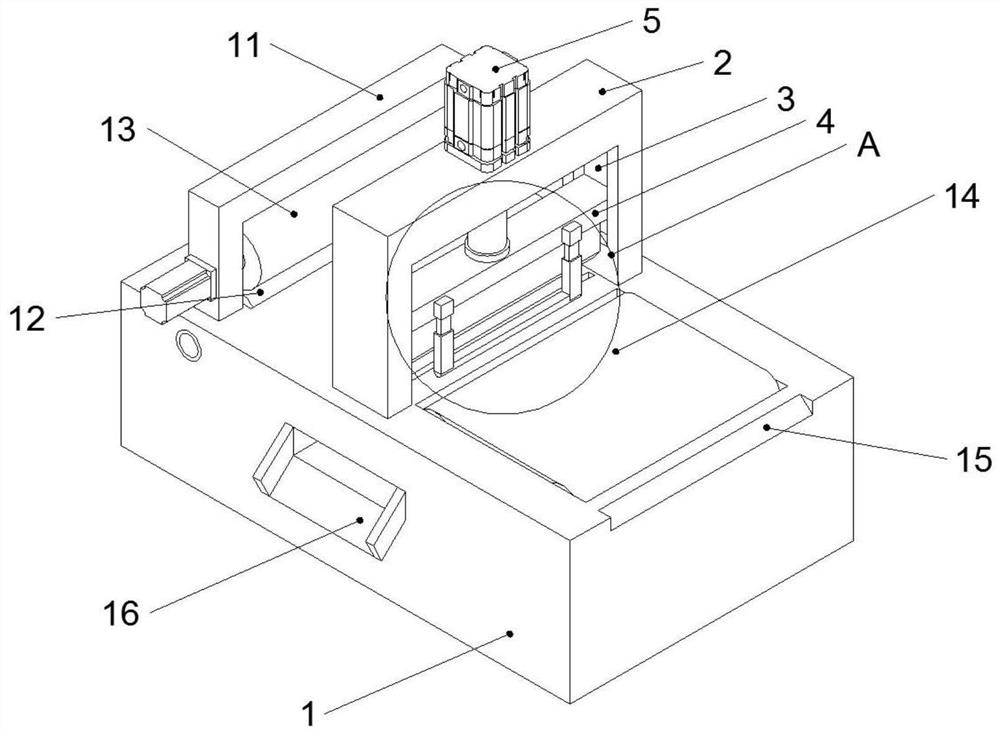

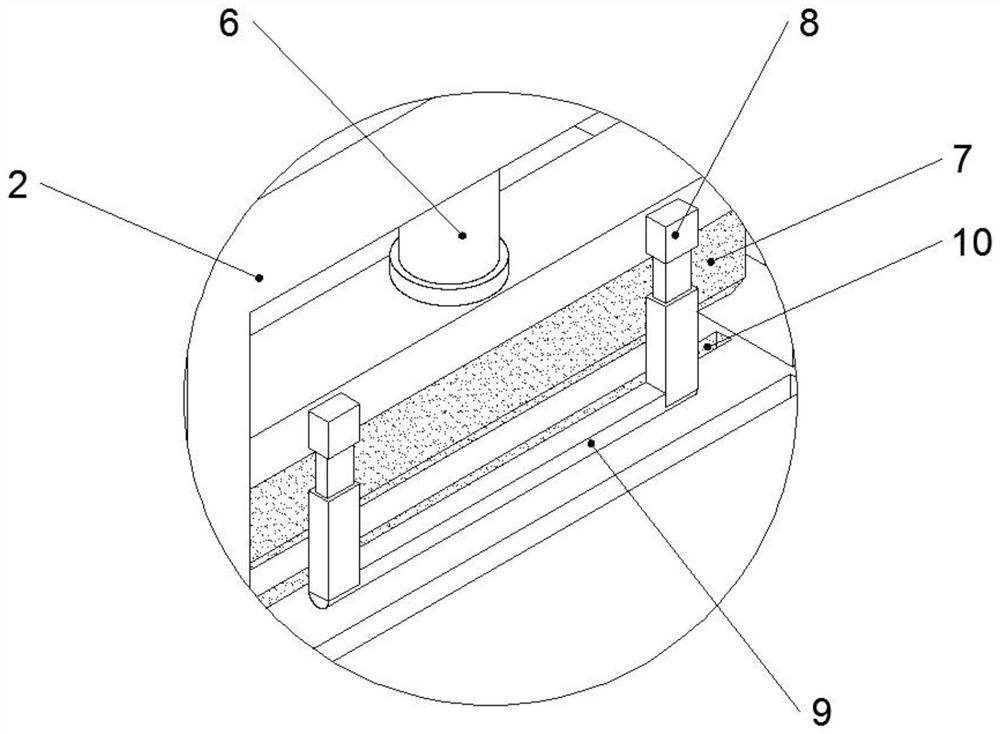

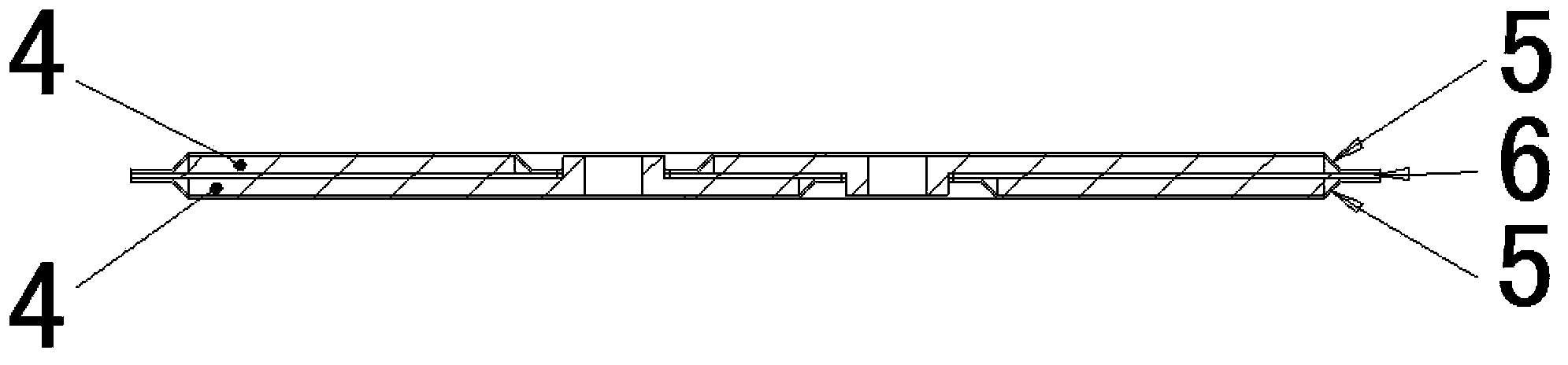

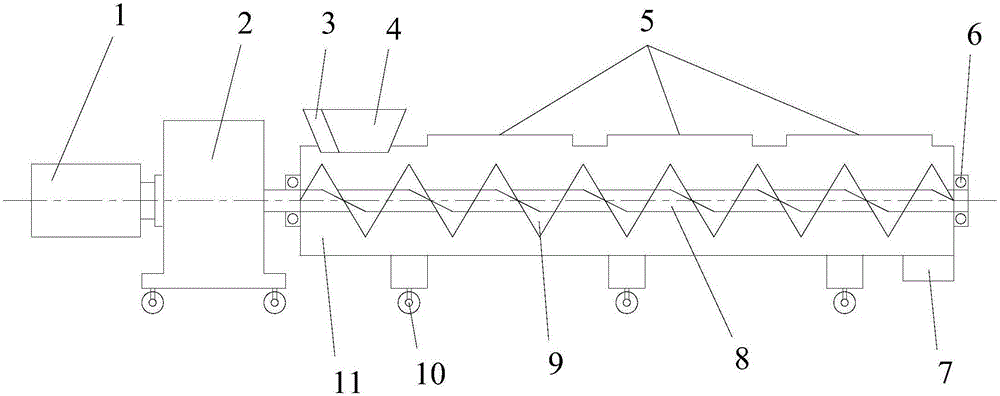

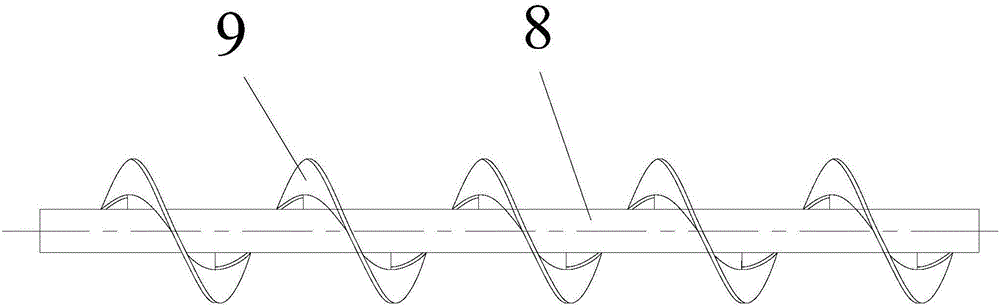

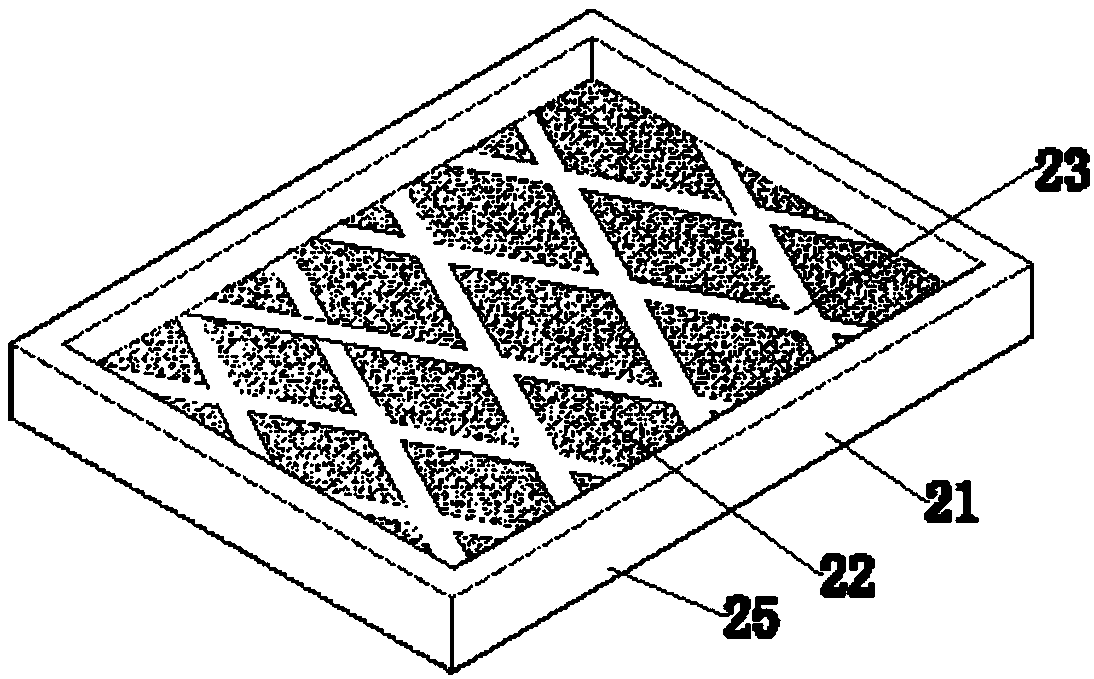

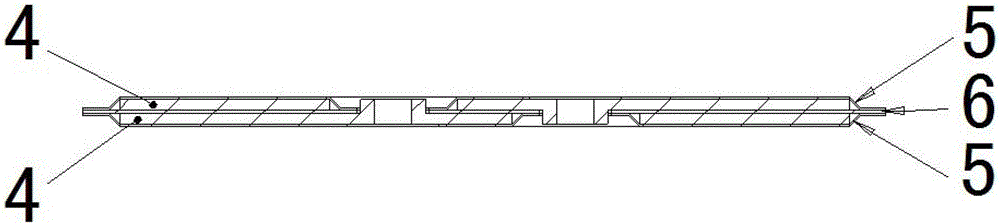

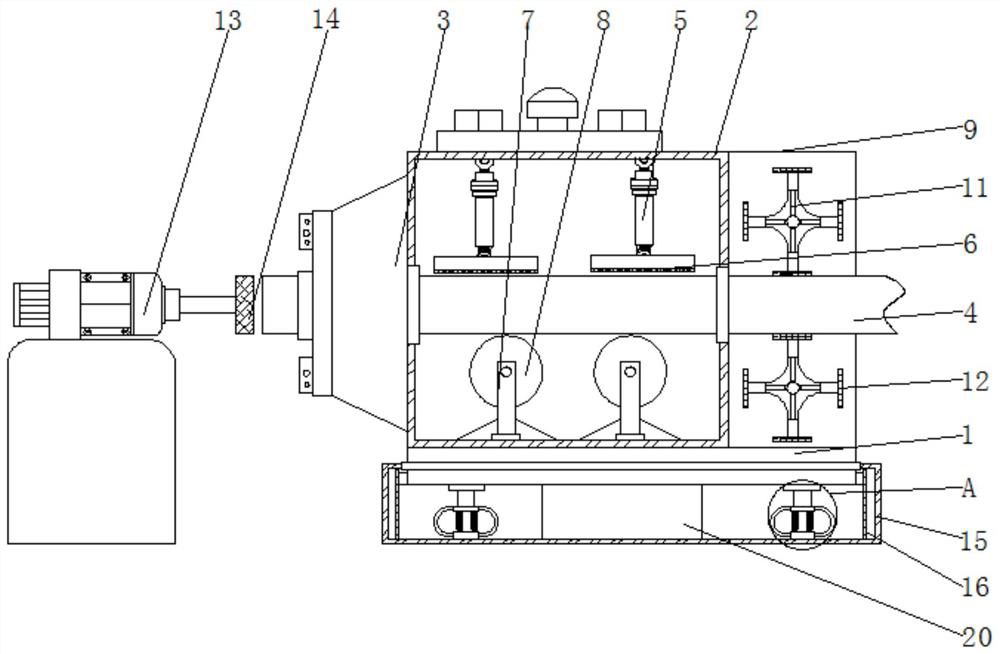

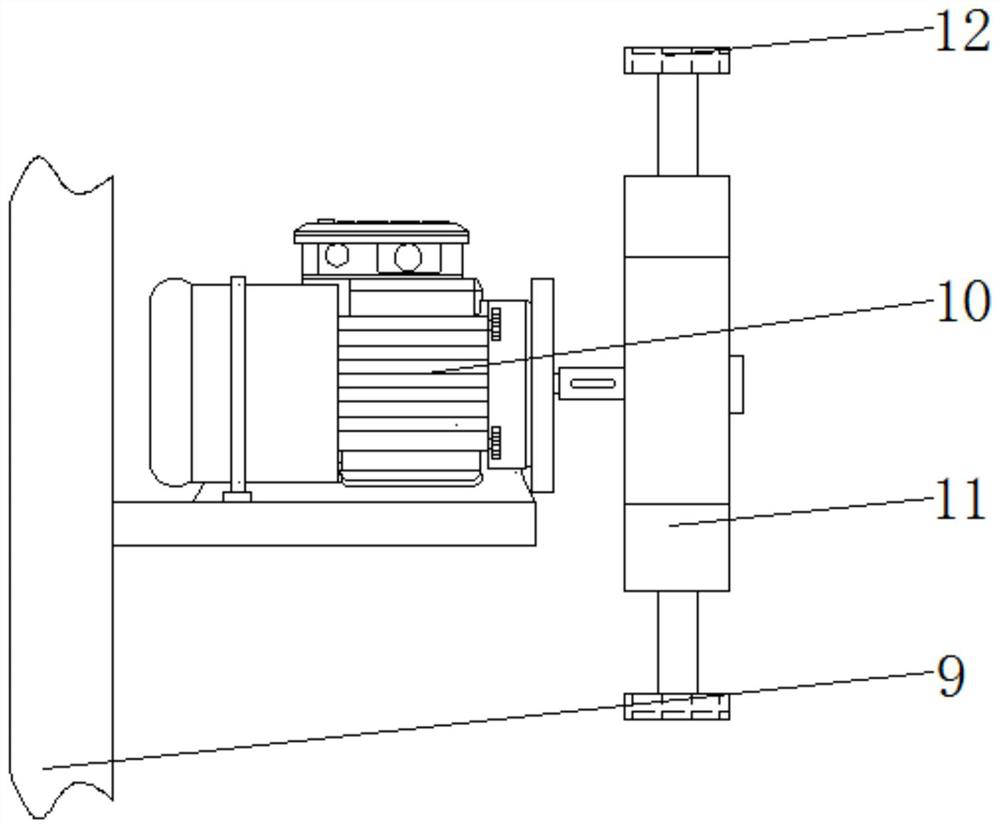

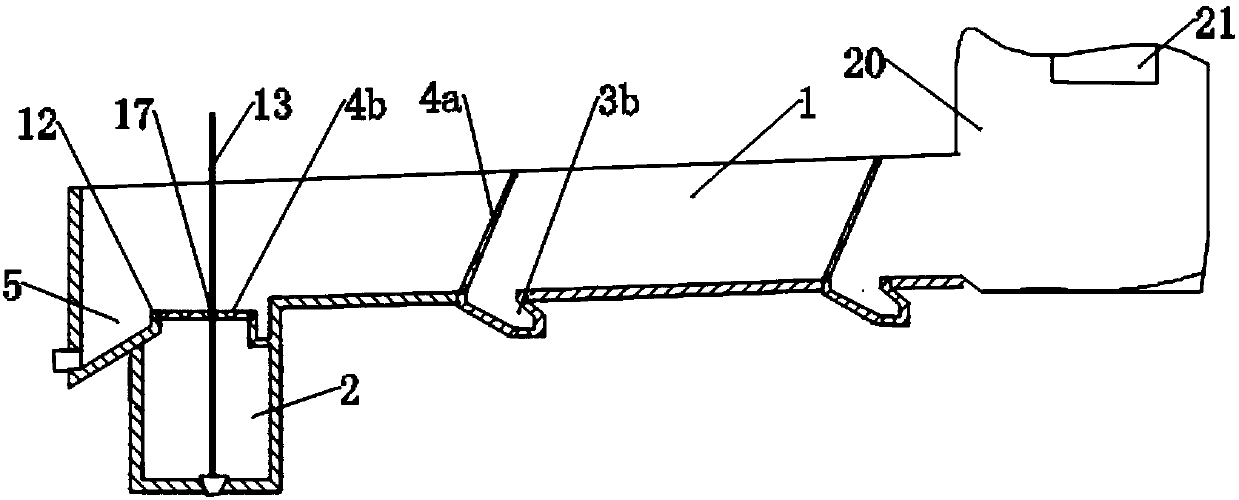

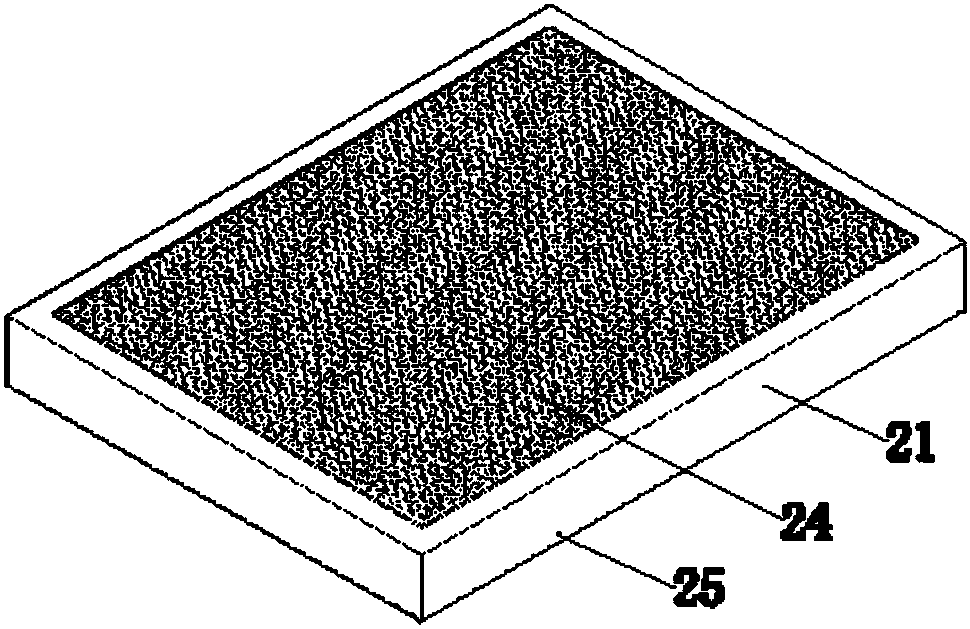

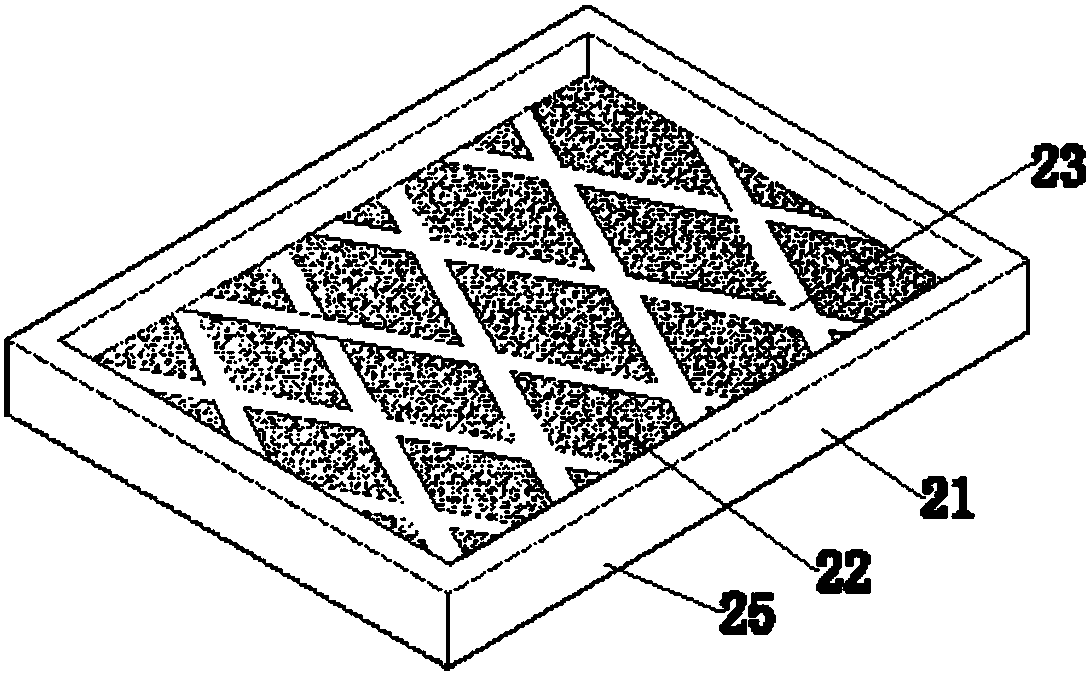

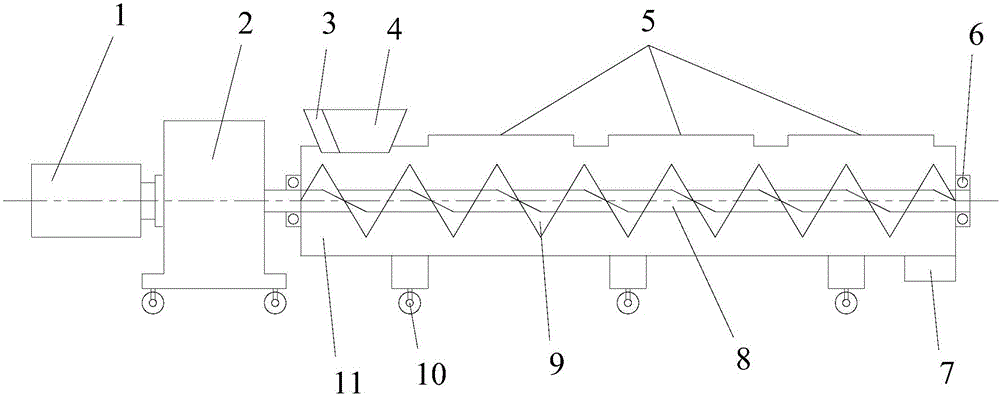

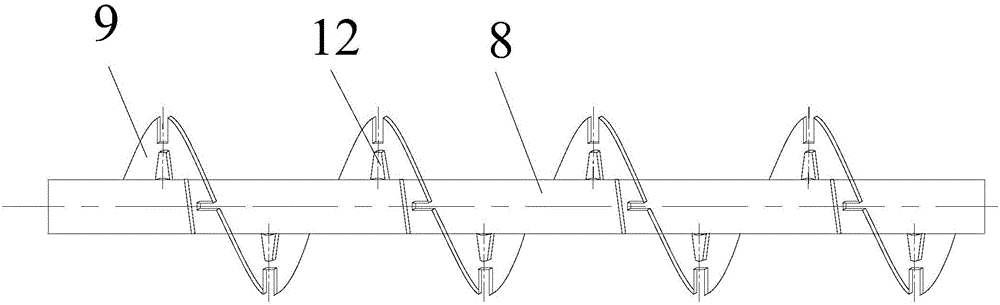

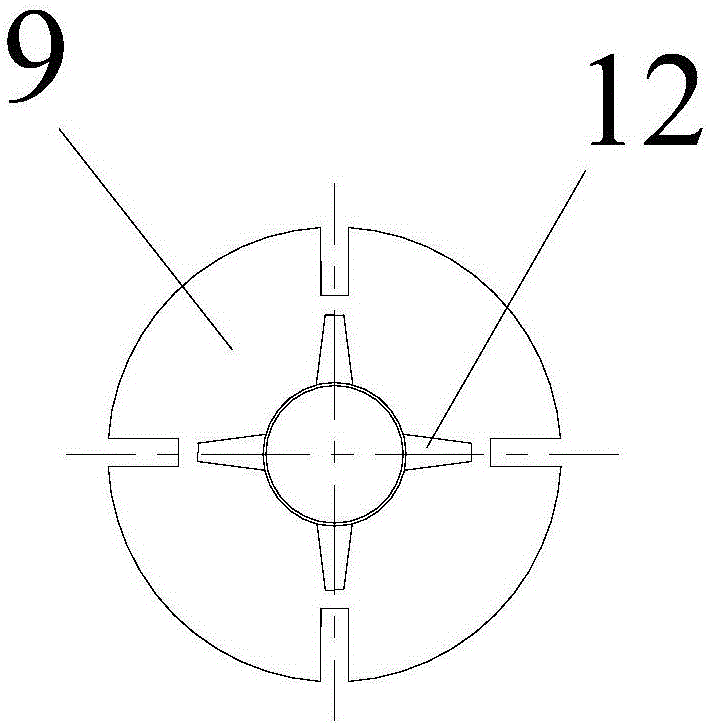

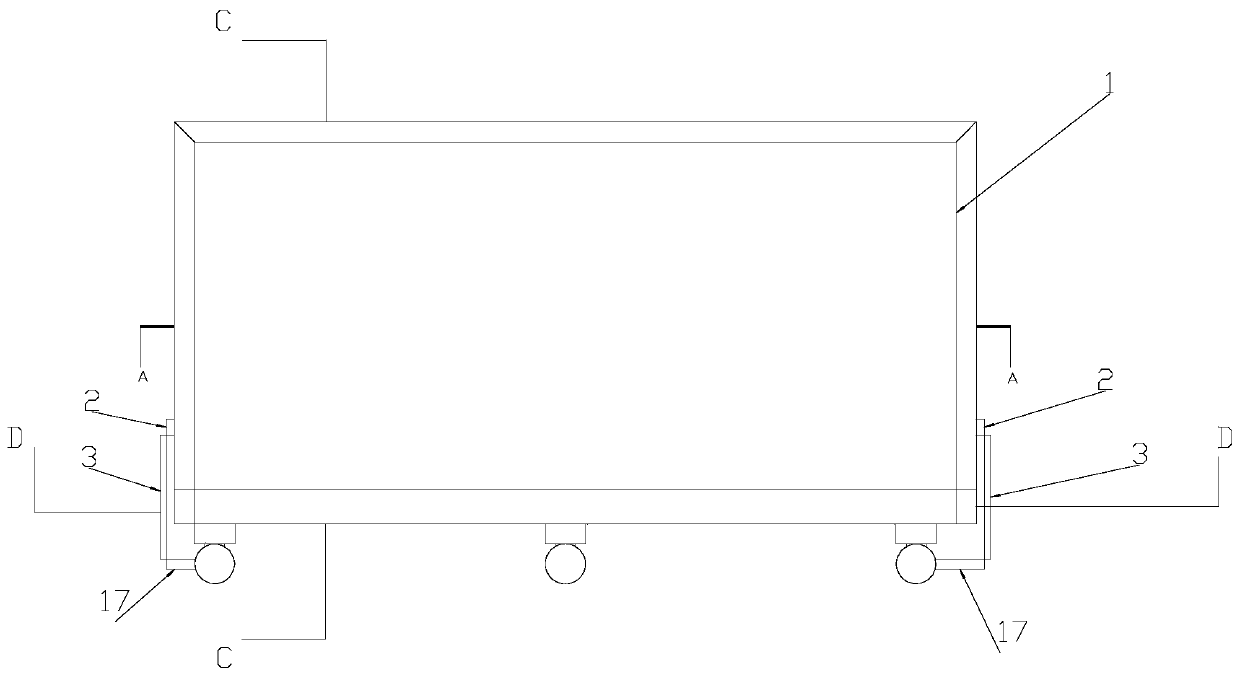

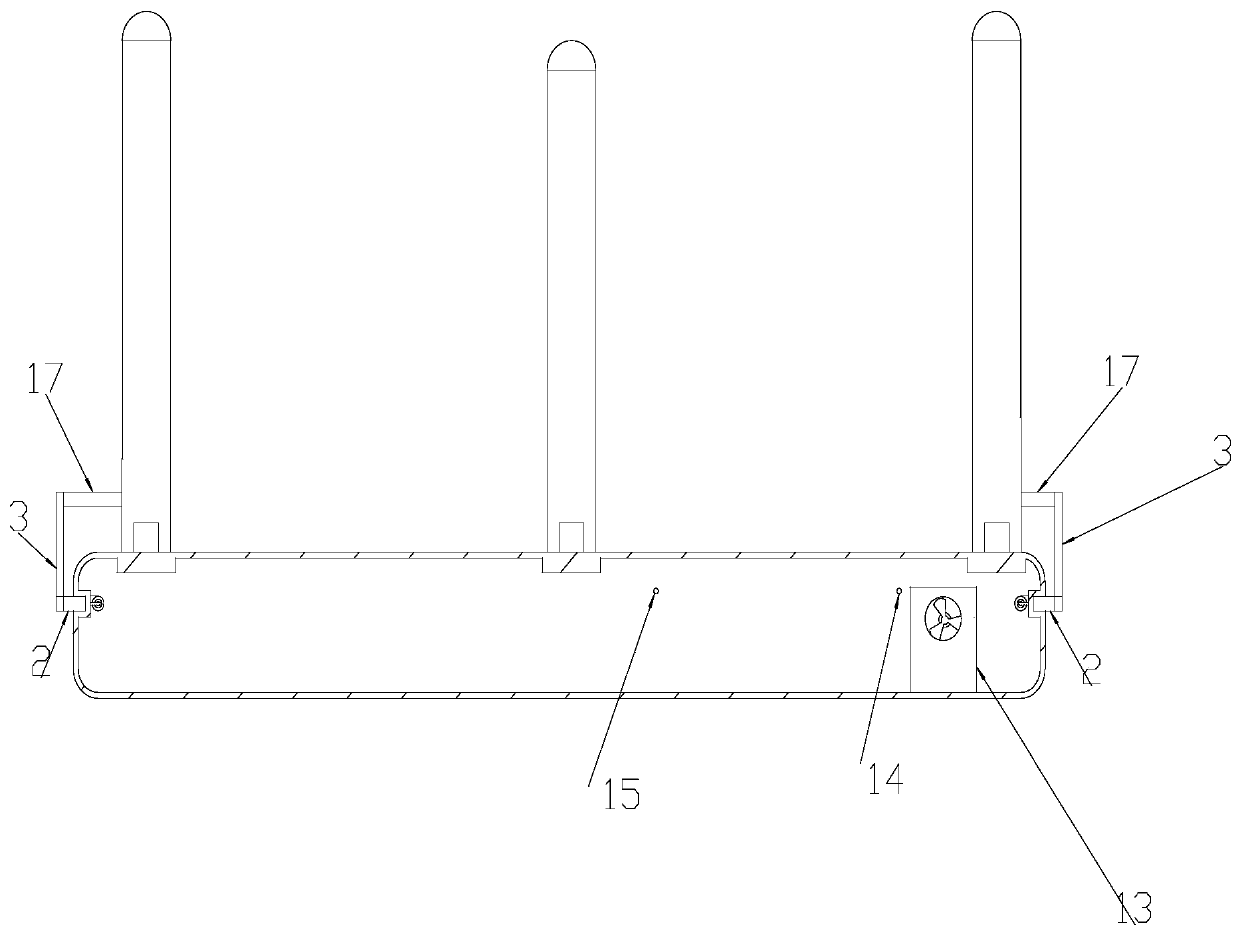

Material distributing screening machine

The invention discloses a material distributing screening machine, comprising a machine case (1), a forced fabric plate (2), a driving device (3), a filtering roller (4), a reducer motor (5) and an iron removing device (24), wherein the machine case (1) is provided with a feeding hole (6) and a plurality of discharging holes (10), the filtering roller (4) comprises a flange disk type roller (11) and a filtering rope type roller (12), the filtering roller (4) is provided with the driving device (3), the reducer motor (5) drives the filtering roller (4) to rotate by virtue of the driving device (3), and material enters from the feeding hole (6), is screened by the filtering roller (4) and is discharged by the discharging hole (10). The invention has the beneficial effects that: more than two materials in different grain sizes can be screened by setting different interstitial screen cuts, the working condition requirement for screening more than two materials can be met, screening efficiency is high, bulk material impact resistance is high, material is distributed more uniformly, no blockage is caused, and an iron piece contained in the material can be removed.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

