Patents

Literature

41results about How to "Reduce trial production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

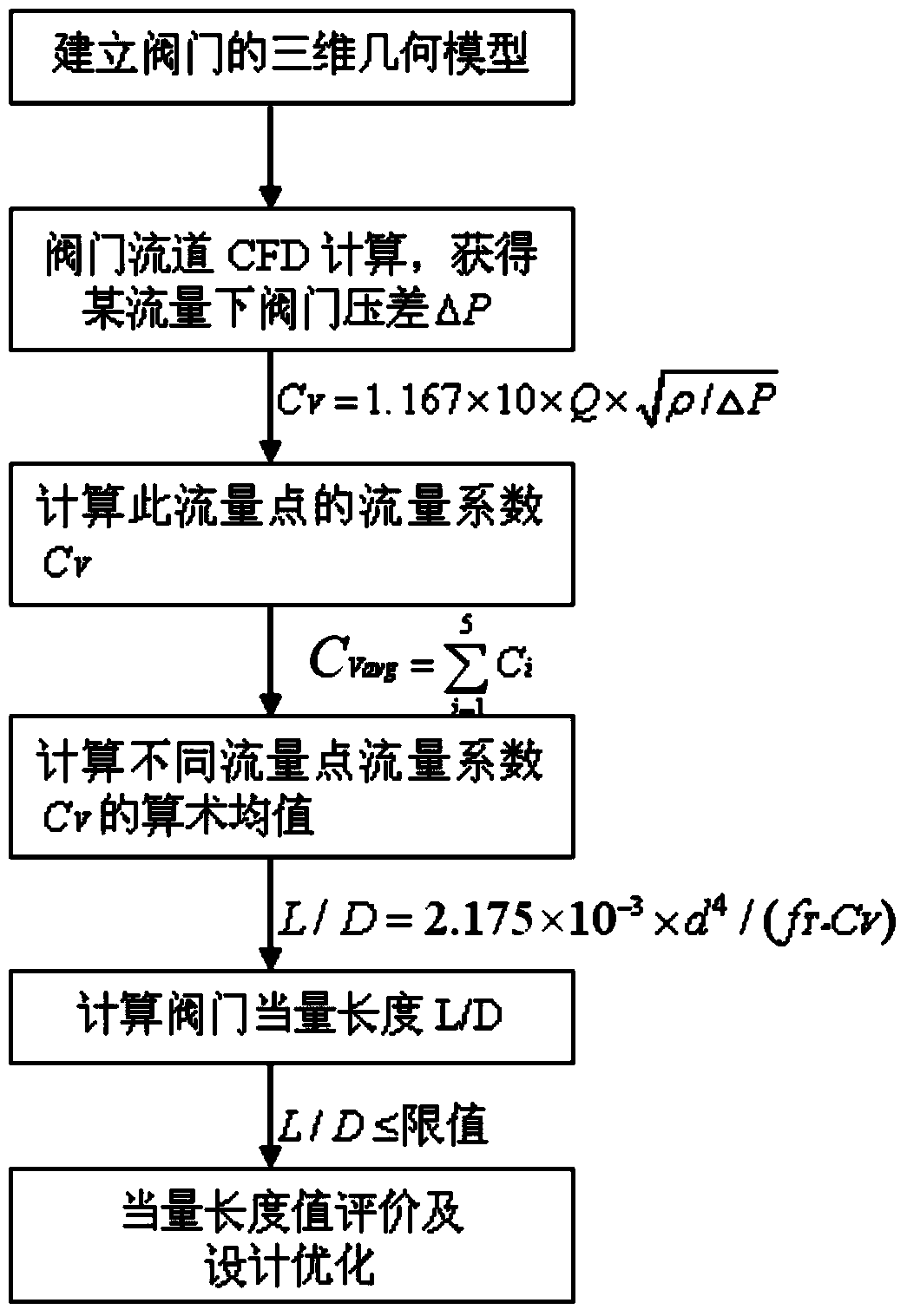

CFD (computational fluid dynamics) based method for computing equivalent length of valve

ActiveCN103729505AAvoid wastingLong development cycleSpecial data processing applicationsTest measurementSoftware engineering

The invention relates to a CFD (computational fluid dynamics) based method for computing equivalent length of a valve. The method includes the steps: establishing a three-dimensional assembly model of the valve, after an extension section is added to an entry and exit position of the valve model, importing the model into CFD software, working out pressure values of multiple working conditions by analog calculation of the CFD software and computing corresponding pressure differences; according to the pressure differences, respectively computing multiple flow coefficient values through a formula, and then computing an average flow coefficient value; computing an equivalent length value of the valve through a formula. Flow performance data of the valve are obtained by the aid of CFD technological analogue simulation, only drawings are needed to be used for completion in a virtual prototype phase in the initial stage of development, and the situations that manpower and material resources are wasted and development cycle is prolonged due to the fact that the valve must be manufactured and subjected to test measurement in order to detect flow performance of the valve in the prior art are avoided, so that development efficiency is greatly improved and cost is saved by the method.

Owner:NEWAY VALVE SUZHOU

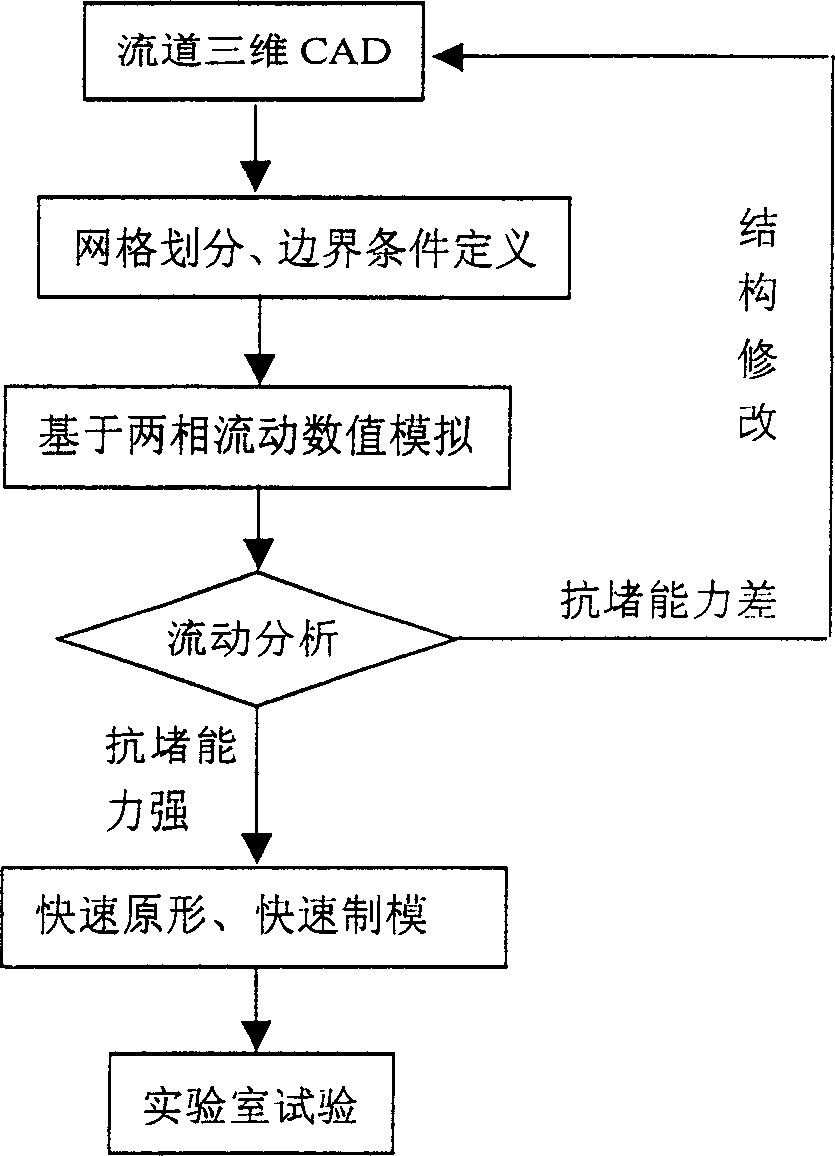

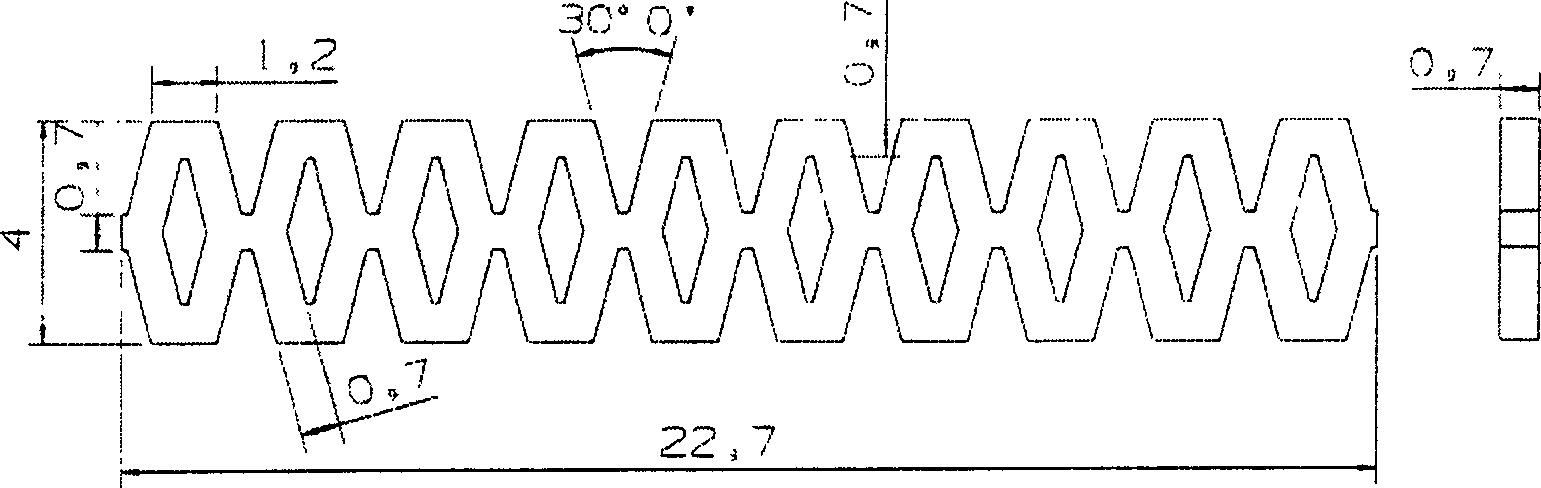

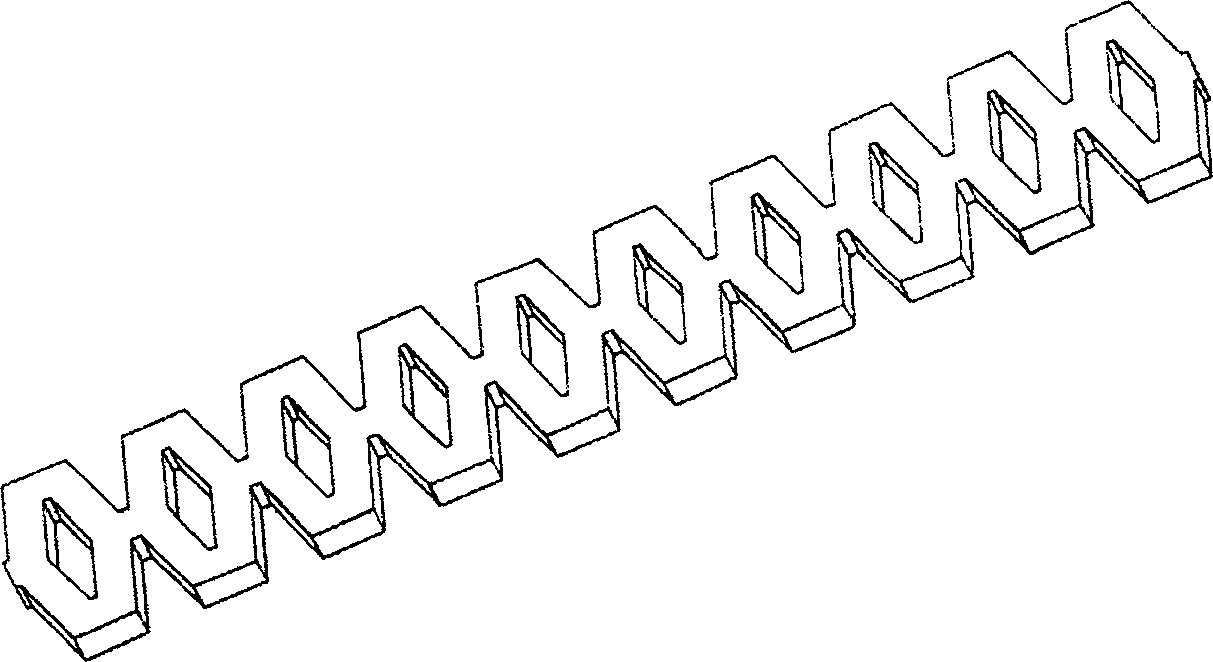

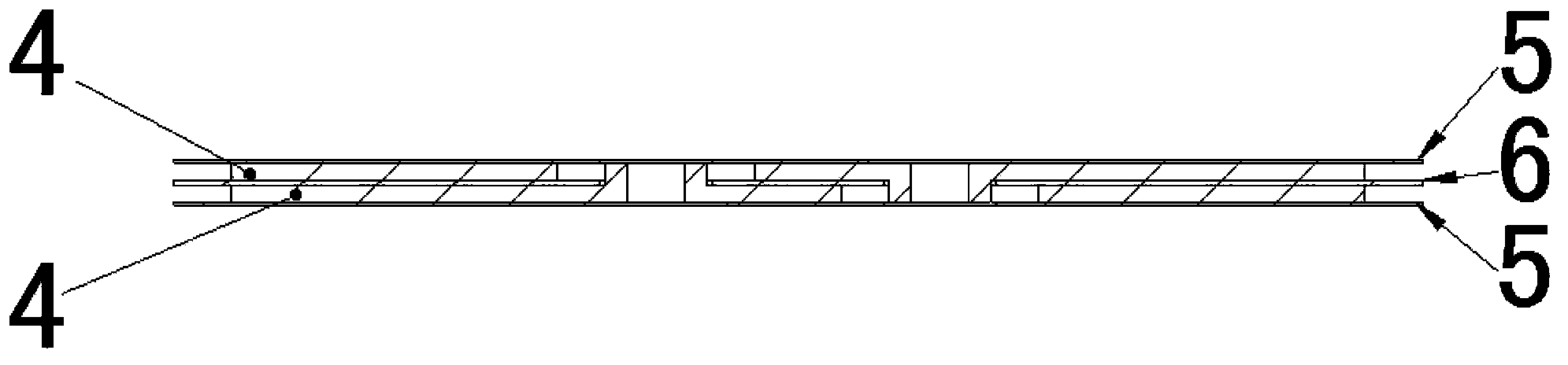

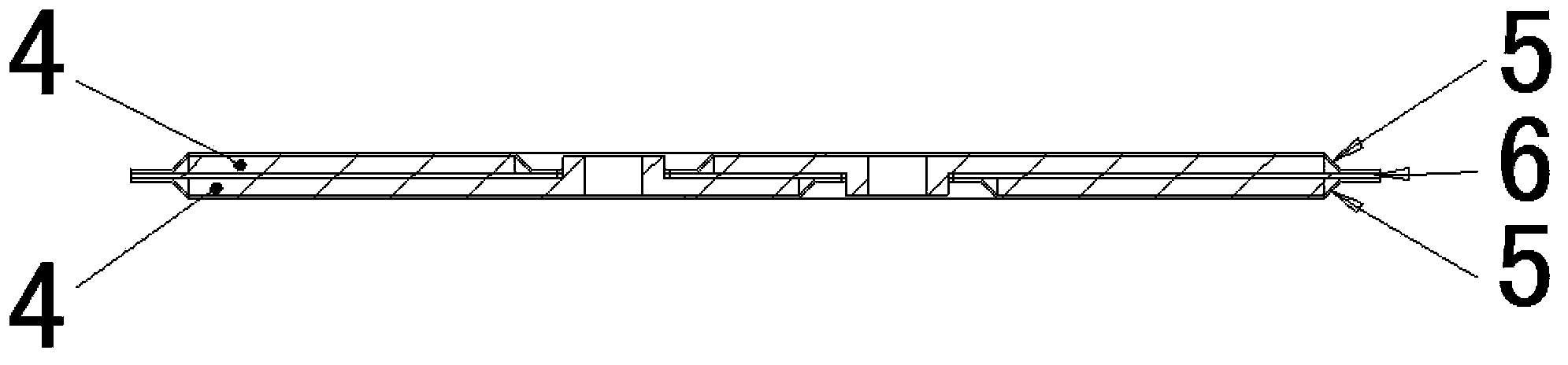

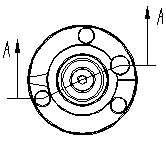

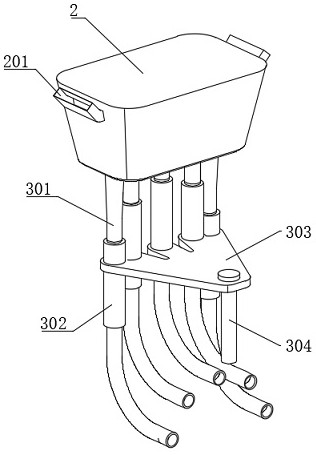

Anti-block designing method of drip irrigation tool based on two-phase simulated flow

InactiveCN1817093AImprove anti-clogging performanceHigh shaping precisionClimate change adaptationWatering devicesMathematical simulationDrip irrigation

An anti-blocking design method based on two-phase stream simulation for the drip irrigator features that according to the mathematical simulation about the two-phase stream in the flow field of said drip irrigator, the region in the flow channel, where the solid is easily deposited, is analyzed out and the influence of the flow channel structure to the delivery and deposition of solid is further analyzed. On this basis, the structure parameters of flow channel are modified and said simulation is repeated until no obvious deposition of solid.

