Cushion block for matching of automobile door cover

A door cover and spacer technology, which is applied in the field of cushion blocks for car door cover matching, can solve the problems of uncontrollable manufacturing tolerances, inability to accurately divide size intervals, difficult modularization, etc., to facilitate assembly data collection and shorten trial production. Cycle time, the effect of reducing the cost of trial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

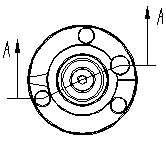

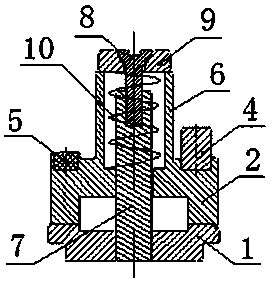

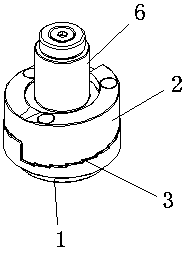

[0021] Such as Figure 1~4 As shown, the cushion block for matching the automobile door cover of this embodiment is composed of a base 1 and a body 2, the bottom surface of the body 2 and the top surface of the base 1 are provided with a spiral ladder 3 that cooperates with each other, and the body 2 passes through the spiral. Shaped ladder 3 is supported on the base 1. The top surface of the body 2 is in a spiral structure around the cylinder, and the top surface of the body 2 protrudes through an interference fit to be provided with an adjustment fixing pin 4, and the top surface of the body 2 is equipped with a magnet 5 through a transition fit. The top surface is flush with the top surface of the body 2 .

[0022] The drop of adjacent steps in the spiral steps 3 is the same, so as to ensure that the spiral steps 3 of the base 1 and the body 2 can overlap at any step, so as to realize the continuity of adjustment. The body 2 and the base 1 are printed or engraved with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com