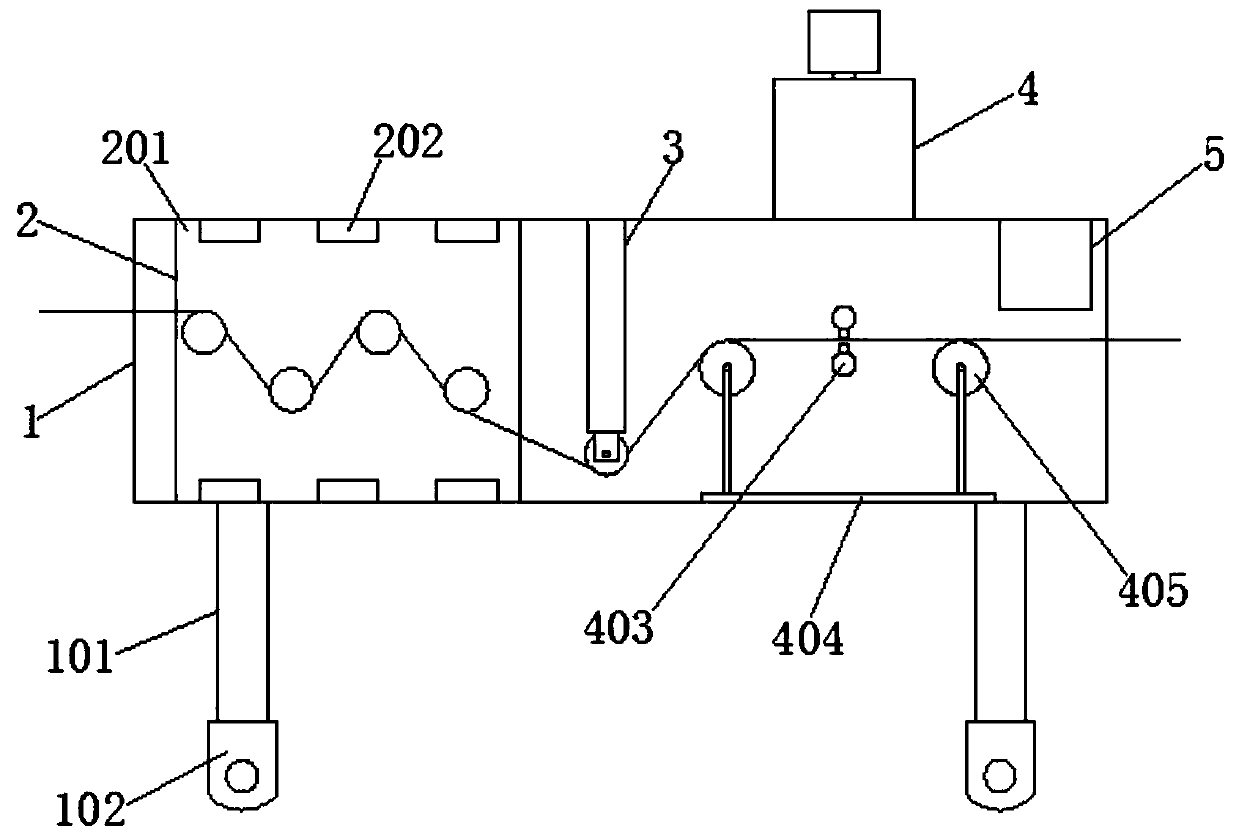

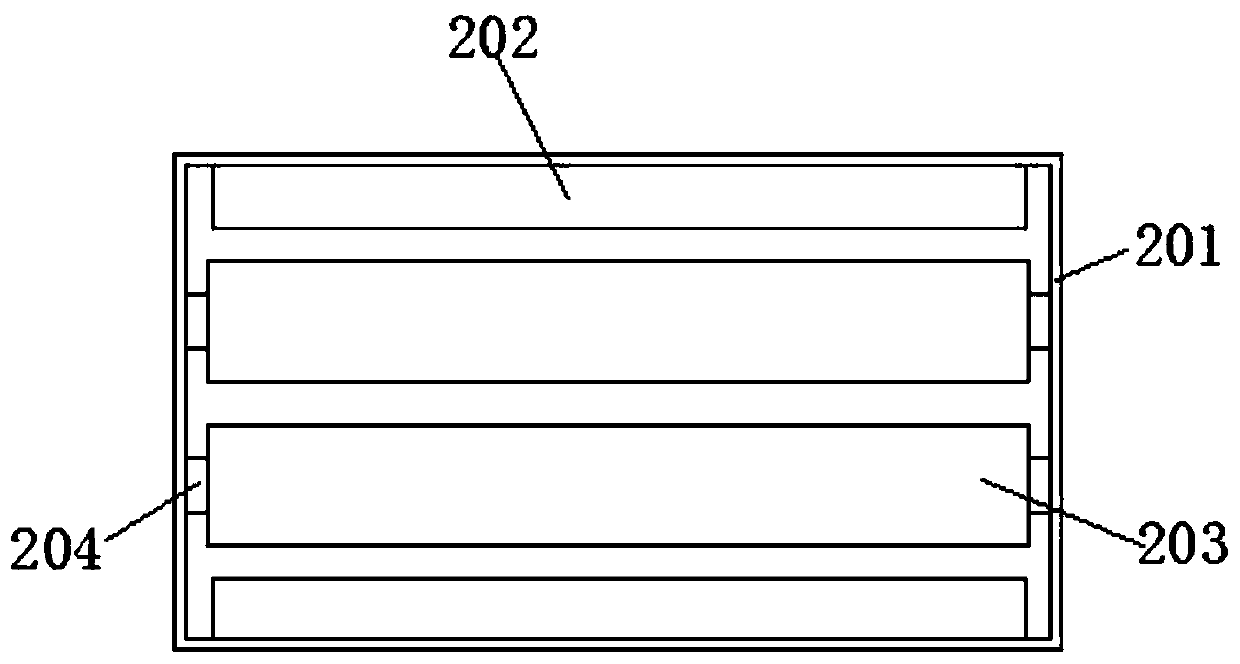

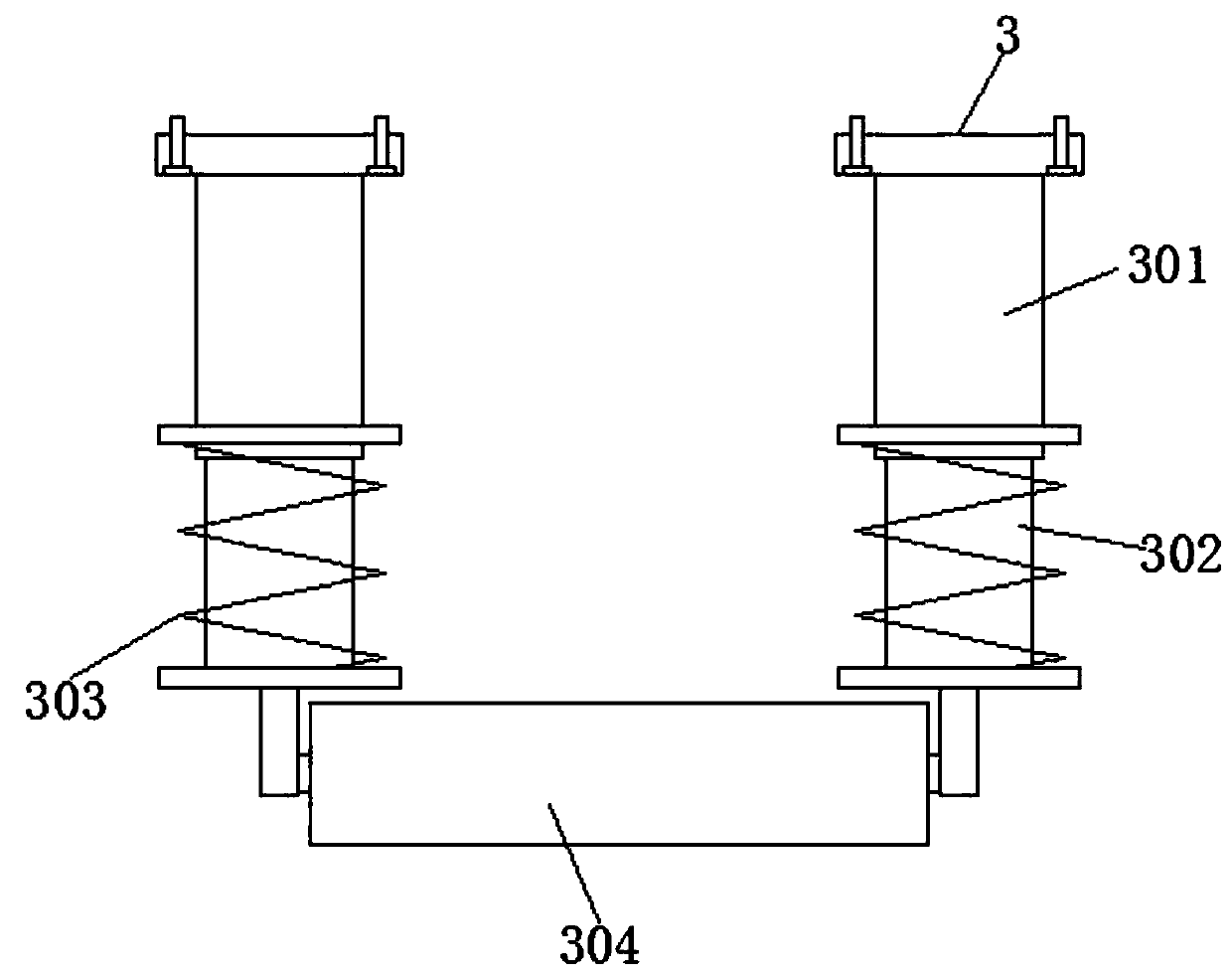

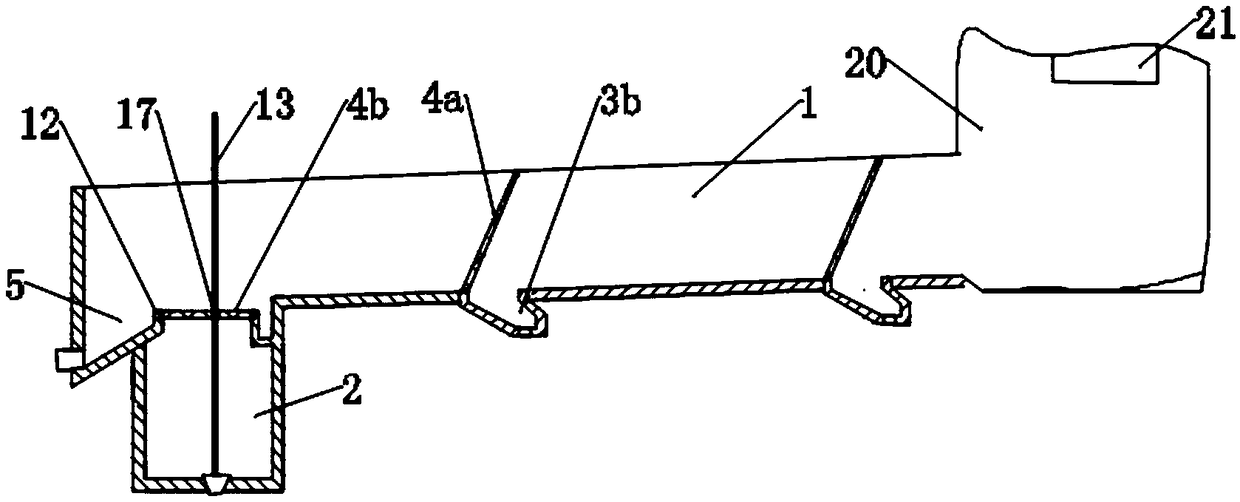

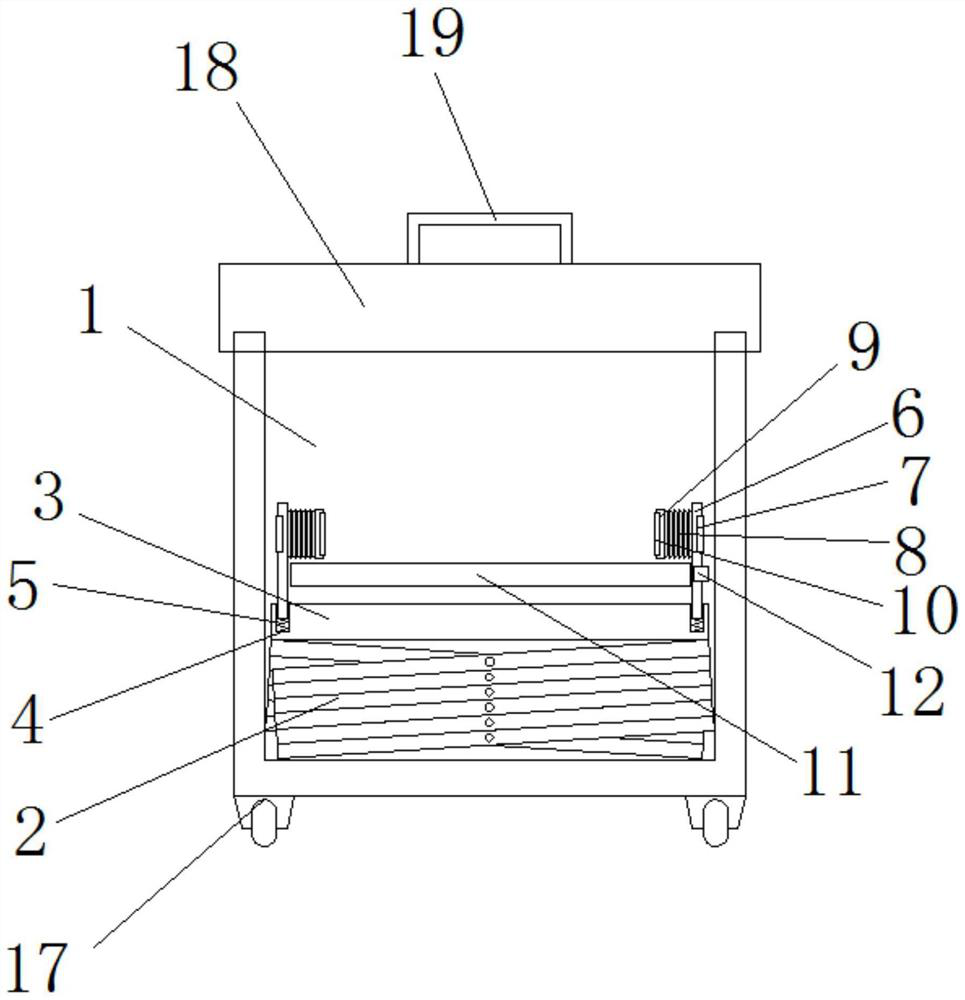

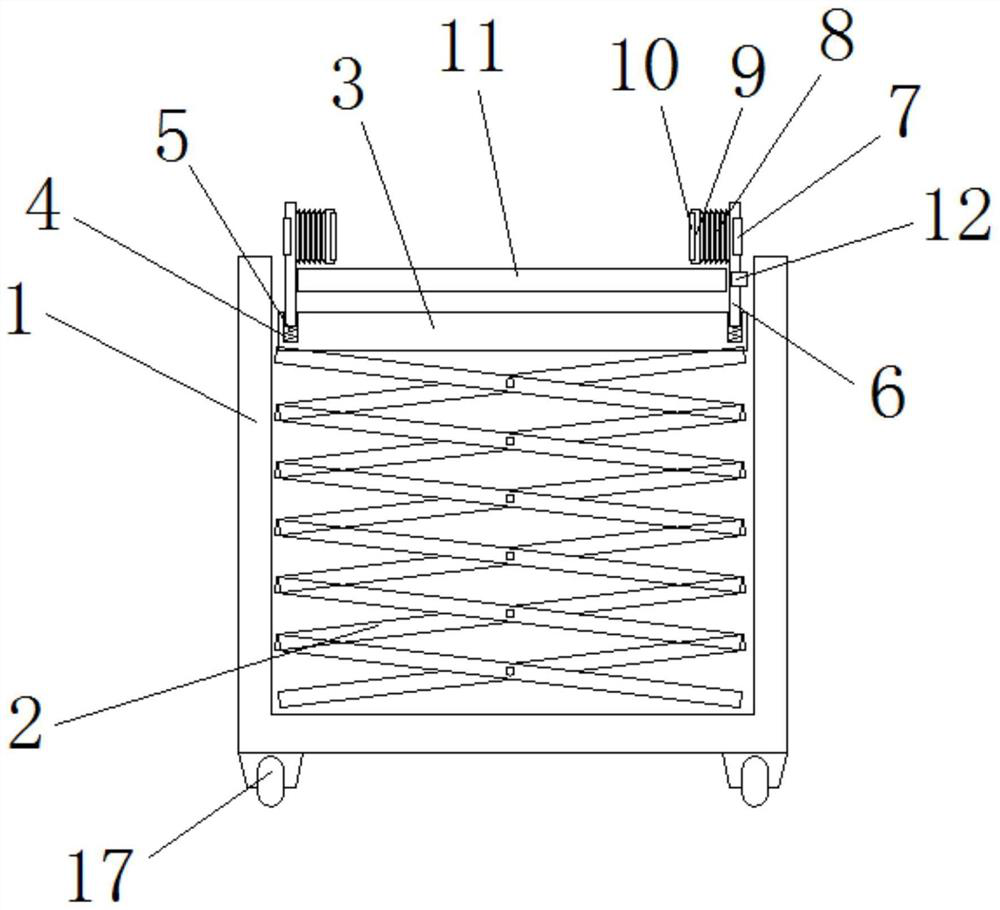

Sterilization device on non-woven fabric production line

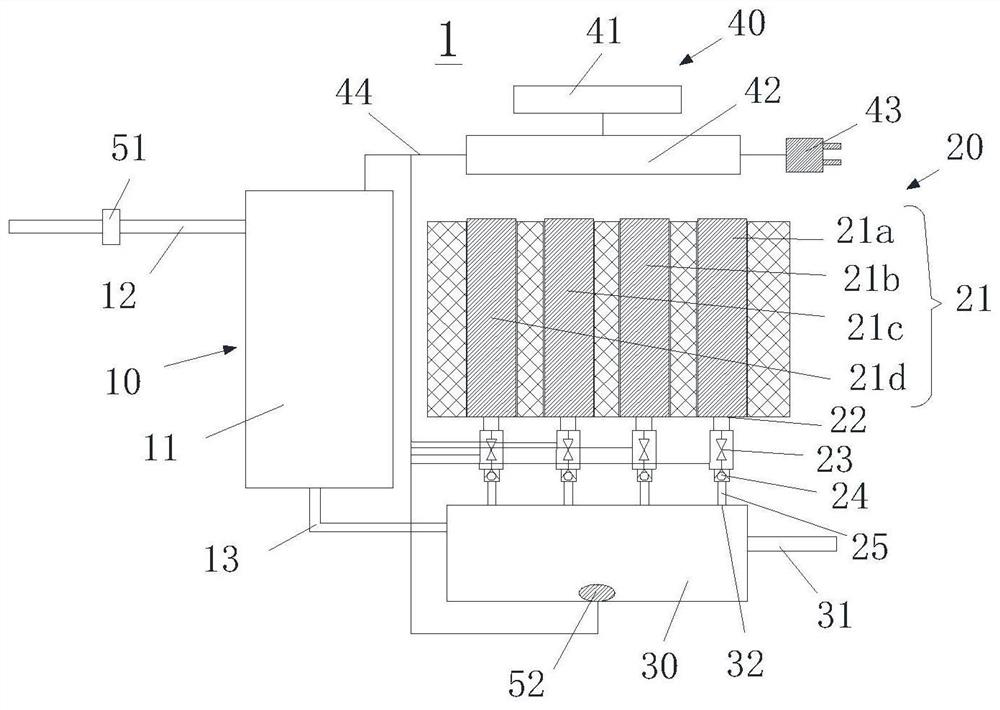

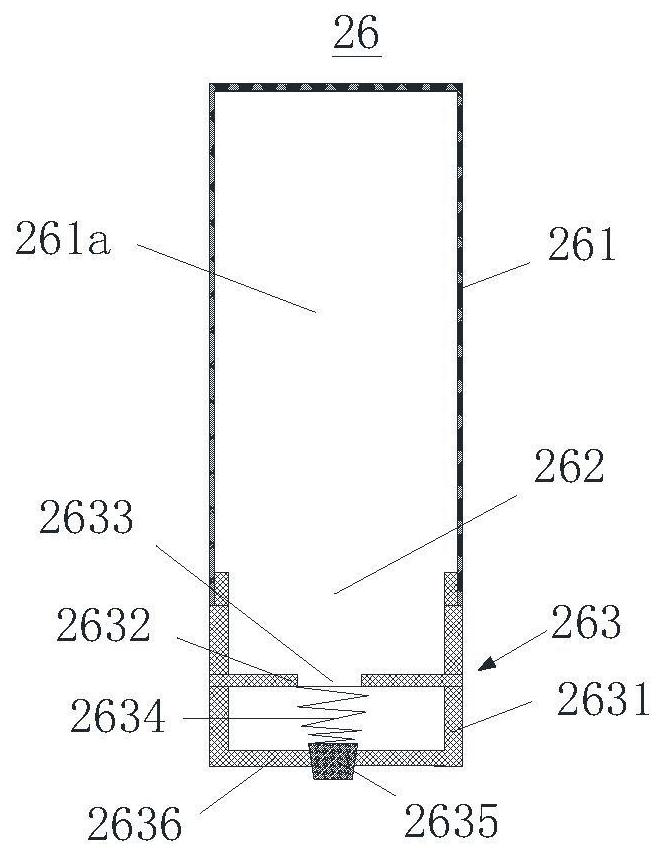

InactiveCN111068089AExtended stayImprove delivery functionDrying gas arrangementsTextile treatment machine arrangementsNonwoven fabricMechanical engineering

The invention discloses a sterilization device on a non-woven fabric production line. The device comprises a machine shell, supporting rods and connecting lugs, the supporting rods are symmetrically welded to the bottom of the machine shell, the connecting lugs are fixedly connected to one ends of the supporting rods, and a first sterilization mechanism, a tensioning mechanism, a second sterilization mechanism and a drying mechanism are sequentially installed in the machine shell. The non-woven fabric winds around a roller in an S shape, on the one hand, the retention time of the non-woven fabric in the shell can be effectively prolonged; and on the other hand, the non-woven fabric can be fully irradiated by ultraviolet rays, and the sterilization effect is good. A water pump is powered on, meanwhile, a valve is opened, and a bacteriostatic agent solution in a tank body is conveyed into a U-shaped pipe through a communicating pipe. The bacteriostatic agent solution is sprayed out in the form of water mist through atomizing nozzles under the action of pressure, so that the bacteriostatic agent solution is sprayed to the surfaces of the two sides of the non-woven fabric so as to inhibit the growth of bacteria and to prevent regeneration of the bacteria.

