Casting method and system suitable for integral multi-way valve based on 3D printing

A 3D printing, integrated technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as multiple revisions of unfavorable models, restrictions on rapid replacement of large integrated hydraulic multi-way valves, and difficulty in casting. , to ensure the surface quality and quality stability, realize the effect of industrial application, and reduce the cost of trial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is a casting method suitable for integral multi-way valves based on 3D printing, including:

[0053] Determine the structural parameters of the valve to be cast;

[0054] Take the direction perpendicular to the axial direction of the main valve hole as the height direction to determine the height L of the valve body of the valve to be cast;

[0055] Determine the number of layers of the gate according to the height L of the valve body;

[0056] According to the structural parameters of the valve to be cast, determine the position of each ingate of each layer, so that all ingates are located on the same side of the valve body to be cast;

[0057] According to the structural parameters of the valve to be cast, arrange the gate models of the corresponding layers and positions;

[0058] Corresponding to the ingate of each layer, the runner model connected with the ingate is respectively arranged;

[0059] Set up the riser model and the sprue model connect...

Embodiment 1-1

[0065] On the basis of Embodiment 1, this embodiment takes the valve to be cast as an integral hydraulic multi-way valve as an example to introduce the method in detail.

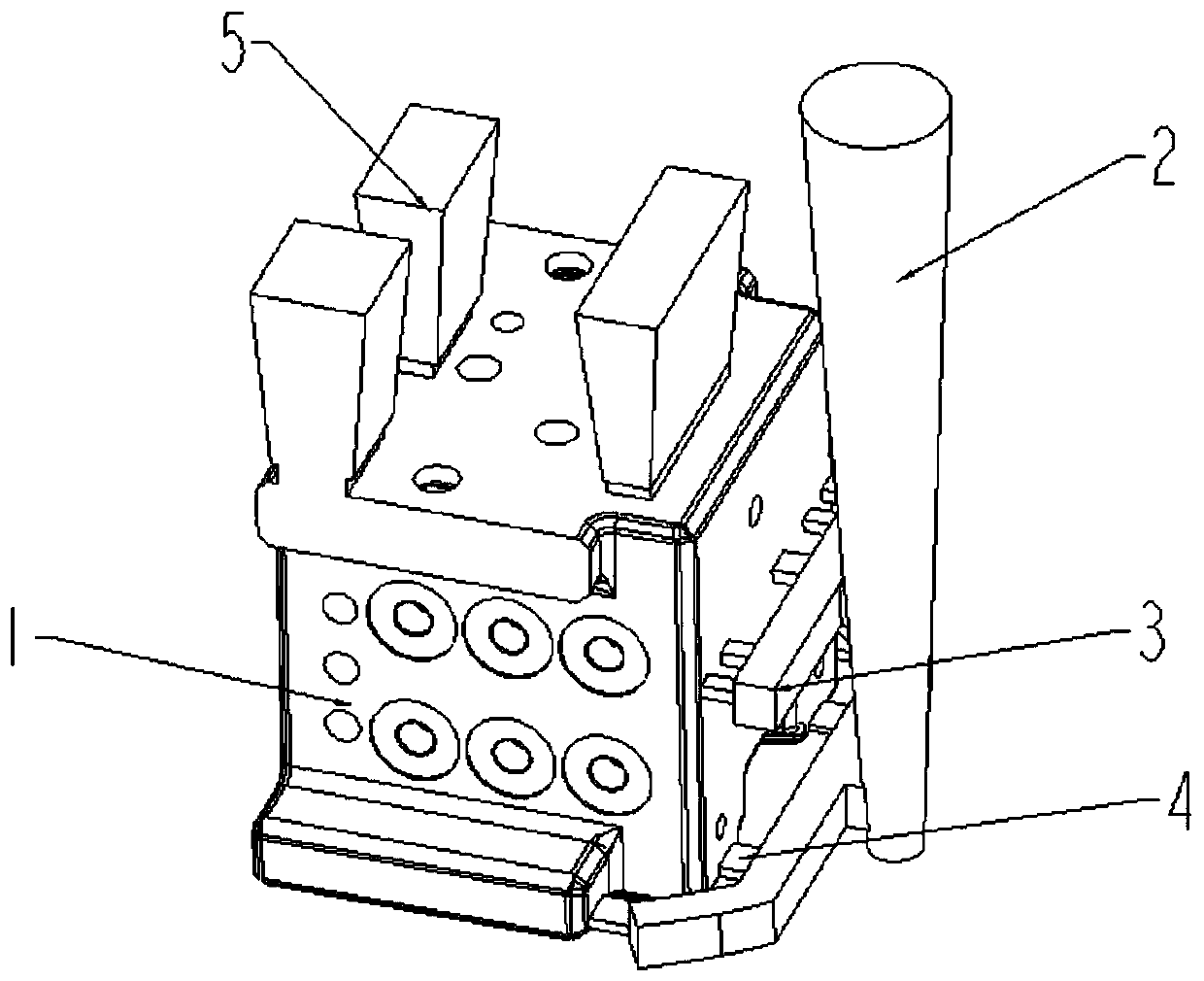

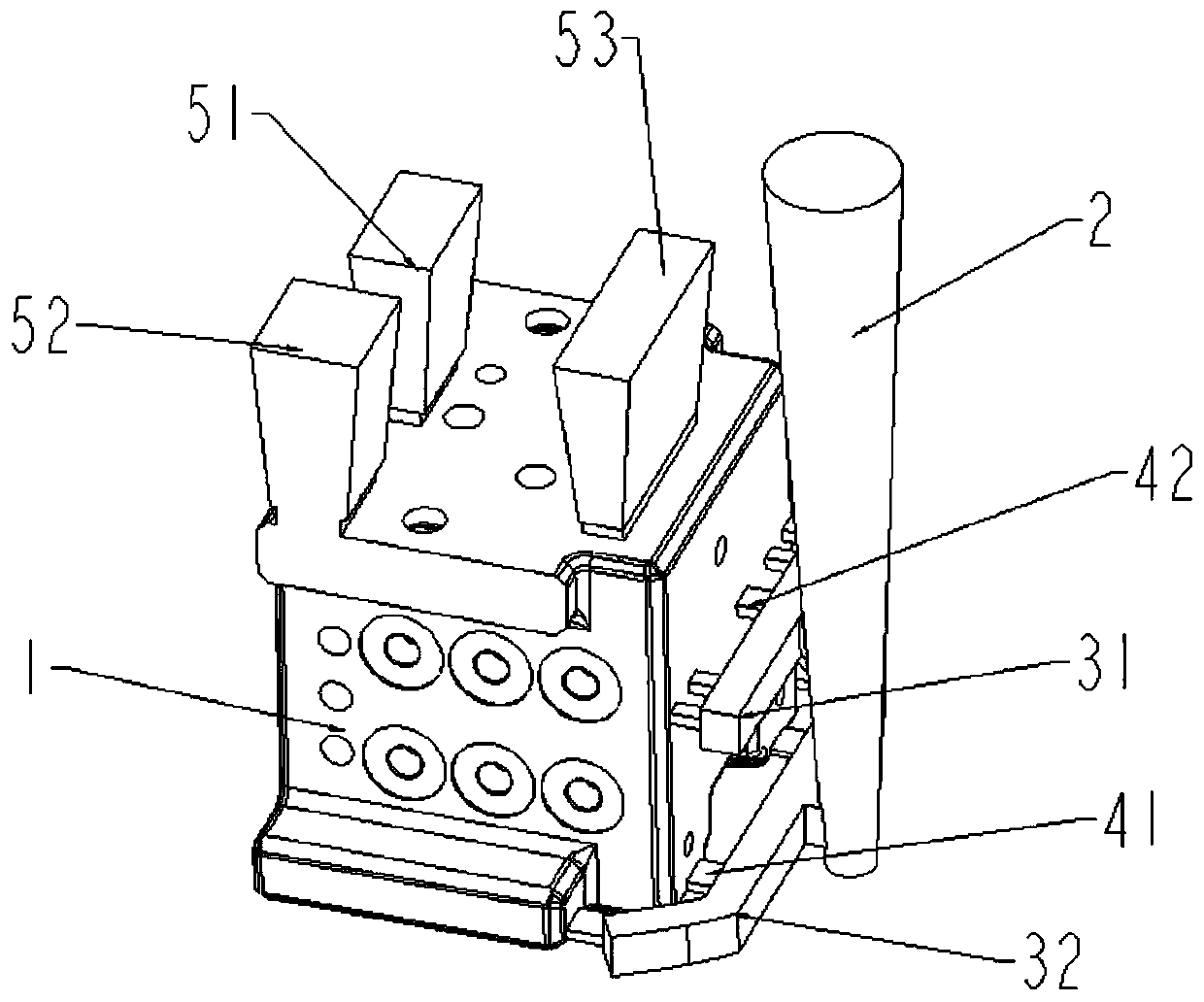

[0066] In this embodiment, after determining the structural parameters of the valve to be cast, the body model 1 of the integral multi-way valve to be cast can be generated, which facilitates more intuitive setting of the ingate, runner, sprue, riser, etc. location, reference figure 1 and figure 2 shown.