Owner:HUAZHONG UNIV OF SCI & TECH

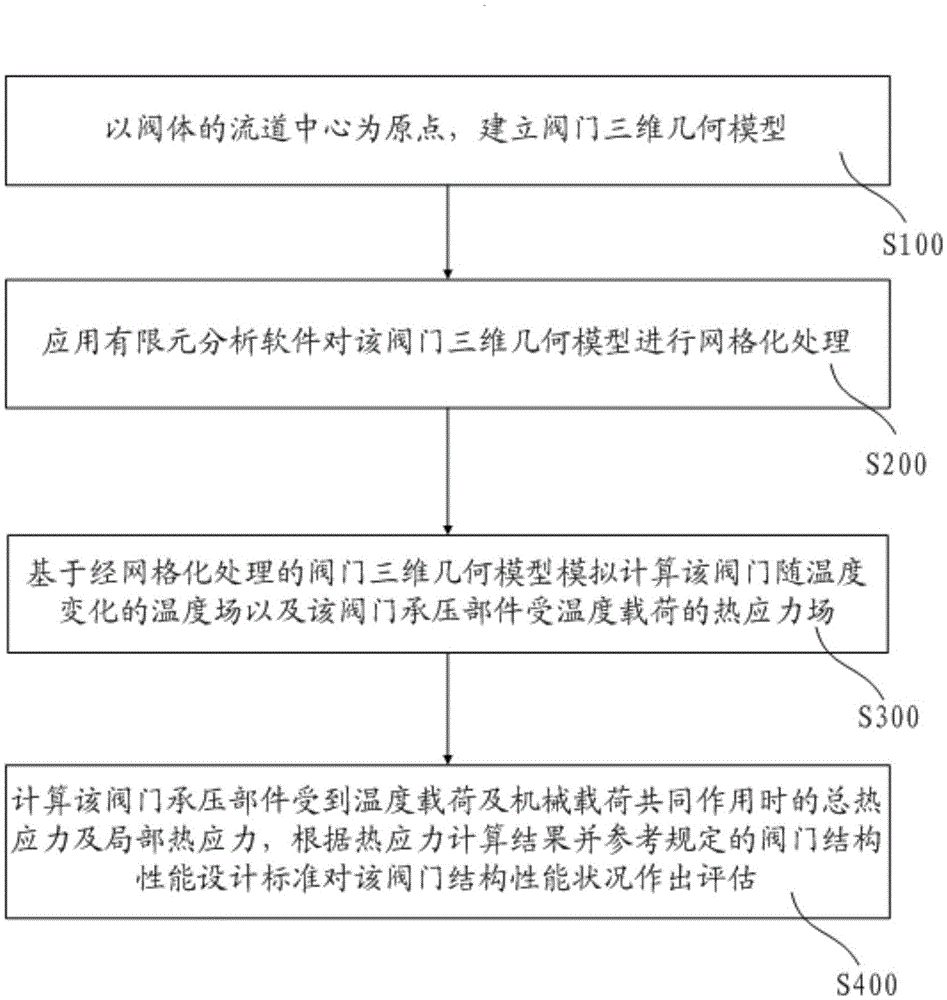

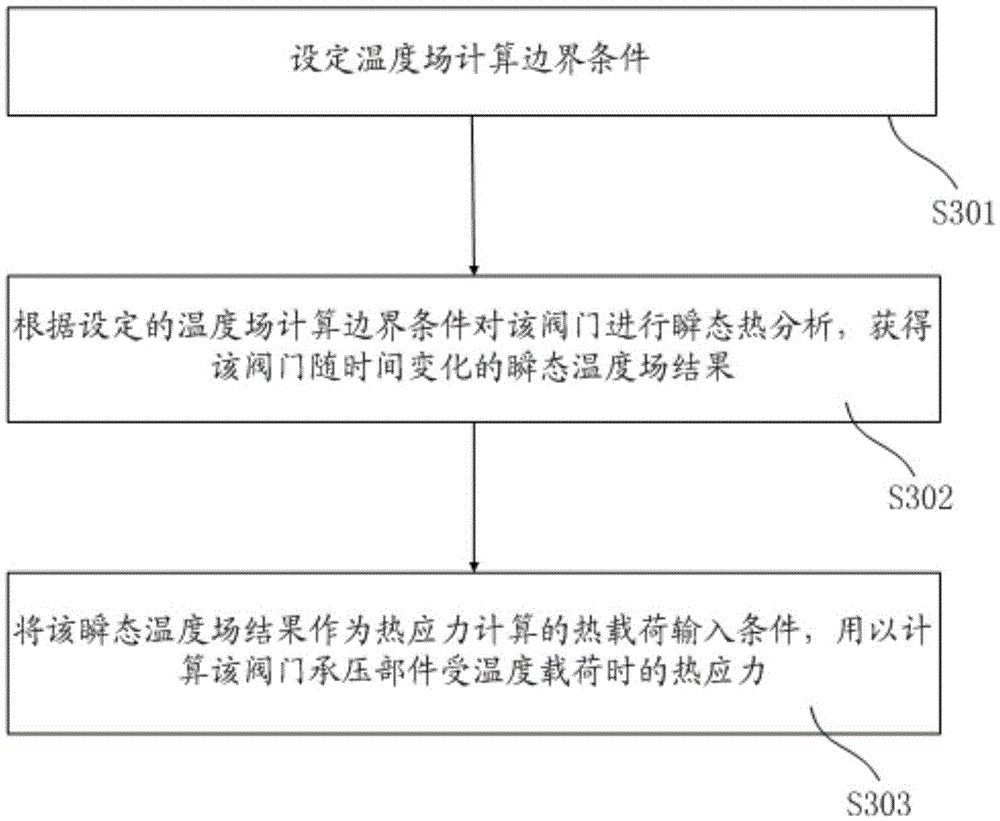

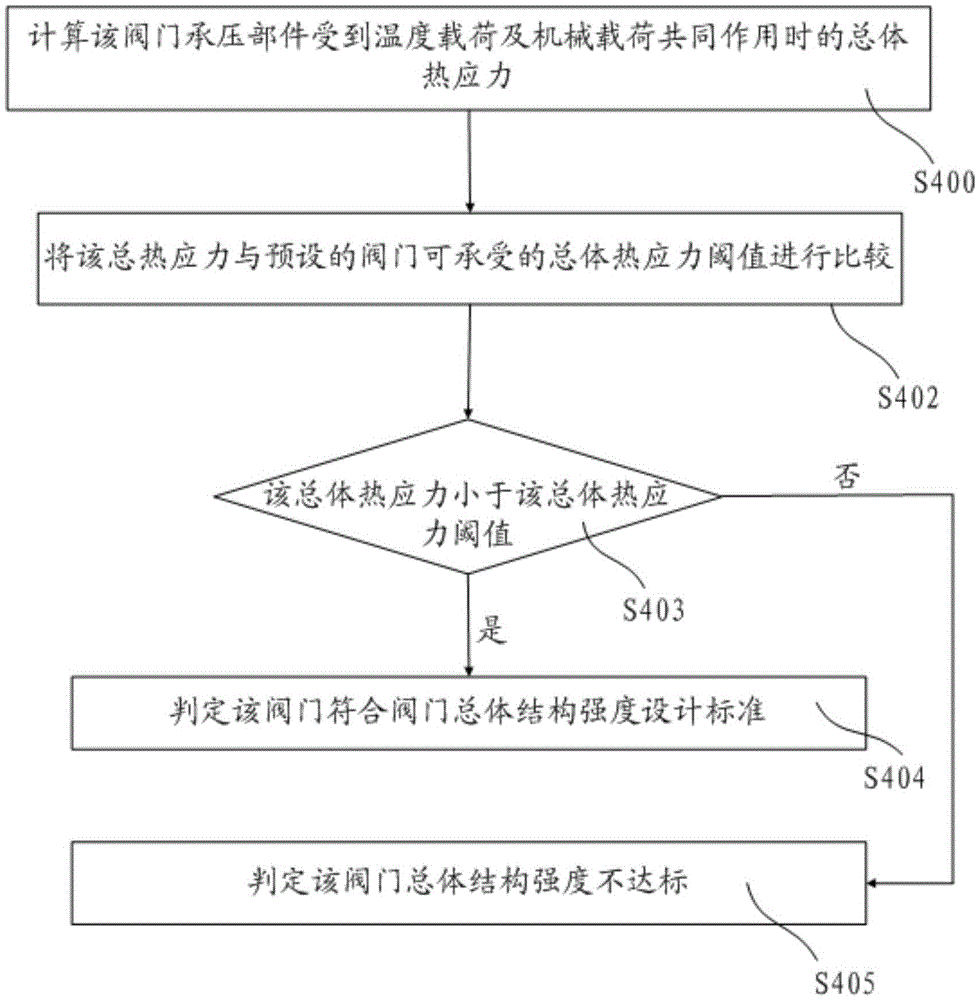

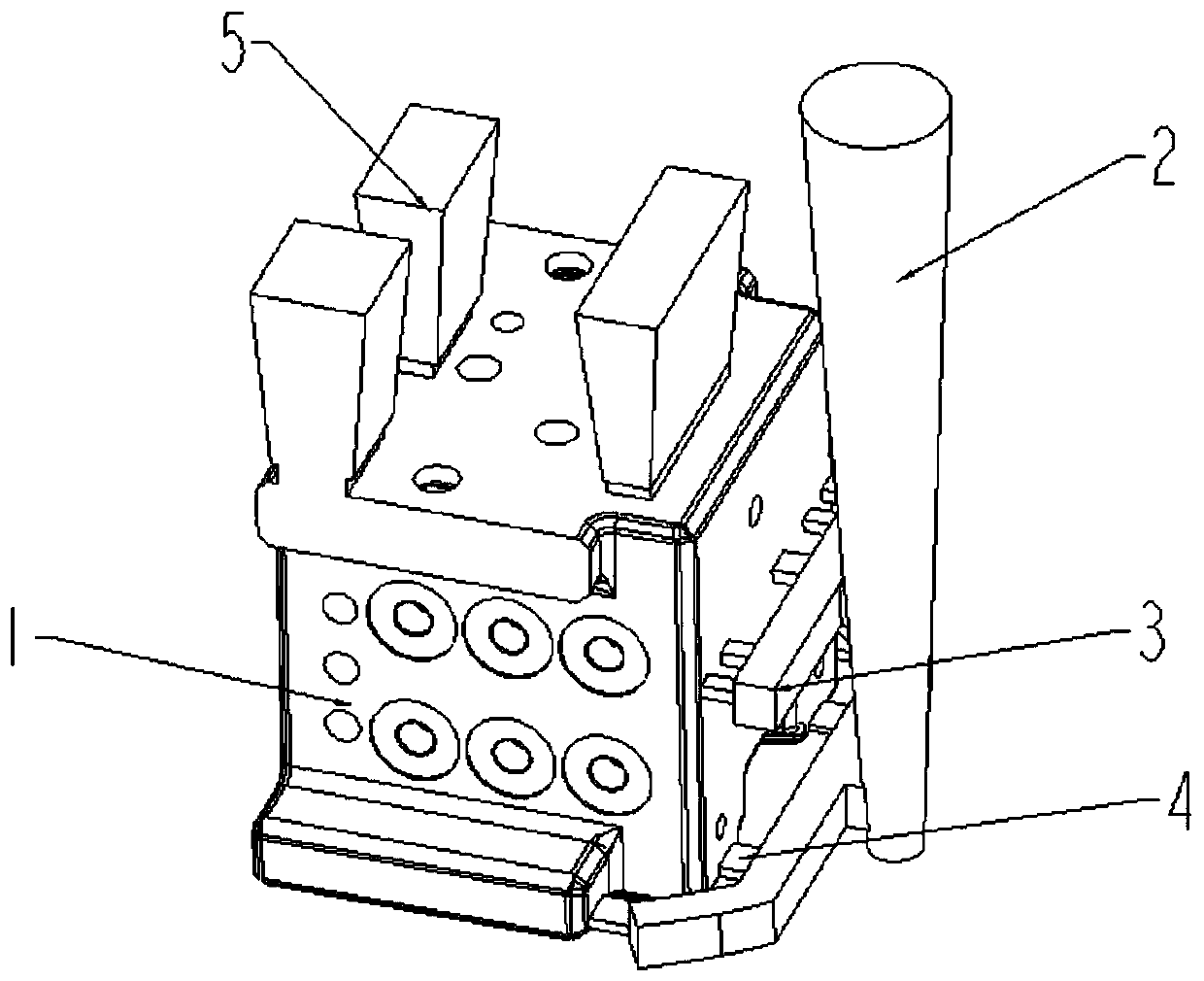

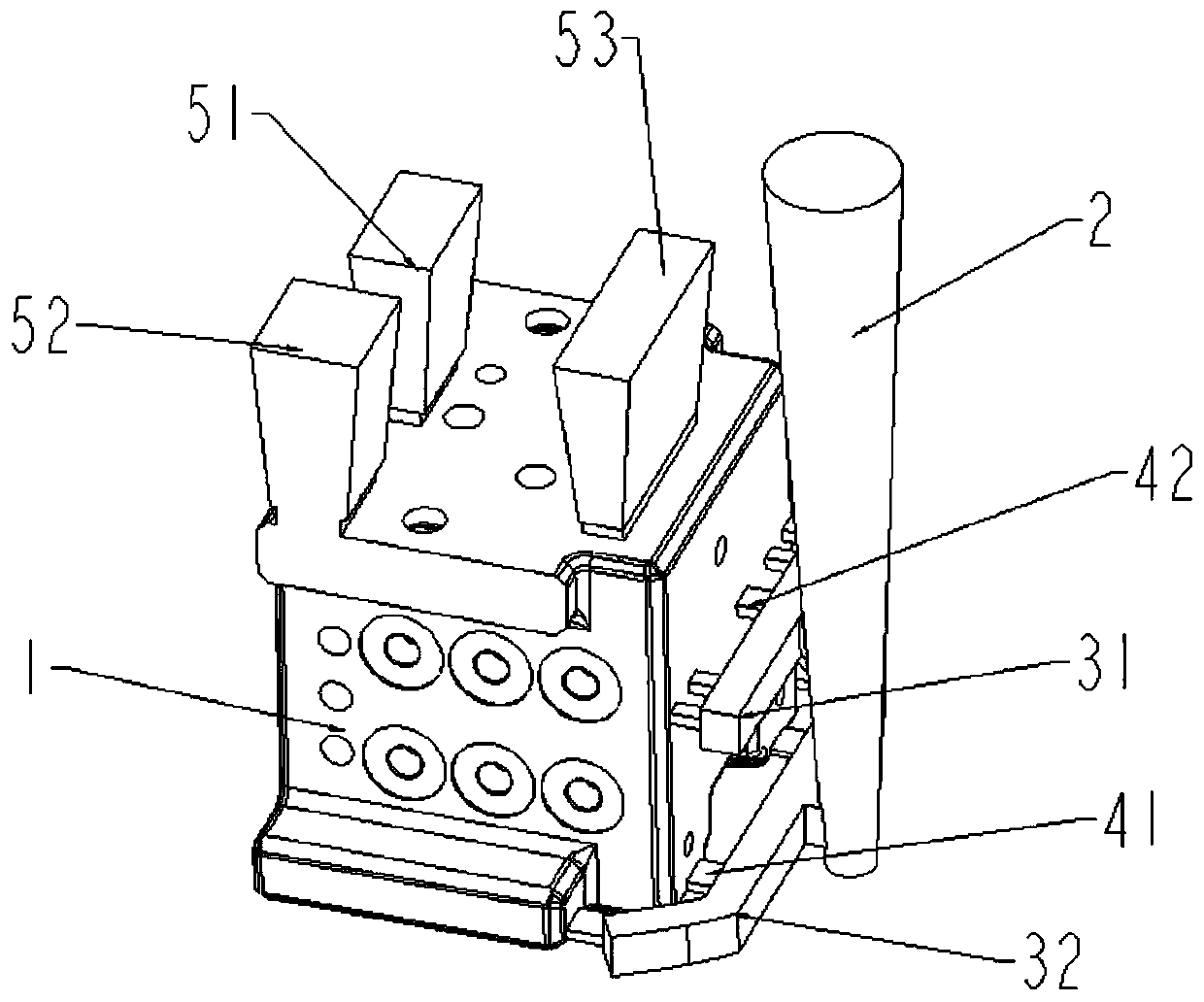

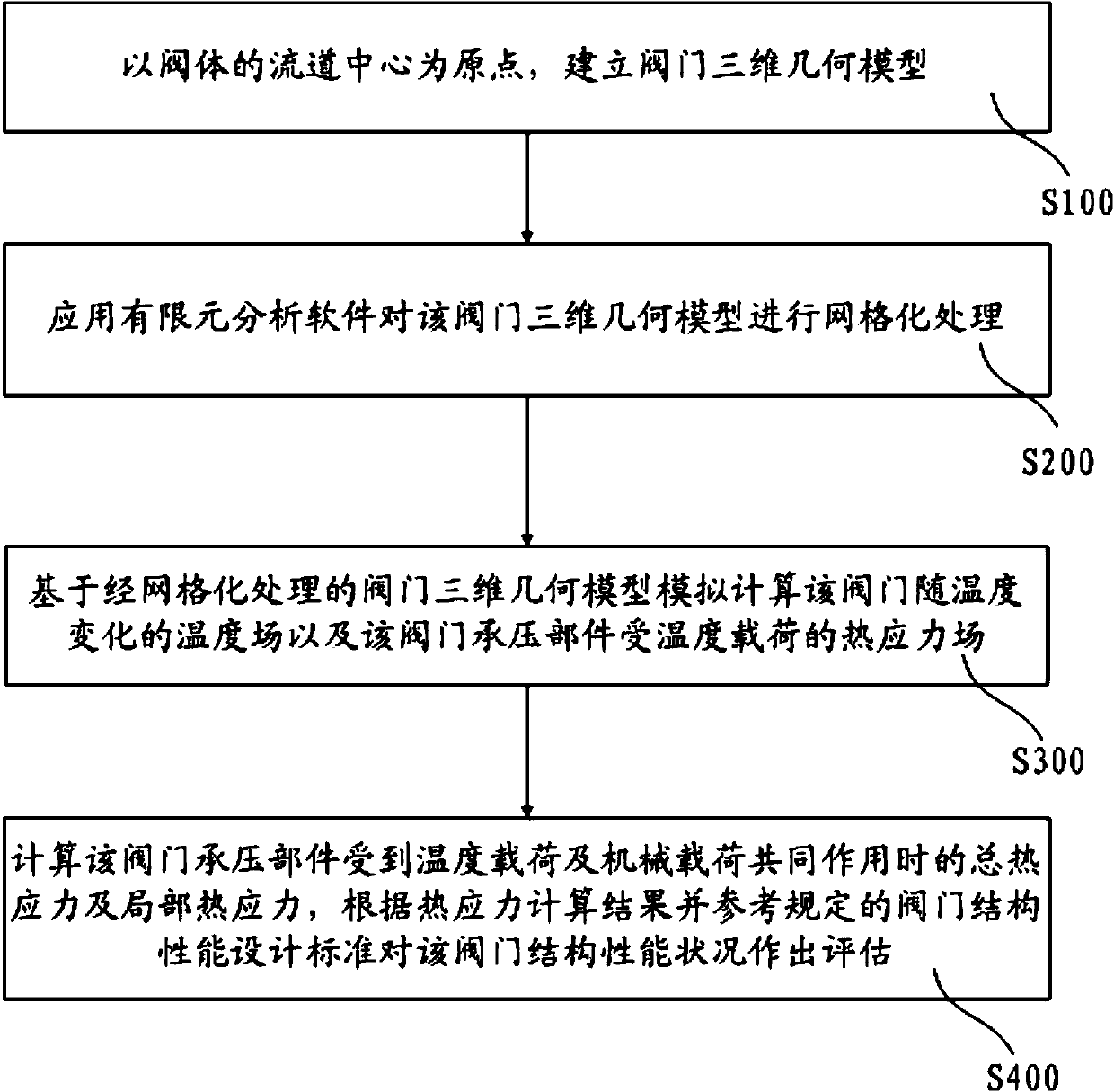

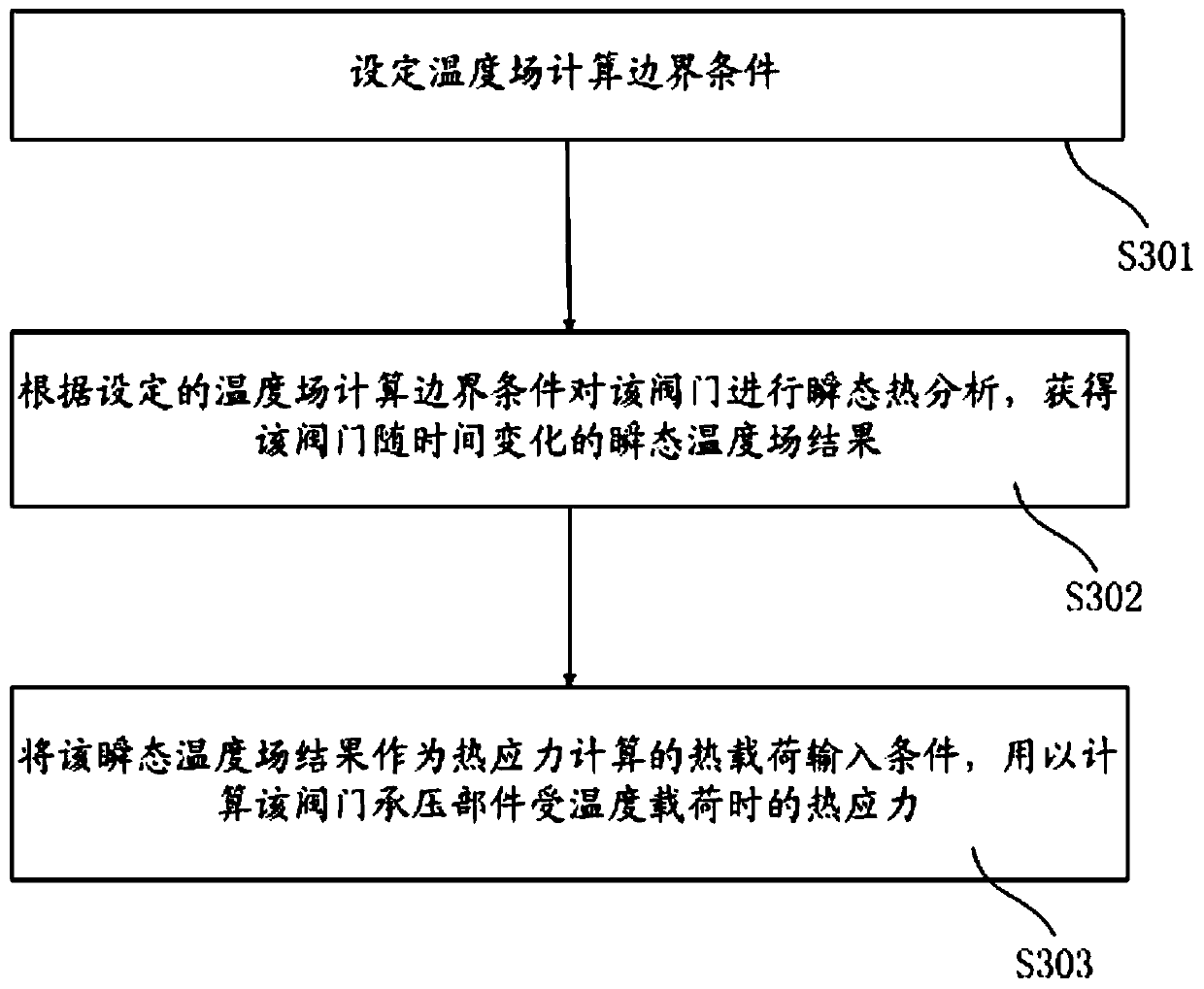

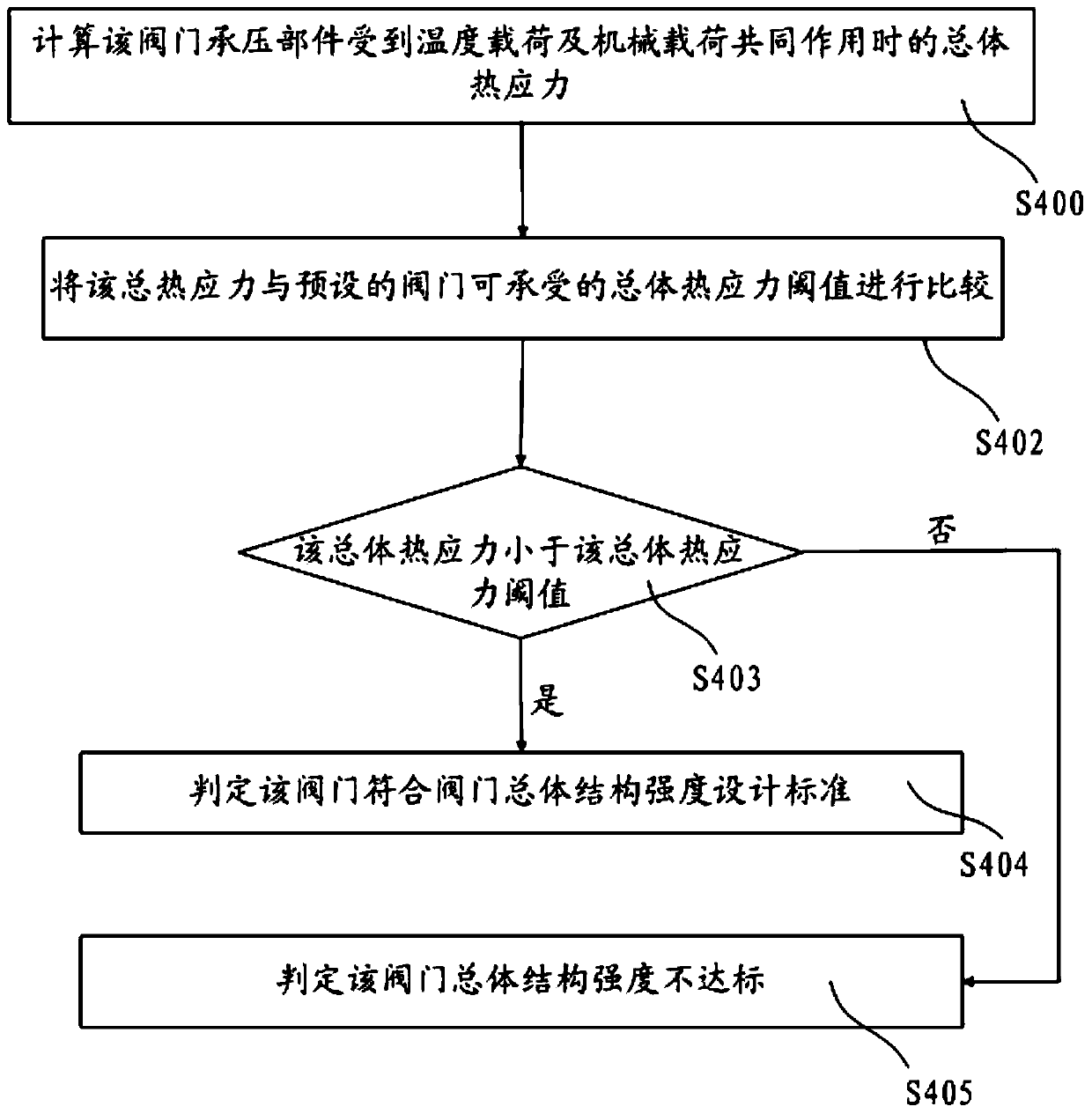

Method and system for evaluating structural performance of high-temperature valve based on valve simulation model

ActiveCN105488292AEliminate potential safety hazardsAvoid elastic failureDesign optimisation/simulationSpecial data processing applicationsAssessment methodsStrength design

The invention discloses a method and a system for evaluating structural performance of a high-temperature valve based on a valve simulation model. The method comprises the following steps of establishing a three-dimensional geometrical model of the valve with the center of a runner of a valve body as an origin; applying finite element analysis software to carry out grid processing on the three-dimensional geometrical model of the valve; carrying out analog computation on a temperature field of the valve, which changes with the temperature, and a hot stress field which bears temperature load based on the three-dimensional geometrical model of the valve; and computing total hot stress and local heat stress when a valve bearing component bears a combined action of the temperature load and the mechanical load, and evaluating the structural performance condition of the valve according to a hot stress computation result and reference to the specified strength design standard of the high-temperature valve structure. According to the method and the system, valve design parameters needed by the high-quality valve with reasonable structural design and reliable structural strength is obtained through modeling calculation, so that the safety for running of a nuclear power plant is improved, the experimental manufacturing cost of a model machine is reduced, and the valve product development cycle is shortened.