Owner:安徽彩祺环保新材料科技有限公司

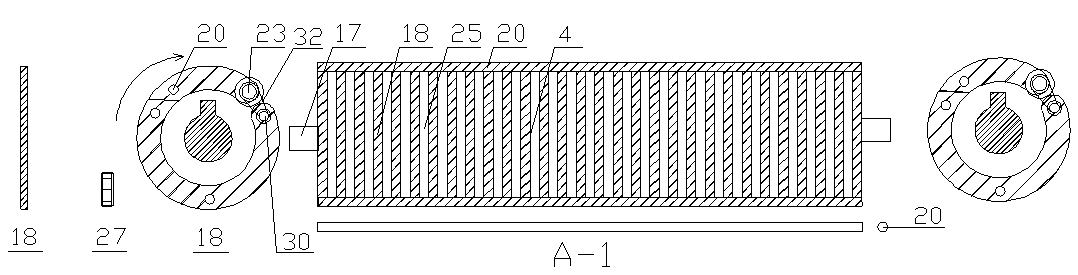

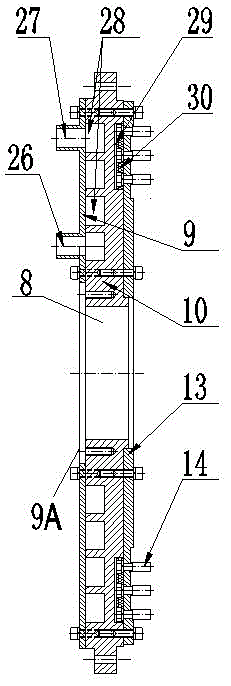

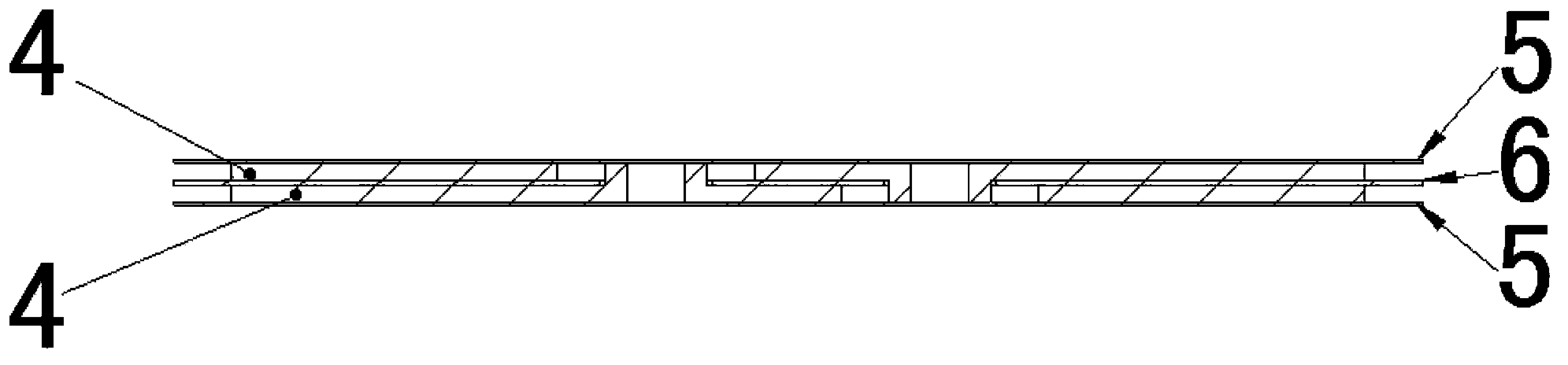

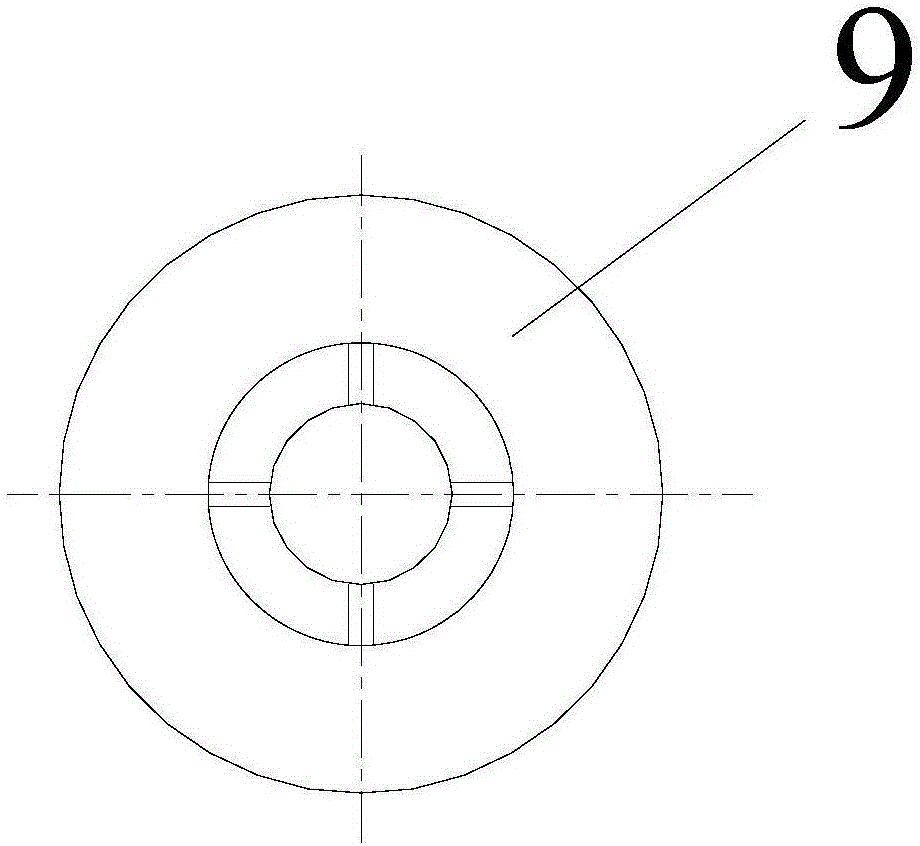

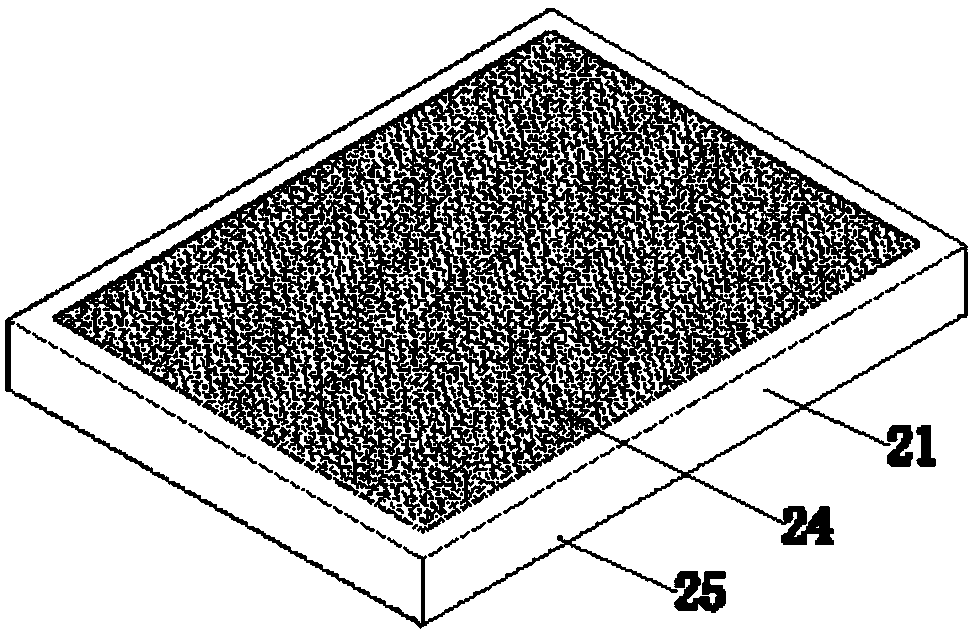

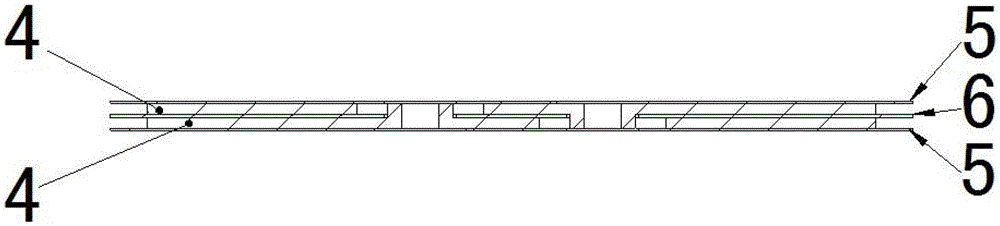

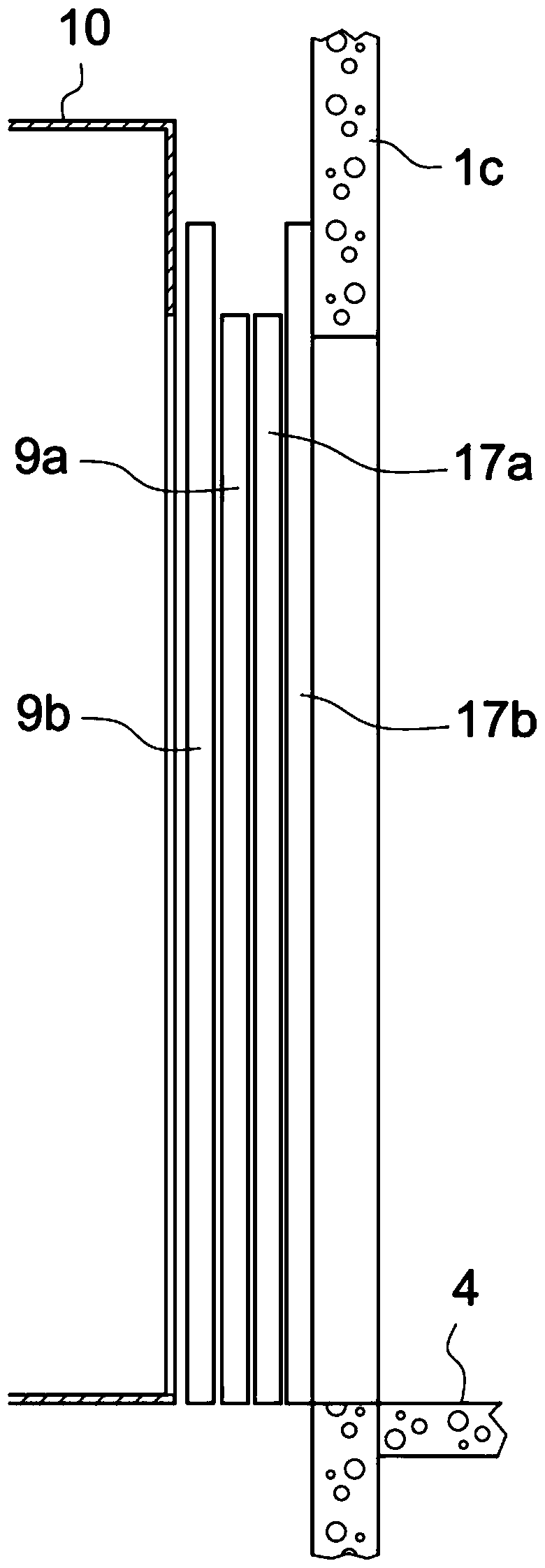

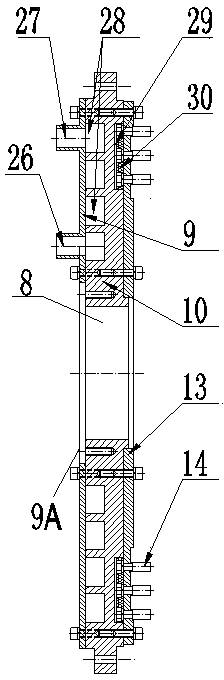

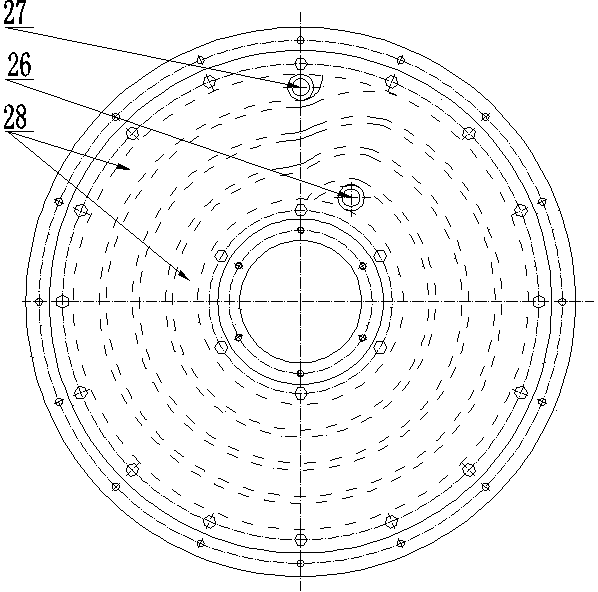

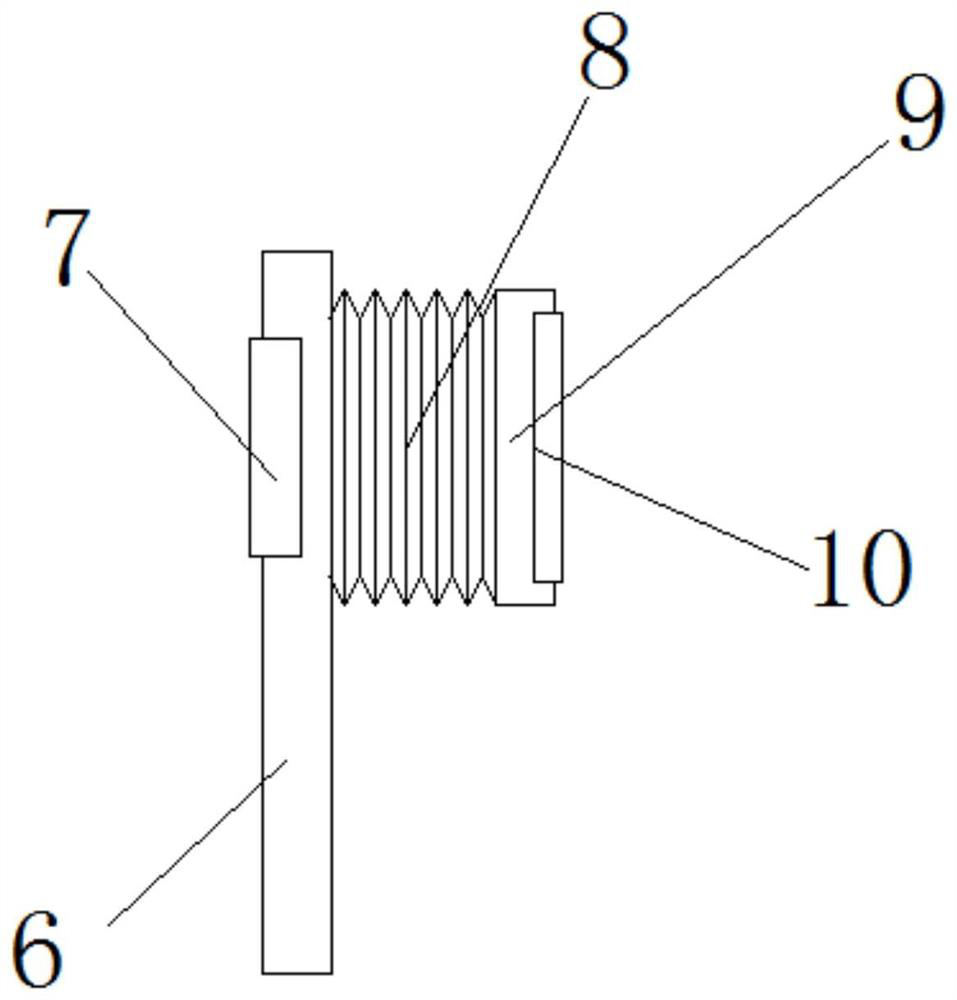

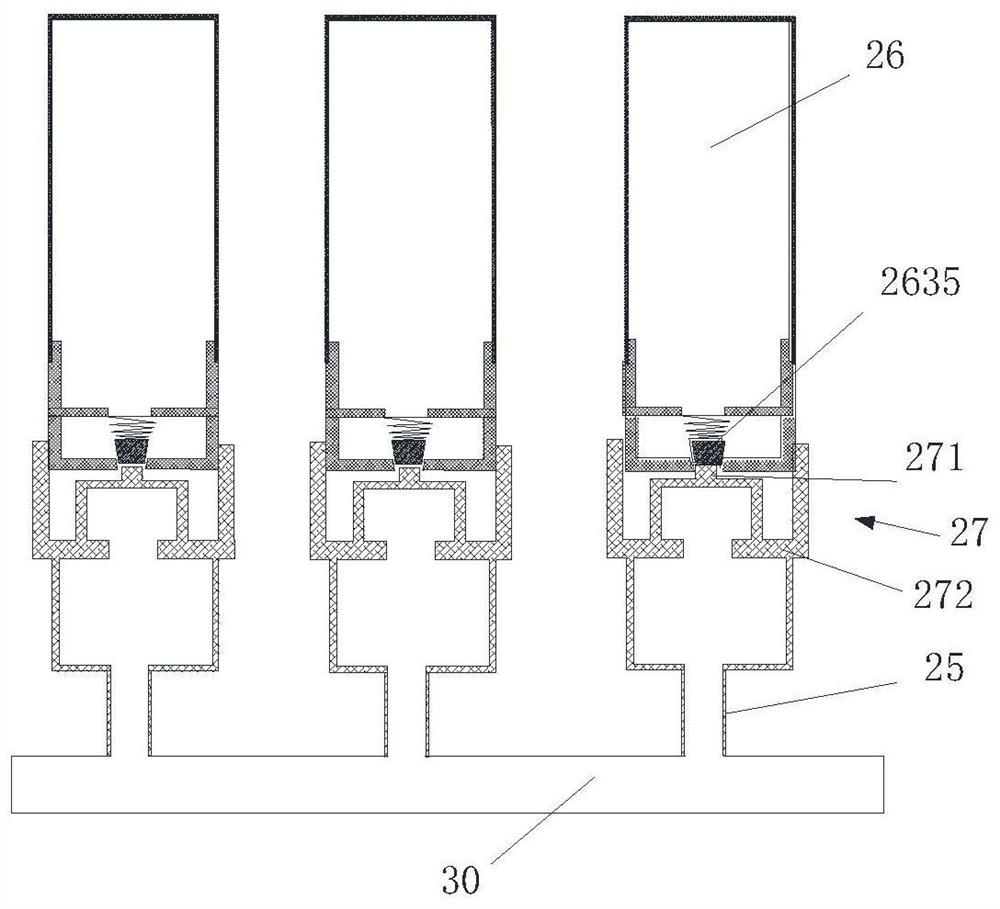

Filtering sieve shaft of sieving machine

ActiveCN102989657ATo achieve the function of forced deliveryRealization without material blockingSievingScreeningEngineeringMaterial distribution

The invention discloses a filtering sieve shaft of a sieving machine. The filtering sieve shaft comprises a sieving face composed of a movable flange plate type sieve shaft (4), a movable sieving strip type sieve shaft (5) and a spring type sieve shaft (24). The filtering sieve shaft has the advantages of guaranteeing sieving granular size and solving the problem that materials are not blocked in the hollow filtering sieve shaft. The filtering sieve shaft has the advantages of being good in anti-impact capacity, efficient in sieving, capable of guaranteeing granular size, free of material blocking, capable of removing iron, even in material distribution, capable of meeting requirements of more than two discharging granular sizes, convenient to overhaul, favorable for replacing parts and the like and is major breakthrough in the field of the sieving machine.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

High polymer for enhancing natural water replenishing capability of skin and activating energy of cells and preparation method thereof

InactiveCN103409479AHigh energyPromote activationCosmetic preparationsToilet preparationsTremellaBeta-glucan

The invention relates to a high polymer for enhancing natural water replenishing capability of skin and activating energy of cells and a preparation method thereof. The high polymer comprises the following components in percentage by weight: 15-25% of trehalose, 7-13% of beta-glucan, 3-8% of tremella polysaccharide, 0.08-0.5% of polysaccharide polymerase and the balance of deionized water. The high polymer can be used in skin care products, and has excellent moisturizing property for skin; and after the high polymer is used, phenomena such as dry skin, darkness and the like are obviously eliminated, and the moisture and elasticity of skin are improved.

Owner:MITANG BIOTECH SHANGHAI CO LTD

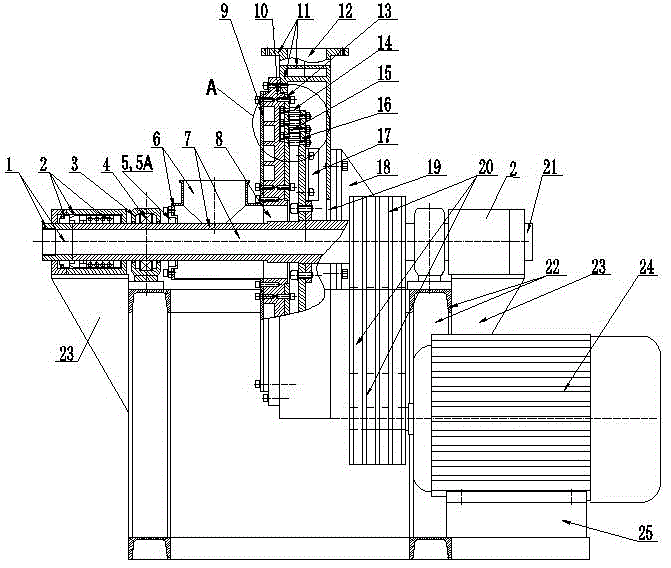

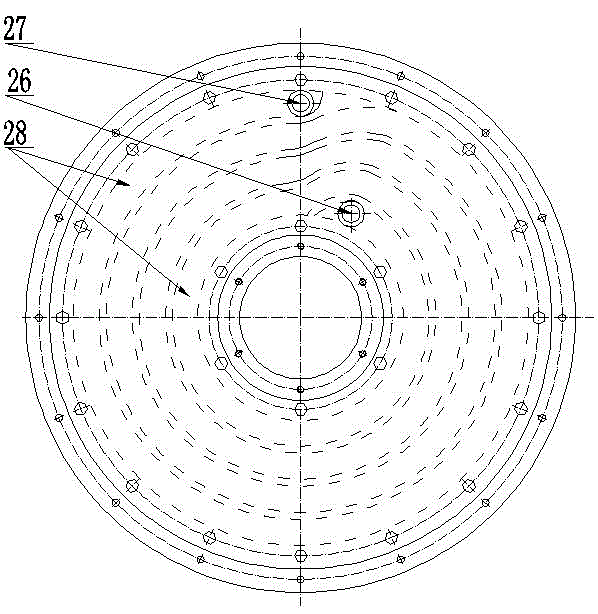

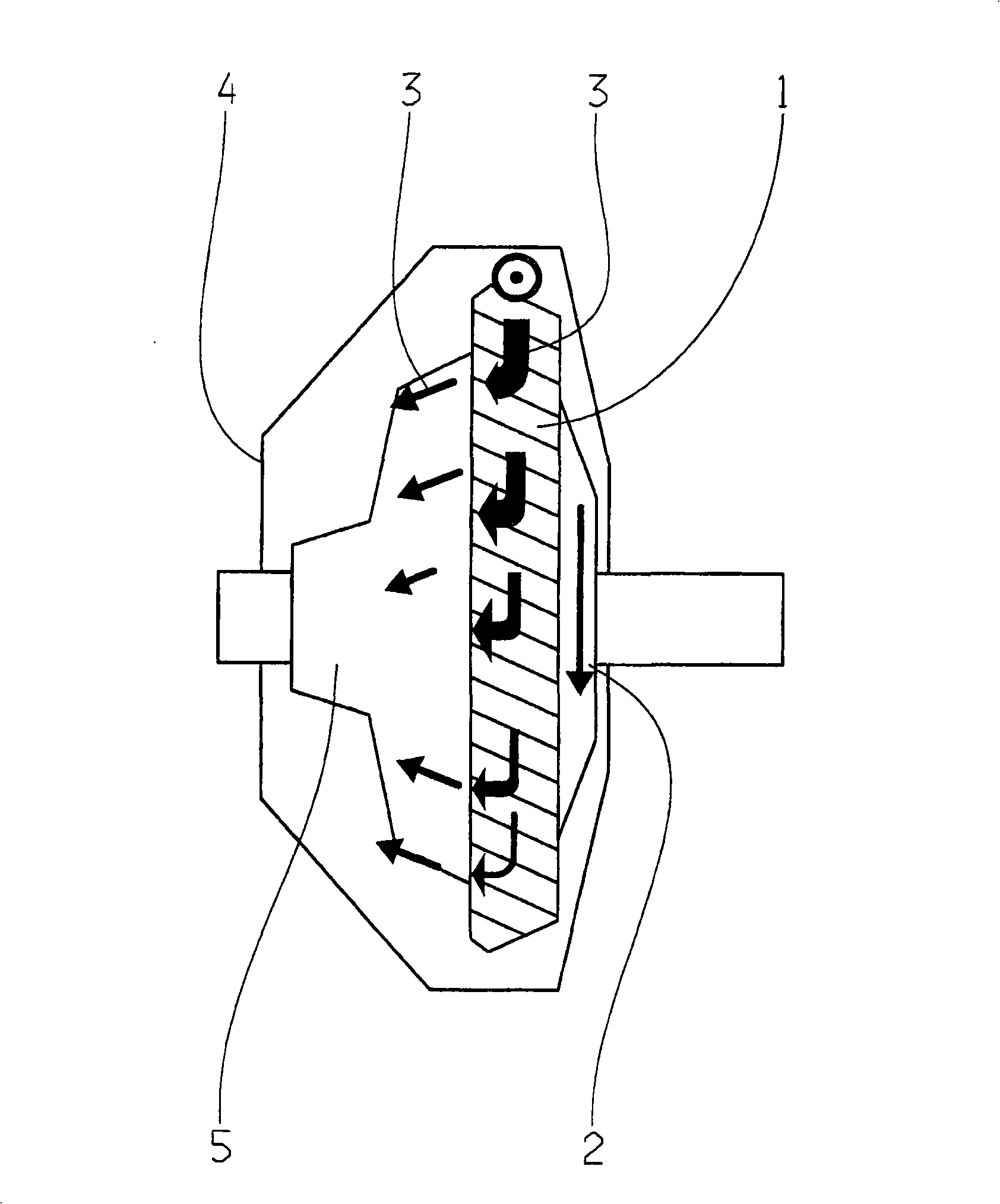

Impact powder-grinding and insect-killing machine with water-cooling function

InactiveCN102744122AReduce the temperatureIncrease in sizeGrain treatmentsInsect catchers and killersElectric machineEngineering

The invention discloses an impact powder-grinding and insect-killing machine with a water-cooling function, and the machine comprises a seat and a motor, wherein a support frame is fixedly connected to the seat, a shell is fixedly connected to the support frame, a discharge port is arranged on the sidewall of the shell, a rotor component is arranged in the shell, and a stator component is fixedly connected to the shell; the rotor component comprises a rotor disc and a rotor pin, and the stator component comprises a shell cover plate; the rotor component is provided with a radiating device, the radiating device of the rotor component comprises a hollow spindle, the middle of the hollow spindle penetrates through the shell and the shell cover plate, and the both ends of the hollow spindle are installed on the seat; the part of the hollow spindle located in the shell is fixedly connected with a connection disc, and the rotor disc is fixedly connected to the connection disc; and a spindle water inlet tube and a spindle water outlet tube are connected at the both ends of the hollow spindle respectively, and the motor is in transmission connection with the hollow spindle. According to the invention, comprehensive measures such as water-cooling and the like are adopted, so that the radiating effect is greatly improved than before, the quality of products in a grain production line is obviously improved, the edible quality of the finished products is obviously improved, and the service lives of the spindle and a motor bearing are prolonged exponentially.

