Sterilization device on non-woven fabric production line

A sterilizing device and production line technology, which is applied in the direction of water supply device, drying gas arrangement, equipment configuration for processing textile materials, etc., can solve the problems of unreasonable design of sterilizing mechanism, unsatisfactory non-woven sterilization effect, bacteria regeneration, etc., and achieve the purpose of inhibiting bacteria growth, prolong residence time, and prevent bacterial regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

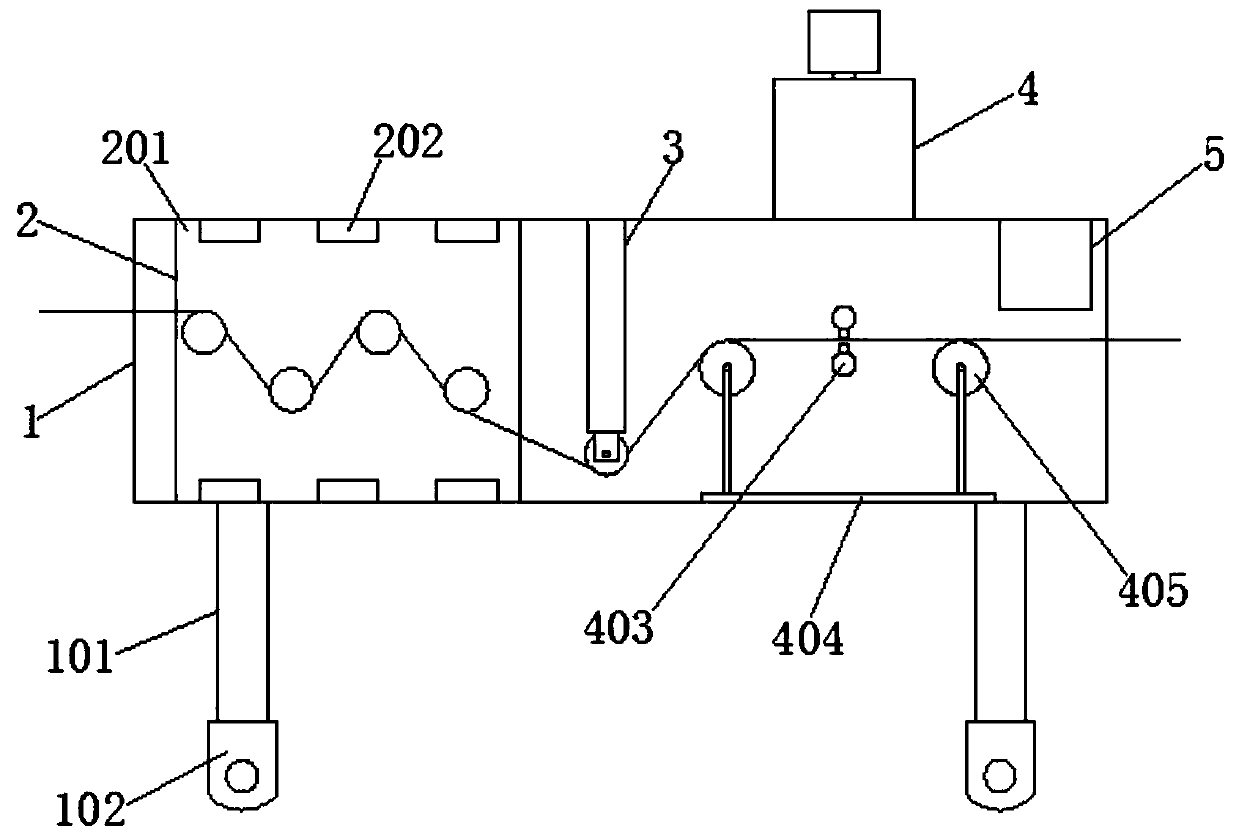

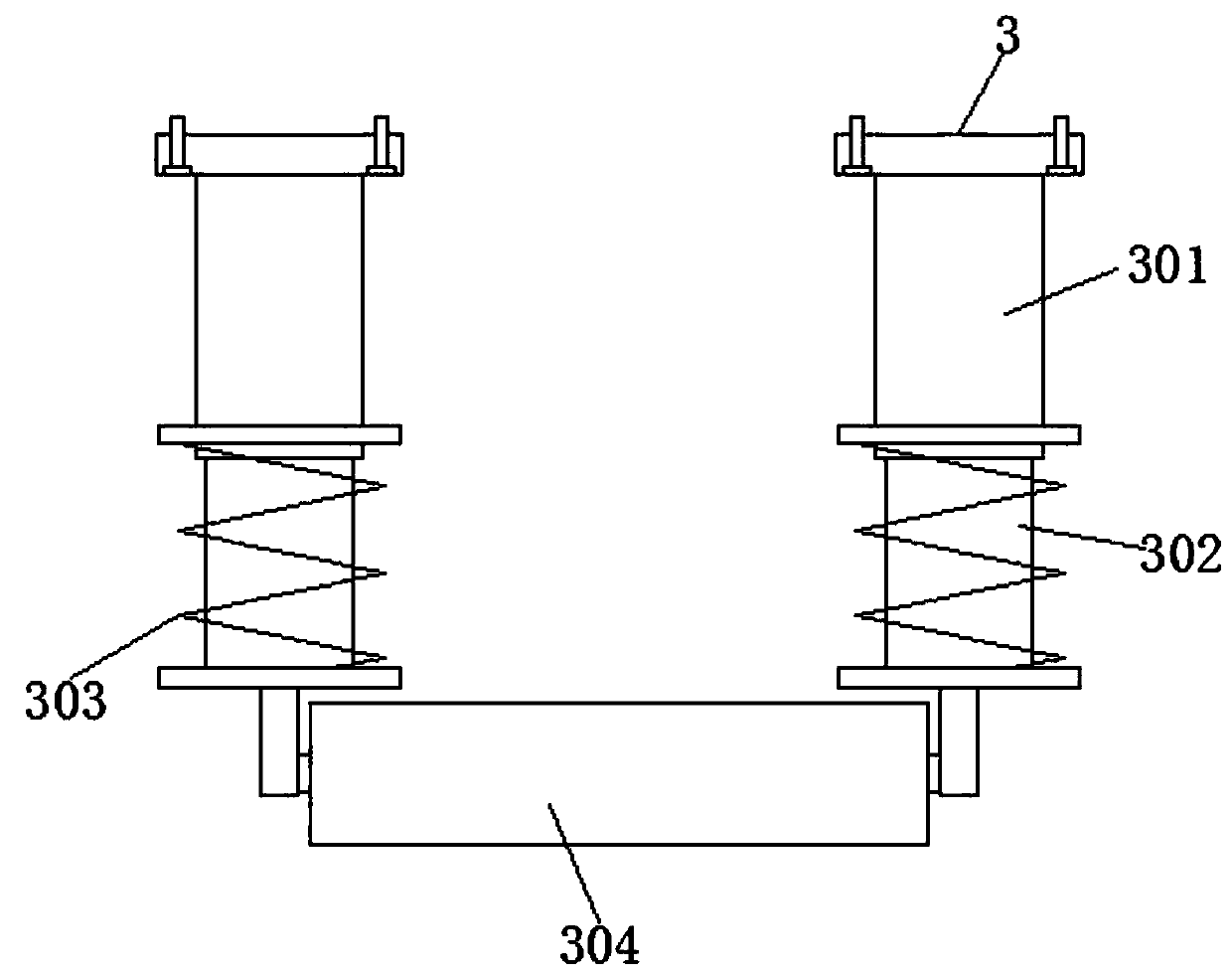

[0028] like Figure 1-6 As shown, the present invention provides a technical solution: a sterilizing device on a