[0067] The integral multi-way valve casting method also includes:

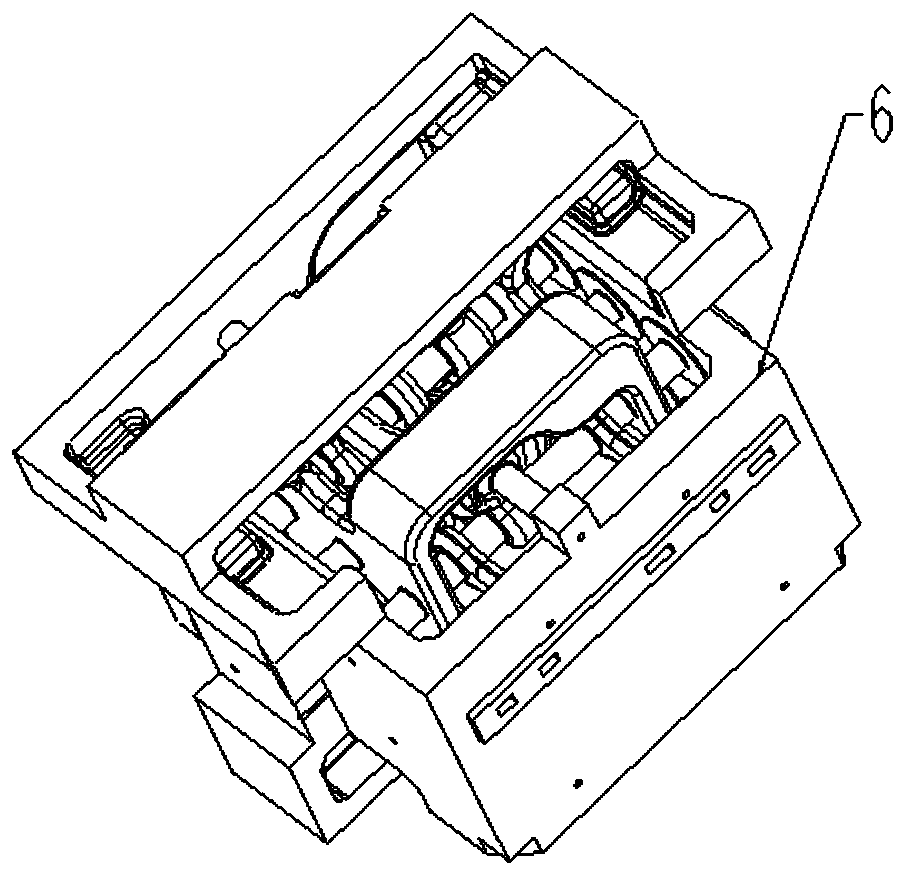

[0068] Set a through-type exhaust channel in the sand core corresponding to the main valve hole; for other valve holes except the main valve hole, set a follow-up exhaust hole in the corresponding sand core that needs to be connected to the periphery of the sand mold. That is, the path of the exhaust hole is set along the central path of the valve hole. The setting of the exhaust channel and the exhaust hole can improve the exhaust ef...

Embodiment 2

[0075] Based on the same inventive concept as Example 1 and Example 1-1, this example introduces a casting system suitable for integral multi-way valves, including a sand mold body, a sprue 2, a runner 3, and an ingate 4 and riser 5;

[0076] Take the direction perpendicular to the axial direction of the main valve hole sand core as the height direction of the sand mold body;

[0077] The sprue 2, runner 3 and ingate 4 are arranged on one side of the sand mold body; there are multiple runners along the height direction of the sand mold body, and a plurality of inner sprues are arranged in the extending direction of each runner. Each runner is connected to the sand mold body through the multiple inner gates; the multiple runners are respectively connected to the sprue, and the riser 5 is arranged on the top of the sand mold body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com