Owner:王洪福

Device for optimizing the feed function of the ring gear of a differential with regard to maximum volume flow rate

InactiveCN101517275AReduce spacingImprove delivery functionGear lubrication/coolingTraffic capacityGear wheel

Owner:ZF FRIEDRICHSHAFEN AG +1

Multifunctional high-efficiency die-cutting machine

PendingCN112518824AImprove the safety of useImprove efficiencyMetal working apparatusStructural engineeringMachine

The invention discloses a multifunctional high-efficiency die-cutting machine which comprises a machine table. A die-cutting frame is fixedly arranged in the middle of the top end of the machine table, sliding grooves are fixedly formed in the two ends of the inner side of the die-cutting frame, a cutter base is slidably connected to the inner sides of the sliding grooves, and a pneumatic cylinderis fixedly arranged in the middle of the top end of the die-cutting frame. A cutter is fixedly arranged at the top end of the cutter base, telescopic frames are fixedly connected to the two sides ofthe cutter base, lower pressing rods are fixedly arranged at the bottom ends of the telescopic frames, and a cutter groove is formed in the position, corresponding to the middle of the cutter, of themiddle of the top end of the machine table in a penetrating manner. A pressing roller frame is fixedly arranged on one side of the top end of the machine table, a lower pressing roller is rotatably connected to the position, corresponding to the pressing roller frame, of the top end of the machine table through bearings, and an upper pressing roller is rotatably connected to the middle of the pressing roller frame through bearings. A finished product conveying belt is fixedly arranged on the other side of the top end of the machine table, and a finished product discharging port is fixedly formed in the other side of the top of the machine table. The multifunctional high-efficiency die-cutting machine is simple and reasonable in structure and novel in design, and has higher multifunctionaluse efficiency in use of die-cutting machines.

Owner:兆均精工科技(苏州)有限公司

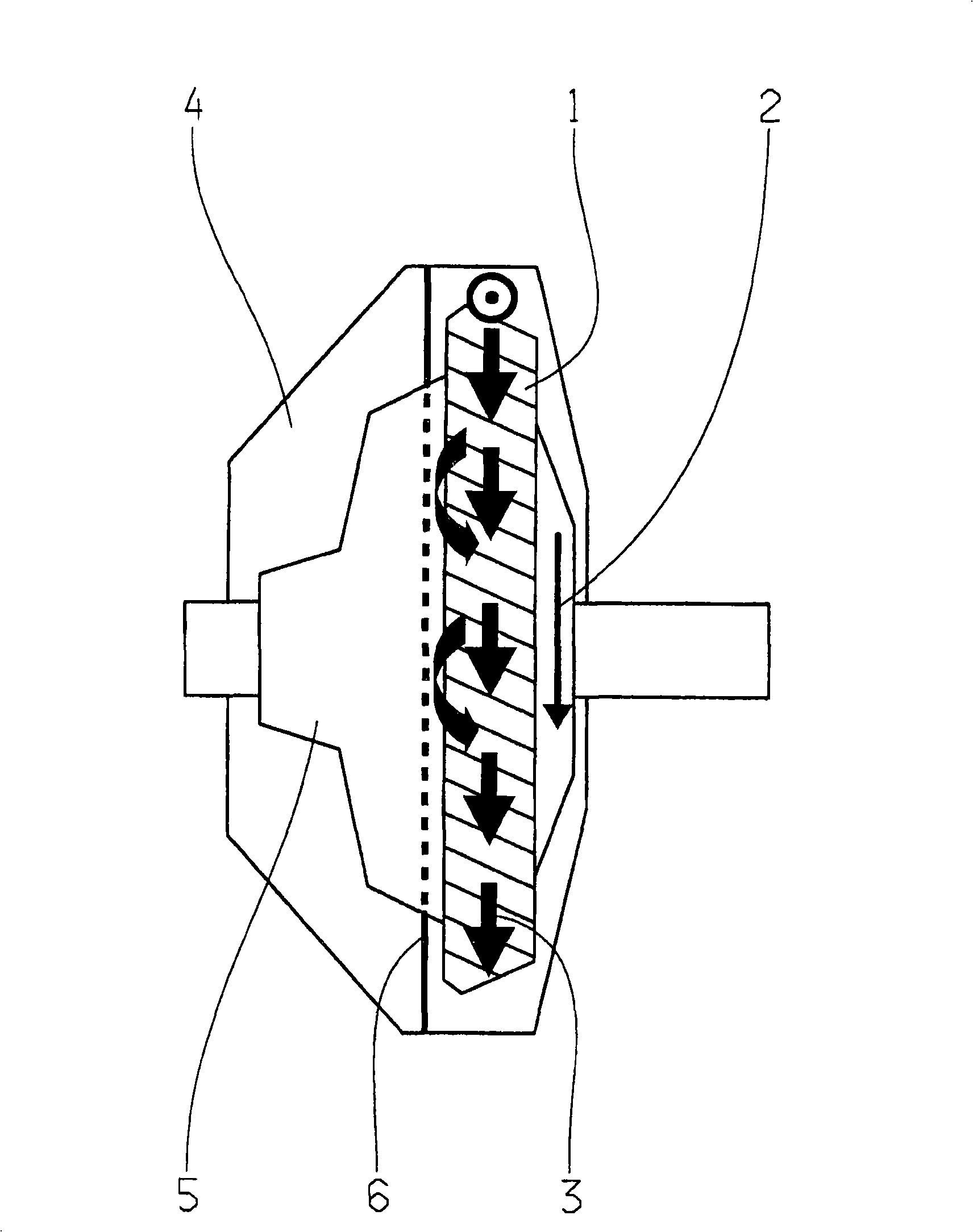

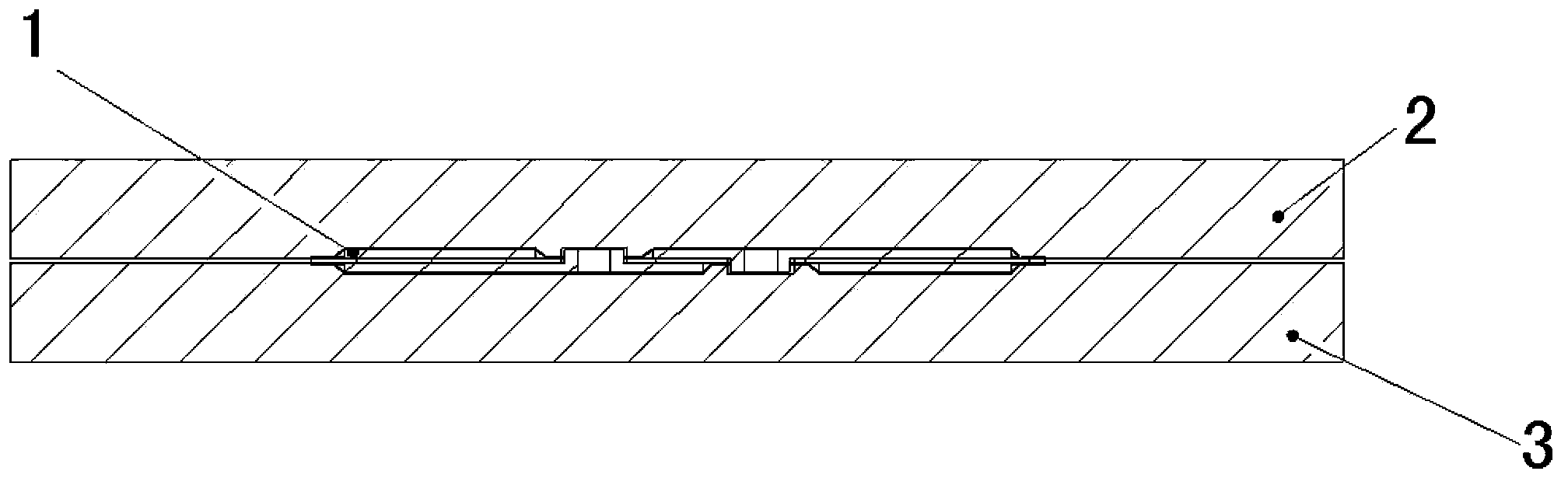

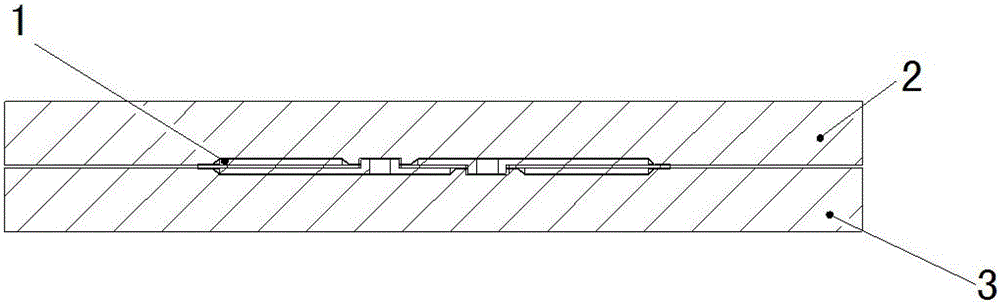

Universal flexible pressing mould for manufacturing laminated busbar

ActiveCN103400661AGood heat transfer functionReduce trial production costsInsulating conductors/cablesBusbarManufacturing engineering

The invention discloses a universal flexible pressing mould for manufacturing a laminated busbar. The universal flexible pressing mould comprises an upper die and a lower die, a busbar to be pressed is arranged between the upper die and the lower die, the upper die comprises an upper die cavity and silicone grease filled in the upper die cavity, and the lower die comprises a lower die cavity and silicone grease filled in the lower die cavity. According to the universal flexible pressing mould for manufacturing the laminated busbar, which is disclosed by the invention, the silicone grease respectively filled in the upper die cavity and the lower die cavity is used for conducting the heat and transferring the pressure and can flexibly form matched concave / convex die structures according to different busbars under the pressure, so that the laminated busbar is pressed and the edge of the laminated busbar is sealed. Therefore, the universal flexible pressing mould disclosed by the invention can meet the pressing requirements of different-structure busbars and has the universality; the upper die cavity and the lower die cavity are filled with the silicone grease so as to have a good pressed flexible formation function and a good heat transfer function; the research, development and trial-manufacture costs of the busbar are reduced, and the machining period is shortened; and the mould is simply and conveniently manufactured and maintained.

Owner:SUZHOU WEST DEANE MACHINERY

Sieving and crushing integrated machine

ActiveCN102896019BReasonable layoutReduce power consumptionSievingScreeningEngineeringSystem structure

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

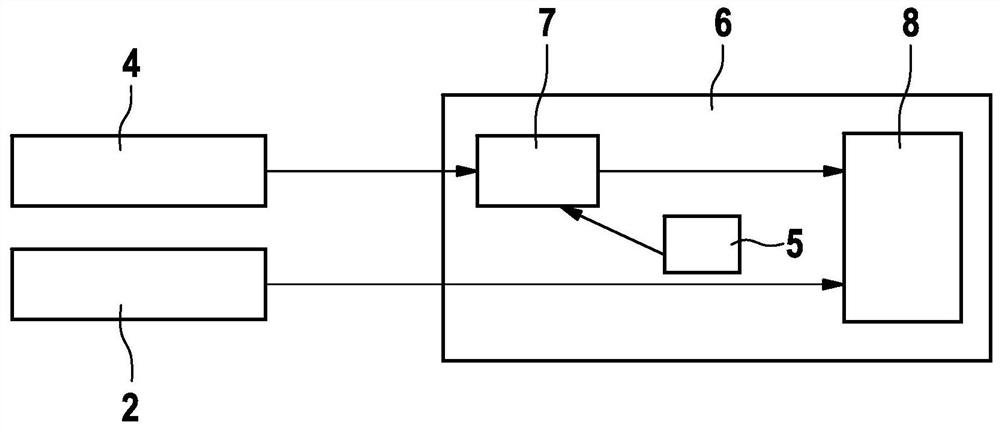

Calibration method and system of solid sound sensitive acceleration sensor and correction method of measurement signal of solid sound sensitive acceleration sensor

PendingCN114838807AImplement the transfer functionImprove delivery functionSubsonic/sonic/ultrasonic wave measurementBone conduction transducer hearing devicesMicrophone signalFrequency analysis

The invention relates to a method for calibrating a solid-borne sound-sensitive acceleration sensor by means of at least one microphone. For this purpose, the acceleration sensor is arranged in a defined position on the body of the user. In addition, at least one acceleration sensor signal and at least one microphone signal are detected, the at least one acceleration sensor signal and the at least one microphone signal being synchronized and caused by the sound of the user. A frequency analysis is performed on the acceleration sensor signal and a frequency analysis is performed on the microphone signal. A frequency-dependent correction function for correcting a transfer function of the acceleration sensor is determined on the basis of a frequency analysis of the acceleration sensor signal and of the microphone signal.

Owner:ROBERT BOSCH GMBH

Belt-type blade spiral mixing conveyor

InactiveCN106005921AImprove delivery functionStrong special typeConveyorsPackagingFailure rateReduction drive

The invention discloses a belt-type blade spiral mixing conveyor. The belt-type blade spiral mixing conveyor comprises a motor, a speed reducer, a material trough, bearings, a spiral shaft, a discharging opening and a spiral blade. The input end of the speed reducer is connected with the motor, the output end of the speed reducer is connected with the material trough, the spiral shaft is arranged in the material trough, the spiral blade is arranged on the spiral shaft, the bearings are arranged at the left end and the right end of the material trough, and the discharging opening is formed in the right end of the lower portion of the material trough. The belt-type blade spiral mixing conveyor is characterized by further comprising windows, a liquid-material hopper and a blocky-material hopper, the liquid-material hopper, the blocky-material hopper and the windows are sequentially arranged at the upper portion of the material trough from left to right, and the spiral blade is a complete spiral blade. The belt-type blade spiral mixing conveyor has the advantages of being good in conveying function, wide in application, suitable for conveying blocky or viscous materials, high in specificity, simple in structure, convenient to wash, maintain and move and low in failure rate.

Owner:SUZHOU GAOTONG MACHINERY TECH CO LTD

Metal smelting and pouring system

PendingCN108620570AReasonable structureMaintain or reduce temperature effectsCasting cleaning apparatusMolten metal conveying equipmentsRefractoryHeating furnace

The invention relates to a metal smelting and pouring system which comprises a pouring device and a furnace door device of a smelting furnace. The pouring device comprises an input runner connected tothe smelting furnace and connected with a buffering tank, the furnace door device comprises a furnace door and a furnace door moving device, the furnace door comprises an outer frame side, a mesh-type framework refractory pouring layer arranged in the outer frame side and a full refractory pouring layer, and furnace door moving device comprises a lifting rope connected between the furnace door and a furnace door driver. The metal smelting and pouring system is reasonable in structure and good in pouring liquid delivery quality, and ingot recycling quality of regenerated aluminum is improved.

Owner:江西恒泰铝材有限公司

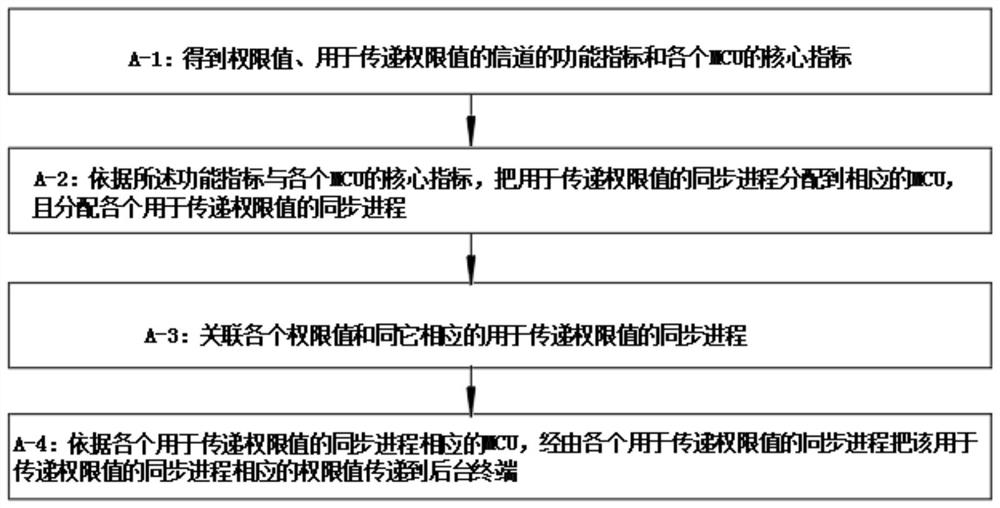

Permission opening control system and method

PendingCN113204431AImprove delivery functionAvoid using effectsProgram initiation/switchingResource allocationComputer networkControl system

The invention relates to a permission opening control system and method, and the system comprises: a permission control module, which is used for carrying out the permission control of a function according to the permission value of a role for the function on a page, wherein the authority control module runs on an MCU, and the MCU is connected with a mobile communication module to execute transmission of an authority value together with a background terminal in a mobile communication network; and units running on the MCUS, which comprise an obtaining unit used for obtaining authority values, function indexes of channels used for transmitting the authority values and core indexes of the MCUs. in combination with another structure and method, the defects that in the prior art, when a client uses permission control, the use effect of the MCUN function is poor, the number of synchronization processes of an MCU core is too large, and the task load is large are effectively overcome.

Owner:南京微鲤科技有限公司

Universal flexible lamination tool for laminated busbar fabrication

ActiveCN103400661BVersatilityImprove delivery functionInsulating conductors/cablesBusbarSilicone grease

The invention discloses a general flexible pressing mold for making laminated busbars, which comprises two parts, an upper mold and a lower mold. The busbar to be pressed is placed between the upper and lower molds. The upper mold includes an upper mold cavity and a filling The silicone grease in the upper mold cavity, the lower mold includes the lower mold cavity and the silicone grease filled in the lower mold cavity. The present invention uses the silicone grease set in the upper and lower mold cavities to conduct heat and transmit pressure, and the silicone grease in the upper and lower mold cavities can flexibly form the matching concave-convex mold structure according to the busbars of different structures under the action of pressure, so that the laminated busbar Press-fit edge banding. Therefore, the present invention can satisfy busbar pressing with different structures, and has versatility; the upper and lower mold cavities are filled with silicone grease, which is flexible under pressure and has good heat transfer function; reduces the cost of busbar research and development and trial production, and shortens the processing cycle; mold manufacturing and maintenance easy and convenient.