Owner:中广核工程有限公司 +1

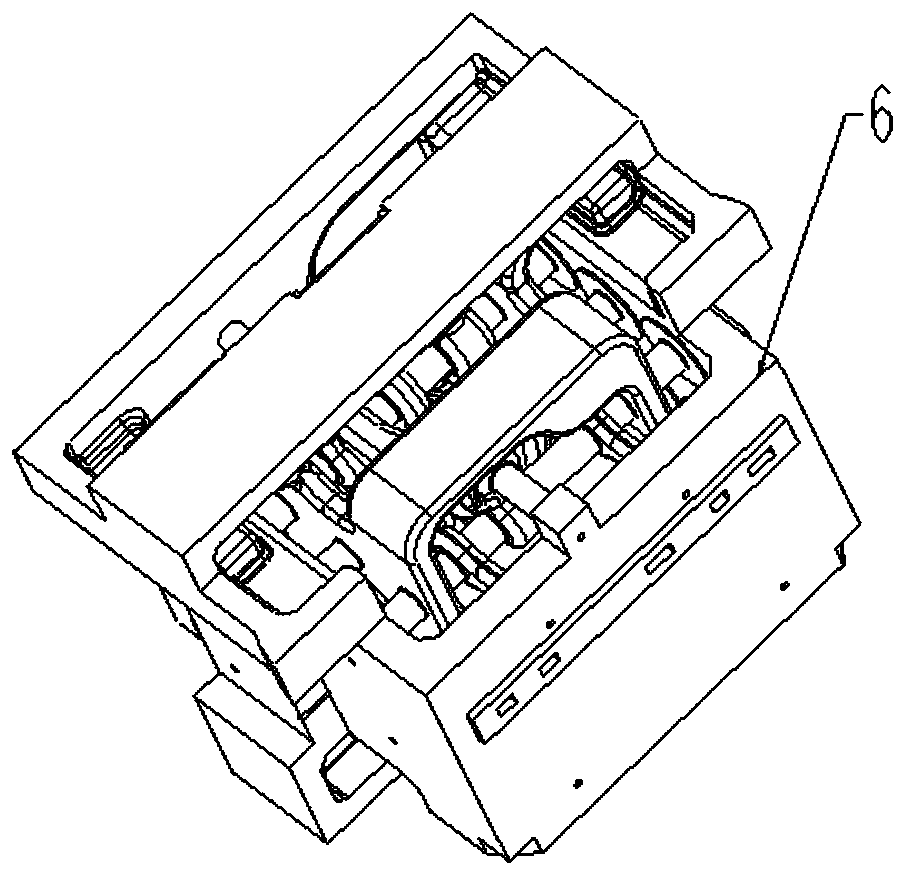

Casting method and system suitable for integral multi-way valve based on 3D printing

PendingCN111468678AReduce breakageImprove consistencyAdditive manufacturing apparatusFoundry mouldsMold fillingEngineering

The invention discloses a casting method and system suitable for an integral multi-way valve based on 3D printing, and belongs to the technical field of valve casting. According to the casting methodand system, inner sprues of multiple layers, multiple cross gates connected with the inner sprues of all the layers and a sprue connected with the multiple cross gates are determined according to thestructural parameters of the to-be-cast integral multi-way valve, and the integral sand mold is printed through 3D printing technology, so that the multi-layer combined type pouring casting method andthe corresponding casting system are achieved, the influences of gravity, scouring force and the like in the liquid mold filling process can be dispersed and balanced, and the casting defects of sandcore breakage, internal defect flashes, main valve hole bending and the like are reduced. And the consistency between the integral sand molds through 3D printing is good, no bonding gap exists in theintegral sand molds, the quality stability and the surface quality of a valve body casting obtained after pouring can be guaranteed, meanwhile, rapid casting of the integral hydraulic valve can be achieved, the integral hydraulic valve is suitable for batch and normalized manufacturing, and rapid upgrading of large-scale integral hydraulic multi-way valve products is better supported.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

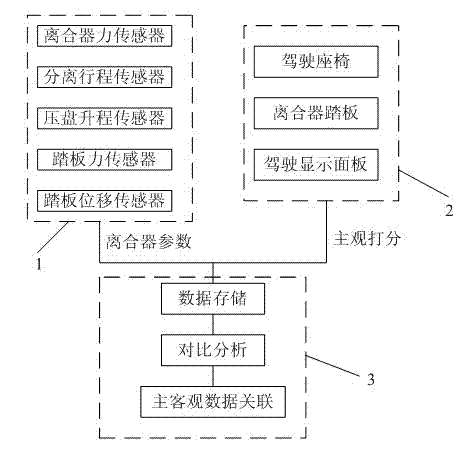

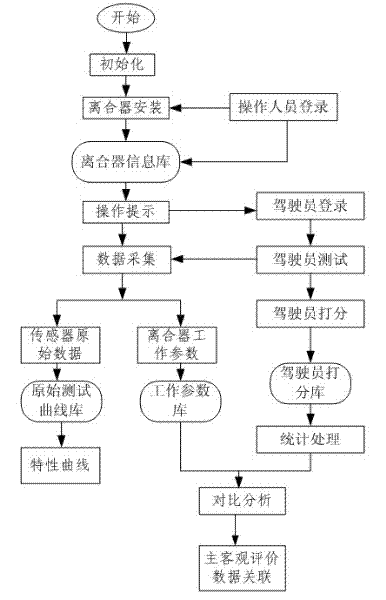

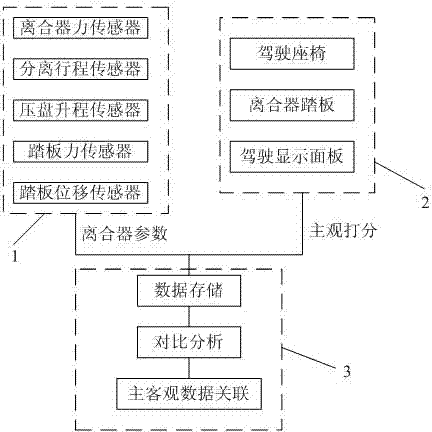

Evaluation method for realizing association between subjective data and objective data of automobile clutch

InactiveCN102507185AShorten the development cycleReduce trial production costsMachine gearing/transmission testingClutchDriver/operator

The invention provides an evaluation method for realizing association between subjective data and objective data of an automobile clutch. The method comprises the following steps that: firstly a database is established in a control computer, and then an operator performs user login on the control computer and sets all information of the experiment; then a test driver performs user login and carries out a separation and combination process test on the automobile clutch according to system prompt, and an objective detection device records and stores the data of each detection sensor of the clutch; after the test is performed once, subjective evaluation scoring for the operating performance of the clutch is carried out, and then the subjective evaluation score is recorded into the database; and after the driver test is finished, the operator can check the test curve of the clutch, carries out contrastive analysis on the association between objective detection parameters and driver subjective evaluation score and evaluates the operating comfortability of the clutch. The method provided by the invention can be used for objectively reflecting the operating performance of different clutches and conveniently eliminating the influence of different vehicle control systems during a real vehicle test.

Owner:HANGZHOU DIANZI UNIV

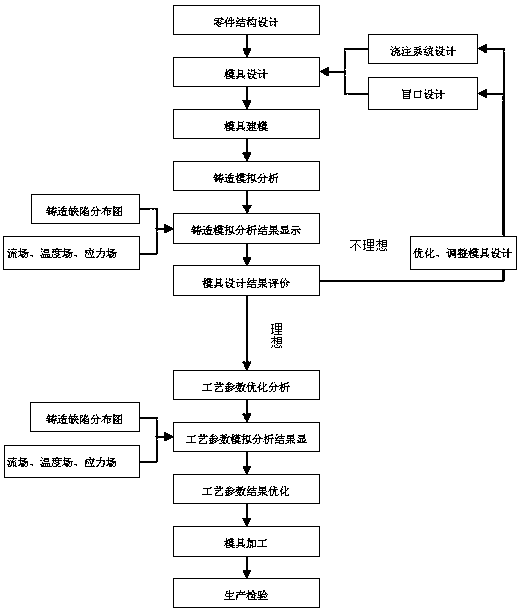

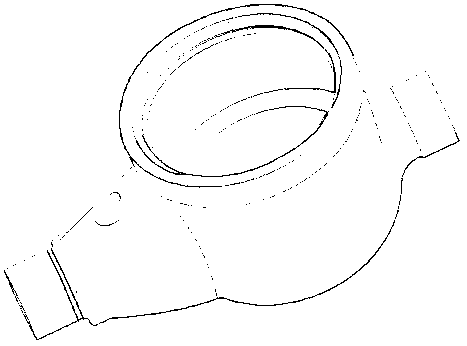

Computer aided design method for thin-wall copper alloy water meter shell casting process

PendingCN110008636AQuality improvementMeet structural requirementsGeometric CADDesign optimisation/simulationThin walledCasting defect

The invention relates to a computer aided design method for a thin-wall copper alloy water meter shell casting process. The computer aided design method comprises the following steps: designing parts;designing a mold; carrying out mold modeling; carryinhg out casting simulation analysis; displaying a casting simulation analysis result; optimizing a design result; carrying out process parameter optimization analysis; displaying a process parameter simulation analysis result; optimizing a process parameter result; processing a mold; carrying out production inspection; the method also comprisesstructure optimization and parameter optimization. According to the design method, the quality of the casting can be improved, the casting defects of the casting can meet the structural requirements,the trial-manufacture time of new products is greatly shortened, and the trial-manufacture cost is reduced.

Owner:FUZHOU UNIV

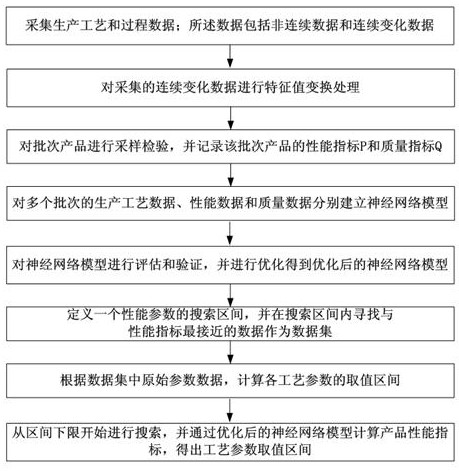

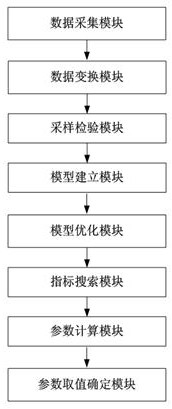

Resin process prediction method and device based on product performance and process data model

InactiveCN113919601AReduce trial production costsImprove stabilityForecastingResourcesData setQuality data

Disclosed is a resin process prediction device based on product performance and process data model which comprises the following steps: collecting a production process and process data; transforming characteristic value of the collected continuous change data; carrying out sampling inspection on batch products, and recording performance indexes and quality indexes of the batch products; respectively establishing neural network models for the production process data, the performance data and the quality data of the plurality of batches; evaluating and verifying the neural network model, and optimizing the neural network model; defining a search interval of a performance parameter, and searching data closest to the performance index in the search interval as a data set; according to the original parameter data in the data set, calculating a value interval of each process parameter; and searching from the lower limit of the interval, and calculating product performance indexes through the optimized neural network model to obtain a process parameter value interval. According to the invention, the problems of difficult optimization of the current production process and low efficiency of the formula experiment process are solved, and the product quality and the performance stability are improved.

Owner:YANTAI JIERUI NETWORK TRADING

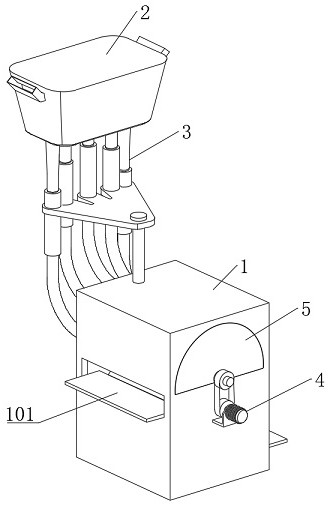

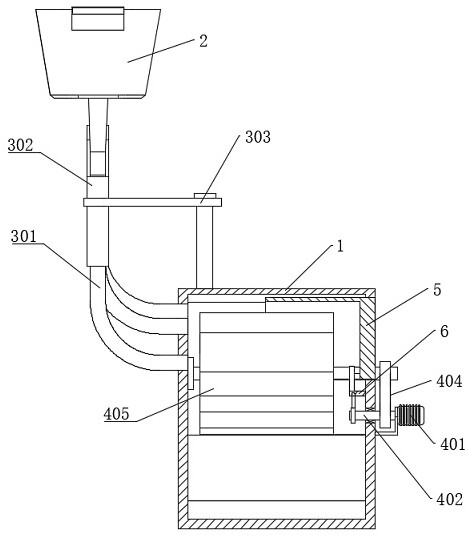

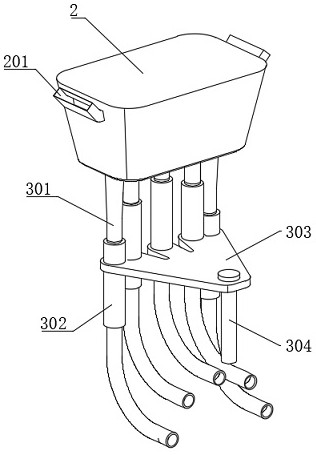

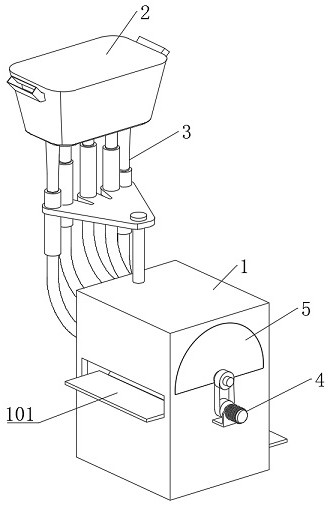

Rapid cigarette rapid packaging device with automatic filling function

ActiveCN112971189AReduce gapImprove uniformityTobacco preparationCigarette manufactureStructural engineeringMechanical engineering

The invention discloses a rapid cigarette rapid packaging device with an automatic filling function, and belongs to the field of cigarette processing. The rapid cigarette rapid packaging device with automatic filling function comprises a cigarette making machine body and a cut tobacco pressing box fixedly installed at the front end of the cigarette making machine body, and a cigarette driving assembly is installed in the cigarette making machine body; the lower end of the cut tobacco pressing box is connected with a cut tobacco kneading and filling assembly, the cut tobacco can spirally descend in the cut tobacco kneading and filling pipe under the action of a cut tobacco kneading spiral groove and a cut tobacco kneading inflation ball through mutual cooperation of the cut tobacco kneading and filling assembly, the cigarette driving assemblyand thesmeicircular guard plate, the cut tobacco are kneaded into a roll, gaps between the tobacco shreds are reduced, The uniformity of tobacco shreds filled into the cigarette drums is effectively improved, the cigarette quality is effectively improved, the error of market evaluation is reduced, the cigarette drums are driven to rotate through the cigarette driving assembly at the same time, filling can be conducted on the cigarette drums at the same time, and the filling efficiency is improved.

Owner:湖南叁谐科技发展有限公司

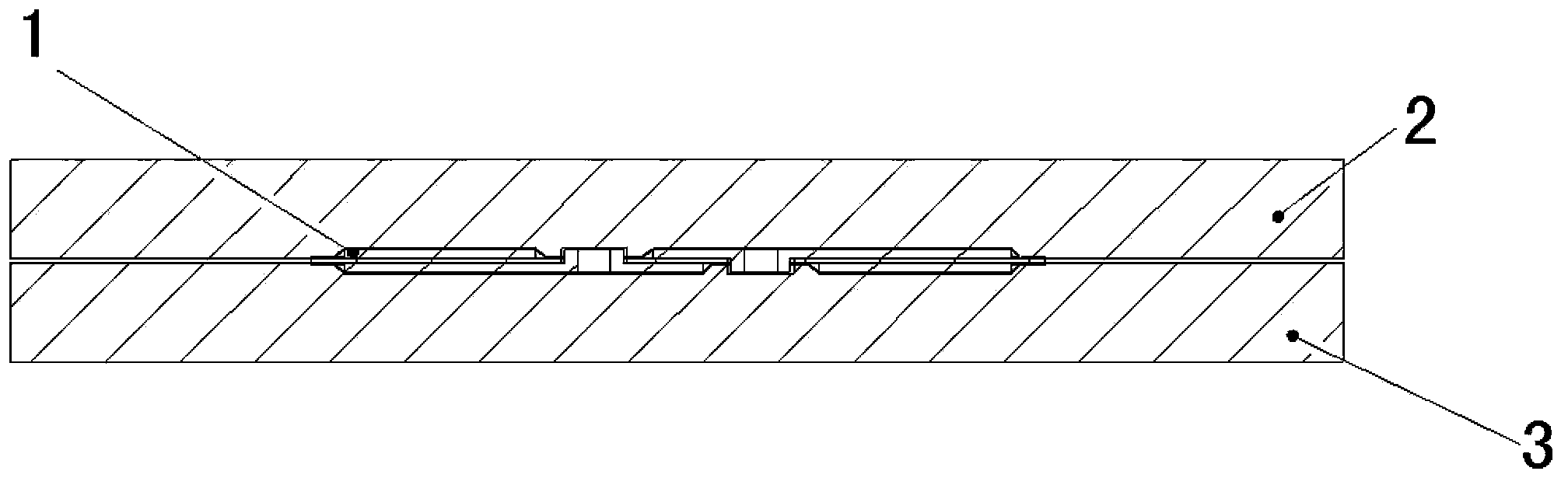

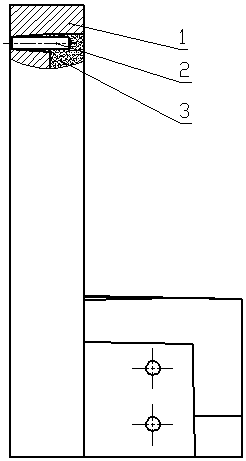

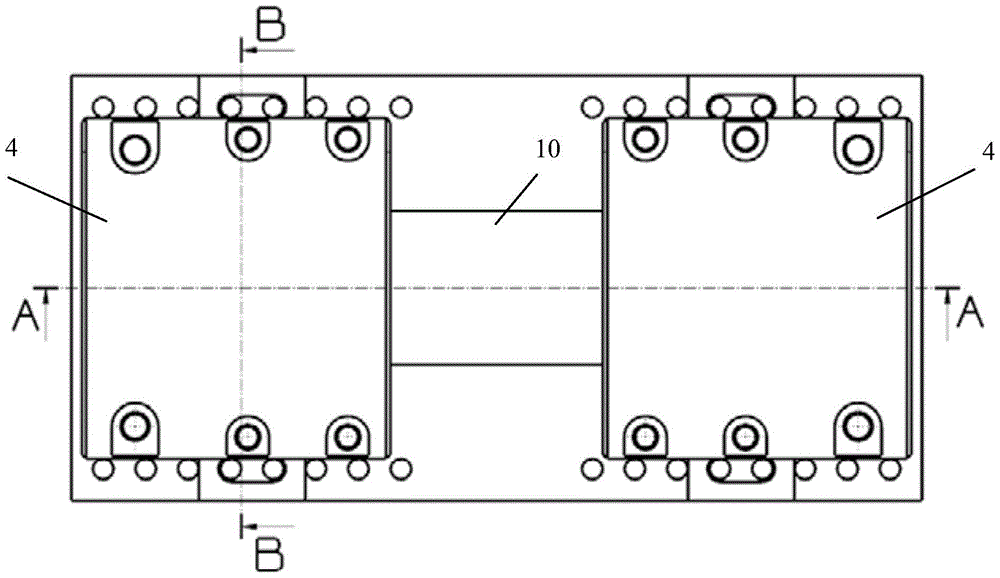

Universal flexible pressing mould for manufacturing laminated busbar

ActiveCN103400661AGood heat transfer functionReduce trial production costsInsulating conductors/cablesBusbarManufacturing engineering

The invention discloses a universal flexible pressing mould for manufacturing a laminated busbar. The universal flexible pressing mould comprises an upper die and a lower die, a busbar to be pressed is arranged between the upper die and the lower die, the upper die comprises an upper die cavity and silicone grease filled in the upper die cavity, and the lower die comprises a lower die cavity and silicone grease filled in the lower die cavity. According to the universal flexible pressing mould for manufacturing the laminated busbar, which is disclosed by the invention, the silicone grease respectively filled in the upper die cavity and the lower die cavity is used for conducting the heat and transferring the pressure and can flexibly form matched concave / convex die structures according to different busbars under the pressure, so that the laminated busbar is pressed and the edge of the laminated busbar is sealed. Therefore, the universal flexible pressing mould disclosed by the invention can meet the pressing requirements of different-structure busbars and has the universality; the upper die cavity and the lower die cavity are filled with the silicone grease so as to have a good pressed flexible formation function and a good heat transfer function; the research, development and trial-manufacture costs of the busbar are reduced, and the machining period is shortened; and the mould is simply and conveniently manufactured and maintained.

Owner:SUZHOU WEST DEANE MACHINERY

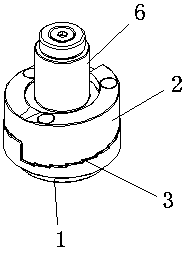

Cushion block for matching of automobile door cover

The purpose of the invention is to provide a cushion block for matching of an automobile door cover. The cushion block is simple in manufacturing and exquisite in structure, can simultaneously meet quantifiable adjustment of fining assembling and adjusting, verifying and data collecting of flatness of an engine cover. The cushion block for matching of the automobile door cover is composed of a base and a body. The bottom surface of the body and the top surface of the base are provided with mutually-matched spiral ladders. The body is supported on the base through the spiral ladders. During using, the cushion block is placed on the lower portion of the automobile door cover, the base is fixed, and by adjusting the relative angle of the base and the body, the spiral ladders of the body and the spiral ladders of the base can be overlapped at the different positions, thus the height of the body is adjusted, and the purpose of adjusting the flatness of the automobile door cover by simulating the thread pitch is achieved. The precision of height adjusting relies on precision of the spiral ladders, and the spiral ladders cannot make contact with the automobile door cover, therefore abrasion of the automobile door cover is less, and even if the top surface of the body is subjected to certain abrasion, the precision of adjusting cannot be affected.