non-woven fabric production line, including a casing 1, a support rod 101 and a connecting ear 102, the bottom of the casing 1 is symmetrically welded with a support rod 101, and the support rod 101 is symmetrically welded. One end of the rod 101 is fixedly connected with a connecting ear 102 , and the inside of the casing 1 is equipped with a No. 1 sterilization mechanism 2 , a tensioning mechanism 3 , a No. 2 sterilization mechanism 4 and a drying mechanism 5 .

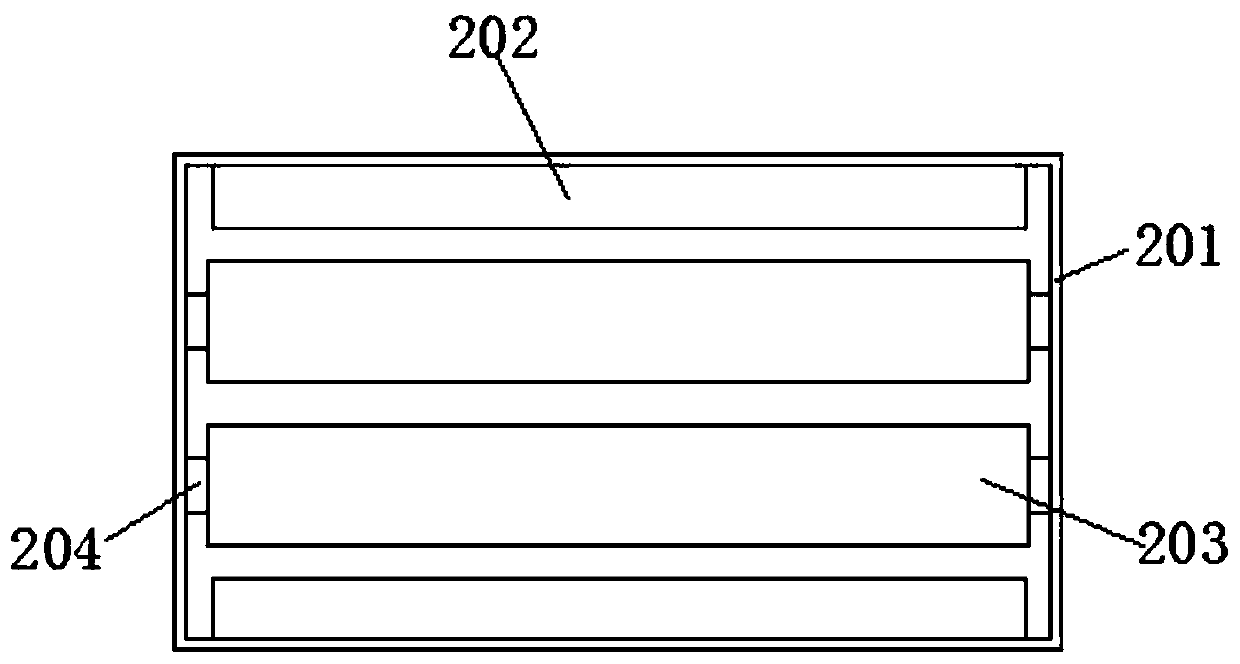

[0029] The No. 1 sterilization mechanism 2 includes a housing 201 , an ultraviolet germicidal lamp 202 , a roller 203 and a bearing 204 .

[0030] Both ends of the housing 201 are conductive structures, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com