Patents

Literature

65results about How to "High shaping precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

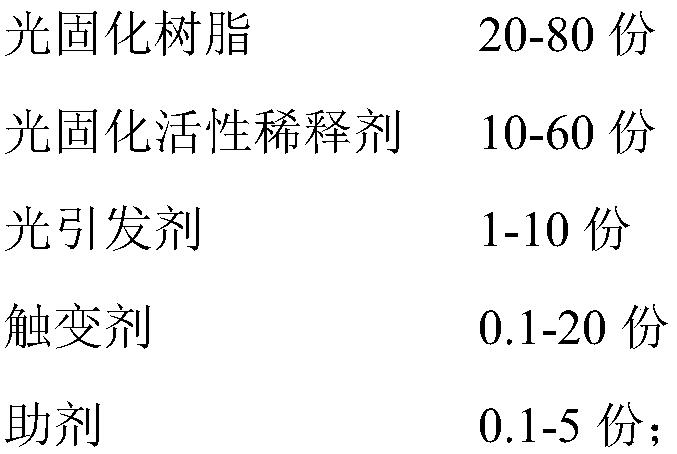

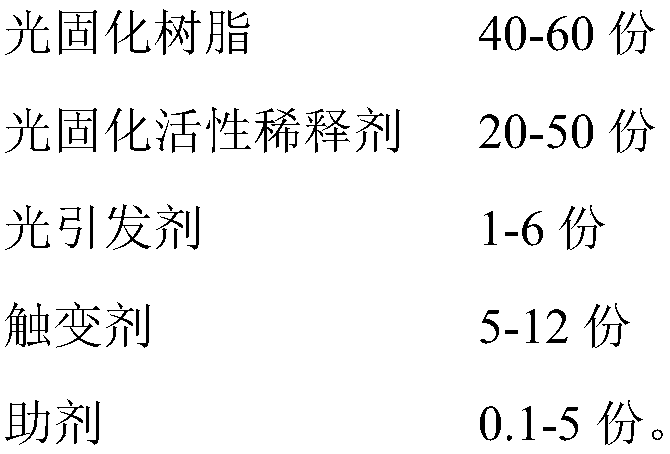

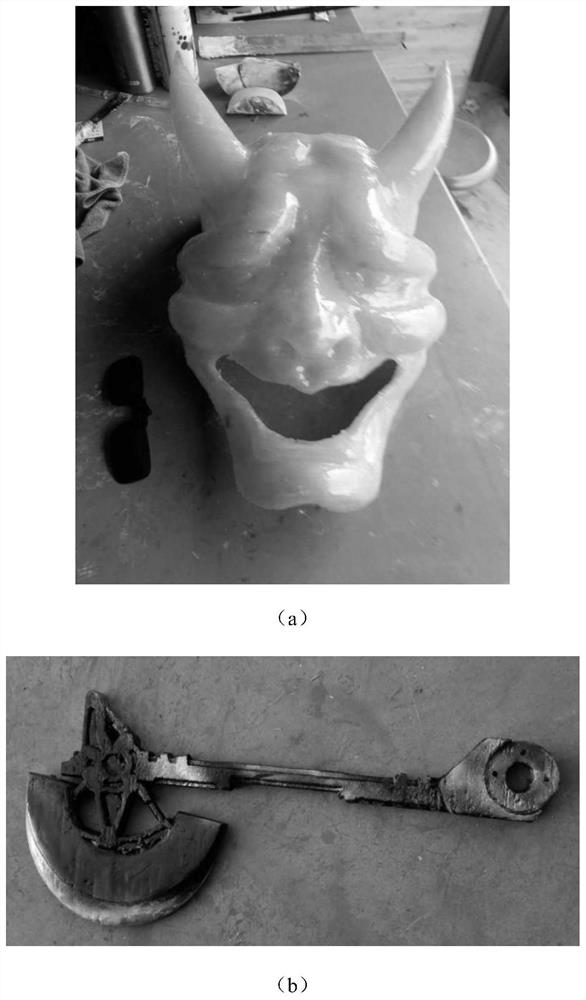

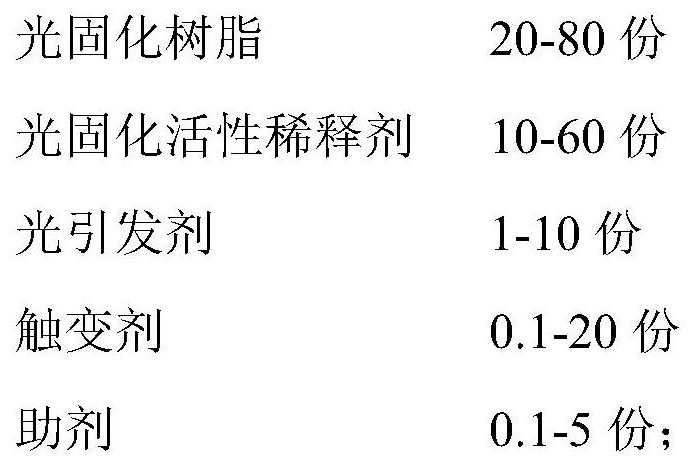

Photocurable 3D printing material as well as preparation method and application thereof

