Method and system for evaluating structural performance of high-temperature valve based on valve simulation model

A technology of structural performance and simulation model, applied in design optimization/simulation, instrumentation, calculation, etc., can solve the problems of low reference value, low prediction accuracy, and high cost of prototype trial production in the field of high temperature valve design, so as to reduce prototype trial production The effect of reducing costs, shortening the R&D cycle, and improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and technical effect of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

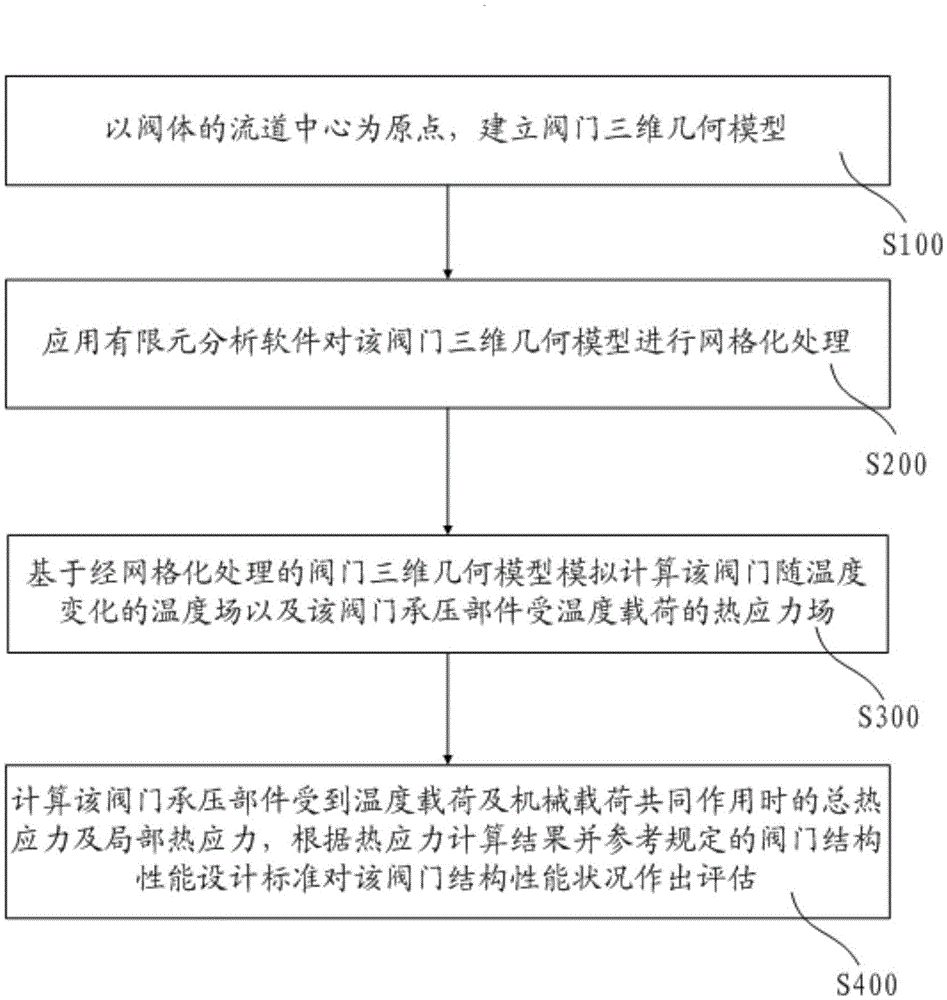

