Method for correcting bending and twisting size of turbine blade

A turbine blade, bending and twisting technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of statistical deformation-verification-dressing that takes a lot of time, high cost, and long cycle, and shortens the problem of bending and torsion control. , the effect of improving production efficiency and reducing trial production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

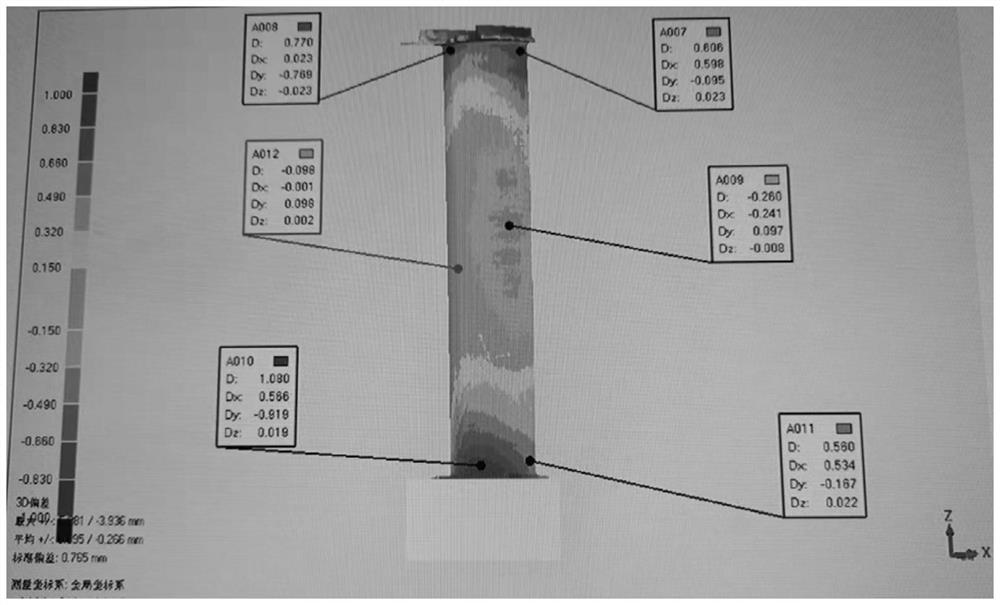

[0043] The maximum height of a certain type of gas turbine blade is 290mm, the chord width is 49-53mm, the maximum thickness of the airfoil is 5.5-13mm, the twist of each section of the airfoil relative to its own theoretical surface is not more than ±15', and the bending is within ±0.25mm Inside.

[0044] When correcting the bending and torsion size of the precision casting turbine blade, the implementation steps are as follows:

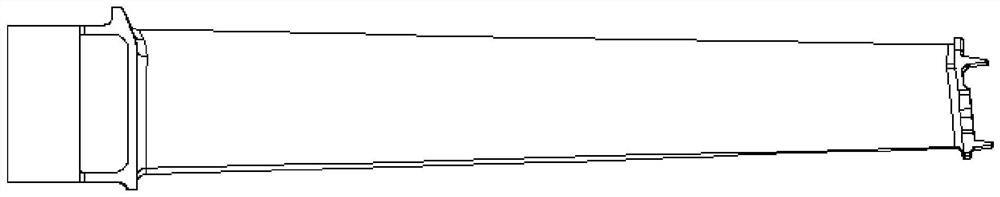

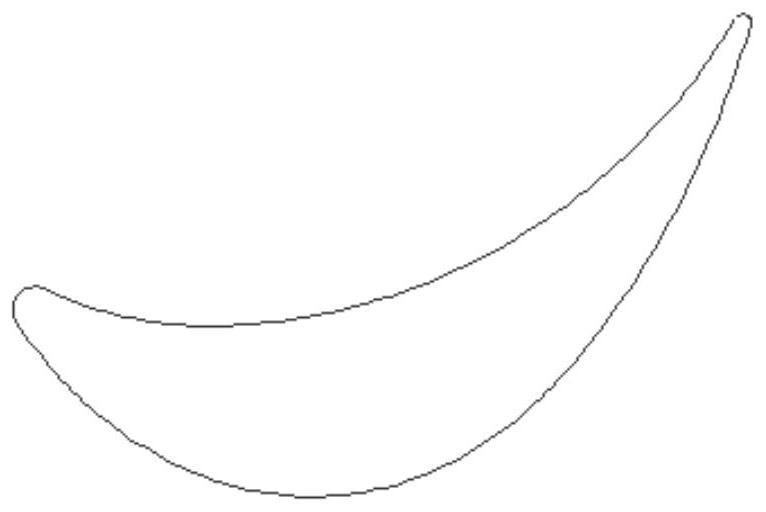

[0045] Step 1: Manufacture the airfoil correction film conforming to the blade back of the precision-cast turbine blade;

[0046] Step 2: Paste 0.2mm wax sheets on both ends of the leaf shape correction membrane;

[0047] Step 3: Press the wax model corresponding to the precision-cast turbine blade, take it out immediately and place the back of the blade on the corresponding position of the blade shape correction membrane pasted with the wax sheet;

[0048] Step 4: Place a 500g sand bag in the middle of the precision casting turbine blade wax mode...

Embodiment 2

[0059] The maximum height of precision cast turbine blades for a certain type of gas turbine is 320mm, the chord width is 48-53mm, the maximum thickness of the blade profile is 5-12mm, and the twist of each section of the blade body relative to its own theoretical profile is not greater than ±15', and the bending Within ±0.25mm.

[0060] When correcting the bending and torsion size of the precision casting turbine blade, the implementation steps are as follows:

[0061] Step 1: Manufacture the airfoil correction film conforming to the blade back of the precision-cast turbine blade;

[0062] Step 2: Paste 0.2mm wax sheets on both ends of the leaf shape correction membrane;

[0063] Step 3: Press the wax model corresponding to the precision-cast turbine blade, take it out immediately and place the back of the blade on the corresponding position of the blade shape correction membrane pasted with the wax sheet;

[0064] Step 4: Place a 500g sand bag in the middle of the precisio...

Embodiment 3

[0074] A certain type of gas turbine working precision casting turbine blade is about 245mm long, the chord width is 75-85mm, and the maximum thickness of the blade shape is about 13mm. The twist of each section of the airfoil relative to its own theoretical profile is not more than ±15', and the bending is within ±0.30mm.

[0075] When correcting the bending and torsion size of the precision casting turbine blade, the implementation steps are as follows:

[0076] Step 1: Manufacture the airfoil correction film conforming to the blade back of the precision-cast turbine blade;

[0077] Step 2: Paste 0.2mm wax sheets on both ends of the leaf shape correction membrane;

[0078] Step 3: Press the wax model corresponding to the precision-cast turbine blade, take it out immediately and place the back of the blade on the corresponding position of the blade shape correction membrane pasted with the wax sheet;

[0079] Step 4: Place a 500g sand bag in the middle of the precision cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com