Experimental device for obtaining basic performance parameters of pipe hydraulic bulging

An experimental device, hydraulic bulging technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as deviation, inability to obtain material performance parameters, and obstruction of material flow in the radial direction, so as to reduce trial production costs and shorten The effect of the industrialization development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

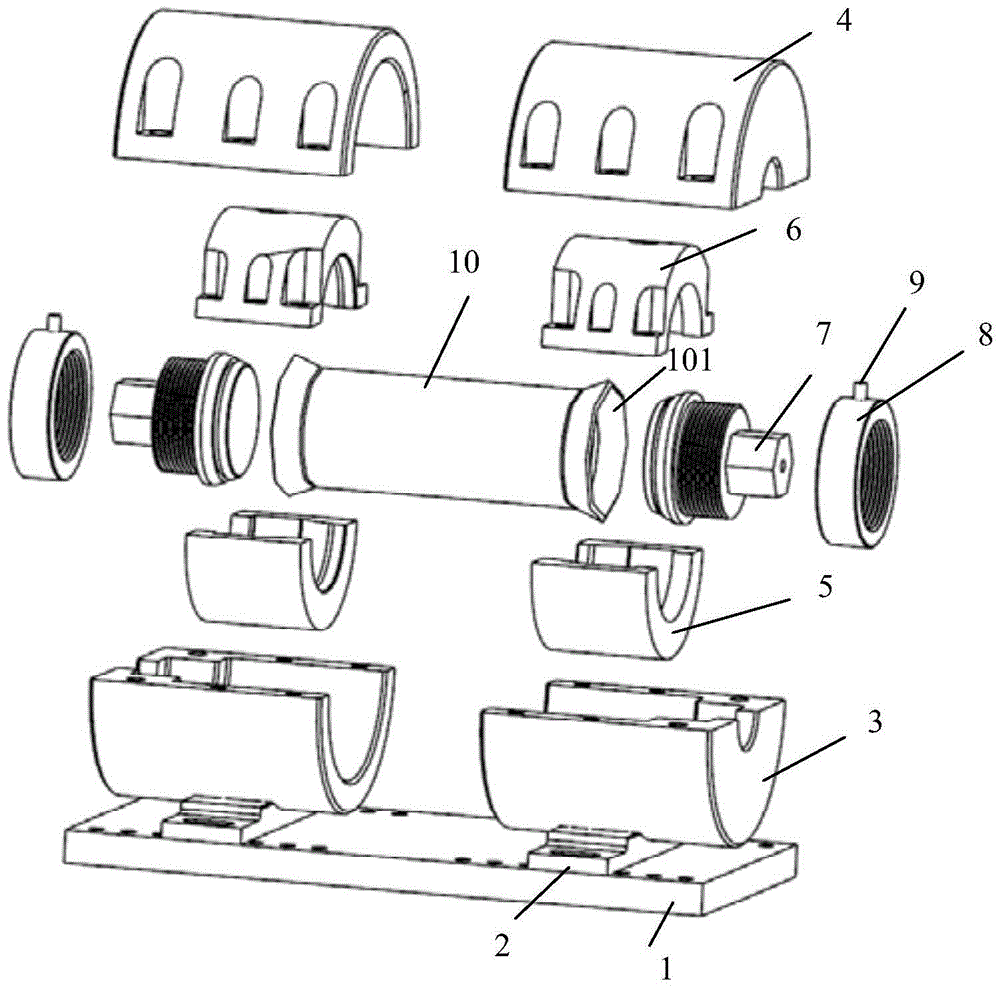

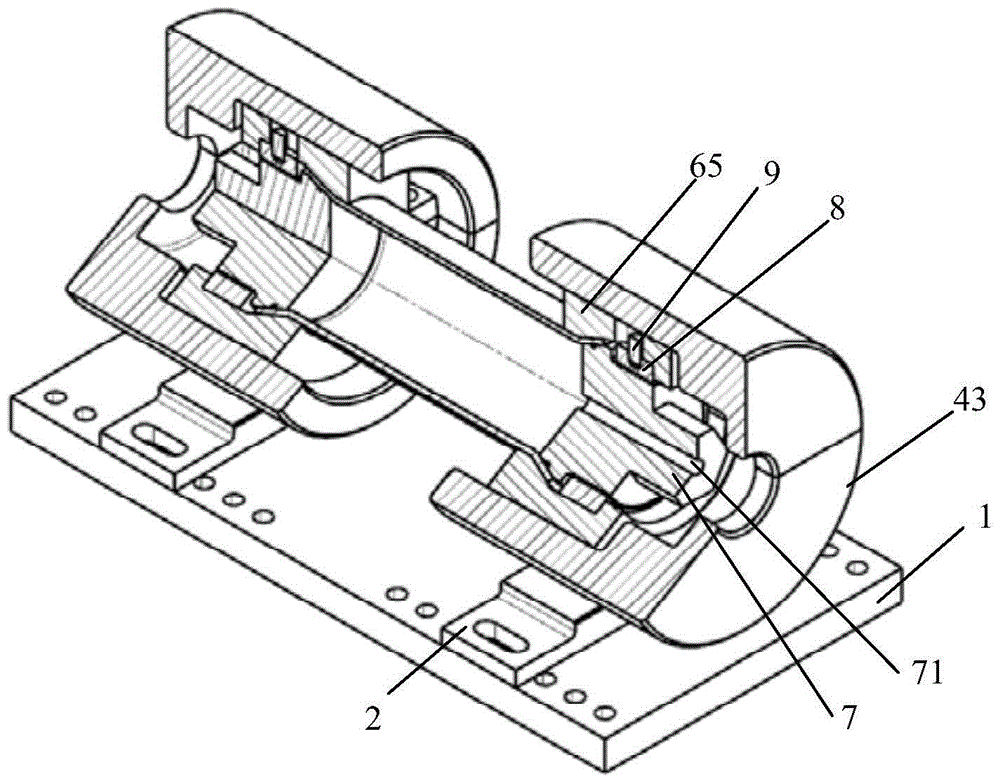

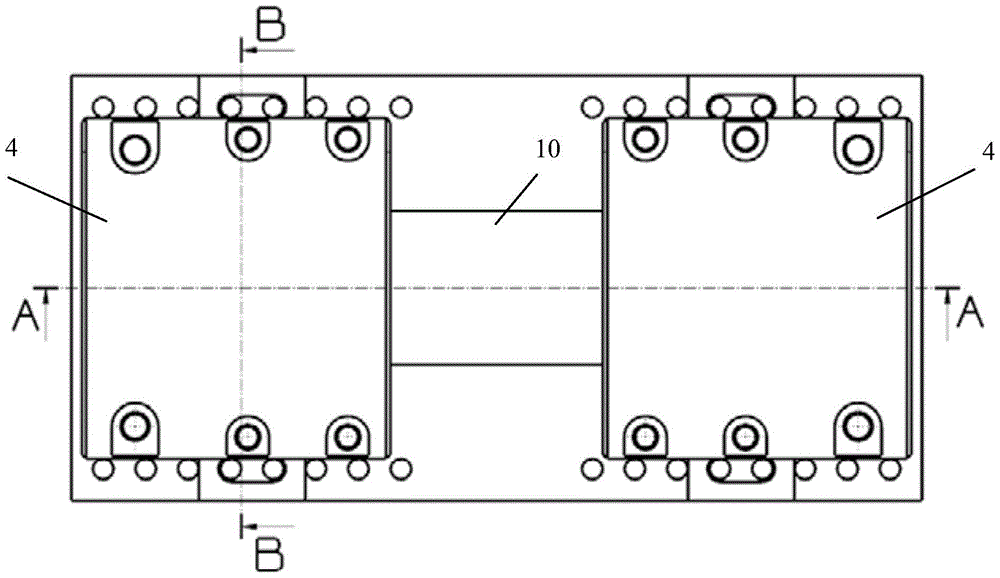

[0015] Such as Figure 1 to Figure 5 As shown, the experimental device for obtaining basic performance parameters of pipe hydraulic bulging includes a base and two end clamping mechanisms. The end clamping mechanism includes a fixed body and a movable body. The movable body can move axially in the fixed body. The movable body has a structure capable of clamping the ends of the pipe, so that the two ends of the pipe can be clamped by the two end clamping mechanisms respectively. The movable body is an inner and outer clamping block and an adjusting block, and the fixed body is a guide block. The base includes a bottom plate 1 and a fixing plate 2. The outer clamping block 65 is divided into upper and lower clamping blocks 6, 5, and the guide block 43 is also divided into upper and lower guide blocks 4, 3 for easy disassembly and assembly. figure 1 The experimental device for obtaining the basic performance parameters of pipe hydraulic bulging includes bottom plate 1, fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com