Owner:CHERY AUTOMOBILE CO LTD

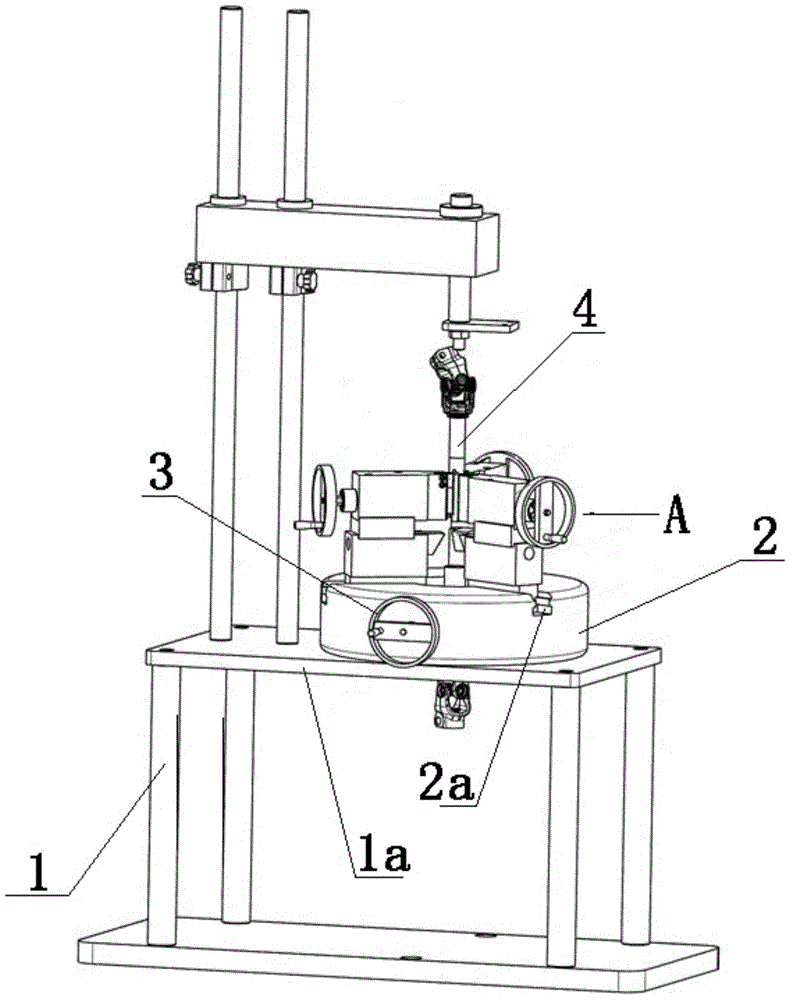

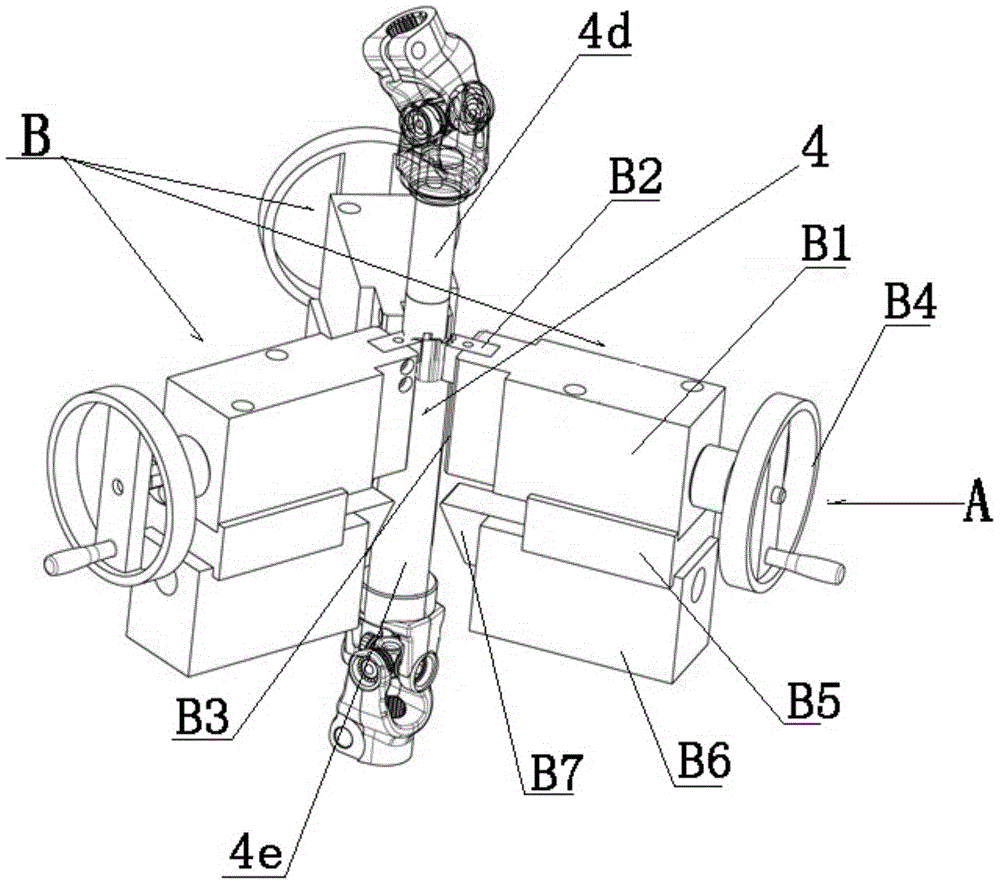

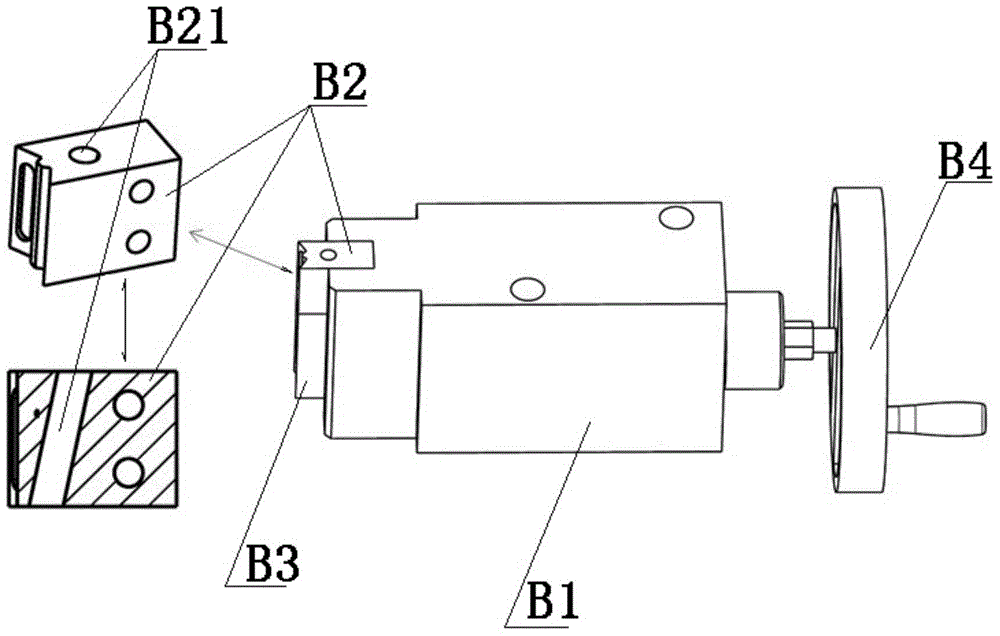

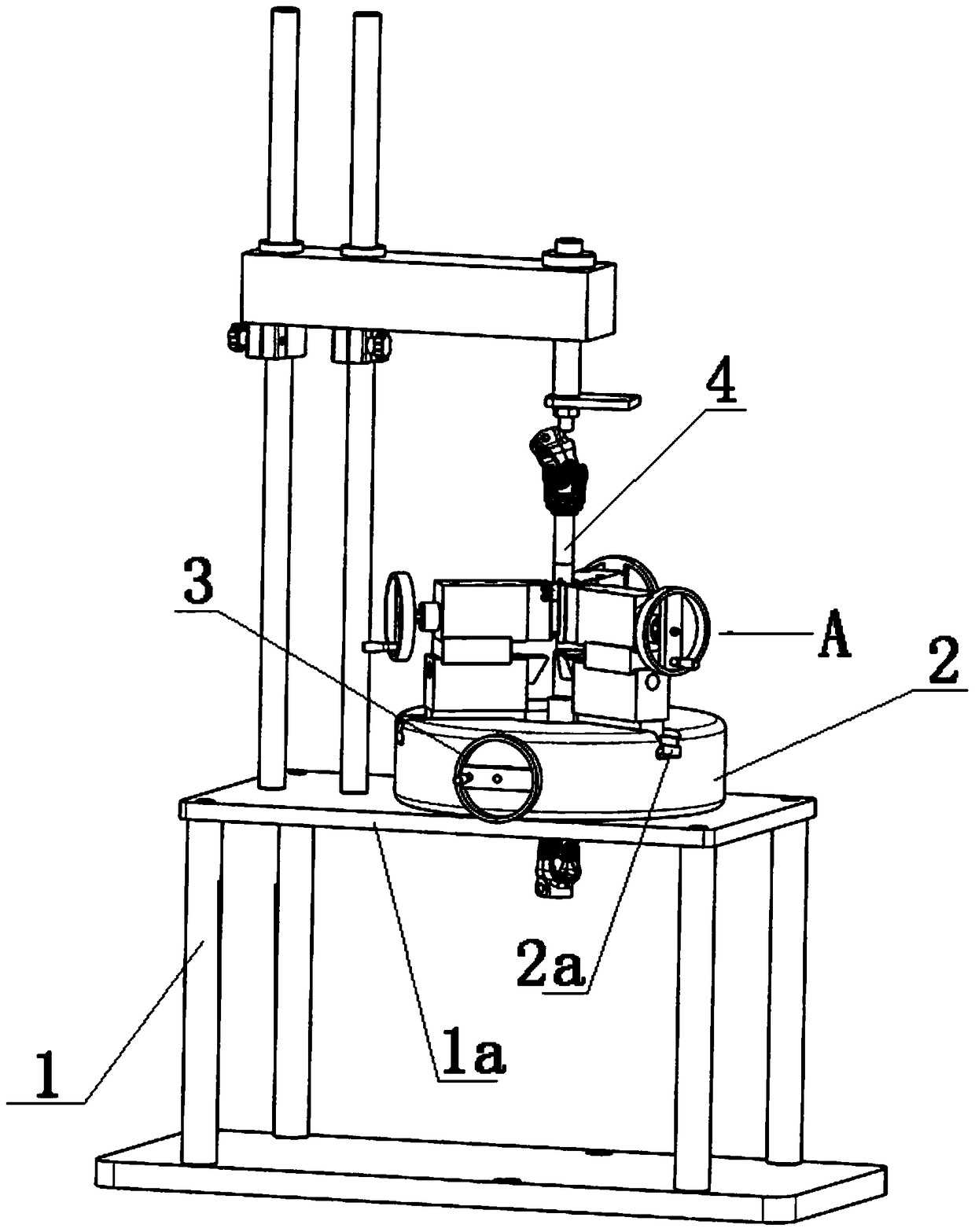

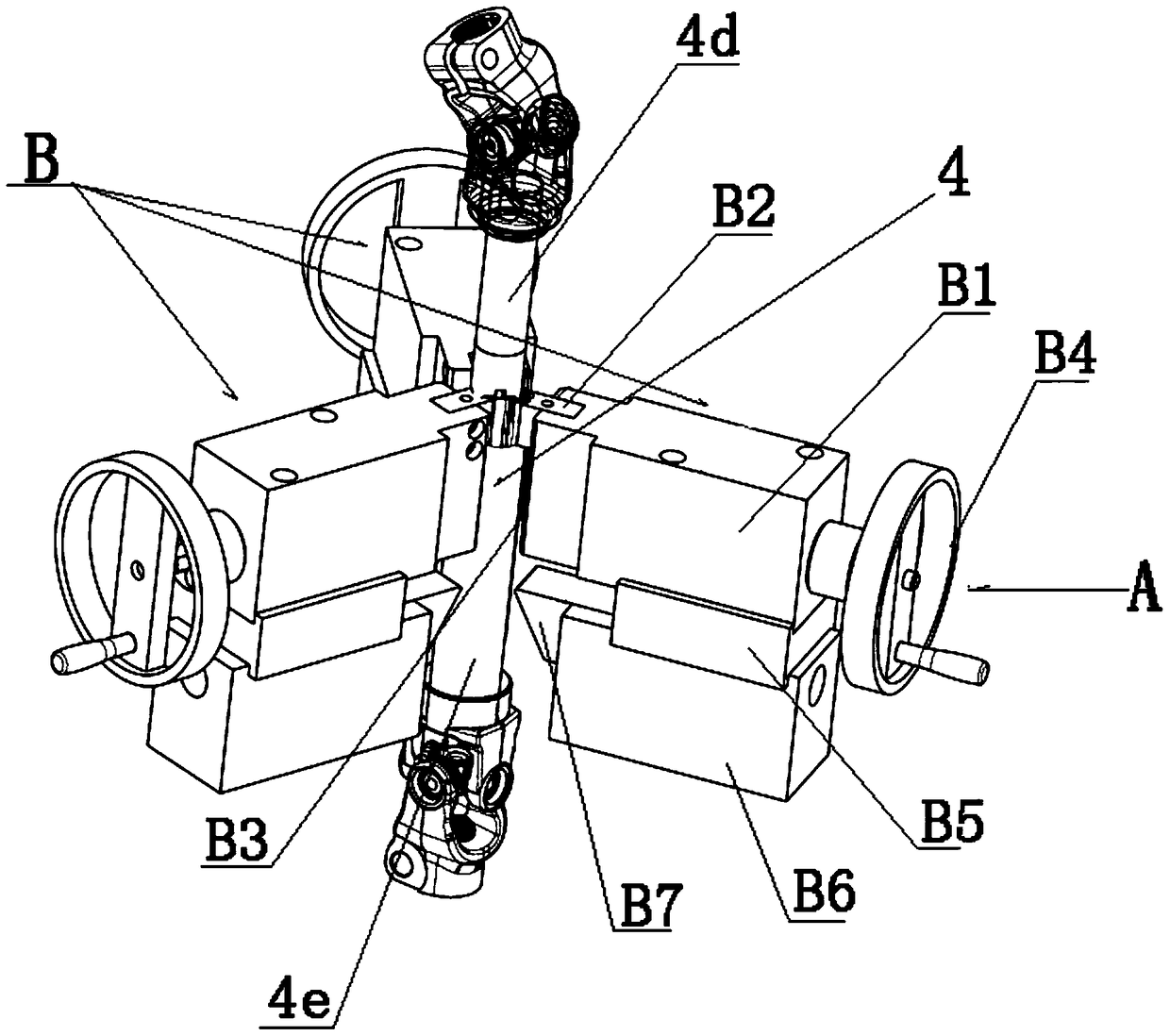

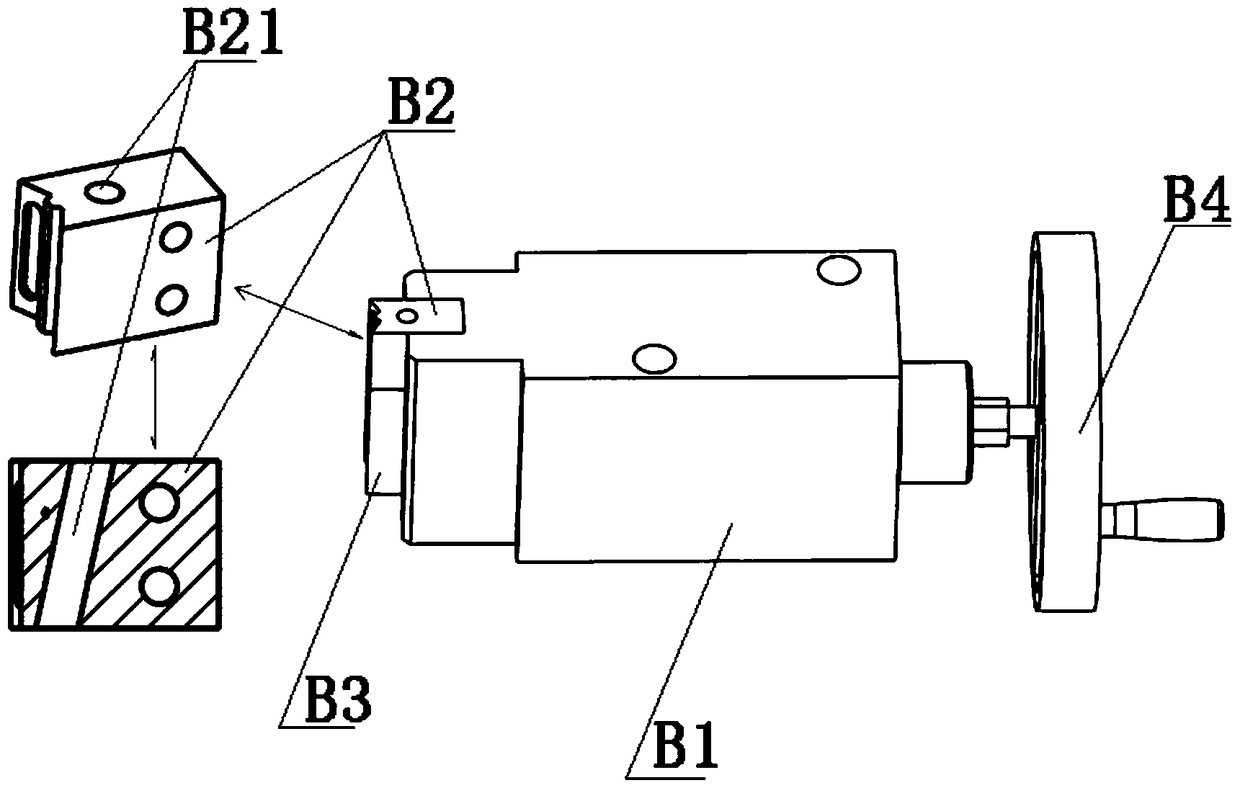

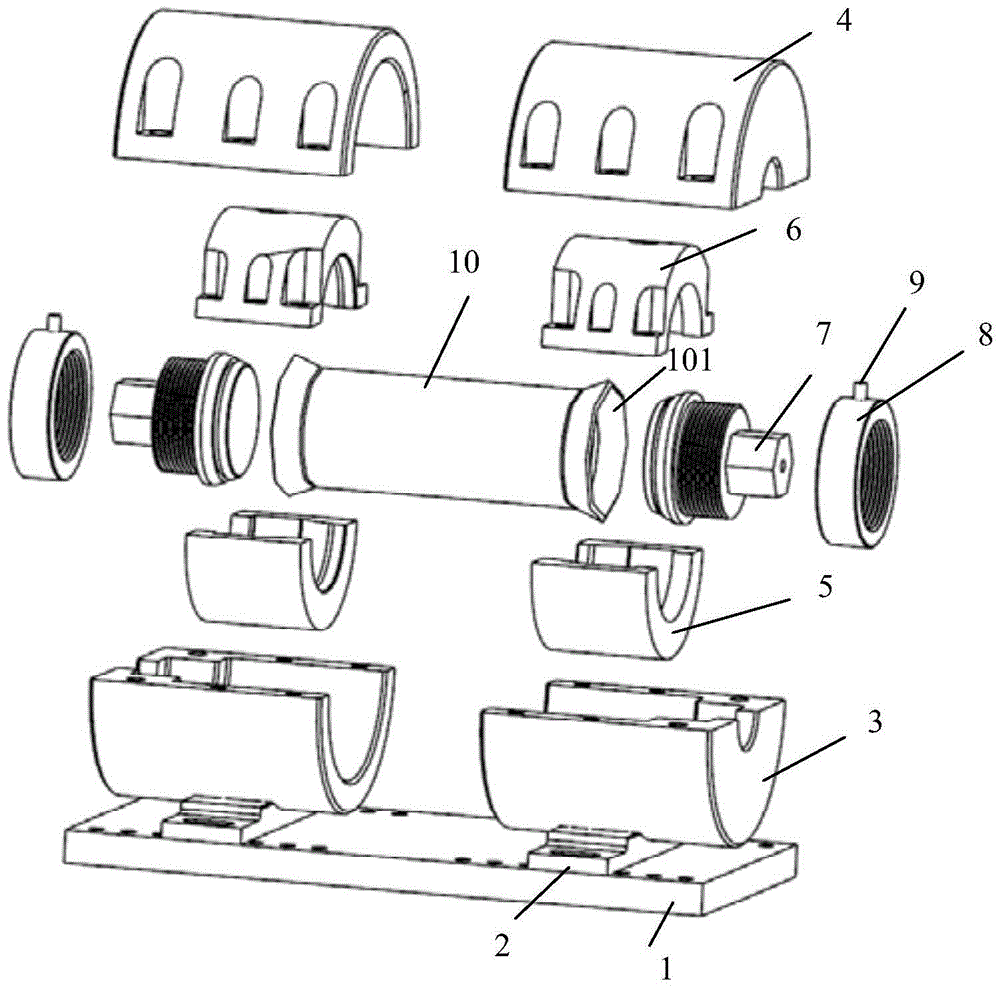

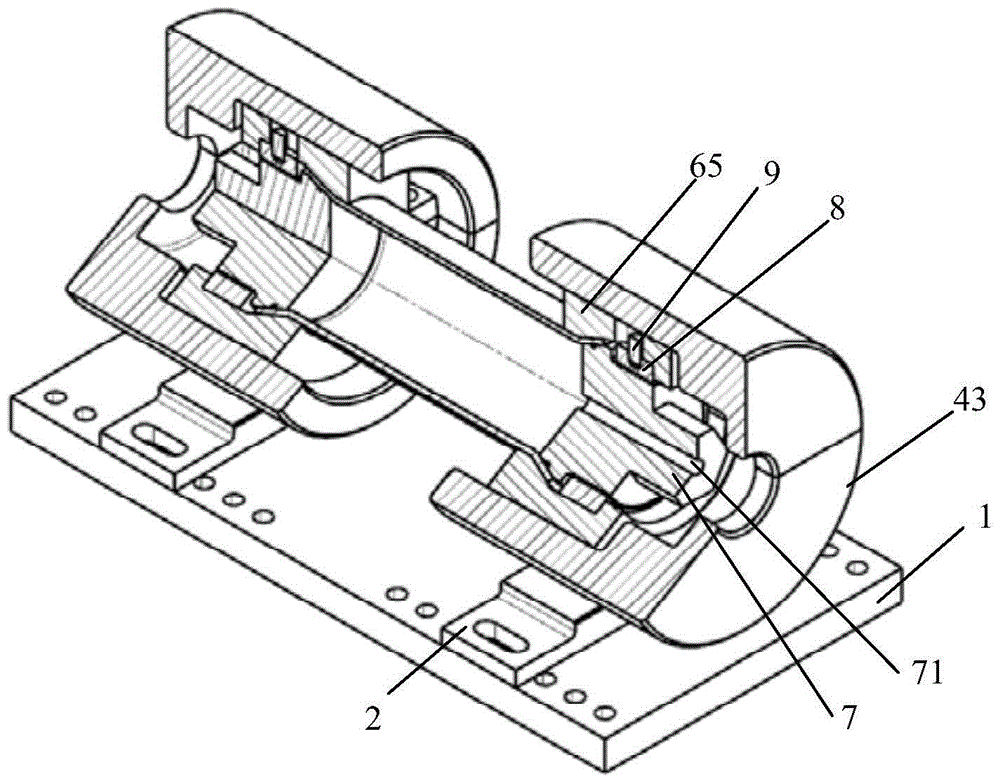

Clamp used for assembling steel ball guide rail type intermediate shaft of steering system and assembling method

ActiveCN106625343AImprove assembly accuracyImprove assembly efficiencyWork holdersSteel ballEngineering

The invention discloses a clamp used for assembling a steel ball guide rail type intermediate shaft of a steering system and an assembling method. The clamp comprises an assembling base arranged on a support platform of a support. An intermediate shaft assembling clamp assembly is arranged on a base guide rail of the assembling base and is controlled to be unfolded or folded by a general feeding hand wheel arranged on one side of the assembling base. The intermediate shaft assembling clamp assembly is used for clamping the to-be-assembled part of the steel ball guide rail type intermediate shaft to the center of the clamp assembly, steel balls are arranged between steel ball rails, positioned under the assistance of leaf springs, of the steel ball guide rail type intermediate shaft through the intermediate shaft assembling clamp assembly, a lower steering shaft and an upper steering shaft are connected in a sleeved manner to form the integral steel ball guide rail type intermediate shaft. According to the clamp used for assembling the steel ball guide rail type intermediate shaft of the steering system and the assembling method, the assembling requirement for the intermediate shaft of the steering system can be met, operation is easy, the assembling work hours are reduced, the assembling precision and efficiency of the intermediate shaft are improved, the clamp and the method are suitable for different types of steel ball guide rail type intermediate shaft products, universality is improved, and the trial manufacture cost of the products is greatly reduced.

Owner:BOSCH HUAYU STEERING SYST CO LTD

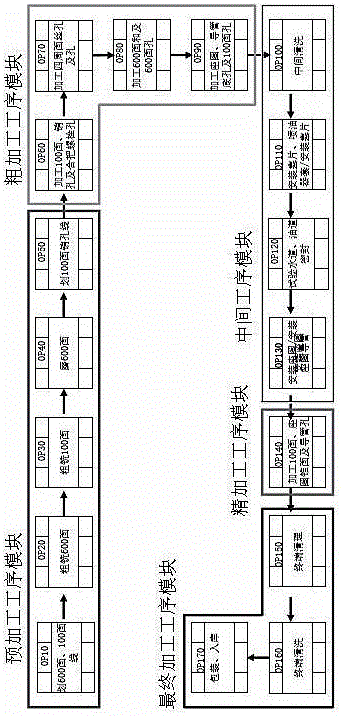

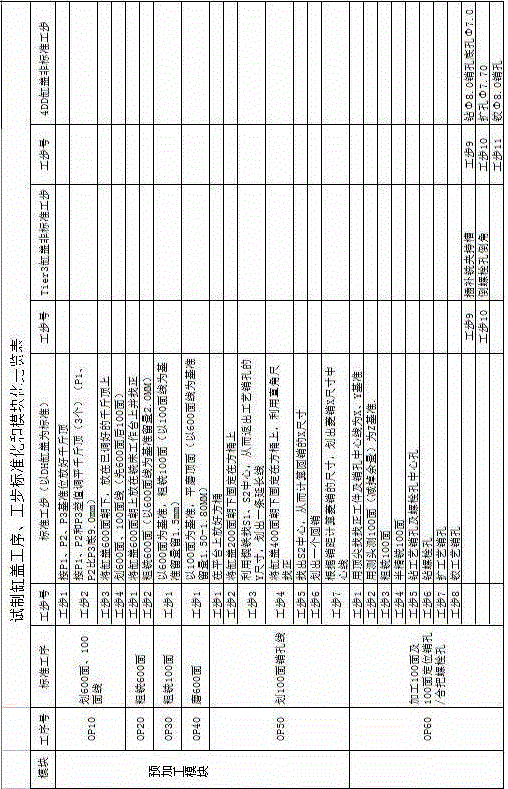

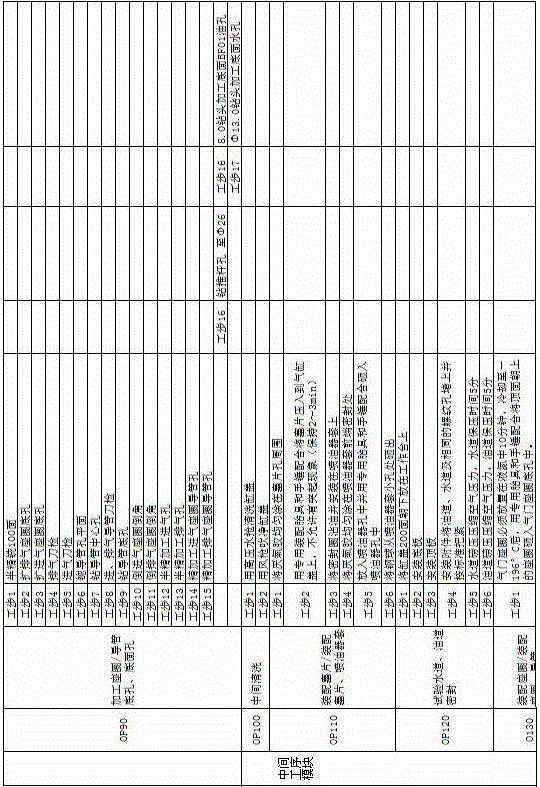

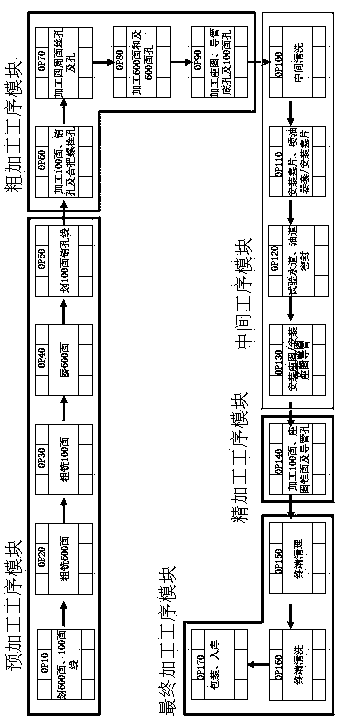

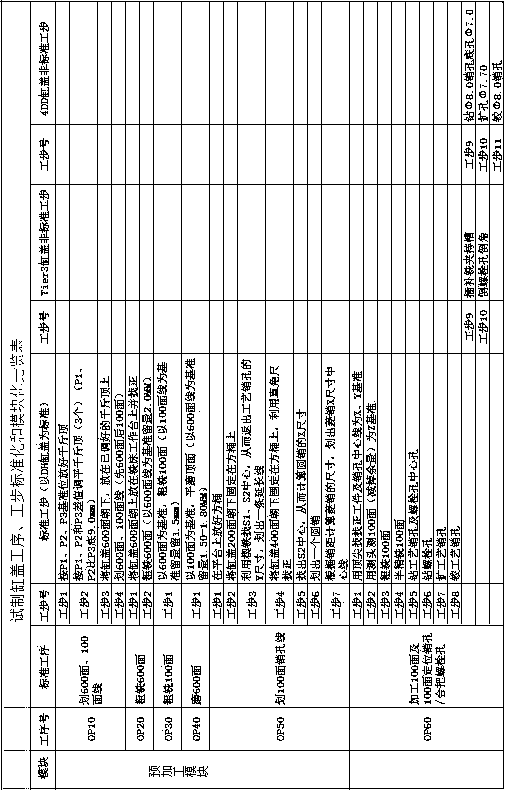

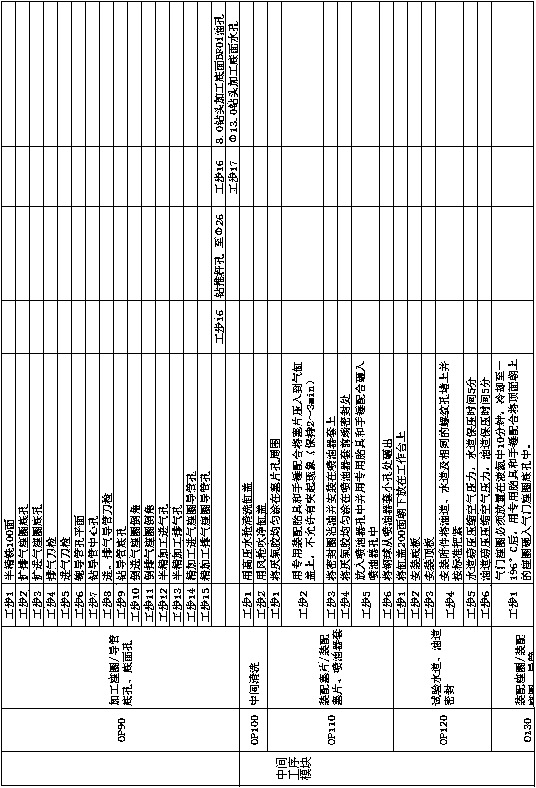

Modularization and standardization management method for trial-manufacturing processing technique of air cylinder cover