Owner:SUZHOU WEST DEANE MACHINERY

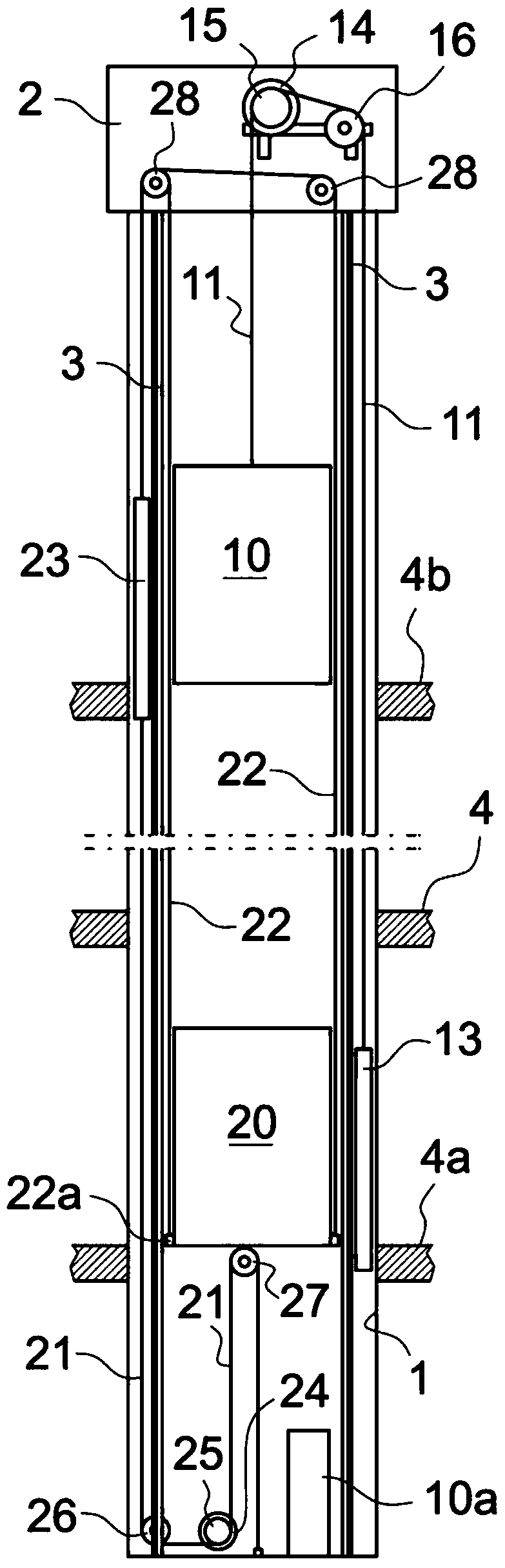

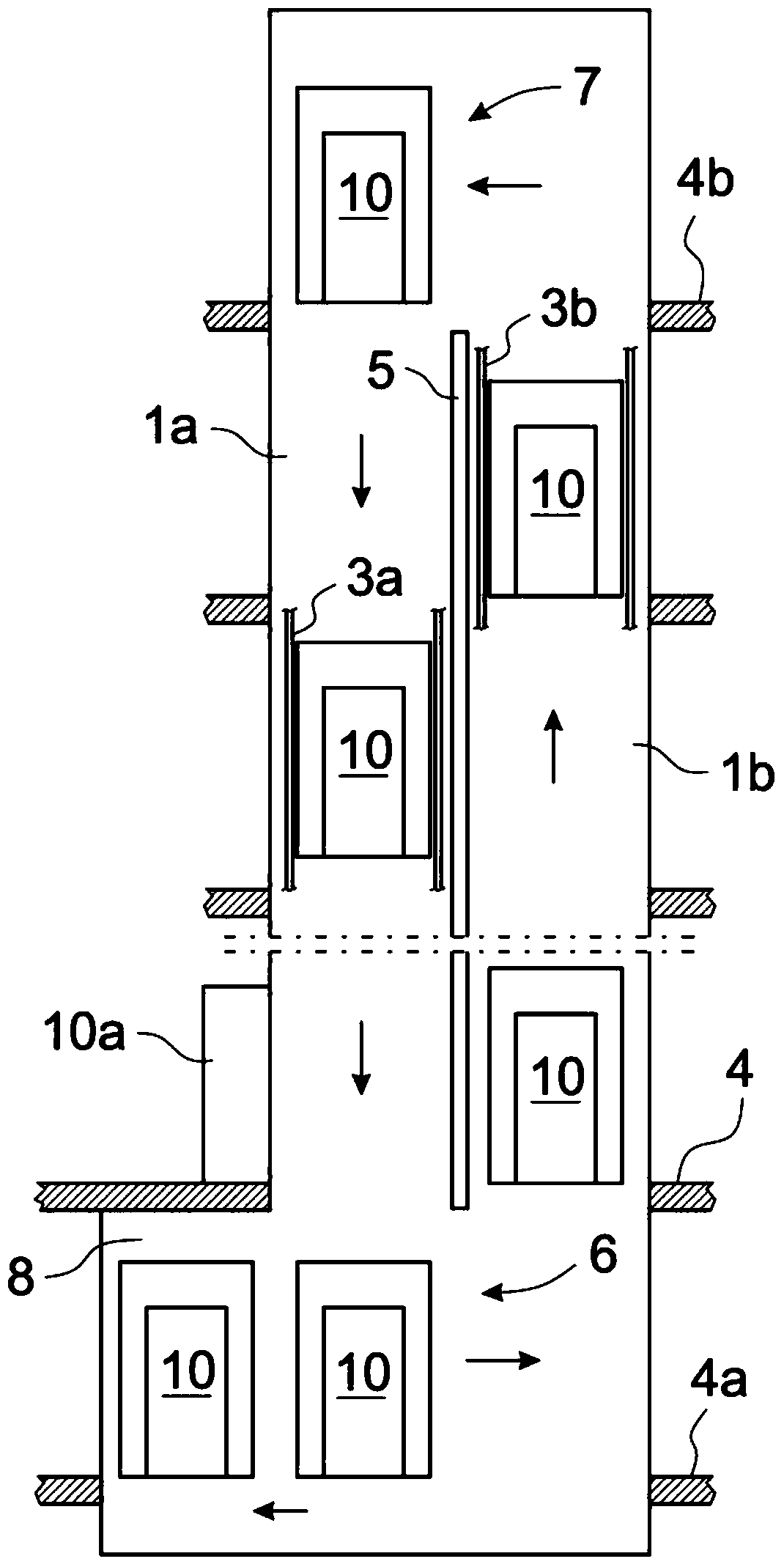

Method and arrangement for closing a door of an elevator

ActiveCN105384039BImprove delivery functionSports safetyElevatorsBuilding liftsControl systemEmbedded system

Owner:KONE CORP

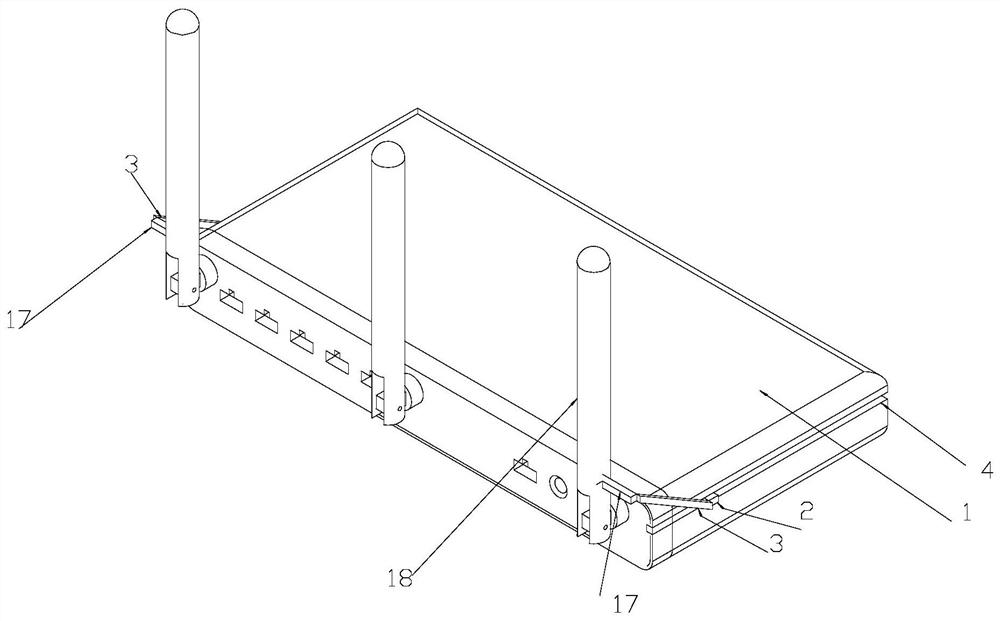

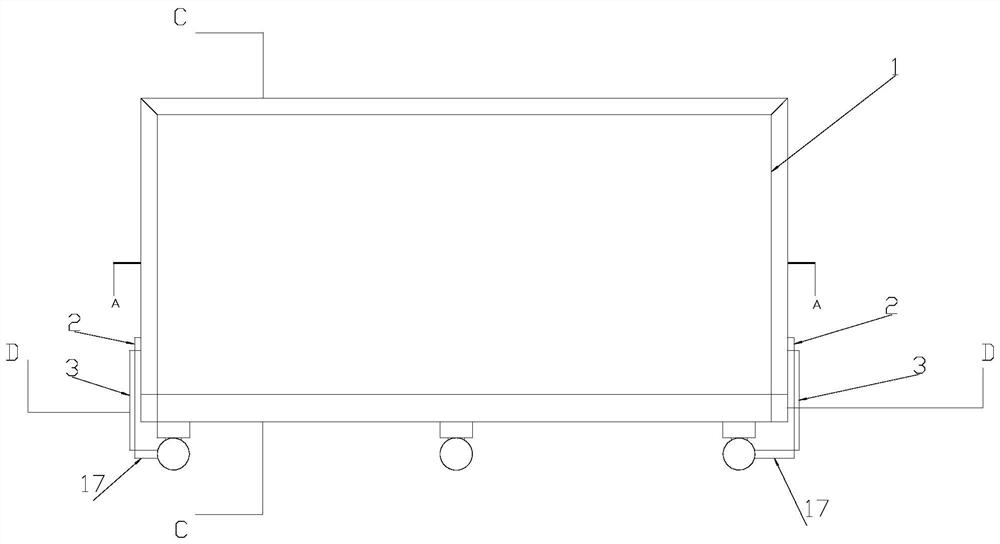

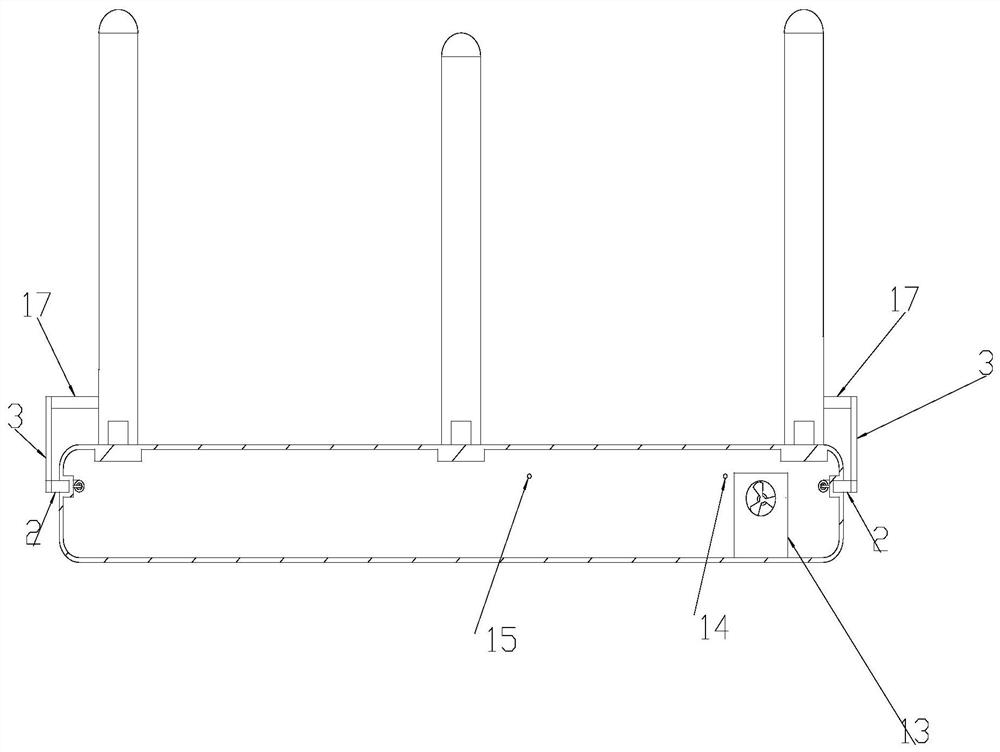

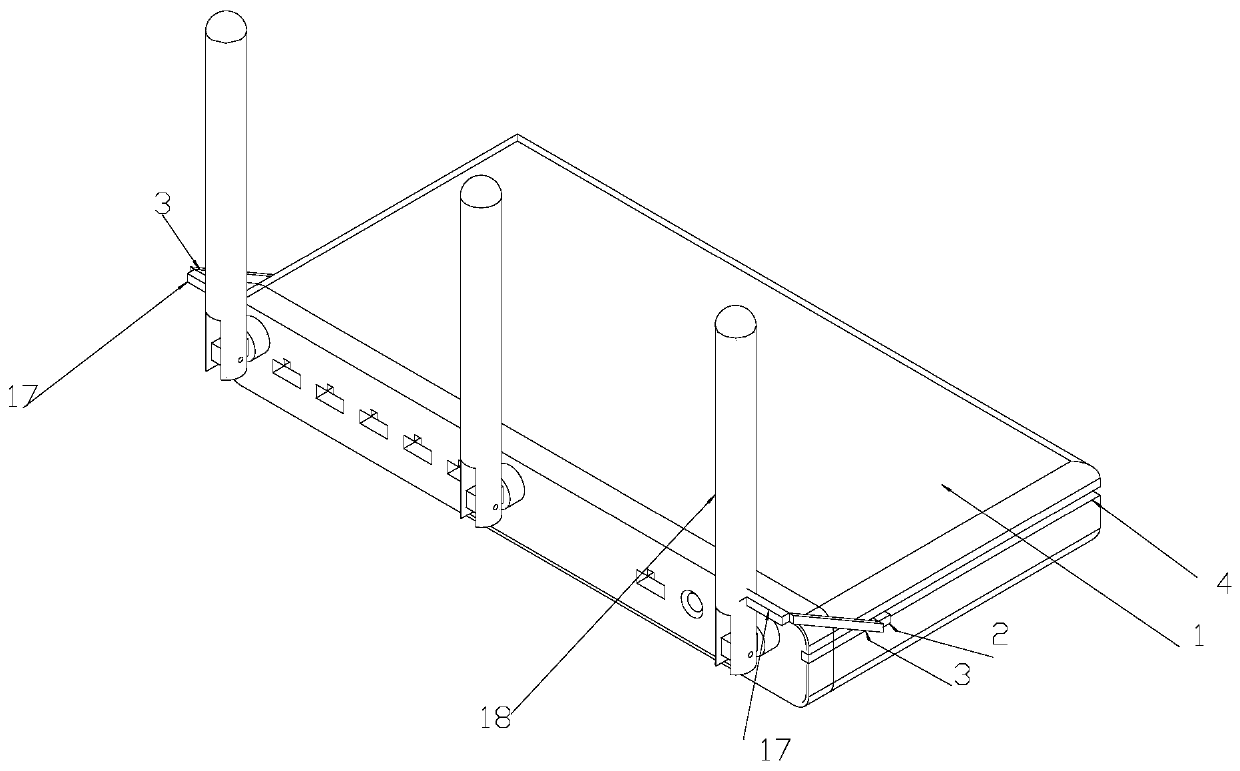

A router with functions of anti-fall, heat dissipation and dust removal

ActiveCN111541618BGood anti-drop functionEffective heat dissipation and dust removalTransmissionCooling/ventilation/heating modificationsGas cylinderDust control

The invention relates to the technical field of smart home appliances, in particular to a router with the function of anti-drop heat dissipation and dust removal. The router with the function of anti-drop heat dissipation and dust removal includes a housing, a signal pole, an anti-drop component, and a heat dissipation and dust removal component. In that: the anti-drop assembly includes chute arranged at both ends of the outer side wall of the housing, a slider arranged in the chute, an air cylinder fixedly arranged at both ends of the inner side wall of the housing, and an internal connection of the air cylinder There is a piston rod, one end of the piston rod is fixedly provided with a connecting rod, and the other end of the connecting rod is fixedly connected with the slider, and is fixedly arranged on the gas collecting box at the lower end of the gas cylinder, and fixedly arranged on the gas collecting box. The air pipe at the upper end of the box and the air film material fixed at the lower end of the gas collecting box, the air pipe is fixedly connected with the air cylinder; the side wall of the signal rod is provided with a fixed block, and the fixed block and the slider pass through The two connecting rods are elastically connected so that the router can be adjusted during the rollover process to ensure that the bottom of the router is on the ground and avoid damage to the router.

Owner:深圳市凯利华电子有限公司

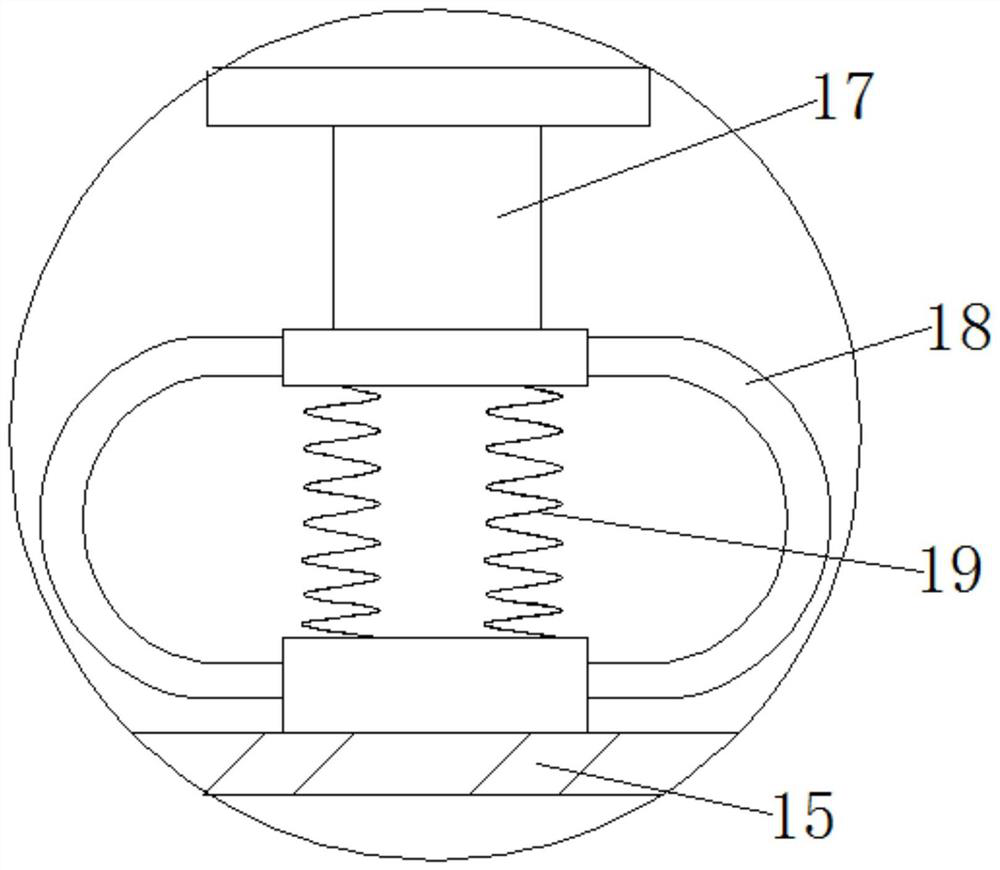

A work piece conveying device of a press machine and its working process

ActiveCN108160846BEasy to transportEasy to operateMetal-working feeding devicesNon-rotating vibration suppressionMachineMachine press

The invention discloses a workpiece conveying device of a pressure machine, and relates to the technical field of conveying machinery. The workpiece conveying device comprises a bottom plate, the topof the bottom plate is fixedly connected with a conveying box, one side of the conveying box communicates with a communication box, and a workpiece penetrates through one side of the communication box; and the side, extending to the inner cavity of the communication box, of the workpiece penetrates through the conveying box to extend to the other side of the conveying box, electric telescopic rodsare fixedly connected to the two sides of the top of the inner cavity of the conveying box, and the output ends of the electric telescopic rods are fixedly connected with fixing plates at the top ofthe workpiece. According to the workpiece conveying device of the pressure machine and a working process thereof, the conveying effect of the device is greatly improved, the stability of the conveyingprocess is high, the operation by workers is facilitated, and the labor intensity of the workers is reduced; and the device is safe and reliable, the device has a good conveying function, the servicelife of the device is prolonged, and damage caused by vibration to the device is avoided, so that the device has a good buffering function.

Owner:新沂阿凡达智能科技有限公司

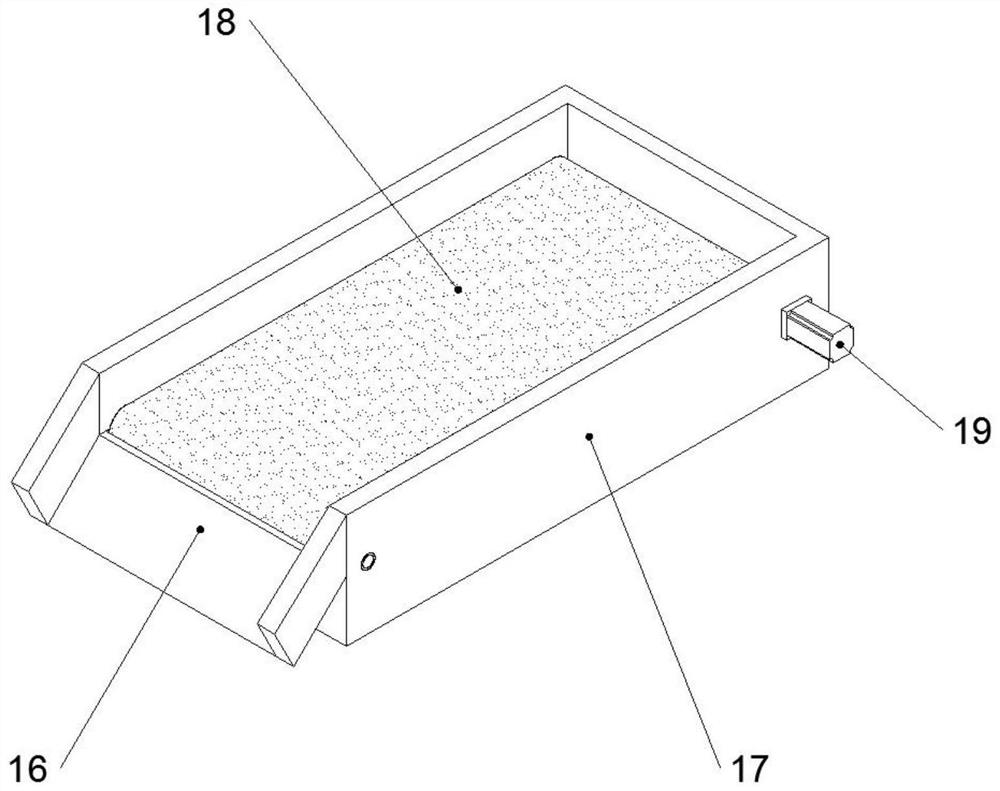

Recycled aluminum smelting cast ingot system

InactiveCN110744018AReasonable structureMaintain or reduce temperature effectsIngot casting plantsBuffer tankEngineering

The invention relates to a recycled aluminum smelting cast ingot system. The recycled aluminum smelting cast ingot system comprises an input passageway connected to a corresponding smelting furnace and a buffer tank. A backflow purification pit is formed between the output end of the input passageway and the buffer tank, and an output port of the backflow purification pit is arranged to protrude out of the bottom wall of the backflow purification pit by a certain height and be lower than the bottom face of the output end of the input passageway. A furnace door device of the smelting furnace comprises a furnace door running gear, and the furnace door running gear comprises a safety protection cable connected to a furnace door. The recycled aluminum smelting cast ingot system is reasonable in structure, the quality of casting liquid conveyed by the system is good, and the recycling quality of cast ingots of recycled aluminum is improved.

