Impact powder-grinding and insect-killing machine with water-cooling function

A technology of impact mill and insect killer, which is applied to the device, application, and grain treatment of catching or killing insects, and can solve the problems of motor bearing damage, low impact strength, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

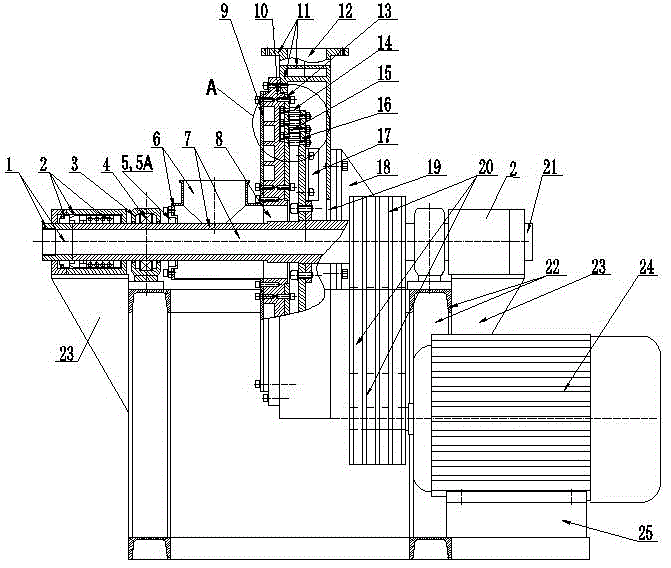

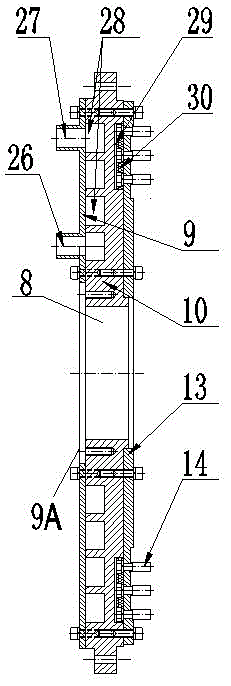

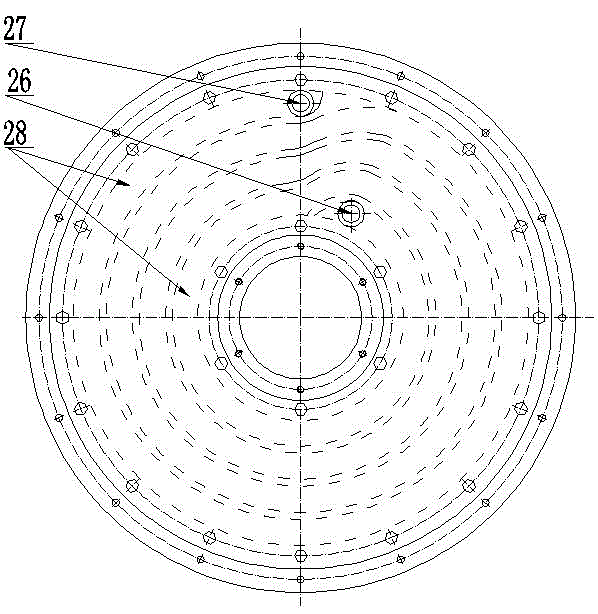

[0030] Such as Figure 1 to Figure 7 As shown, the impact mill insecticide with water-cooling function of the present invention includes a support frame 22, a motor 24, and the front and rear sides of the upper end of the support frame 22 are respectively fixedly connected with a support frame 18 in a welding manner, and the support frame 18 is fixedly connected. There is an organic casing 11, the side wall of the casing 11 is provided with a discharge port 12, a rotor component is arranged inside the casing 11, and a stator component is fixedly connected to the casing 11; the rotor component includes an annular rotor disc 16 and a rotor pin 15 , the stator component includes an annular casing cover plate 10, a disc-shaped stator plate 13 and a stator pin 14, the stator component is fixed on the left end face of the casing 11 through the casing cover plate 10; the rotor pin 15 and the stator pin 14 is provided with a gap; the motor 24 is connected to the rotor part in transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com