The invention provides a modularization and standardization management method for the processing technique of trial-manufacturing an air cylinder cover. The modularization and standardization management method includes the following steps that a, modularization classification is conducted and the processing technique of a cylinder cover is divided into five modules; b, a preprocessing module, a rough processing module, an intermediate processing module, a finish processing module and a foundation process in a final processing module are basic processes; c, a standardized working-step module of the foundation process is formulated; d, a non-standard working-step submodule is formulated; and e, existing modules or modules special for design is combined into a novel product. The modularization and standardization management method for the processing technique of trial-manufacturing the air cylinder cover can reduce the work of production organization and technological preparation of a workshop during a product modeling through the modularization and standardization of the processing technique for trial-manufacturing the air cylinder cover, the demand of the product remodeling is met only by conducting the recombination of the modules; and through the modularization and standardization of the processing technique for trial-manufacturing the air cylinder cover can shorten the design circle of the product, can greatly reduce the trial-manufacture cost, so that the contradiction among the variety, the standard, the designing and manufacturing cycle and the cost of the product is solved.

Owner:DEUTZ DALIAN ENGINE

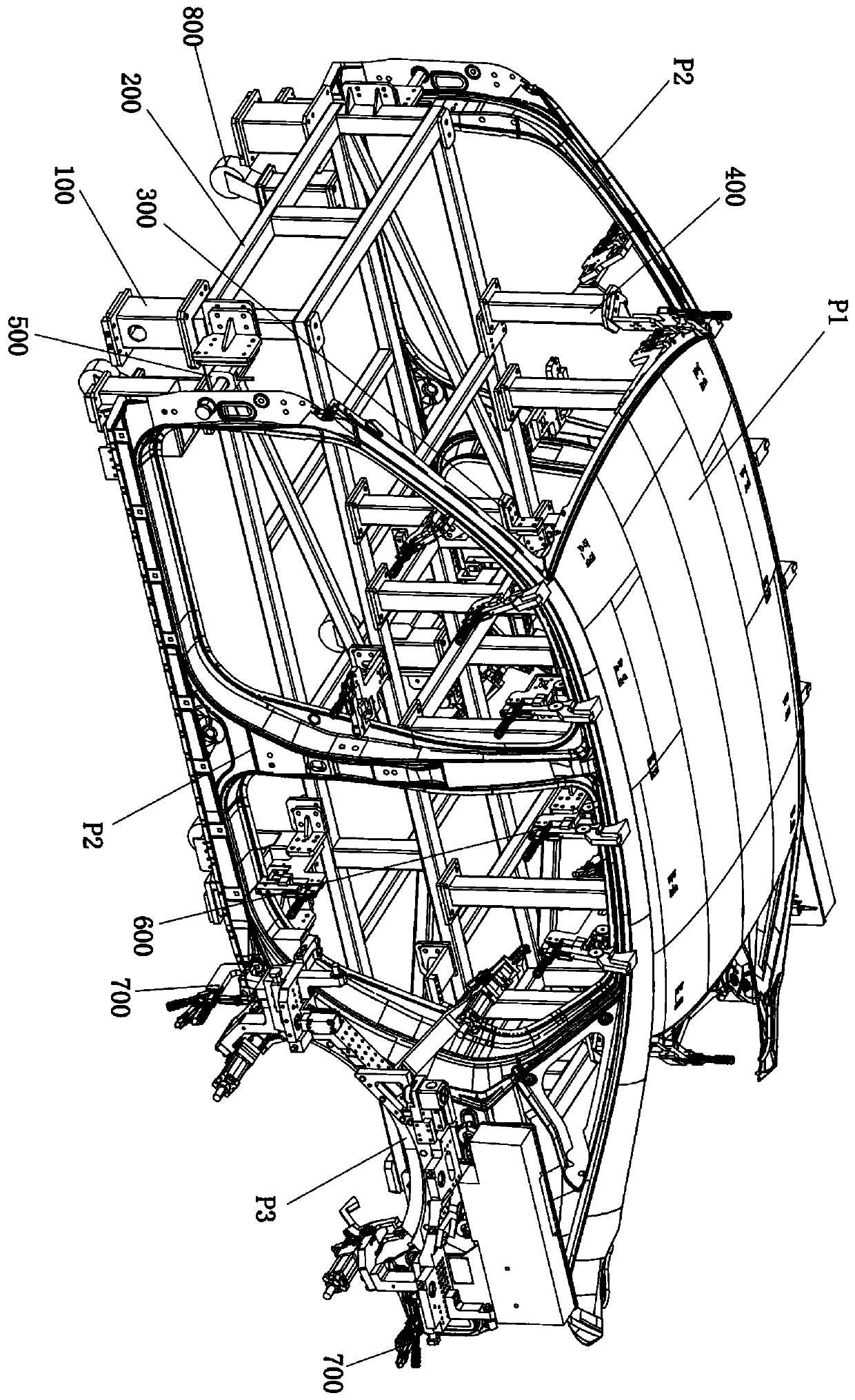

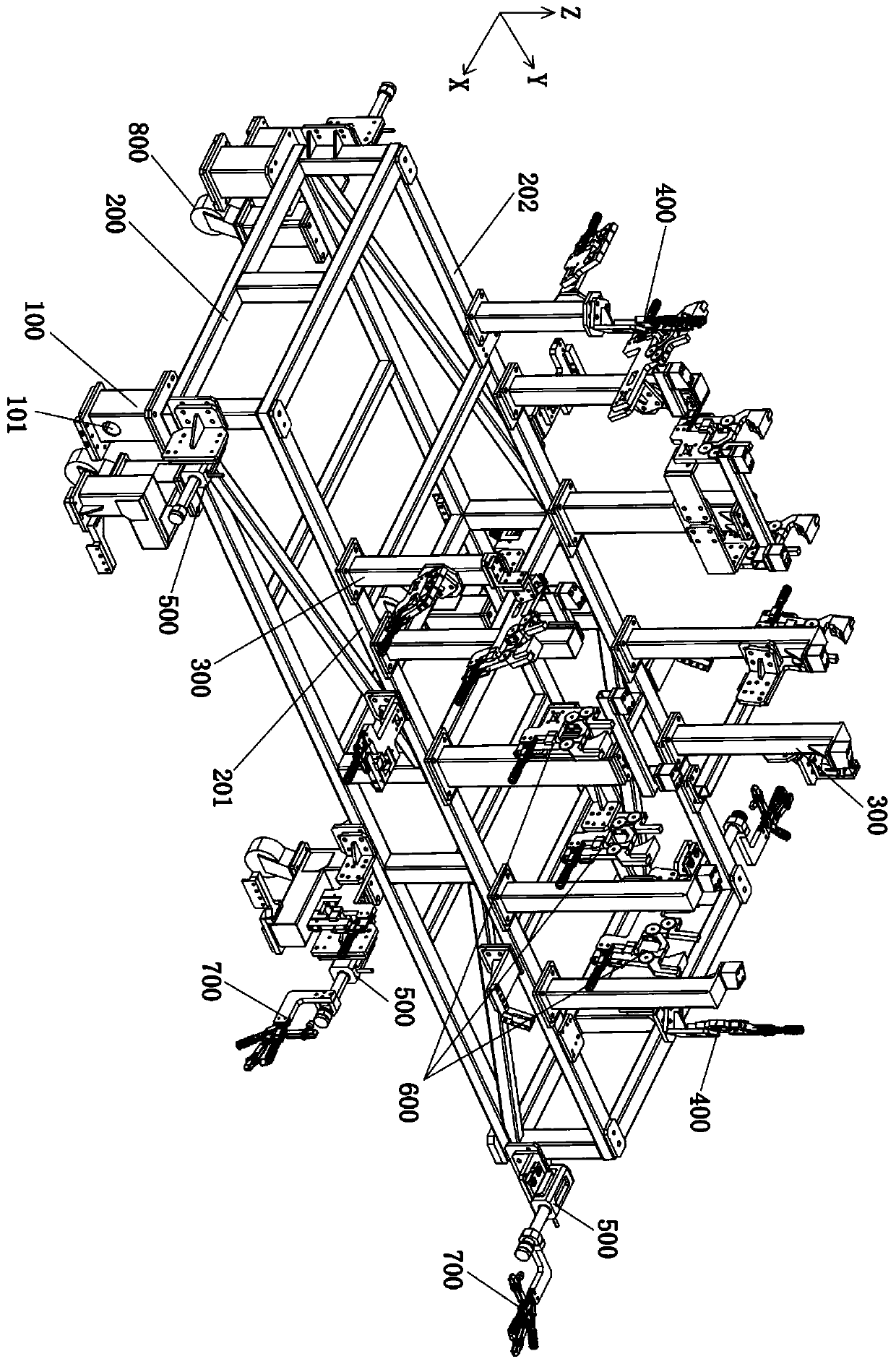

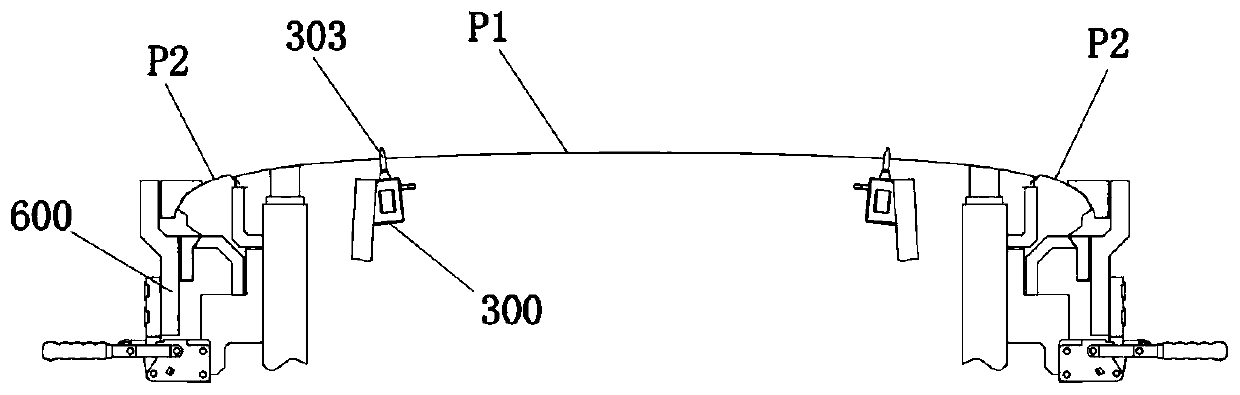

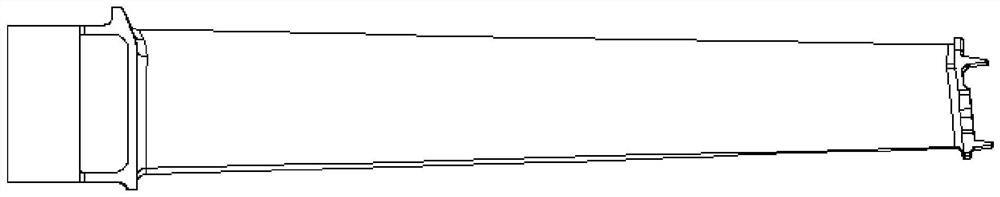

Trial-production device for ceiling laser welding line body

ActiveCN111318986AMeet the needs of multi-process trial productionAvoid wastingWork holdersPolishingEngineering

The invention discloses a trial-production device for a ceiling laser welding line body. The trial-production device comprises a base, a frame, a first ceiling positioning unit, a second ceiling positioning unit, a side wall positioning unit and a side wall clamping unit; the frame is connected to the base; the first ceiling positioning unit is connected with the frame and used for positioning a ceiling outer plate in the Z direction; the second ceiling positioning unit is connected to the frame and used for positioning the ceiling outer plate in the XY direction; the side wall positioning unit is connected with the frame and used for positioning a side wall outer plate in the XZ direction; and the side wall clamping unit is connected with the frame and is used for clamping and fixing theside wall outer plate of the body in white. The trial-production device for the ceiling laser welding line body has simple structure and strong universality, can meet the multi-process trial-production requirements of ceiling laser welding, weld polishing and wheel cover edge rolloff only by providing a single ceiling outer plate and side wall outer plate metal plate stamping part, and can effectively reduce the trial-production cost.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

Method for correcting bending and twisting size of turbine blade

PendingCN114192741AQuick and effective bending and torsion dimensioningDimensional stability in bending and torsionFoundry mouldsFoundry coresInvestment castingTurbine blade

The method for correcting the bending and twisting size of the turbine blade comprises the following steps that firstly, wax sheets with the thickness ranging from 0.4 mm to 1 mm are fixed to the two ends of a blade profile correcting blank film conforming to the blade back of the turbine blade to be corrected, and the treated blade profile correcting blank film is obtained; 2, a wax mold corresponding to the turbine blade to be corrected is placed on the treated blade profile correction tire mold; and 3, a heavy object matched with the shape of the wax mold in the step 2 is placed in the center of the wax mold in the step 2 in the width direction of the wax mold in the step 2 to be pressed, the wax mold with the corrected bending and twisting size is obtained, investment casting is conducted on the obtained wax mold with the corrected bending and twisting size, and the turbine blade with the corrected bending and twisting size is obtained. Through a wax mold pre-deformation mode, the bending and twisting size reverse deformation can be quickly and effectively obtained, qualified castings are manufactured and applied to early wax mold control, the trial-manufacturing cost is reduced, and the production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

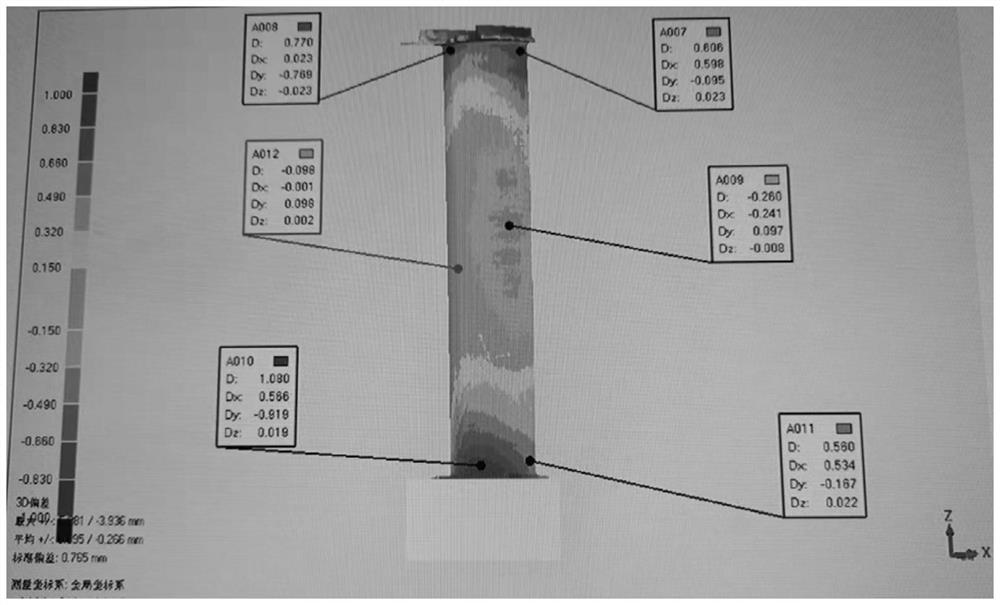

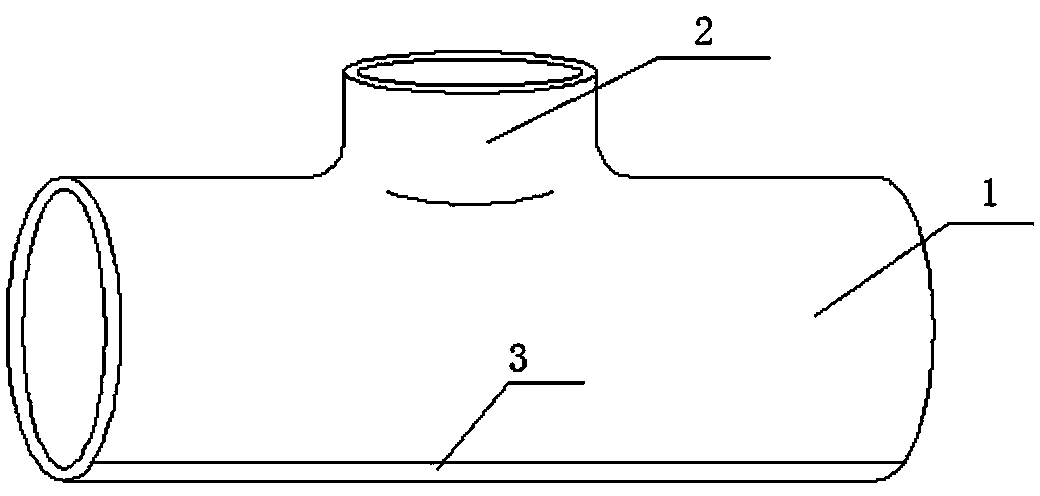

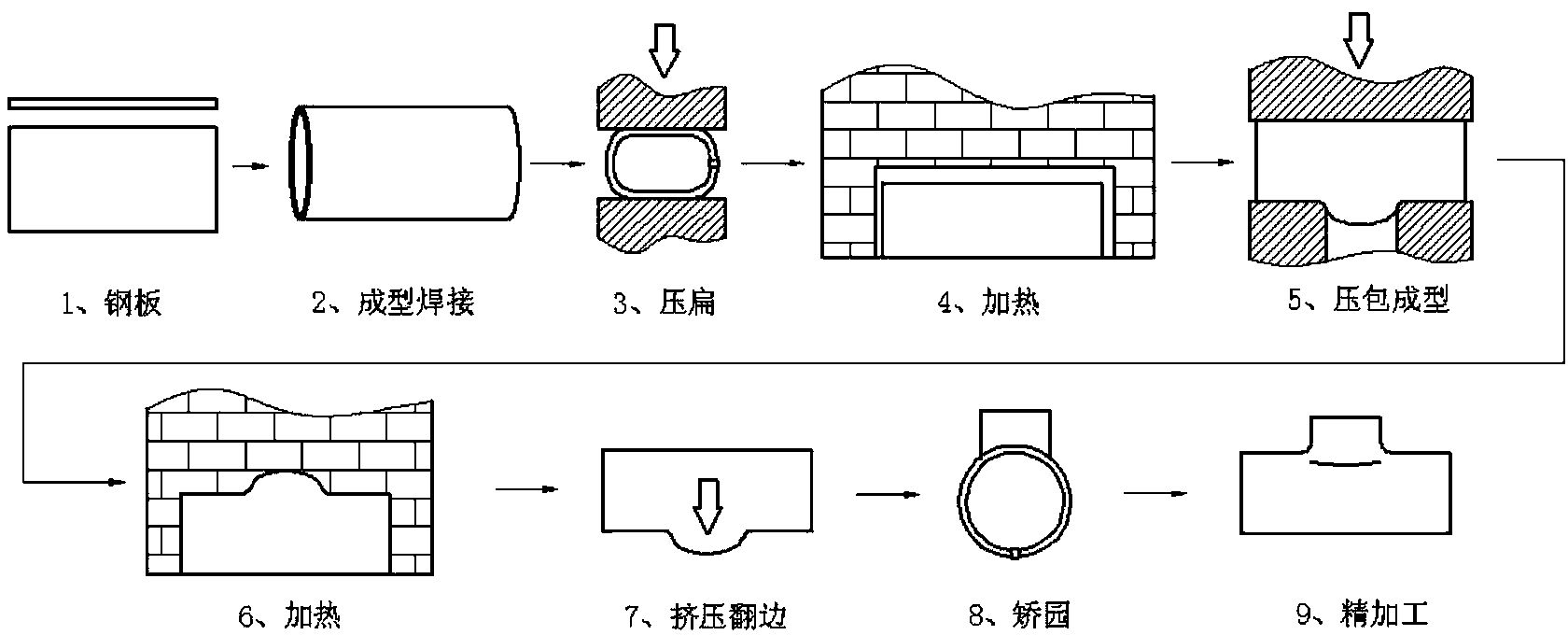

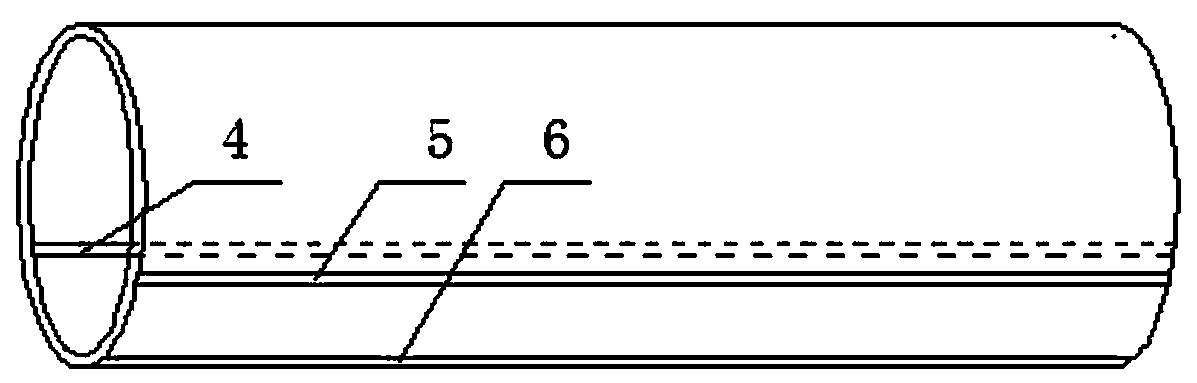

Testing method for verifying reliability of tee joint welding process

ActiveCN103433634ASave assessment timeIncrease productivityWelding apparatusSoftware engineeringWelding process

