A quick packaging device for cigarettes with automatic filling

An automatic filling and cigarette technology, which is applied in the fields of tobacco, tobacco preparation, and paper cigarette manufacturing, can solve the problems of not being able to obtain high-quality cigarettes, poor uniformity of shredded tobacco in the cigarette barrel, and reducing the accuracy of market evaluation, so as to reduce errors , Improve packing efficiency and facilitate fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

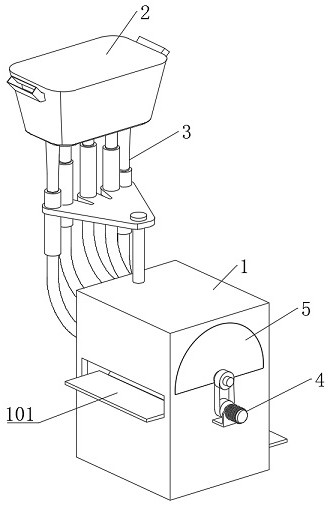

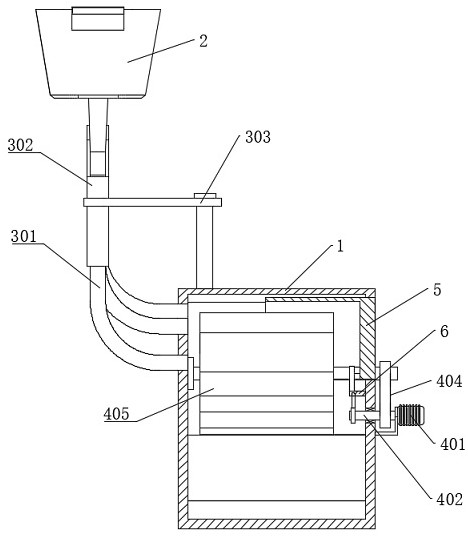

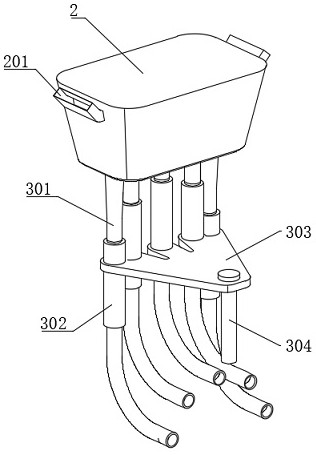

[0048] see Figure 1-10 , a quick packing device for cigarettes with automatic filling, comprising a cigarette body 1 and a shredded tobacco pressing box 2 fixedly installed at the front end of the cigarette body 1, a cigarette driving assembly 4 is installed in the cigarette body 1, and shredded tobacco is connected to the lower end of the shredded tobacco pressing box 2 The rubbing filler assembly 3, the lower end of the shredded tobacco rubbing filler assembly 3 is connected to the cigarette body 1 and matched with the cigarette drive assembly 4, the rear end of the cigarette body 1 is slidably connected with a semicircular guard plate 5 matching the shredded tobacco rubbing filler assembly 3, The rear inner wall of the cigarette body 1 is fixedly connected with an induction support plate 6 located directly below the semicircular guard plate 5; please refer to image 3 , Figure 5 and Figure 6 The shredded tobacco rubbing filler assembly 3 includes a shredded tobacco rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com