Device for optimizing the feed function of the ring gear of a differential with regard to maximum volume flow rate

一种盘形齿轮、体积流量的技术,应用在传动装置零件、齿轮润滑/冷却、皮带/链条/齿轮等方向,能够解决输送量减小、没有公开输送功能等问题,达到输送功能优化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

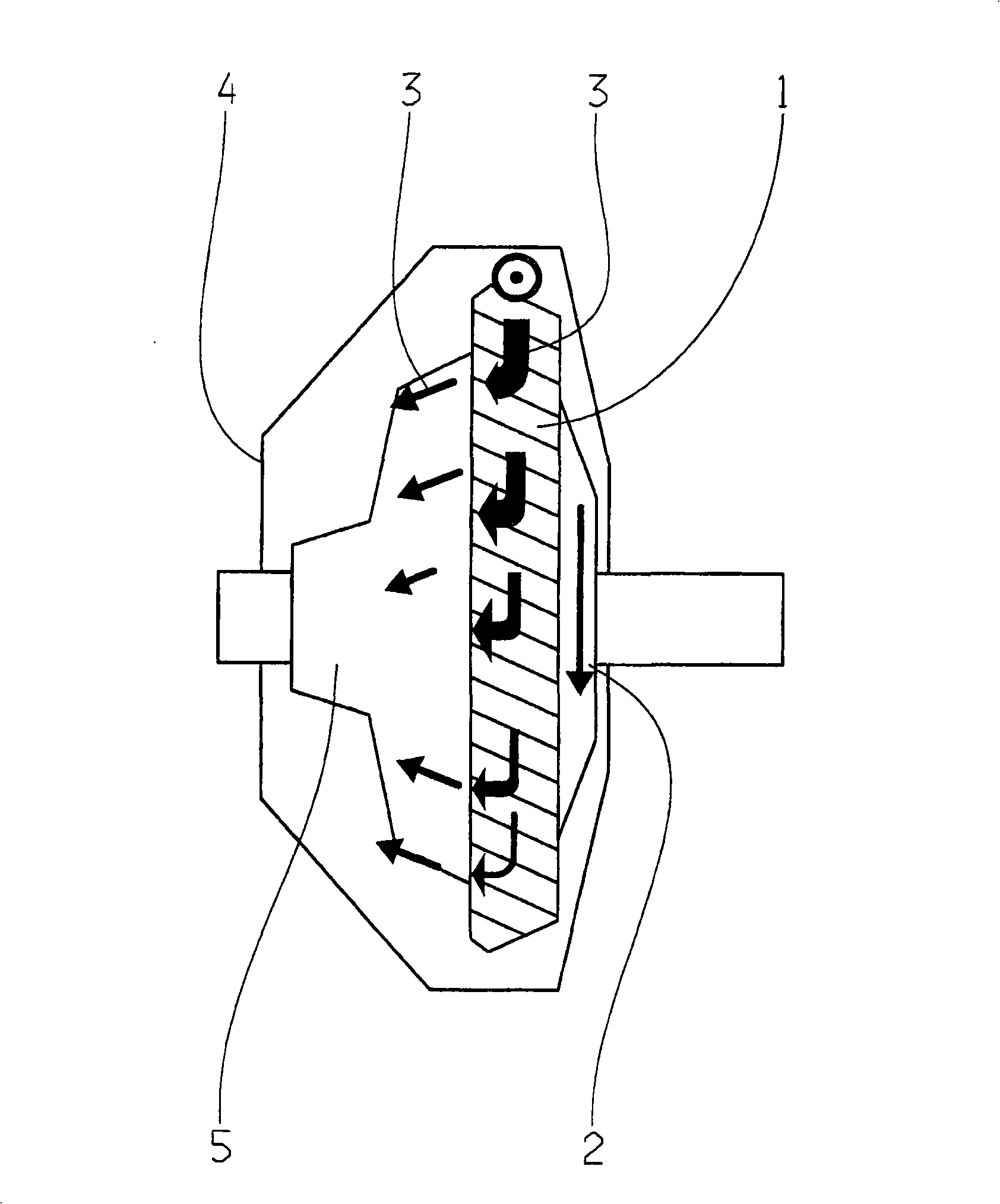

[0011] exist figure 1 A differential is shown which contains a ring gear 1 which rotates in the direction of the arrow 2 in the drawing. The differential case and differential cover are denoted with 5 and 4 respectively. The oil is entrained by the ring gear toothing in the circumferential direction due to the rotational movement of the ring gear 1 and is discharged at the speed of the ring gear 1 . The oil flow formed here is indicated by arrow 3 in the drawing. As can be seen from the figure, the oil flow is swirled due to the open design of the differential, so that the available delivery rate is significantly reduced.