A testing method for verifying the reliability of a tee joint welding process comprises the following steps that a blank tube for manufacturing a tee joint is welded, and a blank welding seam is formed in the blank tube; no less than two sets of testing welding grooves are formed in the blank tube through arc air gouging; the welding process different from the welding process in the first step is used for welding each set of the testing welding grooves to form testing welding seams; different welding processes are used for welding one set of the testing welding grooves and another set of the testing welding grooves; when manufacturing and testing of the tee joint are completed and evaluating is conducted, testing evaluating of the welding process is conducted on each testing welding seam; the most appropriate welding process is chosen to be the welding process of final normal production. The testing method for verifying the reliability of the tee joint welding process greatly saves the evaluating time of the trial production of the tee joint, and improves the production efficiency. The time for tee joint evaluating is greatly shortened, and the cost of welding evaluating and testing of the high-strength tee joint can be greatly lowered.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

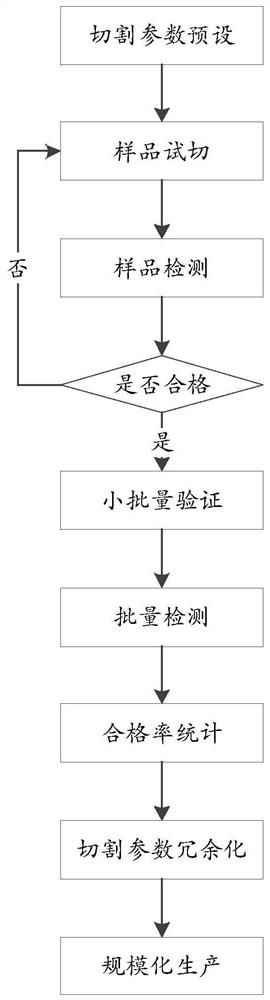

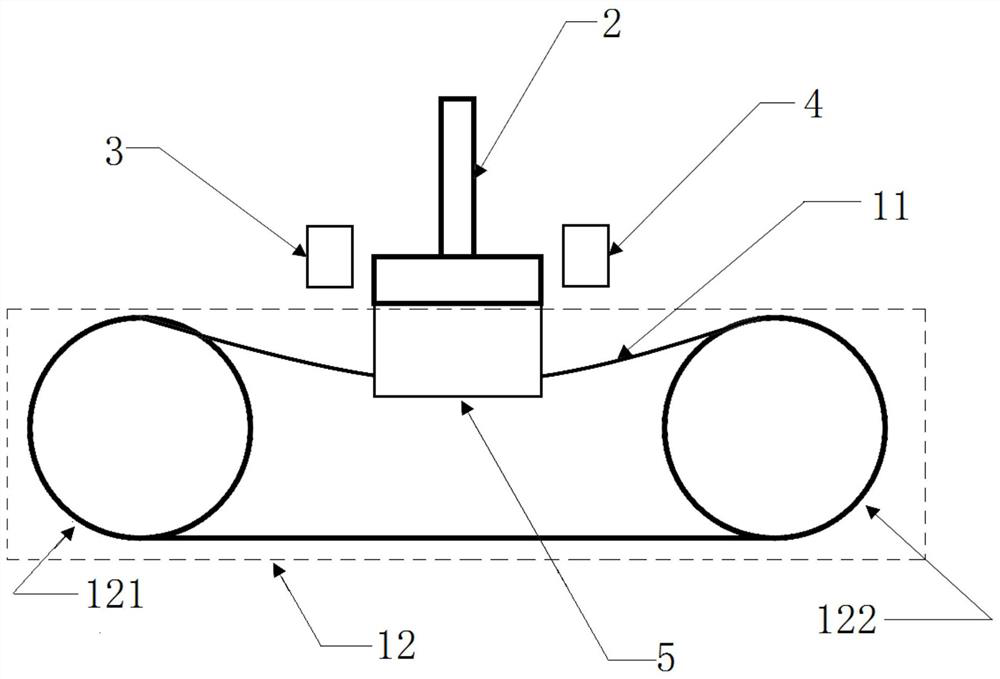

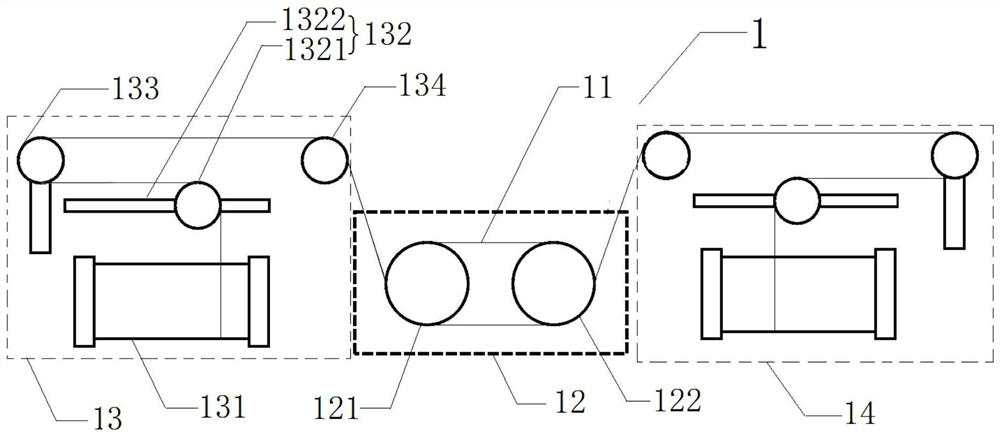

Multi-wire sawing machine wire bow height automatic adjustment control system and method

PendingCN112605843AAffect detection accuracyReduce trial production costsGrinding drivesGrinding feed controlWire cuttingProcess engineering

The invention relates to a multi-wire sawing machine wire bow height automatic adjustment control system and method. The multi-wire sawing machine wire bow height automatic adjustment control system comprises a multi-wire sawing machine, a feeding workbench, a left sensor, a right sensor and a controller; the feeding workbench is installed above the multi-wire sawing machine and right faces a sawing part of the multi-wire sawing machine, and the left sensor and the right sensor are installed on the left side and the right side of the feeding workbench respectively. and the left sensor and the right sensor are both electrically connected with the input end of the controller, and the output end of the controller is electrically connected with the feeding workbench. The left sensor and the right sensor are used for detecting the real-time wire bow height of the multi-wire sawing machine, the controller adjusts the feeding speed of the feeding workbench according to the real-time wire bow height detected by the left sensor or / and the right sensor so as to automatically adjust and control the wire bow height of the multi-wire sawing machine, the sample trial-manufacturing cost can be reduced, the consistency of batch production is improved, the cost of batch production consumables is reduced, the labor cost is reduced, human errors are avoided, and the production efficiency is improved.

Owner:PHASE MOTION CONTROL SOLUTION WUHAN CO LTD

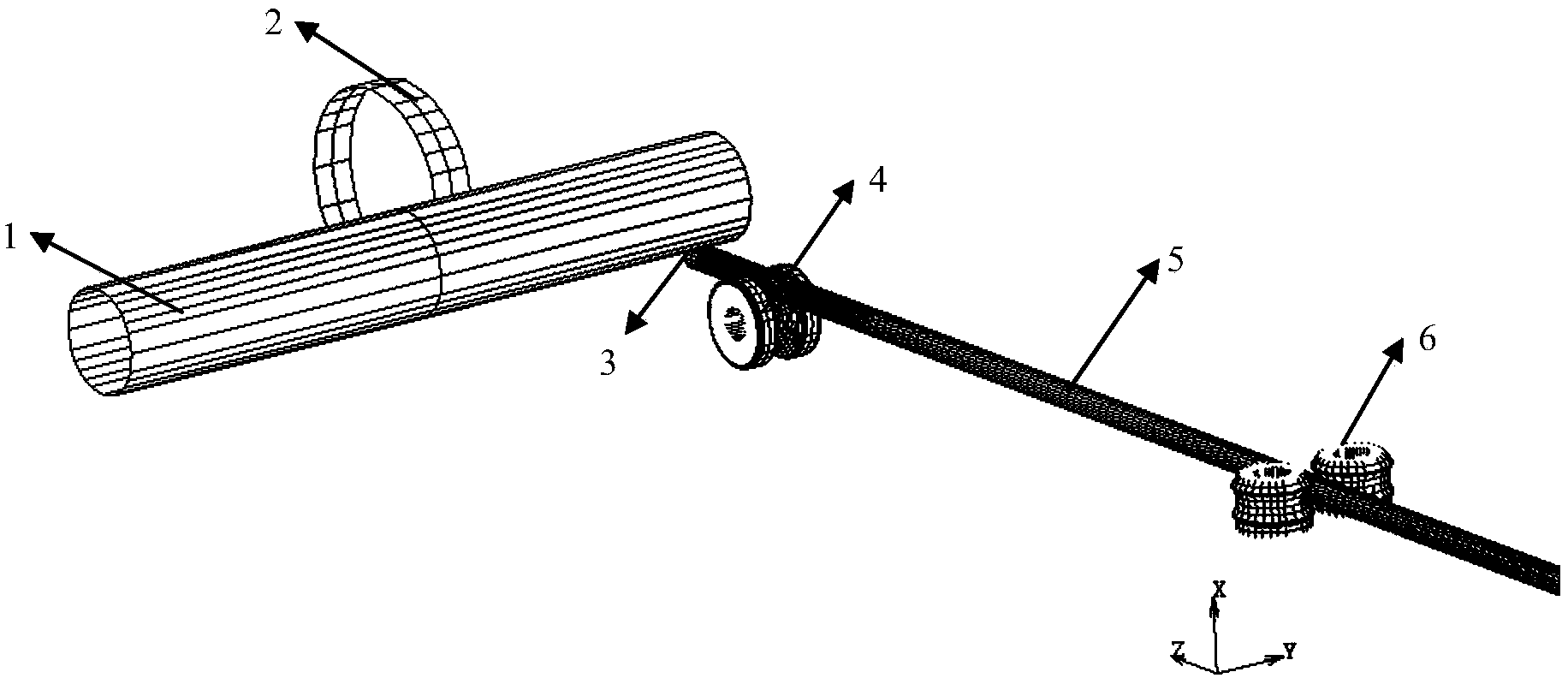

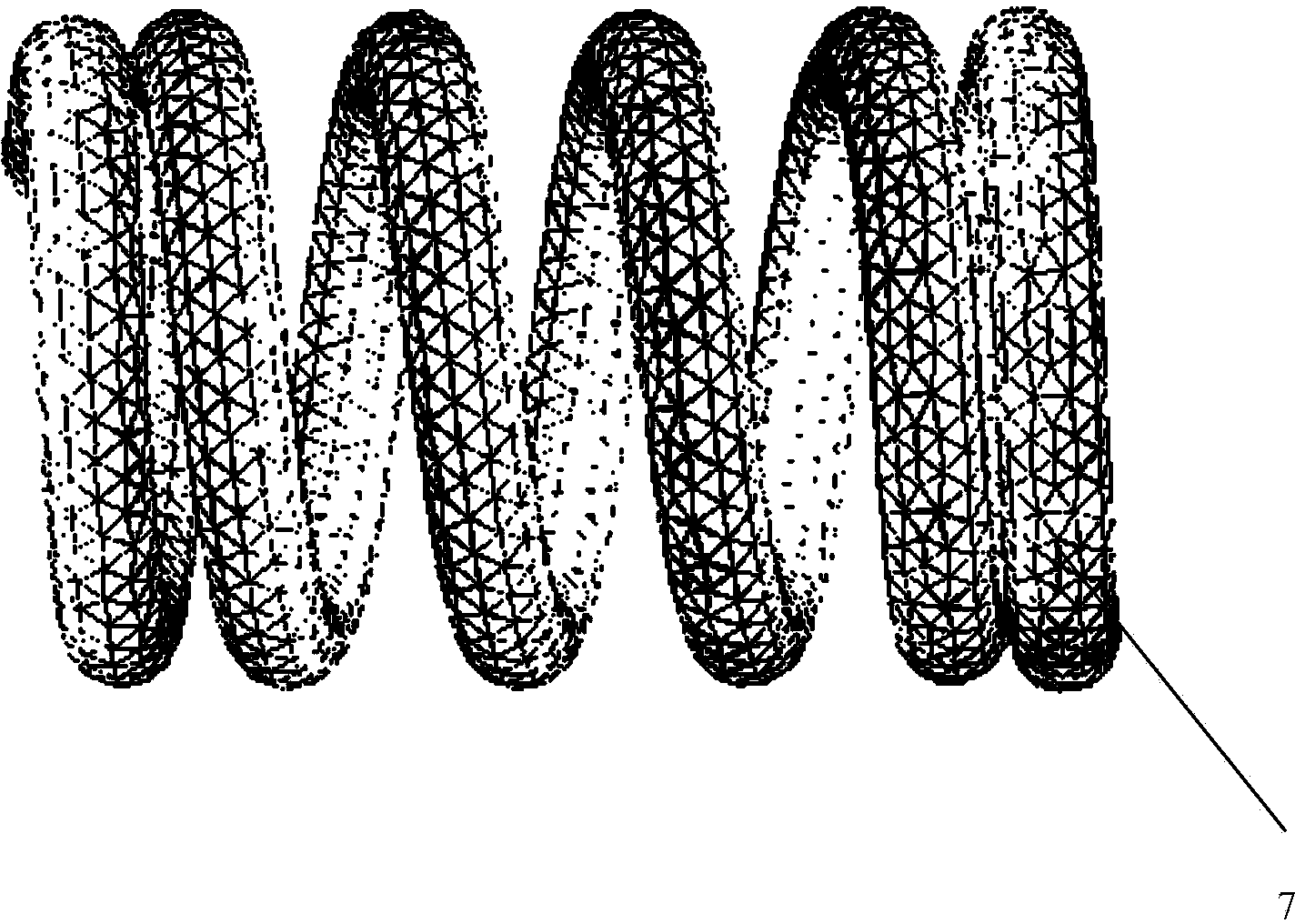

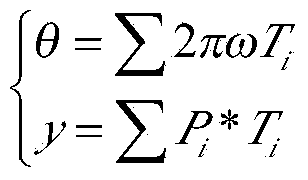

Method for finite element analysis of hot rolling spiral steel spring forming process

InactiveCN104008245AReduce the number of timesImprove manufacturing efficiencySpecial data processing applicationsFinite element limit analysisManufacturing efficiency

A method for finite element analysis of a hot rolling spiral steel spring forming process comprises a first step of simplifying a spring forming device, establishing a mandrel, a snapping block, a guide wheel, a tightening wheel and a tapped wheel model, determining the relative positions of the mandrel, the snapping block, the guide wheel, the tightening wheel and the tapped wheel model, and establishing a bar material finite element model; a second step of defining contact bodies and contact relations; a third step of defining the relations of mandrel rotation motion and axial motion, defining the rotation motion and axial motion as a function of time T, setting time parameters as Ti, enabling the thread pitch of a Ti time period to be Pi, enabling the rotation angle of the mandrel to be theta, enabling the rotation speed to be omega, enabling a motion equation of the mandrel rotation motion and axial motion to be as follows; a fourth step of establishing calculation, checking results, establishing a CAE model and submitting the calculation, and rolling a formed model. According to the method, the physical prototype manufacturing process is replaced with the virtual manufacturing process, the method is used for guiding a rolling forming process of a hot rolling spiral steel spring, trial-manufacture efficiency of a novel product is improved, and the trial-manufacture cost of the novel product is reduced. The method is suitable for simulating spiral cylindrical steel springs of random diameters.

Owner:TIANJIN JL RAILWAY TRANSPORT EQUIP

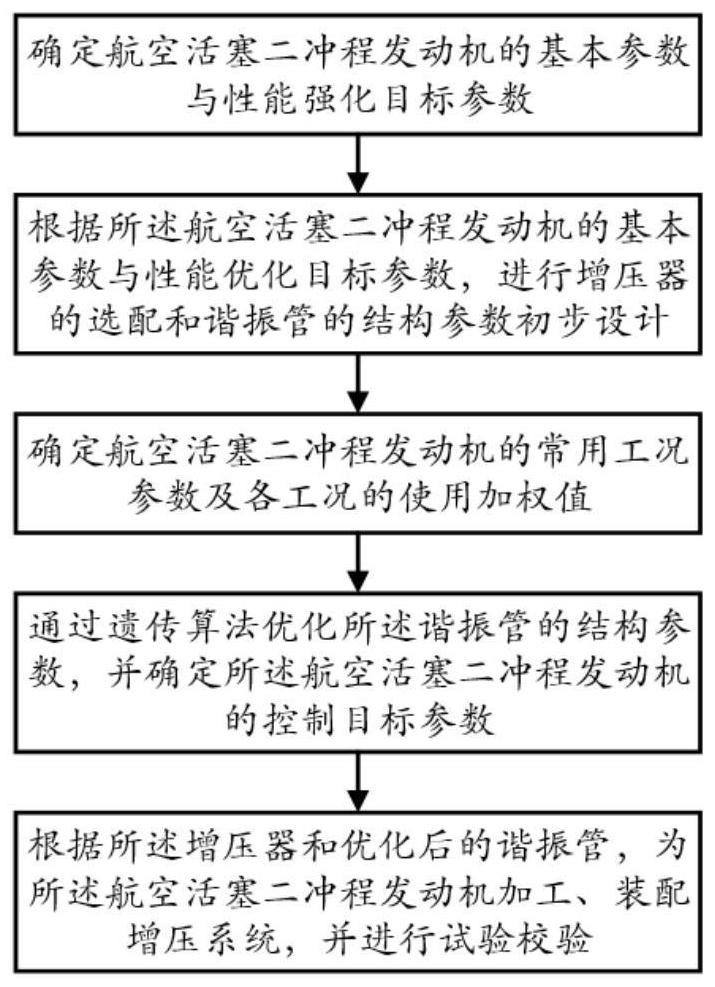

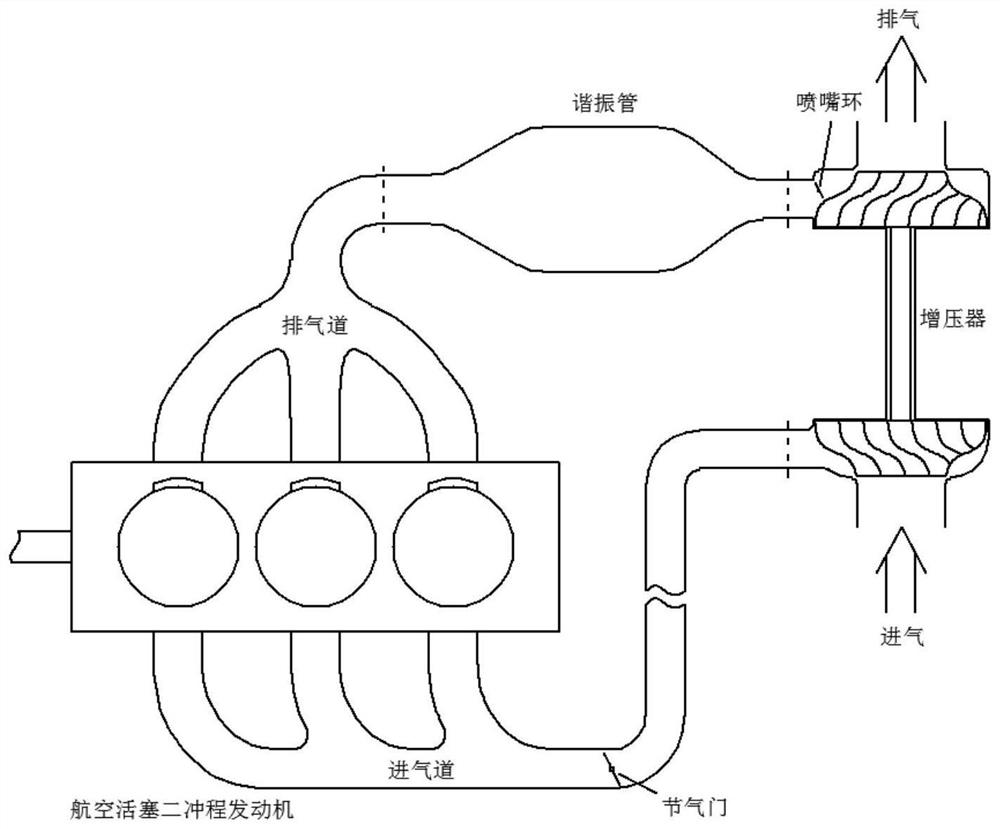

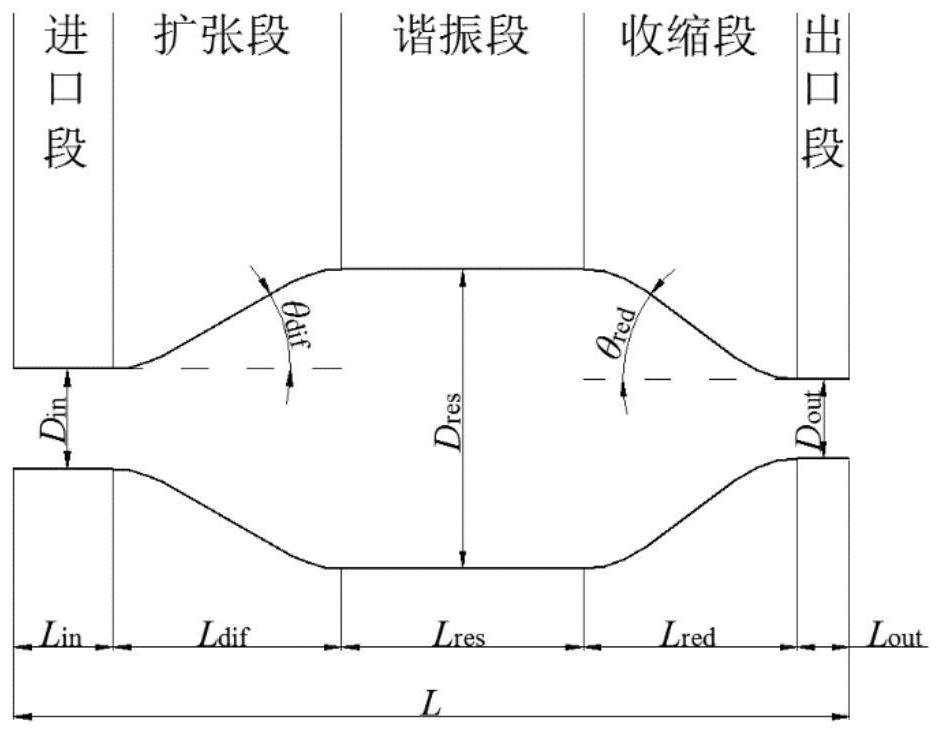

Design method for supercharging system of aviation piston two-stroke engine

PendingCN114647905AScientific and efficient designShorten the development cycleGeometric CADCombustion enginesAviationFlight vehicle

The invention discloses an aviation piston two-stroke engine supercharging system design method, and belongs to the technical field of aviation piston two-stroke engine supercharging system design. The method comprises the steps that basic parameters and performance strengthening target parameters of the aviation piston two-stroke engine are determined; selecting and matching a supercharger and preliminarily designing structural parameters of a resonant tube; determining common working condition parameters of the aviation piston two-stroke engine and a use weighted value of each working condition; optimizing structure parameters of the resonant tube through a genetic algorithm, and determining control target parameters; and according to a supercharger and the optimized resonance tube, a supercharging system is machined and assembled for the aviation piston two-stroke engine, and test verification is carried out. The design method of the aviation piston two-stroke engine supercharging system is suitable for an aircraft with high lift limit, high maximum level flight speed and long endurance, high comprehensive performance under all working conditions is considered, the design period is short, and the trial-manufacturing cost is low.

Owner:AEROSPACE TIMES FEIHONG TECH CO LTD

Method and system for structural performance evaluation of high temperature valves based on valve simulation model

ActiveCN105488292BEliminate potential safety hazardsAvoid elastic failureDesign optimisation/simulationSpecial data processing applicationsMachineStrength design

The invention discloses a method and a system for evaluating structural performance of a high-temperature valve based on a valve simulation model. The method comprises the following steps of establishing a three-dimensional geometrical model of the valve with the center of a runner of a valve body as an origin; applying finite element analysis software to carry out grid processing on the three-dimensional geometrical model of the valve; carrying out analog computation on a temperature field of the valve, which changes with the temperature, and a hot stress field which bears temperature load based on the three-dimensional geometrical model of the valve; and computing total hot stress and local heat stress when a valve bearing component bears a combined action of the temperature load and the mechanical load, and evaluating the structural performance condition of the valve according to a hot stress computation result and reference to the specified strength design standard of the high-temperature valve structure. According to the method and the system, valve design parameters needed by the high-quality valve with reasonable structural design and reliable structural strength is obtained through modeling calculation, so that the safety for running of a nuclear power plant is improved, the experimental manufacturing cost of a model machine is reduced, and the valve product development cycle is shortened.