Owner:江西恒泰铝材有限公司

Impact powder-grinding and insect-killing machine with water-cooling function

InactiveCN102744122BIncrease contact areaImprove heat transfer efficiencyGrain treatmentsInsect catchers and killersElectric machineEngineering

The invention discloses an impact powder-grinding and insect-killing machine with a water-cooling function, and the machine comprises a seat and a motor, wherein a support frame is fixedly connected to the seat, a shell is fixedly connected to the support frame, a discharge port is arranged on the sidewall of the shell, a rotor component is arranged in the shell, and a stator component is fixedly connected to the shell; the rotor component comprises a rotor disc and a rotor pin, and the stator component comprises a shell cover plate; the rotor component is provided with a radiating device, the radiating device of the rotor component comprises a hollow spindle, the middle of the hollow spindle penetrates through the shell and the shell cover plate, and the both ends of the hollow spindle are installed on the seat; the part of the hollow spindle located in the shell is fixedly connected with a connection disc, and the rotor disc is fixedly connected to the connection disc; and a spindle water inlet tube and a spindle water outlet tube are connected at the both ends of the hollow spindle respectively, and the motor is in transmission connection with the hollow spindle. According to the invention, comprehensive measures such as water-cooling and the like are adopted, so that the radiating effect is greatly improved than before, the quality of products in a grain production line is obviously improved, the edible quality of the finished products is obviously improved, and the service lives of the spindle and a motor bearing are prolonged exponentially.

Owner:王洪福

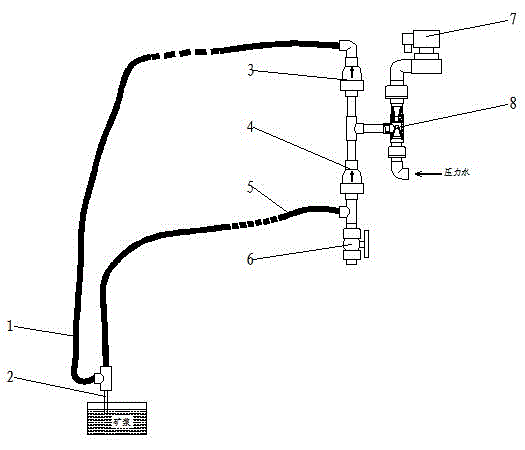

Water-driven automatic pulp extraction conveyor

InactiveCN105300736AImprove delivery functionEasy to installWithdrawing sample devicesPipeline systemsSolenoid valvePulp and paper industry

A water-driven automatic pulp extraction conveyor can be mounted anywhere and takes pressure water as power. By virtue of the characteristic that clean water does not influence the grade of a sample, pressure water is taken as power to automatically extract and convey the sample; one end of a pulp suction pipe is inserted into pulp, and the other end of the pulp suction pipe is connected with a pulp storage pipe and a flush water pipe through a tee joint; the flush water pipe is connected with a check valve 1; the pulp storage pipe is connected with a check valve 2 and a pulp discharge valve through a tee joint; the check valve 1 and the check valve 2 are communicated with the suction inlet of a water jetter; the water outlet of the water jetter is connected with a solenoid valve controlled by a PLC; the pipe diameters of the pulp suction pipe is smaller than those of the pulp storage pipe and the flush water pipe. According to the water-driven automatic pulp extraction conveyor, a conventional automatic sampler is structurally simplified, and a motor transmission system is omitted, so that the installation is simple, quick and convenient; altitude difference and a special installation space are not needed; the pulp sample conveying function is added, so that the sample does not need to be collected on site; meanwhile, the purchase, installation and running costs are low, and the maintenance times are reduced.

Owner:吴平

Teaching apparatus storage device

ActiveCN112744456AAvoid damageFunction as a shock absorberConveyorsContainers to prevent mechanical damageElectric machineryEngineering

The invention discloses a teaching apparatus storage device which comprises a storage box, wherein the bottom of the inner cavity of the storage box is fixedly equipped with a lifting mechanism; a base is fixedly mounted on the top of the lifting mechanism; telescopic cavities are arranged on the tops of the two sides of the base; side plates are movably connected in the telescopic cavities; springs are fixedly connected between the bottom sides of each group of side plates and the bottom sides of the corresponding telescopic cavities; a base frame is fixedly mounted between the middles of the two groups of the side plates; a plurality of supporting rollers are rotatably connected on the base frame; the two ends of the base frame are rotatably connected to turnover frames; power rollers are rotatably connected on the turnover frames; a conveyor belt is arranged outside the supporting rollers and power rollers; a motor is fixedly mounted on the side wall of the base frame; and the top of the storage box is movably connected to a top cover. The teaching apparatus storage device is simple in structure, is convenient and practical, can effectively protect, store and coney teaching apparatuses.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

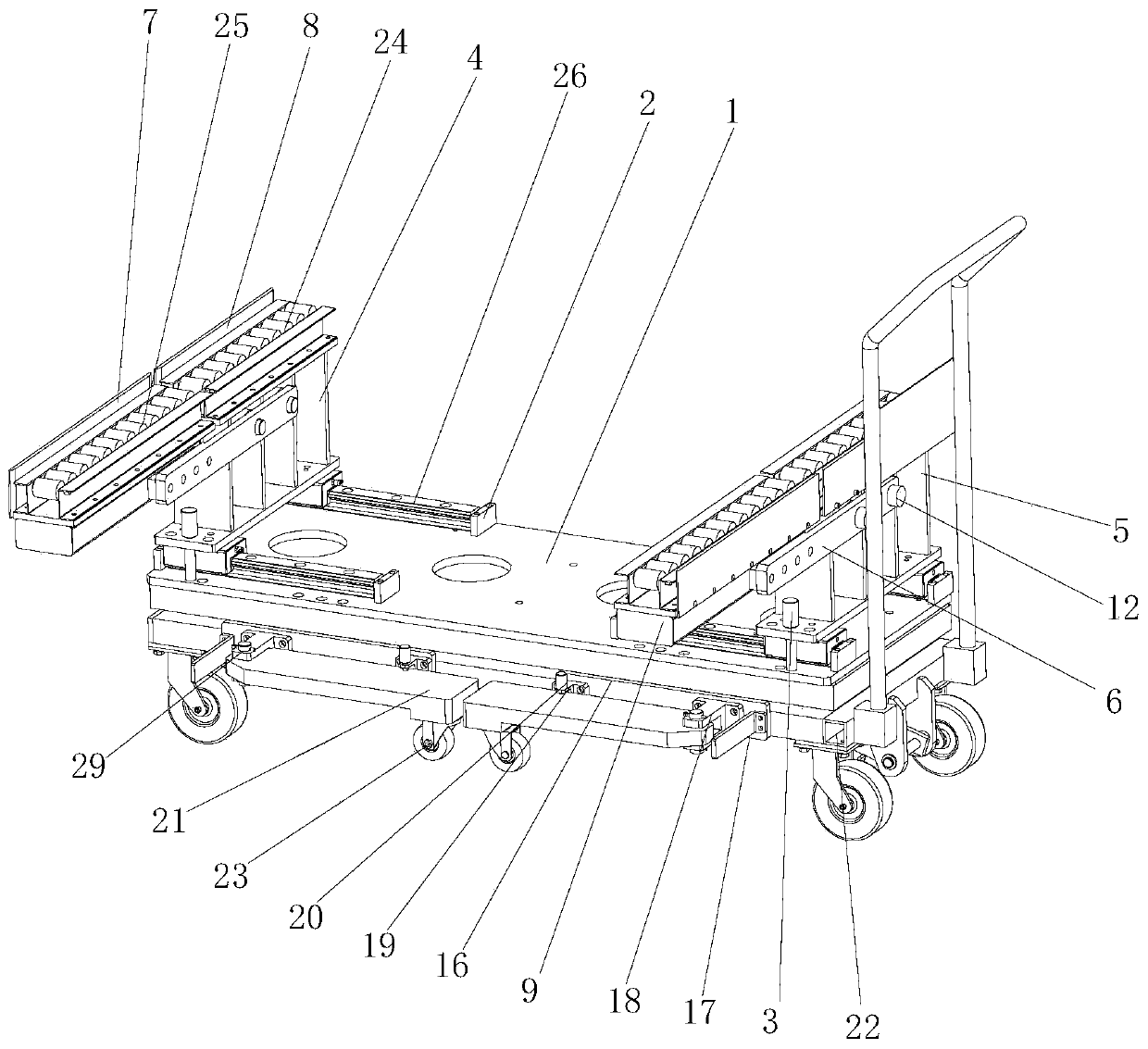

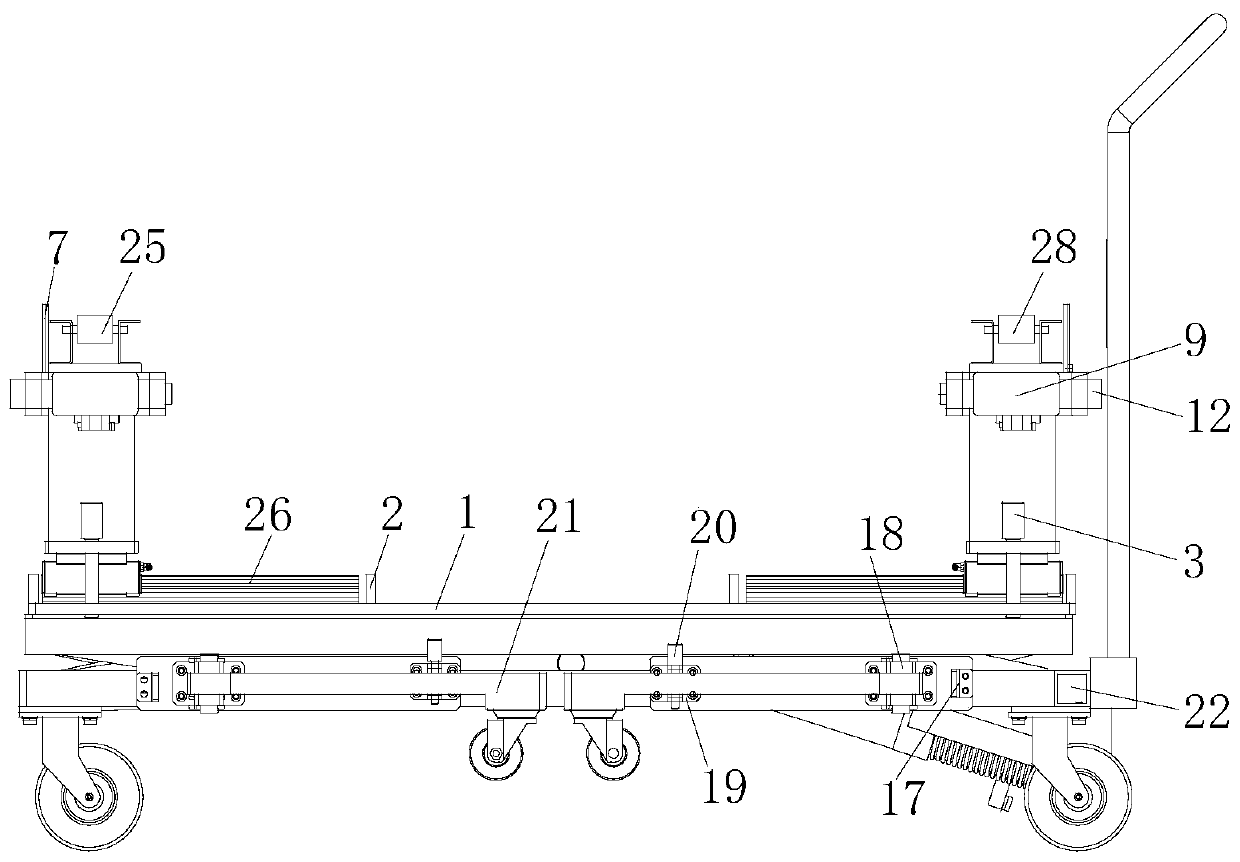

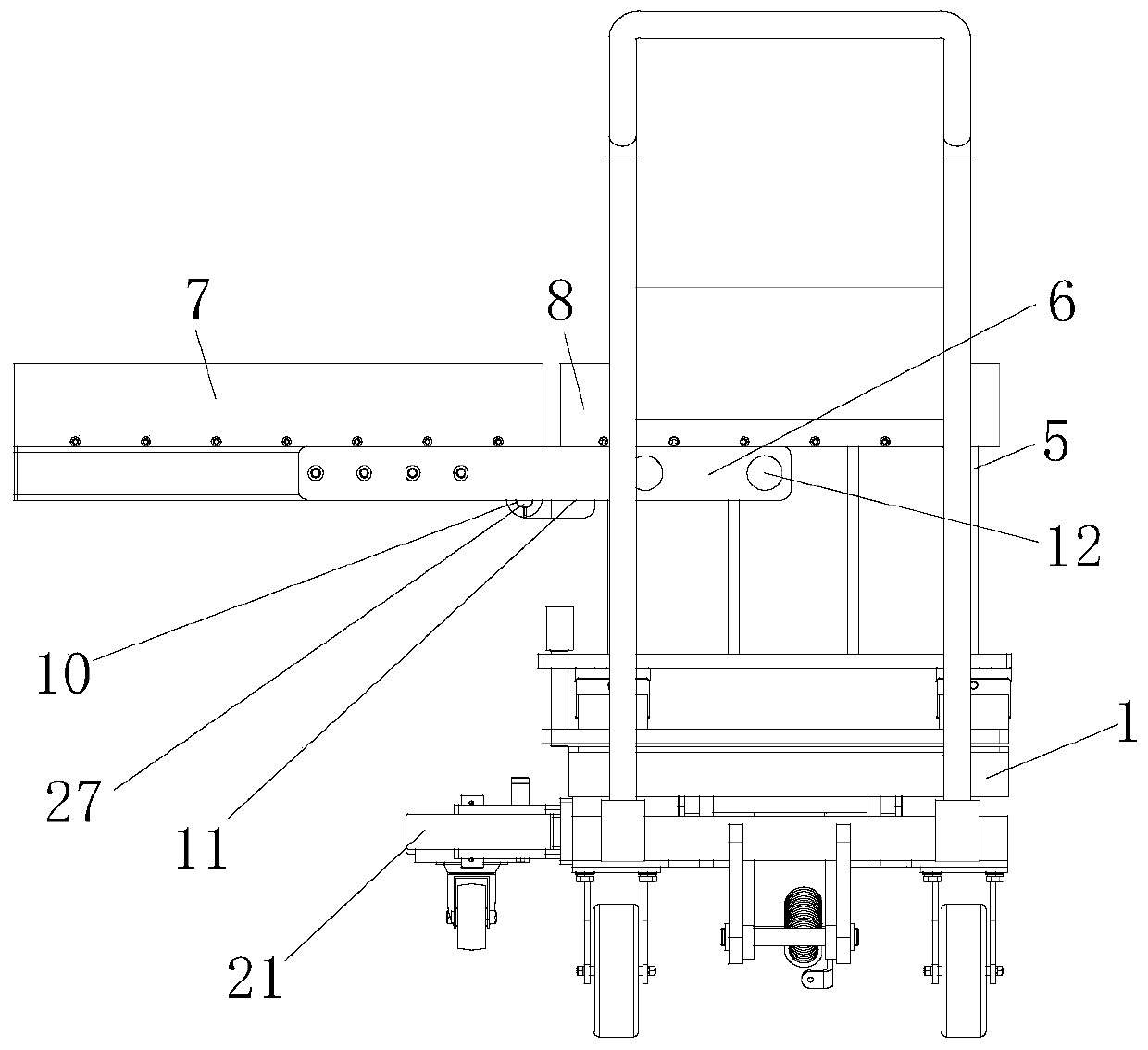

Trolley

PendingCN111232039AEasy to transportImprove delivery functionHand carts with multiple axesHand cart accessoriesStructural engineeringMechanical engineering

Owner:广州萝锋智能科技有限公司

Tooth-shaped blade spiral mixing conveyor

InactiveCN106044087AImprove delivery functionImprove the mixing effectPackagingFailure rateReduction drive

The invention discloses a tooth-shaped blade screw mixing conveyor, which comprises a motor, a reducer, a trough, a bearing, a screw shaft, a discharge port, and a screw blade. The input end of the reducer is connected to the motor, and the output end is connected to the motor. The trough is connected, and a screw shaft is arranged in the trough, and a helical blade is arranged on the screw shaft. Bearings are arranged at the left and right ends of the trough, and a discharge port is arranged at the right end of the lower part of the trough. It is characterized in that: it also includes Window, night material funnel, powder material funnel, the upper part of the trough is provided with night material funnel, powder material funnel, window in turn from left to right, and the spiral blade is a complete spiral blade. The beneficial effects of the invention are: good conveying function, wide application, better mixing performance and conveying performance than ordinary spiral blades, simple structure, convenient cleaning and maintenance, convenient movement, and low failure rate.

Owner:SUZHOU GAOTONG MACHINERY TECH CO LTD

Router with anti-falling, heat-dissipating and dust-removing functions

ActiveCN111541618AIt has the function of anti-drop heat dissipation and dust removalGood anti-drop functionData switching networksCooling/ventilation/heating modificationsDust controlStructural engineering

The invention relates to the technical field of intelligent household appliances, in particular to a router with anti-falling, heat-dissipating and dust-removing functions. The router with the anti-drop heat dissipation and dust removal functions comprises a shell, a signal rod, an anti-drop assembly and a heat dissipation and dust removal assembly; the anti-falling assembly comprises sliding grooves formed in the two ends of the outer side wall of the shell, sliding blocks arranged in the sliding grooves and air cylinders fixedly arranged at the two ends of the inner side wall of the shell, piston rods are connected into the air cylinders, and first connecting rods are fixedly arranged at one ends of the piston rods. The other ends of the first connecting rods are fixedly connected with the sliding blocks, the air collecting boxes iare fixedly arranged at the lower end of the air cylinders, the air pipes are fixedly arranged at the upper ends of the air collecting boxes, the air filmmaterial is fixedly arranged at the lower end of the air collecting boxes, and the air pipes are fixedly connected with the air cylinders. The side wall of the signal rod is provided with fixing blocks, and the fixing blocks are elastically connected with the sliding blocks through second connecting rods, thereby enabling the router to be aligned in a side turning process, guaranteeing that the bottom surface of the router touches the ground, and preventing the router from being damaged.