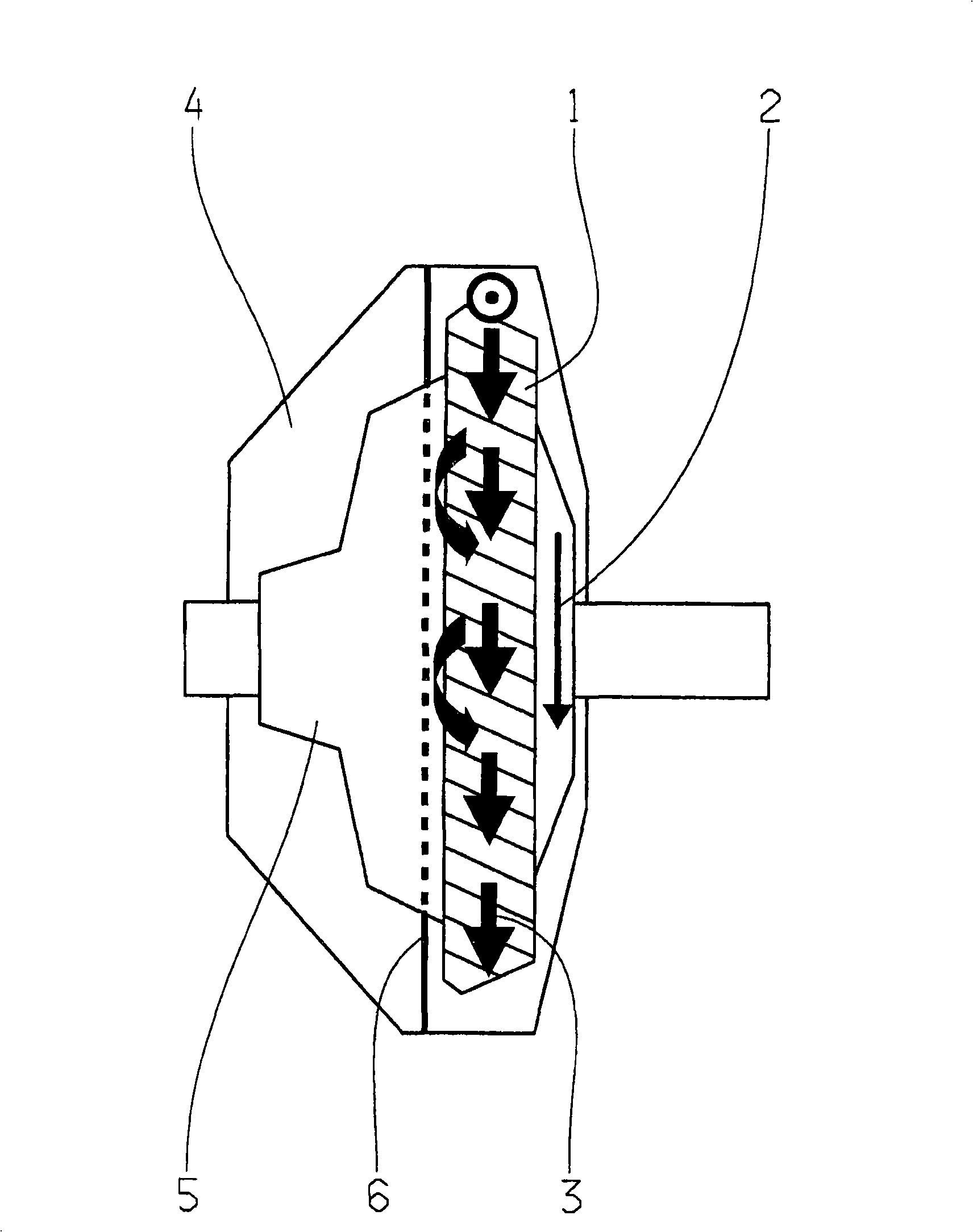

[0012] In order to solve this problem, it is proposed according to the invention that, viewed in the axial direction, next to the ring gear 1 on the side of the ring gear facing the differential carrier 5 and coaxially with the ring gear with the smallest possible A spacer 6 is mounted at a distance, which serves as an oil wiper ring and which seals with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com