Owner:中广核工程有限公司 +1

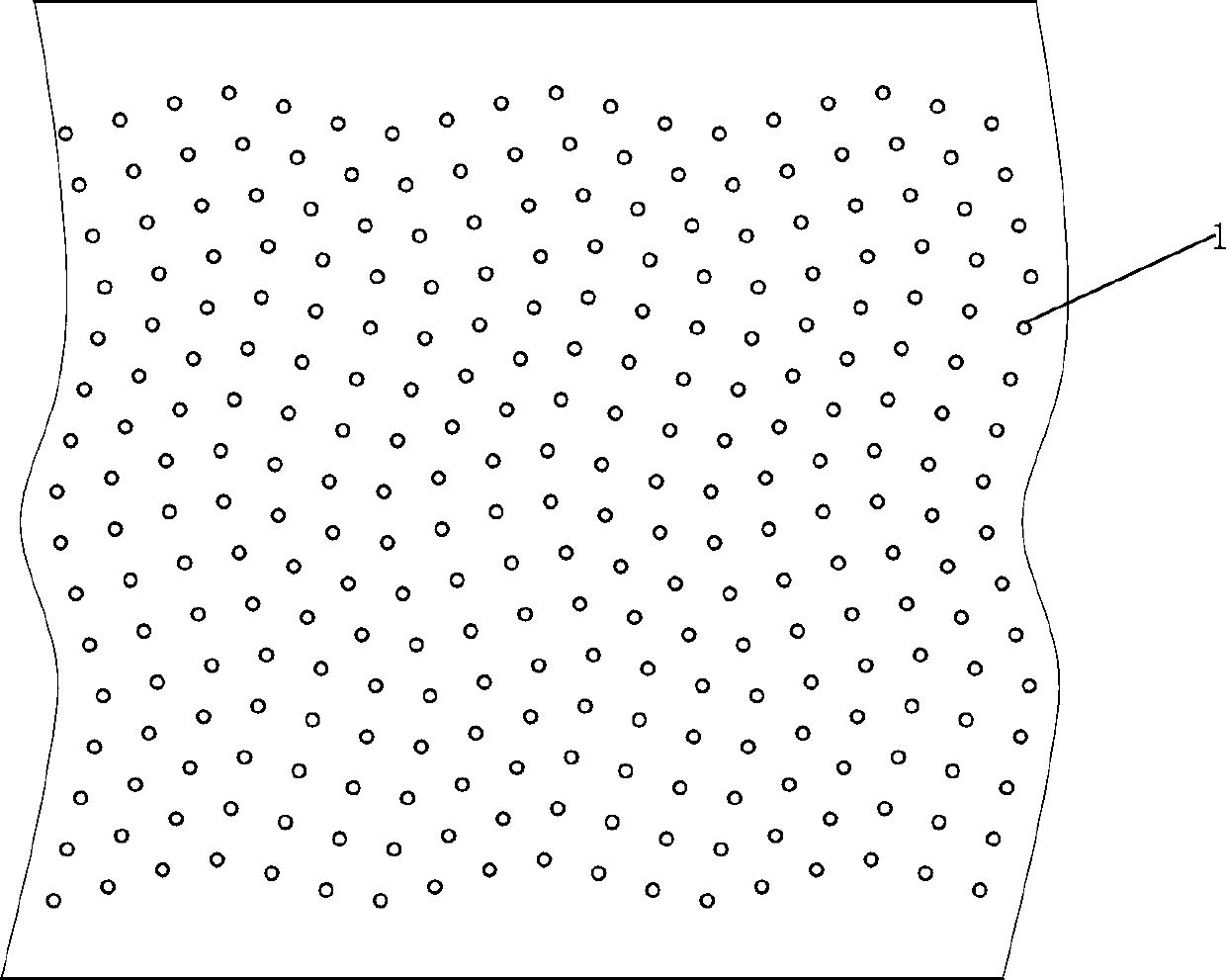

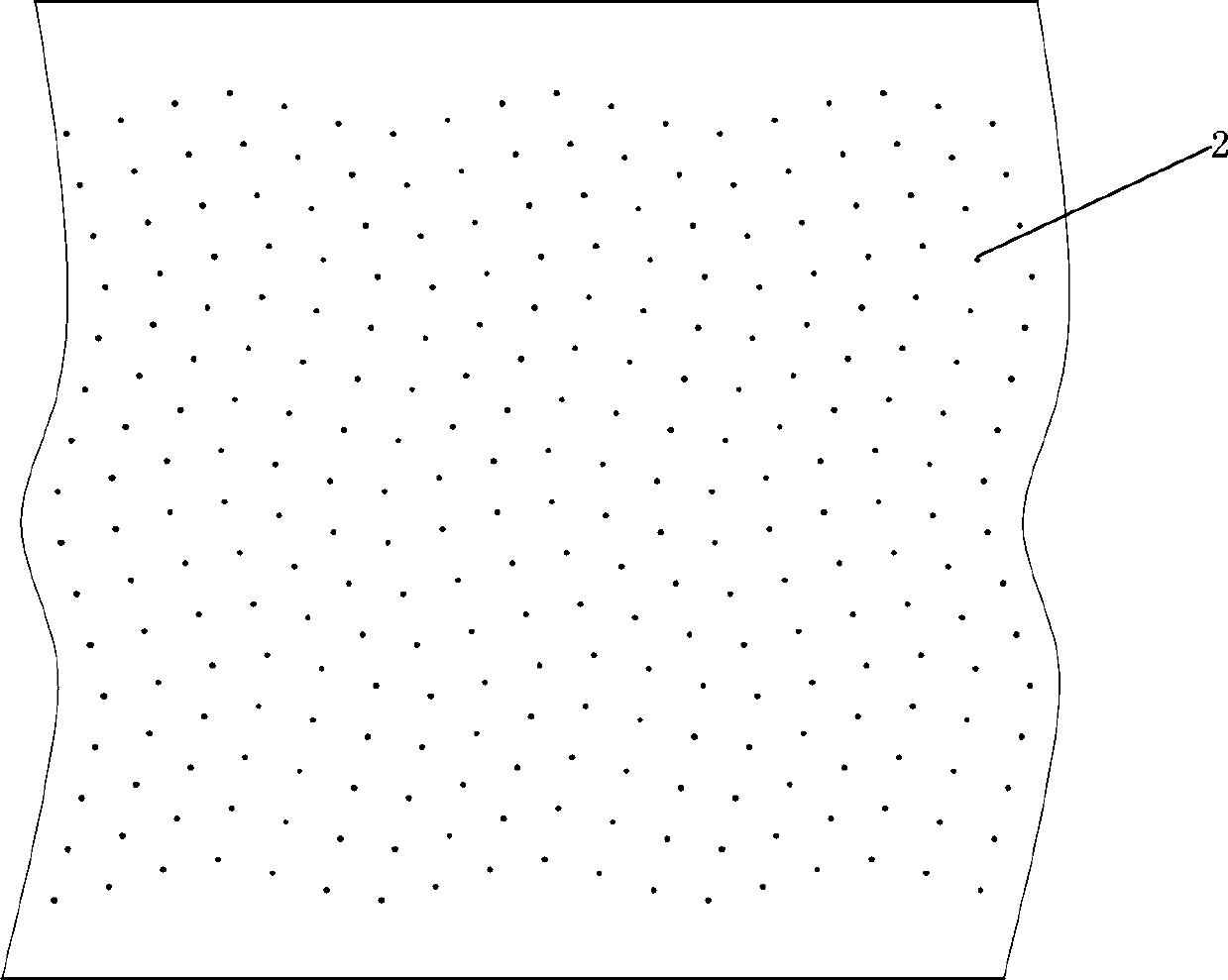

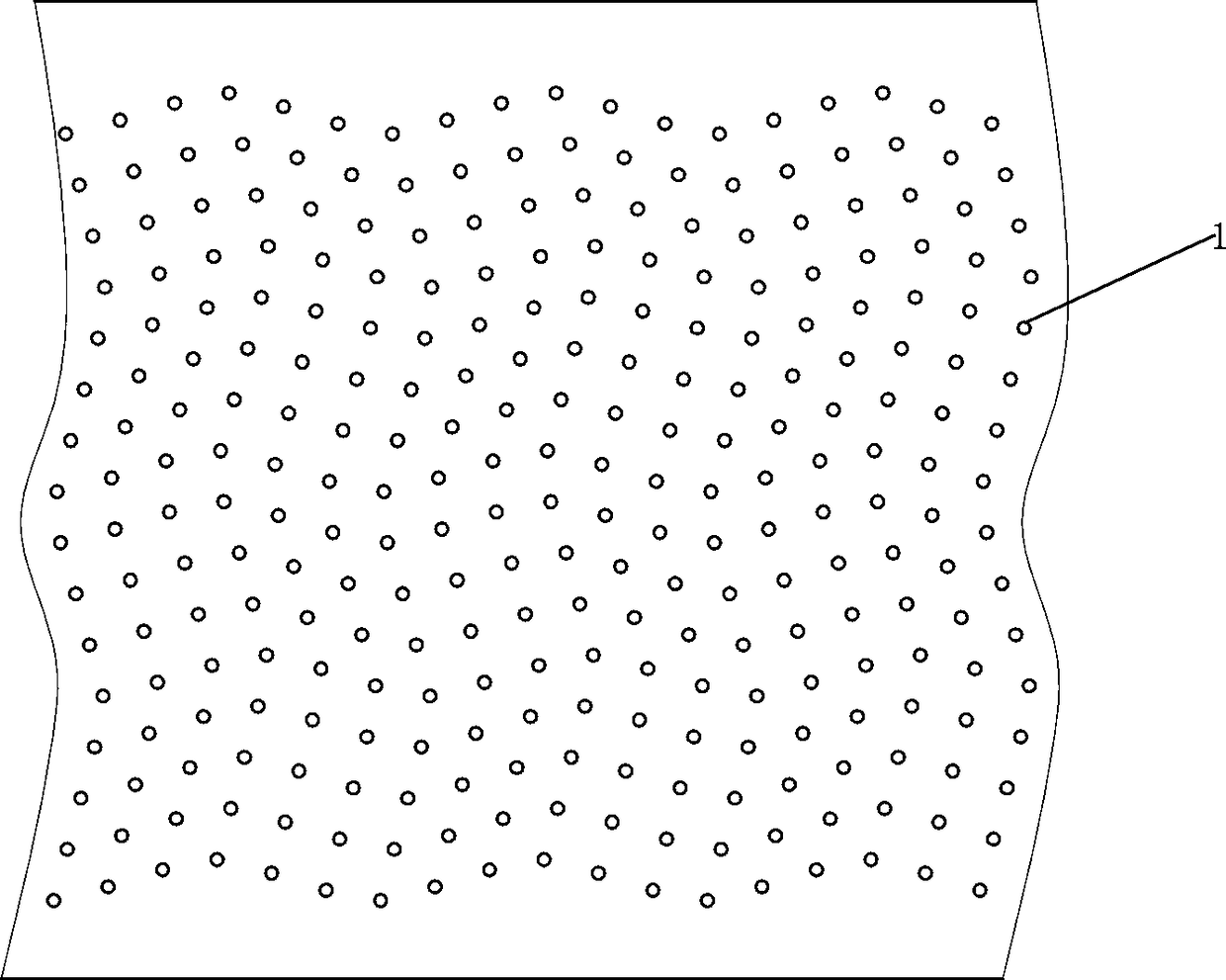

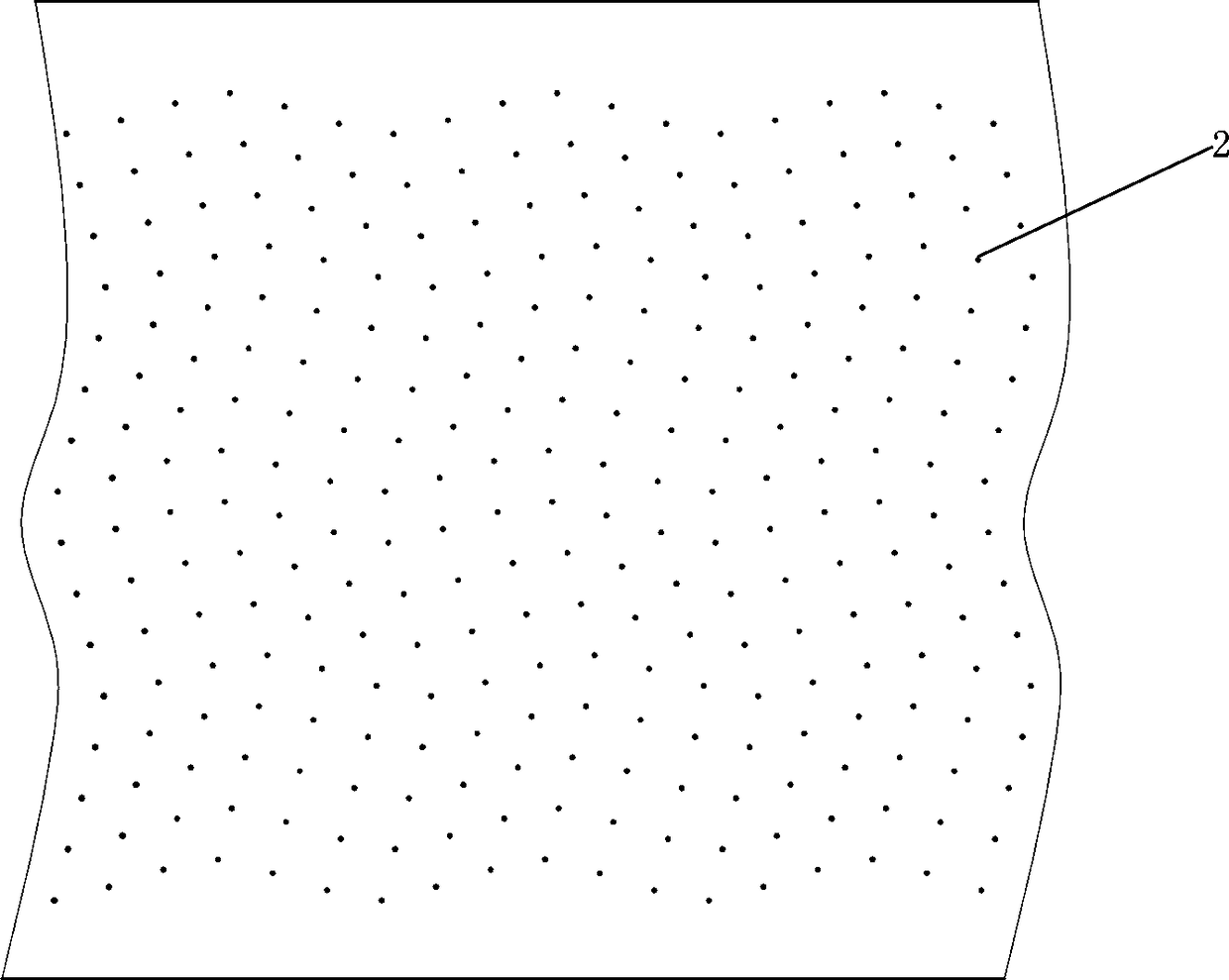

Real-time acupuncture trajectory simulation system

ActiveCN108085874BShorten trial production timeReduce trial production costsNeedling machinesPhysical medicine and rehabilitationAcupuncture

The invention discloses a real-time needling track simulating system. A needling effect picture is drawn and displayed according the following steps of 1, obtaining all coordinate information of needling of a needling machine, setting a longitudinal dimension L of a needle plate of the needling machine and a longitudinal forwarding step length s of a fiber net, calculating needling frequency N ofthe needling machine after a needling cycle is completed, and setting needling simulation frequency M of the needling machine, wherein N is equal to a quotient obtained after L is divided by s; 2, obtaining initial needling point distribution information; 3, adding s to each ordinate of all needling points in the initial needling point distribution information to obtain needling point distributioninformation of the second needling simulation, and repeating the step till needling point distribution information of the M-th needling simulation is obtained; 4, combining all needling point distribution information of each time of needling simulation; 5, drawing and displaying the needling effect picture. With an assistance from the real-time needling track simulating system, the needling machine can greatly shorten the trial manufacture time of products in a new type, reduce the dependence on operators and decrease the trail manufacture cost.

Owner:SHANTOU SANHUI NONWOVEN MACHINERY FACTORY

Real-time needling track simulating system

ActiveCN108085874AShorten trial production timeReduce trial production costsNeedling machinesSimulation systemNeedle track

The invention discloses a real-time needling track simulating system. A needling effect picture is drawn and displayed according the following steps of 1, obtaining all coordinate information of needling of a needling machine, setting a longitudinal dimension L of a needle plate of the needling machine and a longitudinal forwarding step length s of a fiber net, calculating needling frequency N ofthe needling machine after a needling cycle is completed, and setting needling simulation frequency M of the needling machine, wherein N is equal to a quotient obtained after L is divided by s; 2, obtaining initial needling point distribution information; 3, adding s to each ordinate of all needling points in the initial needling point distribution information to obtain needling point distributioninformation of the second needling simulation, and repeating the step till needling point distribution information of the M-th needling simulation is obtained; 4, combining all needling point distribution information of each time of needling simulation; 5, drawing and displaying the needling effect picture. With an assistance from the real-time needling track simulating system, the needling machine can greatly shorten the trial manufacture time of products in a new type, reduce the dependence on operators and decrease the trail manufacture cost.

Owner:SHANTOU SANHUI NONWOVEN MACHINERY FACTORY

A kind of manual core making core head forming method

ActiveCN106363135BCore making is convenientIncrease productivityFoundry mouldsFoundry coresNuclear engineeringDiameter ratio

The invention provides a core head forming method of manual core making. The core head forming method of manual core making comprises the following steps: firstly, a core head forming metal rod is placed in a core box core head hole, one end surface of the core head forming metal rod is parallel and level to the bottom end surface of the core box core head hole, the other end of the core head forming metal rod enters a cavity of a core box, and then the core box is filled with core sands to make a core; and after the core is made, the core sands with the core head forming metal rod are baked, and the core head forming metal rod is cured in the core sands, wherein during pouring, the core head forming metal rod has the action of positioning and supporting the core sands. The core head forming method of manual core making is suitable for manual core making; when a core head is too small and long without liability in forming, the problem that the core head is not liable to form as being too small (with the diameter smaller than 10mm) and having the length-diameter ratio being larger than 5 during manual core making is solved; and according to the core head forming method, the core is convenient to make, the core sands can be positioned and supported, and the production efficiency is improved.

Owner:襄阳新兴精密制造有限公司

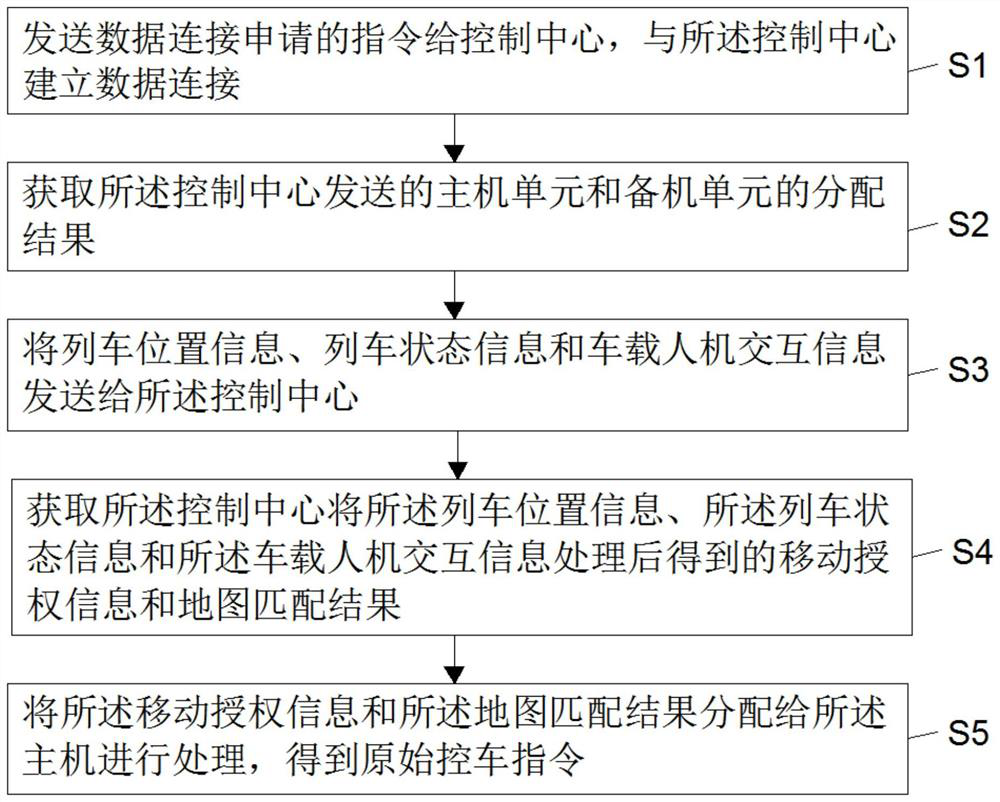

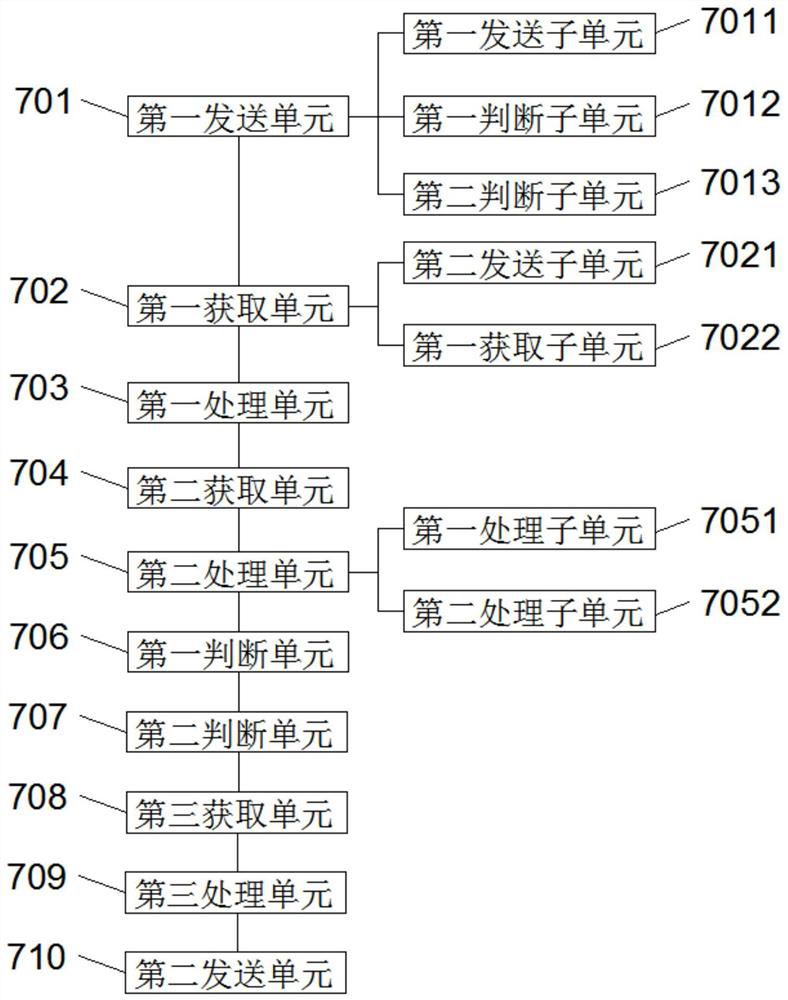

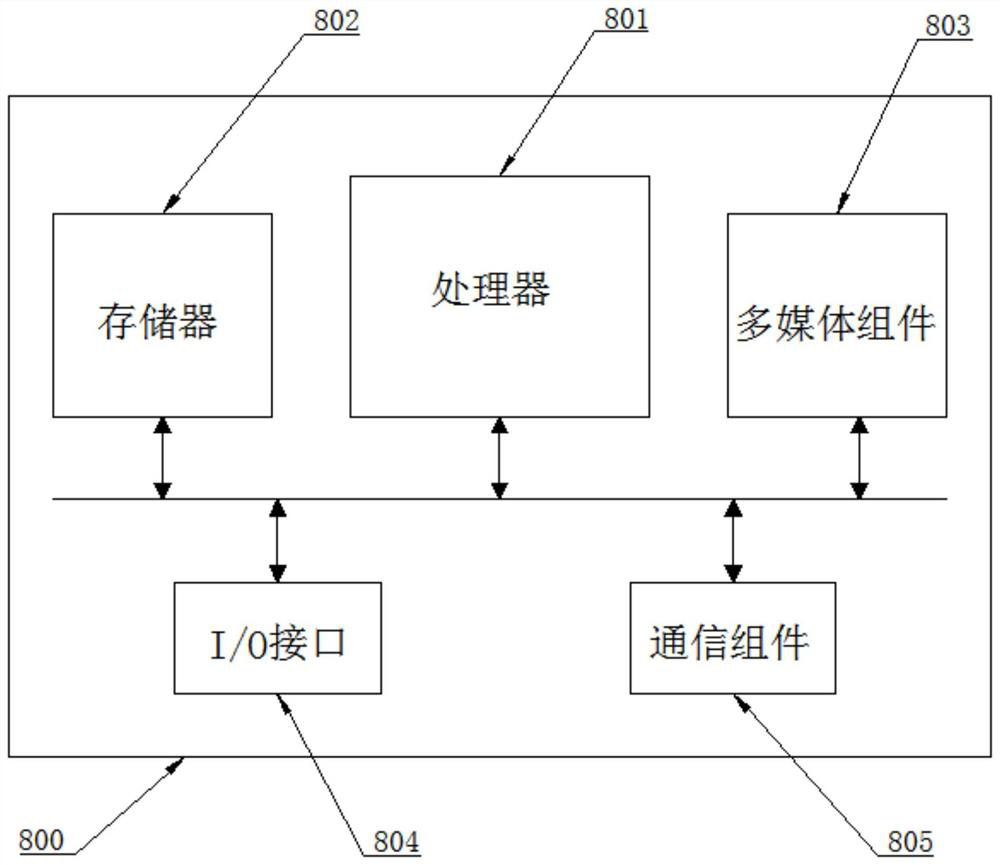

Vehicle control method, device and equipment and readable storage medium

ActiveCN113428192AReduce trial production costsImprove reliabilityRailway traffic control systemsData connectionData synchronization