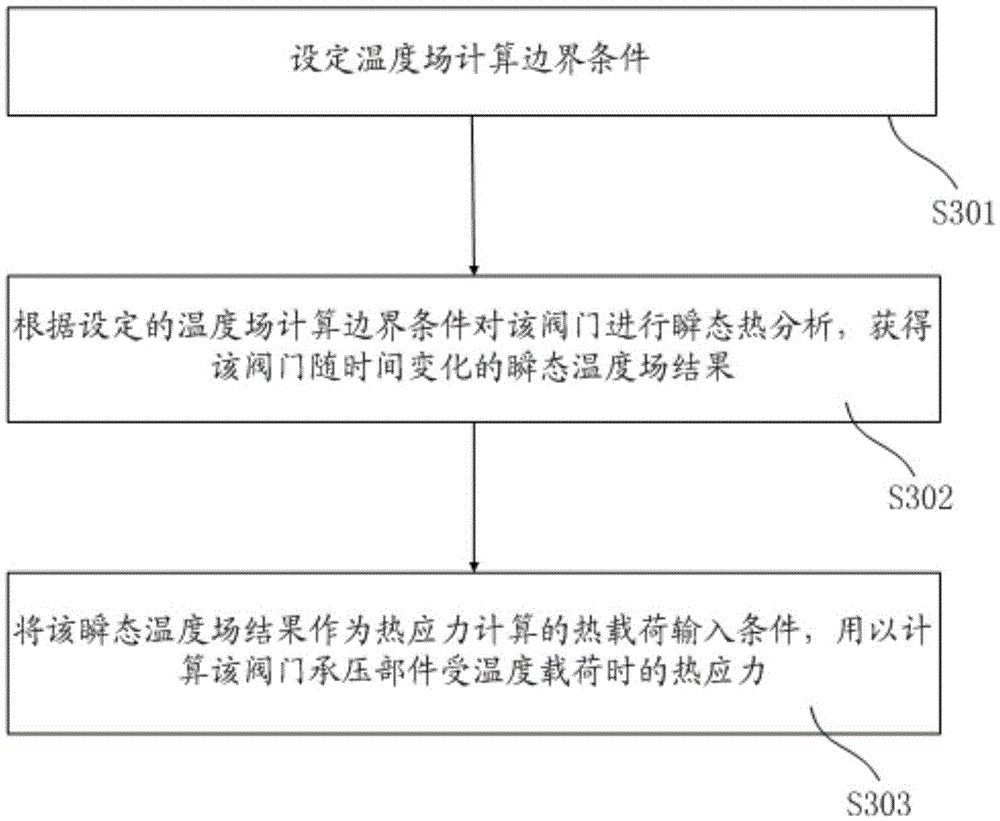

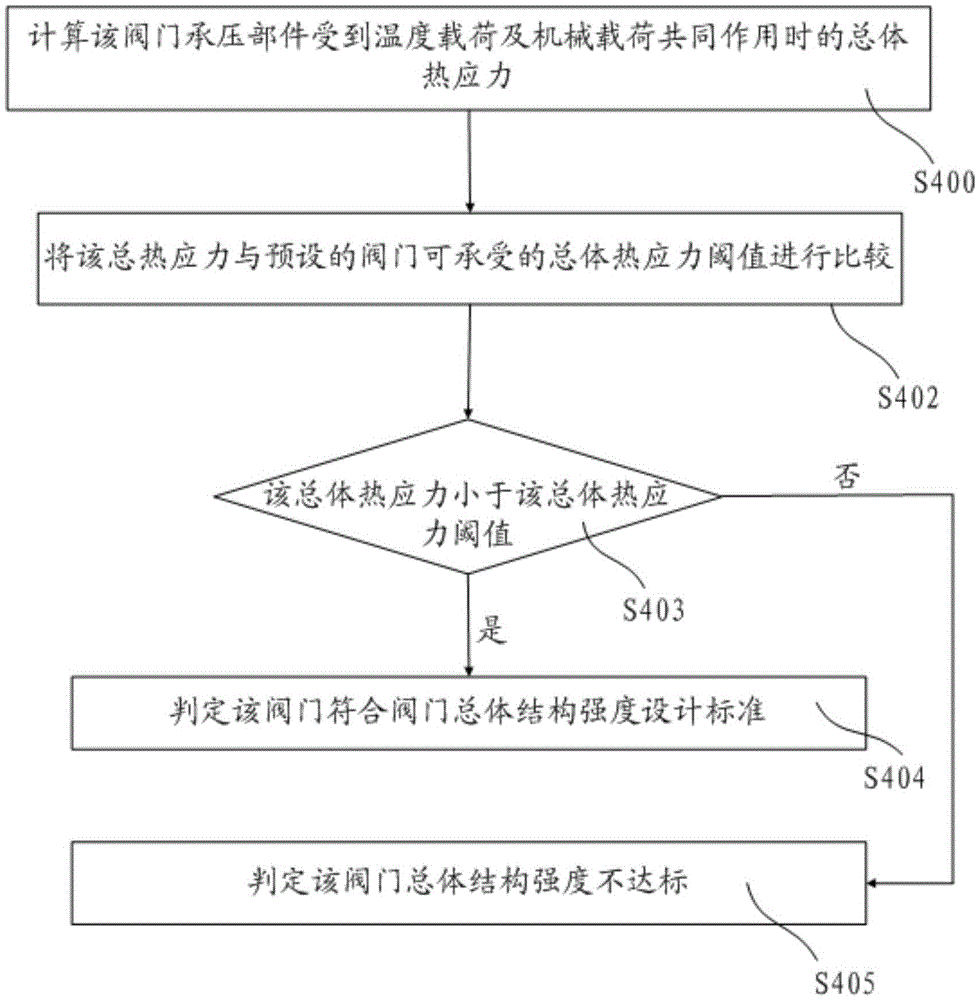

[0030] In view of the prior art, the valve structure and the geometric design parameters of each component can only be roughly determined on the basis of referring to conventional valves, and the structural performance of the pressure relief valve beyond the design reference under high temperature conditions can be predicted through repeated tests, which is costly and time-consuming. Due to the technical defects of being long and causing unnecessary waste, the present invention proposes a high-temperature valve structural performance evaluation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com