Modularization and standardization management method for trial-manufacturing processing technique of air cylinder cover

A technology of processing technology and management method, which is applied in the trial production processing of diesel engine cylinder heads and the field of diesel engines, can solve the problems of long inventory backlog, difficulty, and time-consuming, and achieve the effect of shortening the product design cycle and reducing the cost of trial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

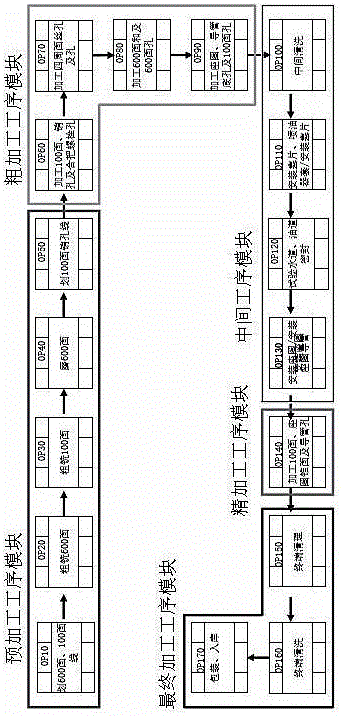

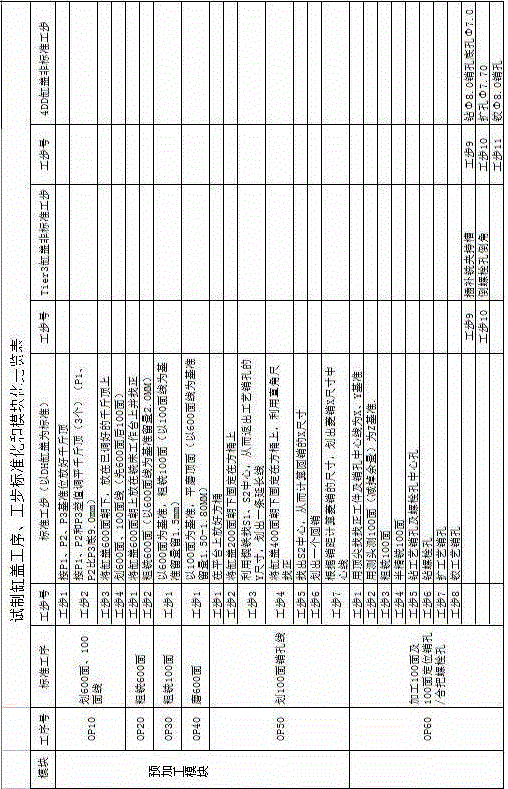

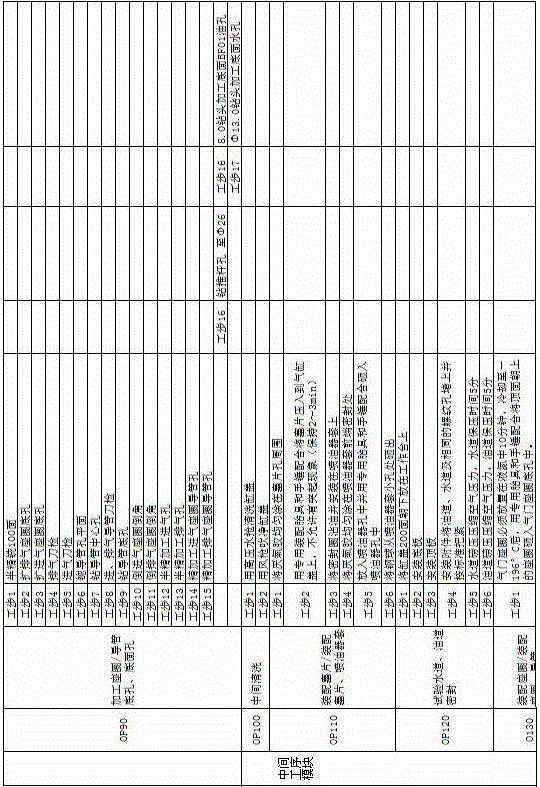

[0015] The new concept of modularization and standardization of cylinder head trial production processing technology suitable for workshop cylinder head trial production. The significance of modularization and standardization of existing cylinder heads is to produce different products without imposing on each product from process to process. Instead, design a variety of modules and combine them in different ways to form different products, so as to solve the contradictions between product varieties, specifications, design and manufacturing cycles, and costs. Research on the modularization and standardization of the cylinder head trial production process, the basic modules and sub-modules are produced, and then the function analysis is carried out according to the new trial products, and then the existing modules are selected or individual special modules are designed for combination. If the total function of the combined product fully meets the requirements of the new trial pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com