The invention relates to the field of rail transit, in particular to a vehicle control method, device and equipment and a readable storage medium, and the method comprises the steps: sending a data connection application instruction to a control center, and building data connection with the control center; obtaining a distribution result of host units and a standby unit sent by the control center; sending the train position information, the train state information and the train-mounted man-machine interaction information to the control center; obtaining mobile authorization information and a map matching result which are obtained after the control center processes the train position information, the train state information and the vehicle-mounted man-machine interaction information; and distributing the mobile authorization information and the map matching result to hosts for processing to obtain an original vehicle control instruction. The data interaction mode that the two host units independently keep communication with the center is adopted, the center is used for filtering redundant data and implementing dual-computer switching, time and data are synchronous, and the stability is also guaranteed.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

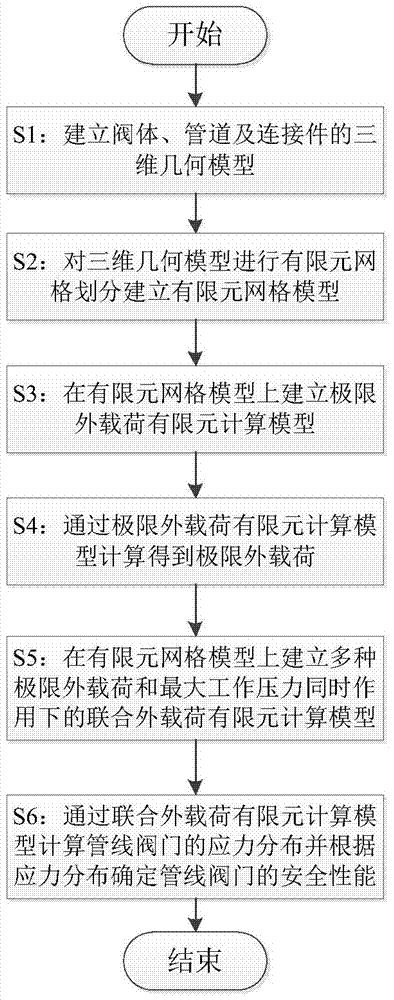

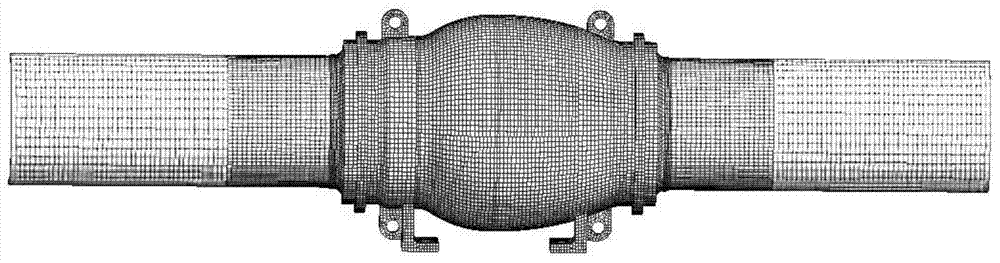

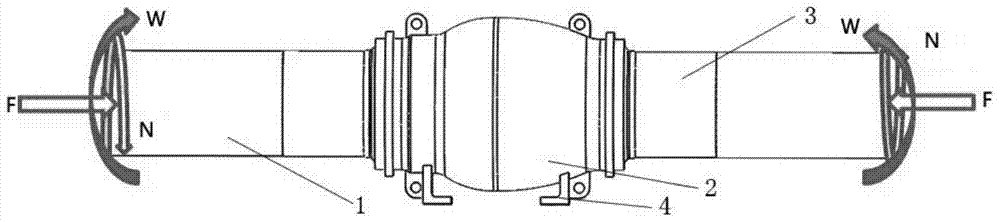

A Safety Assessment Method for Pipeline Valves Based on Calculation of Ultimate External Load

ActiveCN104392070BReduce trial production costsLow costSpecial data processing applicationsStress distributionWorking pressure

The invention relates to a safety assessment method for pipeline valves based on limit external load calculation, which includes the following steps: S1: establishing a three-dimensional geometric model of the valve body, pipeline and connecting parts; S2: performing finite element grid division on the three-dimensional geometric model to establish a limited element mesh model; S3: establish the finite element calculation model of the ultimate external load on the finite element mesh model; S4: calculate the ultimate external load through the finite element calculation model of the ultimate external load; S5: establish the multi- Combined external load finite element calculation model under the simultaneous action of two extreme external loads and maximum working pressure; S6: Calculate the stress distribution of pipeline valves through the combined external load finite element calculation model and determine the safety performance of pipeline valves according to the stress distribution. Using the method of the invention, the influence of the external load on the pipeline valve can be considered before the production of the prototype, and whether the strength and performance of the valve meet the design requirements can be judged, potential risks can be predicted, and the product development cycle can be shortened.

Owner:NEWAY VALVE SUZHOU

A jig for assembling a steel ball guide rail type intermediate shaft of a steering system and an assembling method thereof

ActiveCN106625343BImprove assembly accuracyImprove assembly efficiencyWork holdersEngineeringSteel ball

The invention discloses a clamp used for assembling a steel ball guide rail type intermediate shaft of a steering system and an assembling method. The clamp comprises an assembling base arranged on a support platform of a support. An intermediate shaft assembling clamp assembly is arranged on a base guide rail of the assembling base and is controlled to be unfolded or folded by a general feeding hand wheel arranged on one side of the assembling base. The intermediate shaft assembling clamp assembly is used for clamping the to-be-assembled part of the steel ball guide rail type intermediate shaft to the center of the clamp assembly, steel balls are arranged between steel ball rails, positioned under the assistance of leaf springs, of the steel ball guide rail type intermediate shaft through the intermediate shaft assembling clamp assembly, a lower steering shaft and an upper steering shaft are connected in a sleeved manner to form the integral steel ball guide rail type intermediate shaft. According to the clamp used for assembling the steel ball guide rail type intermediate shaft of the steering system and the assembling method, the assembling requirement for the intermediate shaft of the steering system can be met, operation is easy, the assembling work hours are reduced, the assembling precision and efficiency of the intermediate shaft are improved, the clamp and the method are suitable for different types of steel ball guide rail type intermediate shaft products, universality is improved, and the trial manufacture cost of the products is greatly reduced.

Owner:BOSCH HUAYU STEERING SYST CO LTD

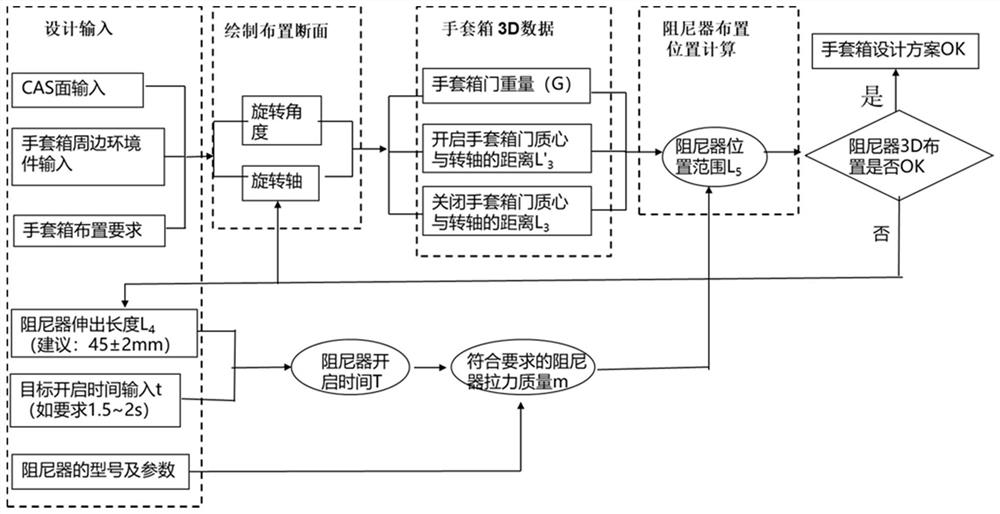

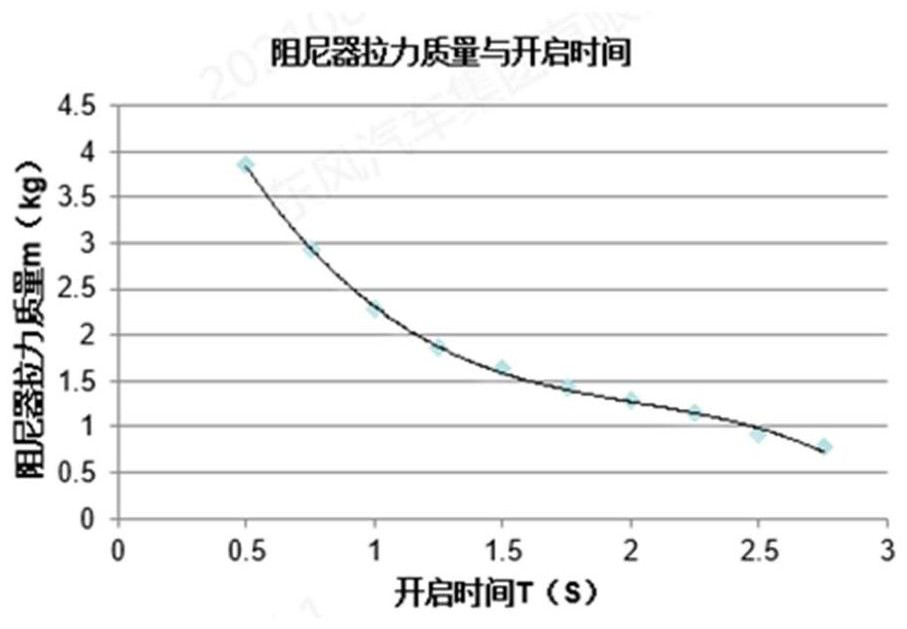

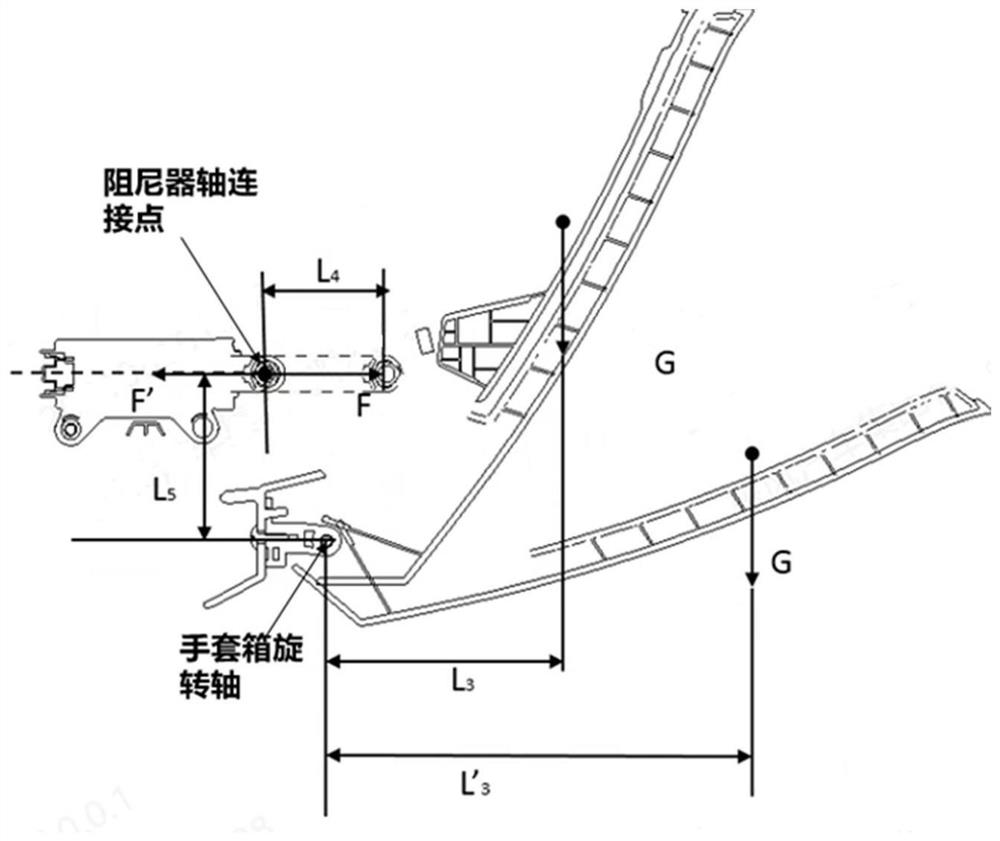

Parameterized glovebox damper arrangement method

PendingCN113886966APrecise positioningAccurate and fast layout positionGeometric CADDesign optimisation/simulationRotational axisDamper

The invention discloses a parameterized glovebox damper arrangement method which comprises the steps of inputting basic data of a glovebox and a damper, wherein the basic data at least comprise CAS surface parameters, glovebox surrounding environment parameters, glovebox arrangement requirements, damper extension length, target opening time t, damper models and corresponding parameters; drawing a section for arranging the damper, wherein drawing parameters of the section at least comprise a rotation angle and a rotation axis; generating 3D data of the glovebox according to the basic data of the glovebox, wherein the 3D data of the glove box at least comprises the weight G of a glovebox door, the distance between the mass center of the glovebox door and the rotating shaft is L'3 when the glovebox door is completely opened, and the distance between the mass center of the glovebox door and the rotating shaft is L3 when the glovebox door is closed; generating the damper opening time T and the damper counterweight mass m according to the basic data of the damper; and calculating to obtain a damper arrangement position range L5. According to the invention, the arrangement position of the glovebox damper can be accurately and rapidly positioned, the design period is shortened, and the manufacturing risk is reduced.

Owner:DONGFENG MOTOR GRP

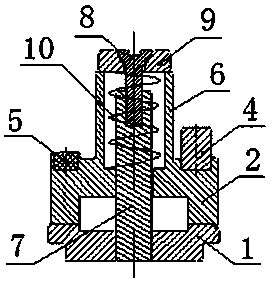

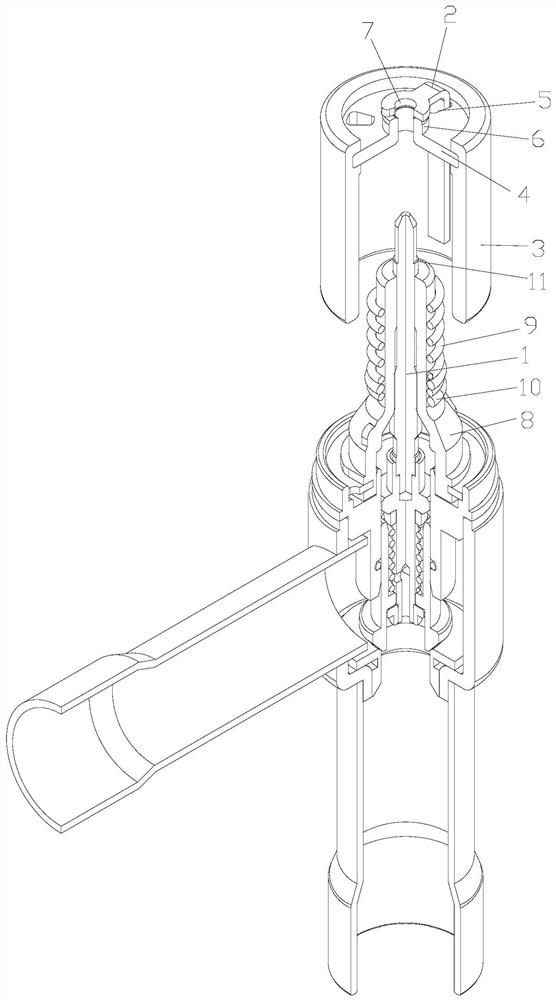

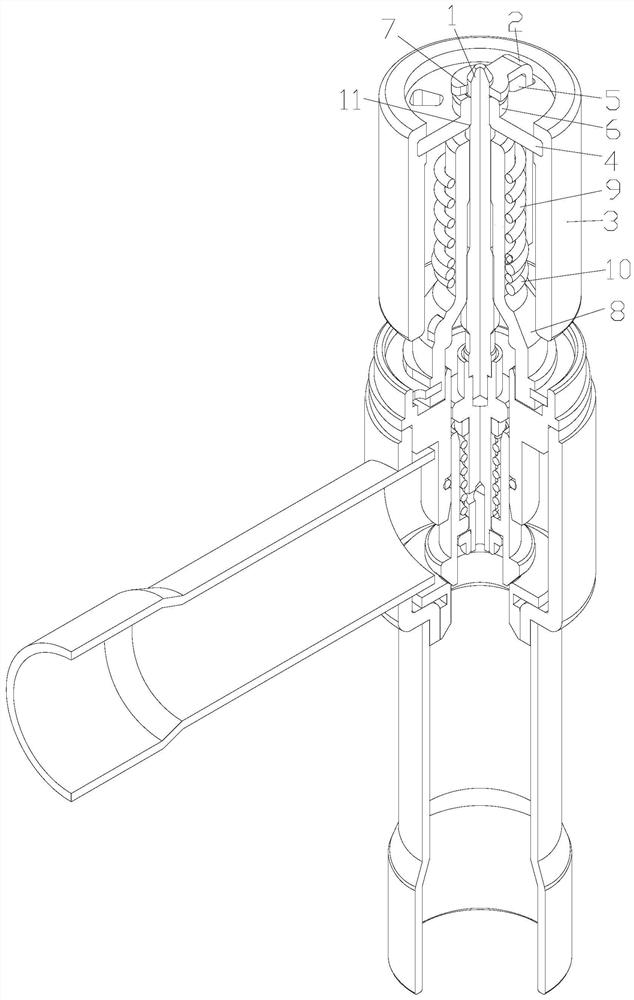

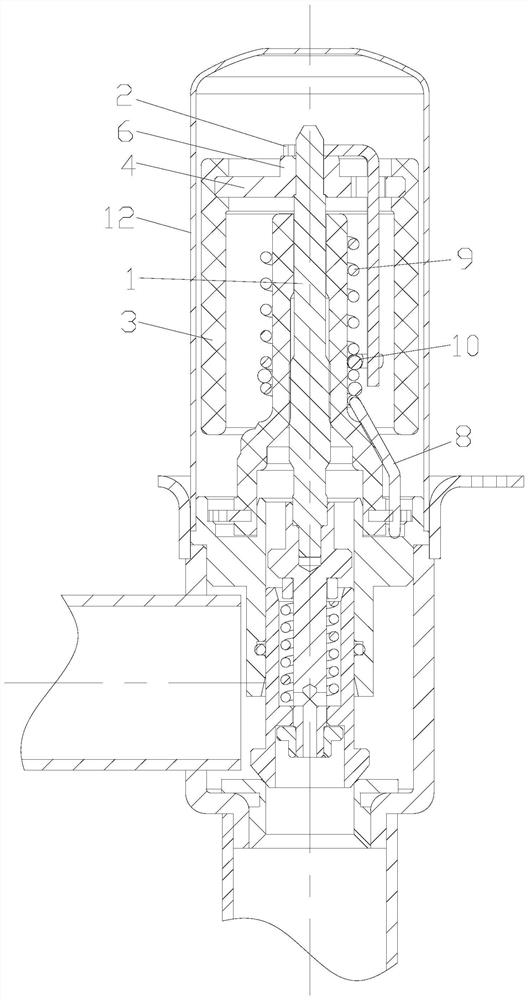

Electronic expansion valve

ActiveCN109708343BReduce the cost of mass production and trial productionReduce trial production costsMechanical apparatusEfficient regulation technologiesEngineeringElectronic expansion valve

The invention provides an electronic expansion valve. The electronic expansion valve includes a rotor assembly, a screw (1) and a guide piece (2). The rotor assembly is sleeved outside the screw (1), and the guide piece (2) forms a circumferential limit with the rotor assembly. The guide piece ( 2) It is welded and fixed to the screw rod (1), and the rotor assembly drives the screw rod (1) to rotate through the guide piece (2). According to the electronic expansion valve of the present invention, the cost of product trial production can be reduced, and the utilization rate of product components can be improved.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

Modularization and standardized management method of cylinder head trial production processing technology

The invention provides a modularization and standardization management method for the processing technique of trial-manufacturing an air cylinder cover. The modularization and standardization management method includes the following steps that a, modularization classification is conducted and the processing technique of a cylinder cover is divided into five modules; b, a preprocessing module, a rough processing module, an intermediate processing module, a finish processing module and a foundation process in a final processing module are basic processes; c, a standardized working-step module of the foundation process is formulated; d, a non-standard working-step submodule is formulated; and e, existing modules or modules special for design is combined into a novel product. The modularization and standardization management method for the processing technique of trial-manufacturing the air cylinder cover can reduce the work of production organization and technological preparation of a workshop during a product modeling through the modularization and standardization of the processing technique for trial-manufacturing the air cylinder cover, the demand of the product remodeling is met only by conducting the recombination of the modules; and through the modularization and standardization of the processing technique for trial-manufacturing the air cylinder cover can shorten the design circle of the product, can greatly reduce the trial-manufacture cost, so that the contradiction among the variety, the standard, the designing and manufacturing cycle and the cost of the product is solved.

Owner:DEUTZ DALIAN ENGINE

A quick packaging device for cigarettes with automatic filling

ActiveCN112971189BReduce gapImprove uniformityTobacco preparationCigarette manufactureStructural engineeringMechanical engineering

Owner:湖南叁谐科技发展有限公司

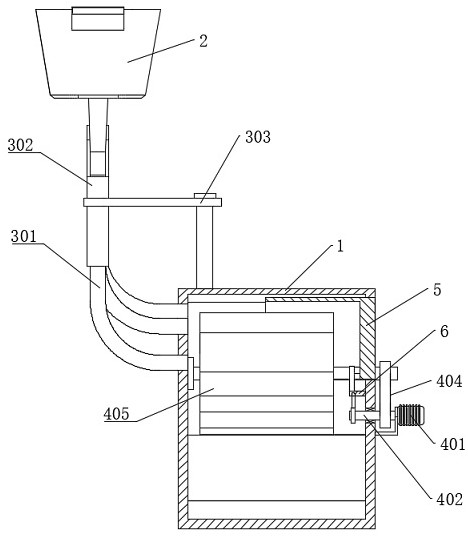

Experimental device for obtaining basic performance parameters of pipe hydraulic bulging

ActiveCN104596858BReduce trial production costsShorten the industrialization development cycleMaterial strength using tensile/compressive forcesEngineering

The invention provides an experiment device for acquiring pipe hydro-bugling basic property parameters. The experiment device can acquire accurate material performance parameters. The experiment device for acquiring pipe hydro-bugling basic property parameters comprises a base and two end clamping devices, the end clamping mechanism comprises a fixing body and a movable body, the movable body can axially move in the fixed body, and the movable body has a structure capable of clamping a pipe end so that two ends of the pipe can be respectively clamped by the two end clamping mechanisms.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com