CFD (computational fluid dynamics) based method for computing equivalent length of valve

A calculation method and equivalent technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of long development cycle, high development cost, low efficiency, etc., achieve the effects of stable calculation, improved measurement accuracy, and simplified analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

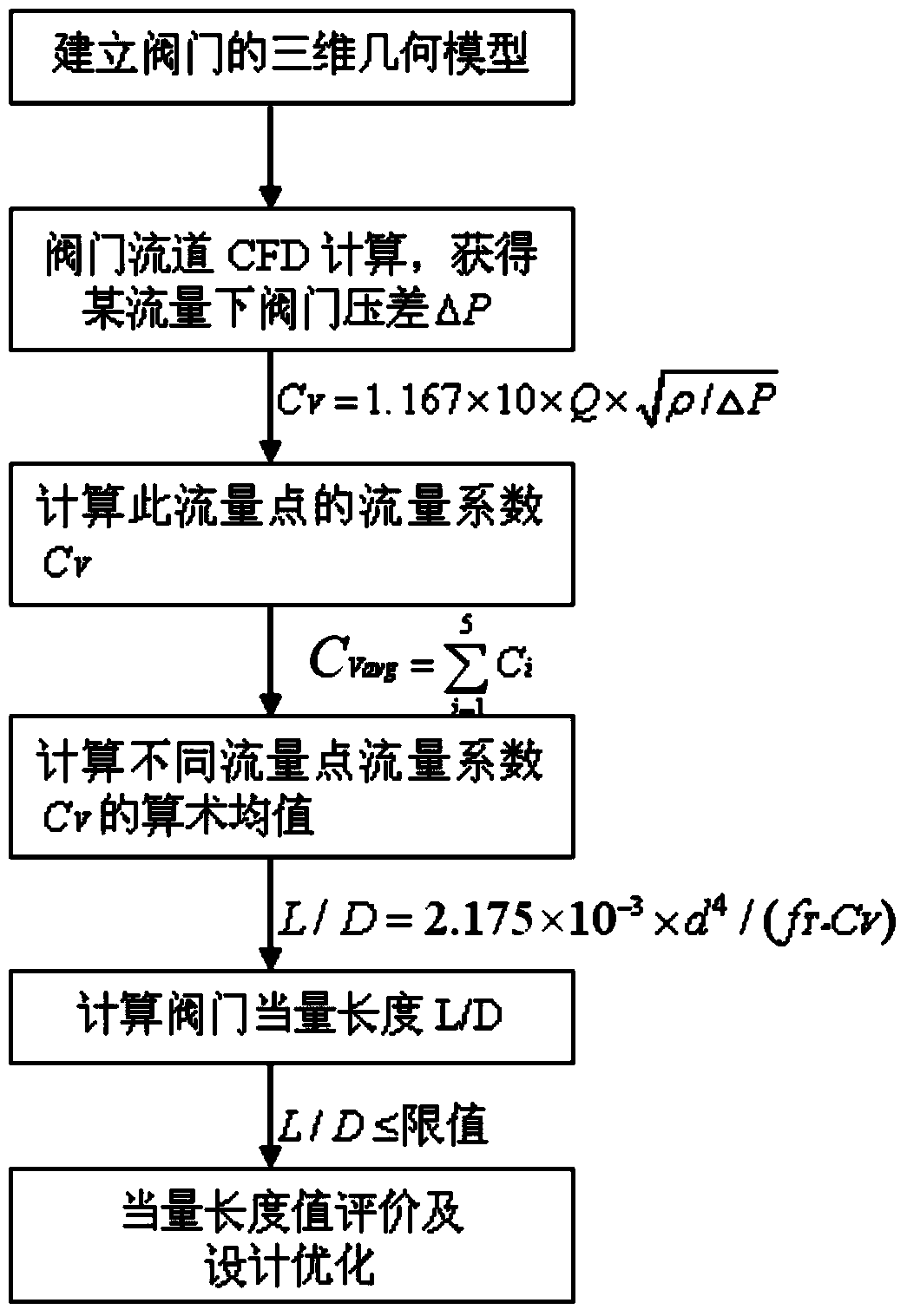

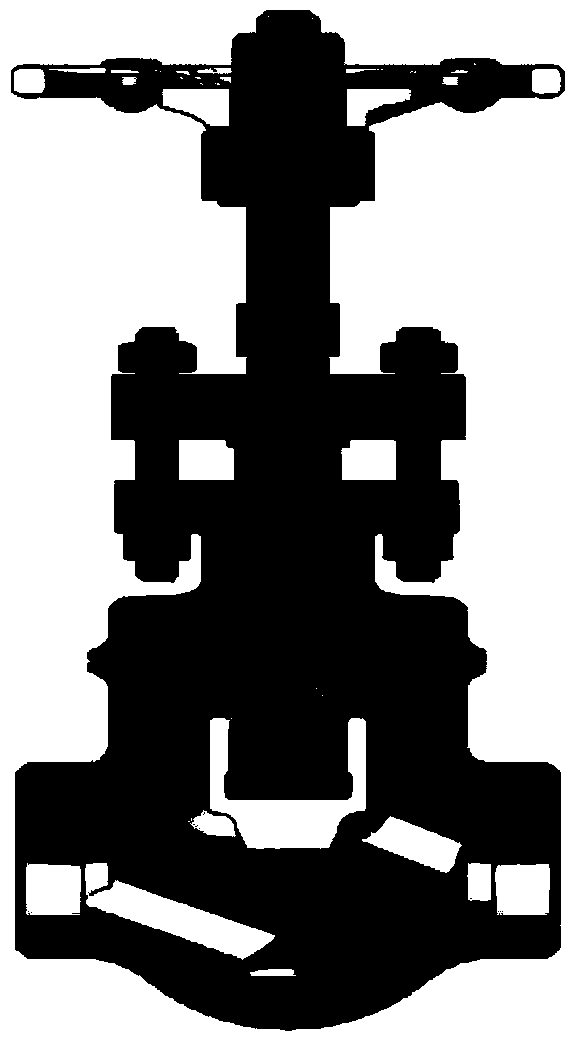

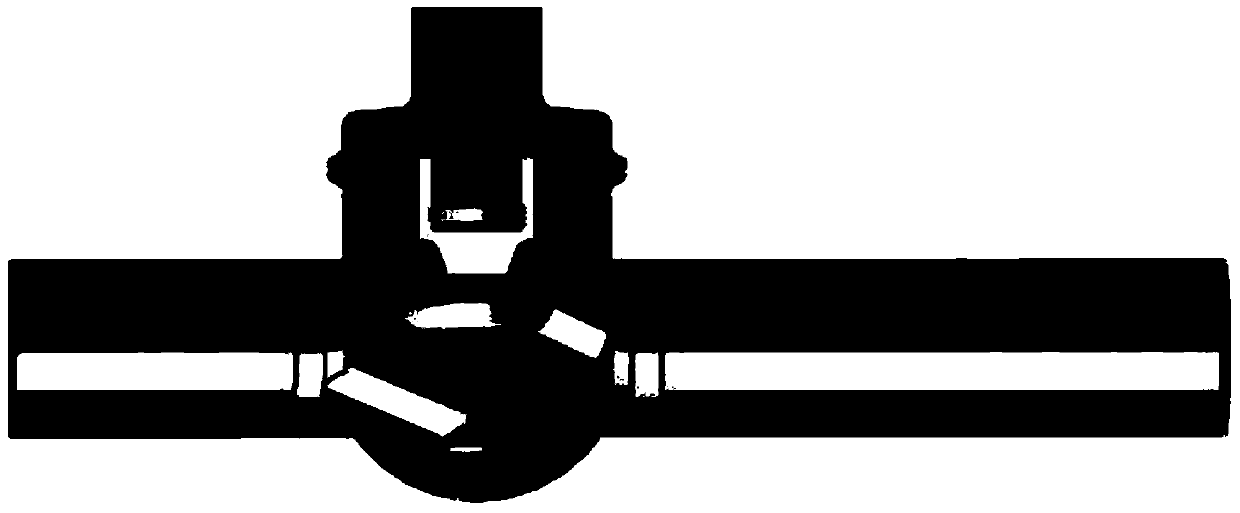

[0040] A kind of valve equivalent length calculation method based on CFD described in the present invention, such as figure 1 Shown, comprise the following steps: set up the three-dimensional assembly model of valve, this method preferably adopts three-dimensional software SolidWorks to set up the three-dimensional assembly model of valve, as figure 2It is a three-dimensional assembly model of a valve in a specific embodiment; in order to simplify the analysis and calculation process, on the premise of not affecting the analysis results, the components that do not affect the generation of the flow channel and are not in direct contact with the fluid medium, and the small parts that do not affect the calculation results are removed. Components, only create a 3D model of the flow channel closure. At the same time, in order to fully develop the fluid medium, the measuring point can reach a stable state, and make the calculation stable, it is necessary to add an extension section...

Embodiment 2