Owner:深圳市凯利华电子有限公司

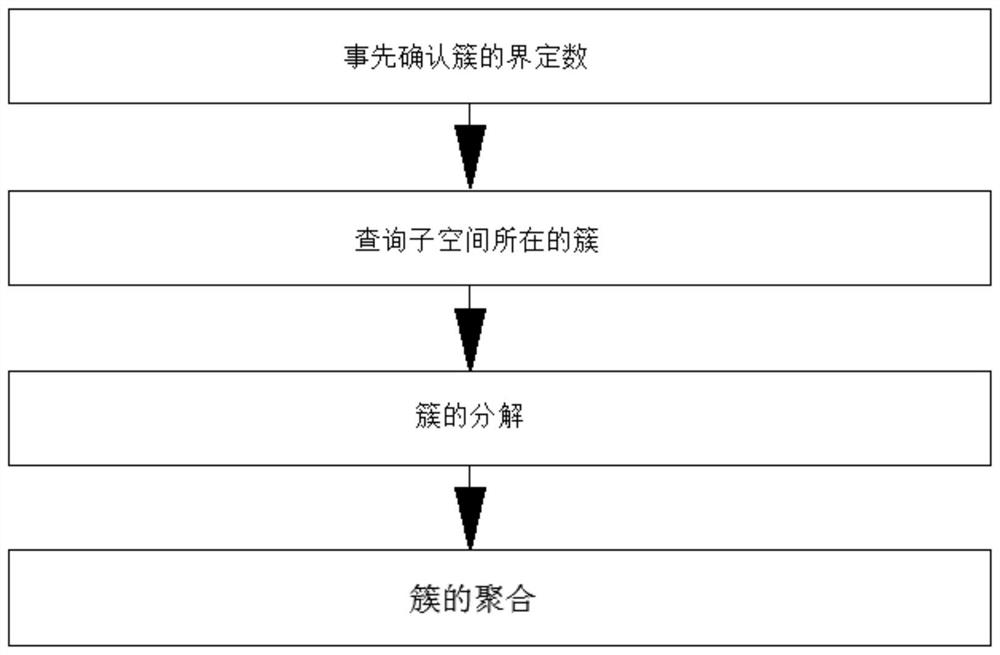

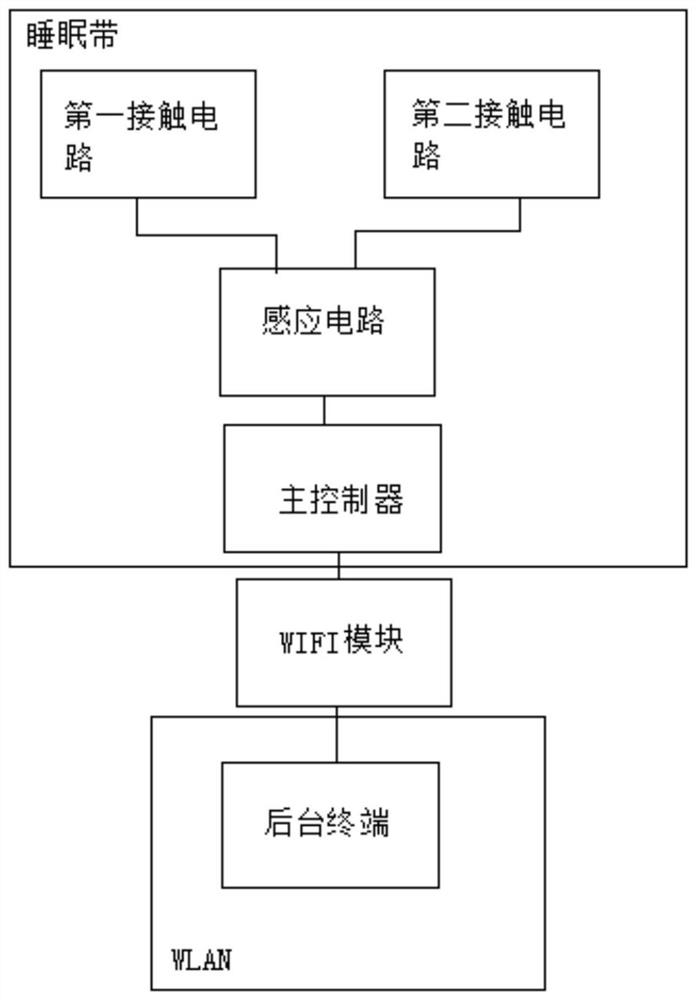

Application system based on membrane switch and application method thereof

InactiveCN112312478AImprove delivery functionNetwork traffic/resource managementElectric switchesComputer hardwareMembrane switch

The invention discloses an application system based on a membrane switch and an application method thereof. The application method comprises the following steps: an induction circuit generating a contact signal and transmitting the contact signal to a main controller; the main controller periodically transmitting the contact signals to a background terminal in the WLAN in a signal message mode tobe stored and displayed; the main controller periodically transmitting the contact signals to a background terminal in the WLAN in a signal message mode to be stored and displayed. The method comprises the steps of subspace clustering and subspace digital signal control in the cluster. The defects that in the prior art, when contact signals of a sleep band with a membrane switch are transmitted, WLAN traffic burden is not small, WLAN congestion is often formed, and the background terminal needs to continuously process digital signals in all signal messages so that the background terminal can face the large traffic burden are effectively overcome.

Owner:南京大陆豪薄膜开关技术有限公司

Single-stranded nucleic acid molecule having delivery function and gene expression regulating ability

ActiveUS11142769B2Improve delivery functionLow costOrganic active ingredientsAntipyreticSingle strandGene expression

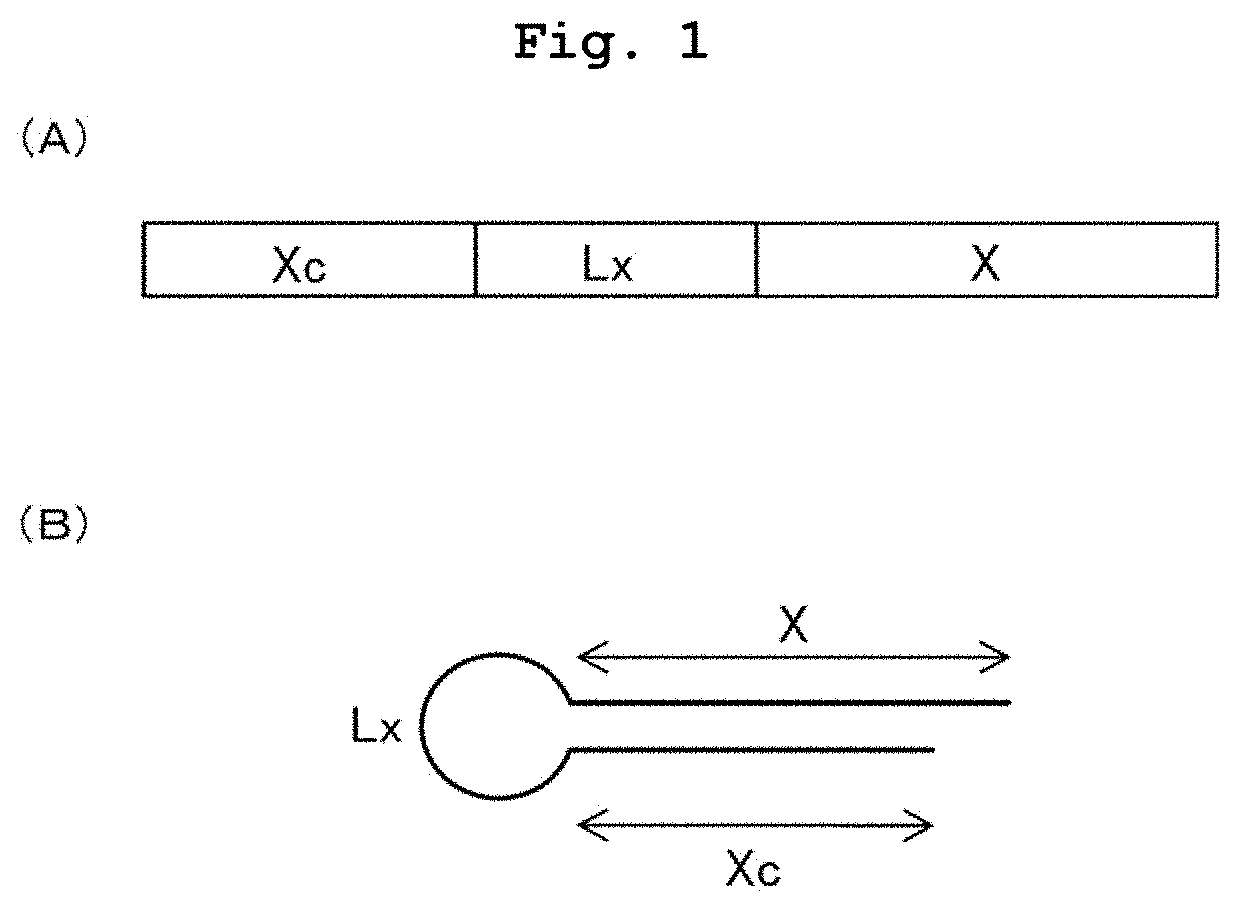

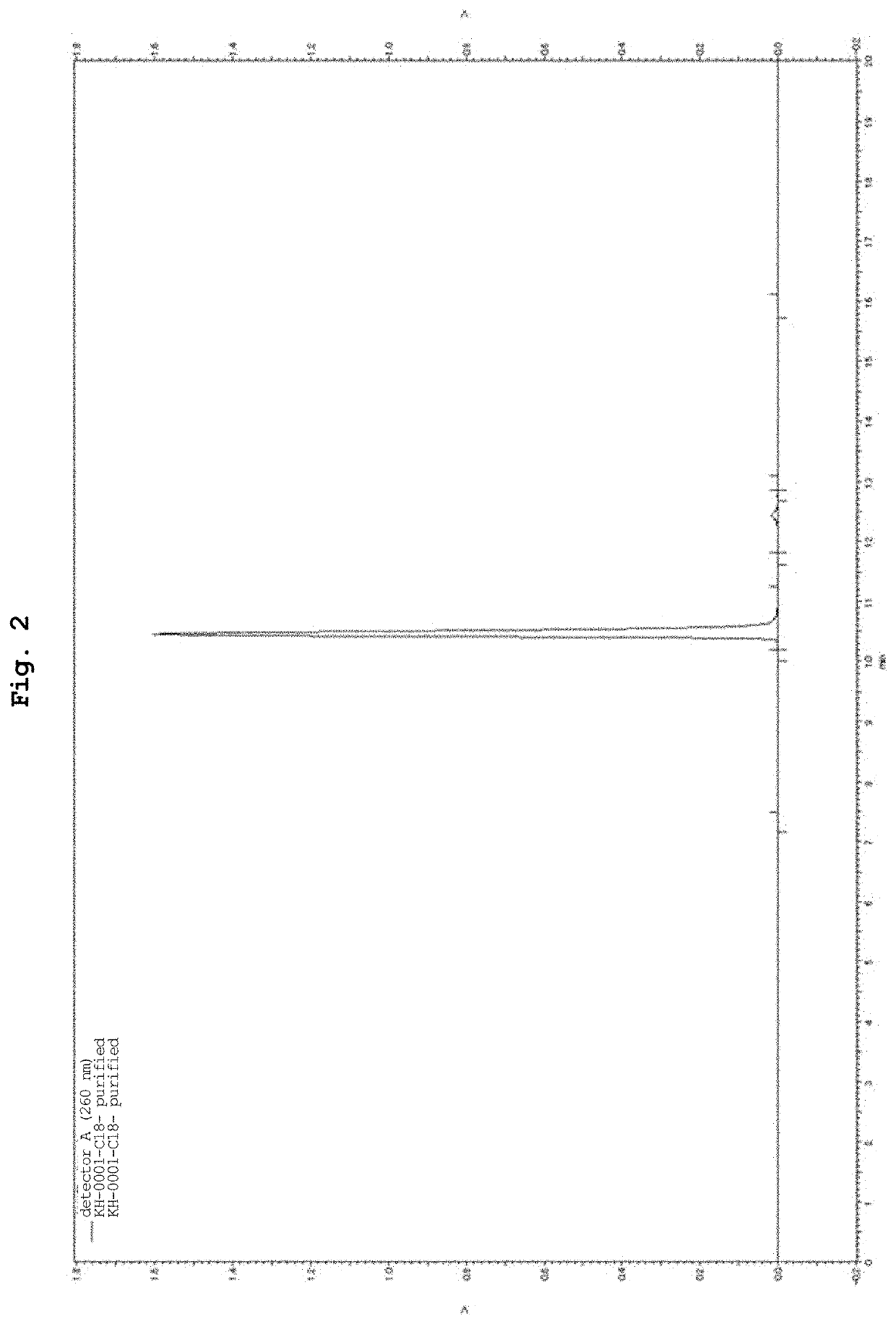

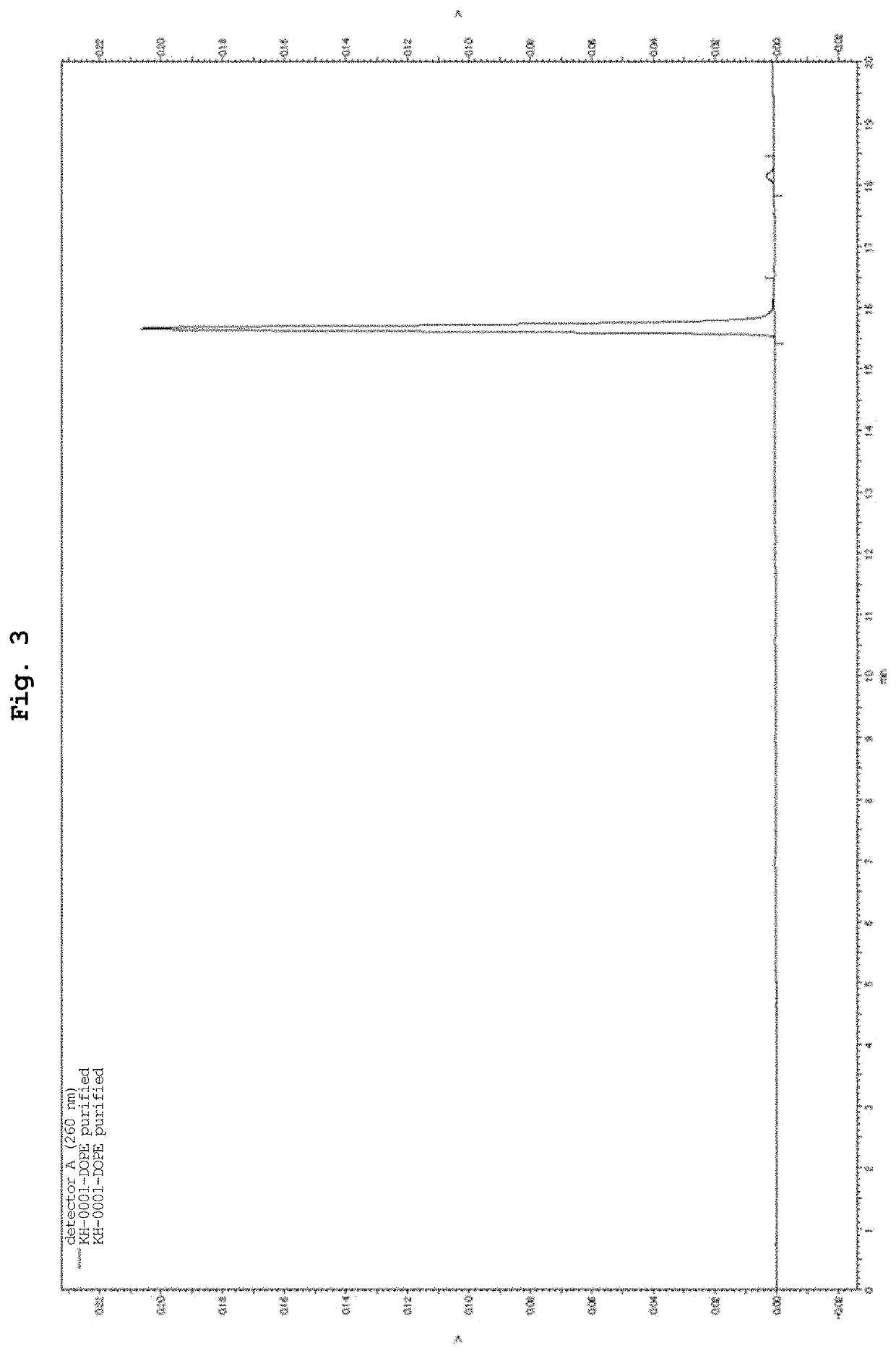

The present invention provides a single-stranded nucleic acid molecule having a delivery function and capable of inhibiting expression of a target gene. The single-stranded nucleic acid molecule of the present invention is a single-stranded nucleic acid molecule composed of a region (Xc), a linker region (Lx) and a region (X), wherein said region (Xc) is complementary to said region (X), at least one of said region (X) and said region (Xc) contains an expression inhibitory sequence that inhibits expression of the target gene, and a bio-related substance having a delivery function is bonded to at least one selected from the group consisting of the 5′-terminus, the 3′-terminus, and said linker region (Lx).

Owner:BONAC CORP

Composition for preventing and treating cancer cells and cardiovascular disease, and preparation method thereof

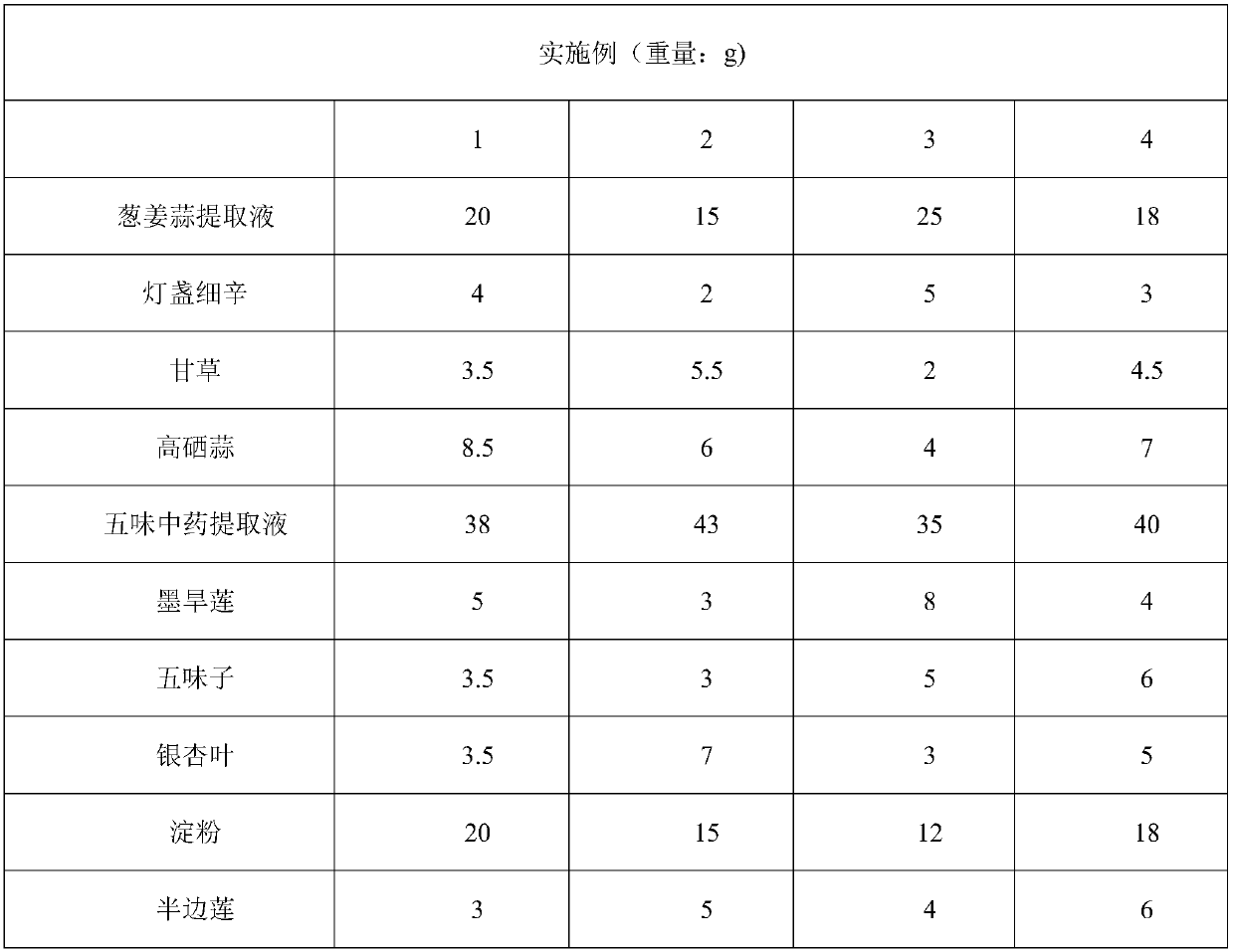

InactiveCN109675006AFully sterilizedImprove the heating effectGinkgophyta medical ingredientsAntineoplastic agentsCancer cellSide effect

The invention relates to the technical field of health care products, and discloses a composition for preventing and treating cancer cells and cardiovascular disease, and a preparation method thereof.The composition is prepared from the following raw materials in percentage by weight: 15-25% of onion, ginger and garlic extracting solutions, 2-4% of herba lobeliae chinensis, 2-5% of herba erigerontis, 2-4% of licorice roots, 7-10% of high-selenium garlic, 35-41% of extracting solutions of five traditional Chinese medicine, 3-8% of herba ecliptae, 2-5% of fructus schisandrae chinensis, 2-5% ofginkgo leaves and 16-25% of starch. The composition has the advantages that by taking the composition, the blood delivery function of the heart and the hematopoietic function of the liver are improved, the viscosity of blood is lowered, the expansibility of blood vessels is improved, a plurality of necessary generation conditions of thrombi are eliminated from the human body to remove the thrombi,thrombus coagulation is prevented to protect human body organs, and the cardiovascular disease caused by the thrombi can be prevented and treated without side effects.

Owner:王景胜

Preposed purified water feeding device and washing equipment with same

PendingCN114797608AImprove water qualityImprove washing effectTransportation and packagingSpecific water treatment objectivesWater sourceEnvironmental engineering

The invention relates to a preposed purified water feeding device and washing equipment. The pre-positioned purified water feeding device comprises a water purification module which is provided with a water inlet capable of being connected with an external water source; the automatic treatment agent feeding module comprises at least one treatment agent chamber; a liquid mixing chamber configured to receive and mix the purified water from the water purification module and the treatment agent from the treatment agent chamber to form a treatment agent mixed liquid, and having a discharge port configured to discharge the treatment agent mixed liquid into a predetermined device; and the control module is configured to be capable of controlling automatic feeding of the treating agent. According to the preposed purified water feeding device, the damage of water to target equipment and target treated objects is reduced by improving the water quality, and the mixing and dissolving degree of the treating agent and the water can be improved while the automatic feeding of the treating agent is realized.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com