[0046] On the basis of a CFD-based valve equivalent length calculation method described in Example 1, when setting volume flow boundary conditions, ensure that the inlet flow velocity is within a reasonable speed range of 3-8m / s, and at the same time ensure that complete turbulent flow is generated , the minimum Reynolds number is not less than 4×10 4 , the outlet pressure is set to 0; for a globe valve with a nominal diameter of DN25, when the volume flow boundary condition is set, the corresponding inlet volume flow value is selected from 4-12m3 / h and 5 values are selected to obtain five working conditions:

[0047] Calculation working condition 1: set the volume flow Q1=4m3 / h at the inlet surface; set the pressure P=0 at the outlet surface;

[0048] Calculation working condition 2: set the volume flow Q2=6m3 / h at the inlet surface; set the pressure P=0 at the outlet surface;

[0049] Calculation working condition 3: set the volume flow Q3=8m3 / h at the inlet surface; set ...

Embodiment 3

[0065] In the above embodiments, the valve equivalent length calculation method based on CFD is realized. In the initial stage of valve design, it is in the virtual prototype stage. After calculating the equivalent length, it is necessary to further judge whether the equivalent length meets the requirements. If it meets the requirements, Then develop and produce according to the previous design. If the requirements are not met, the flow channel structure needs to be optimized. The specific implementation method is: compare the calculated equivalent length value with the limit value of the technical requirements. According to the relevant technical requirements, the limit value here is limited according to different valve types, such as the limit value requirements of globe valves and check valves. is 340, and the equivalent length of the cut-off valve with diameter DN25 in the above-mentioned embodiment 2 is calculated as 275, which is significantly smaller than the limit value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com