ActiveCN108410162AImprove thixotropyHigh forming precisionAdditive manufacturing apparatusSodium BentonitePolyamide

The invention relates to a photocurable 3D printing material as well as a preparation method and application thereof. The photocurable 3D printing material is prepared from the following raw materialcomponents in parts by weight: 20 to 80 parts of photocurable resin, 10 to 60 parts of photocurable active diluent, 1 to 10 parts of photo-initiator, 0.1 to 20 parts of thixotropic agent and 0.1 to 5parts of auxiliaries, wherein the thixotropic agent is at least one of attapulgite, montmorillonite, bentonite, fumed silica, polyamide wax and mica powder; the photocurable resin is at least one of aliphatic polyurethane and aliphatic epoxy resin. The photocurable 3D printing material has high thixotropy, and can be applied to the nozzle printing process of FDM (Fused Deposition Modeling). Compared with an SLA (Stereolithigraphy Apparatus), the photocurable 3D printing material has the advantages that the production cost of 3D printing products can be lowered effectively, high molding speed and high precision are achieved, complex-contour or large-sized 3D printing products can be made.

Owner:广州有得新材料科技有限公司

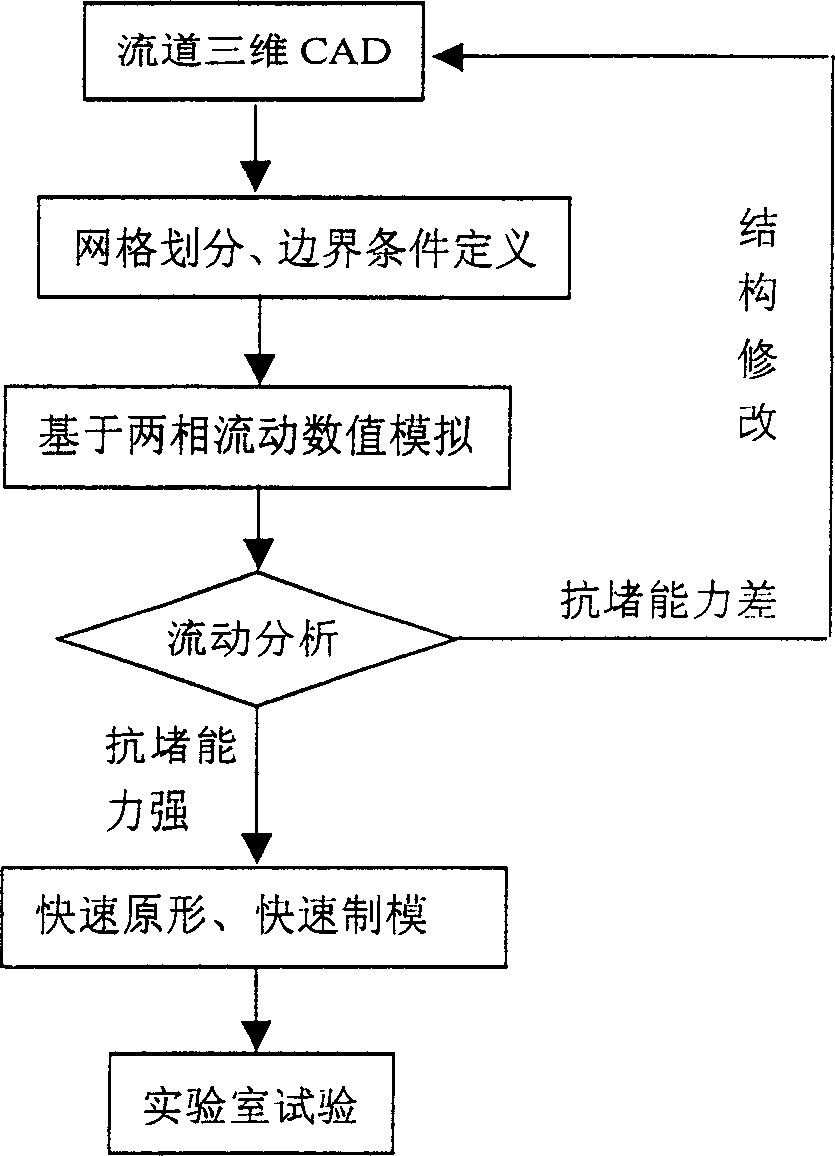

Anti-block designing method of drip irrigation tool based on two-phase simulated flow

InactiveCN1817093AImprove anti-clogging performanceHigh shaping precisionClimate change adaptationWatering devicesMathematical simulationDrip irrigation

An anti-blocking design method based on two-phase stream simulation for the drip irrigator features that according to the mathematical simulation about the two-phase stream in the flow field of said drip irrigator, the region in the flow channel, where the solid is easily deposited, is analyzed out and the influence of the flow channel structure to the delivery and deposition of solid is further analyzed. On this basis, the structure parameters of flow channel are modified and said simulation is repeated until no obvious deposition of solid.

Owner:HUAZHONG UNIV OF SCI & TECH

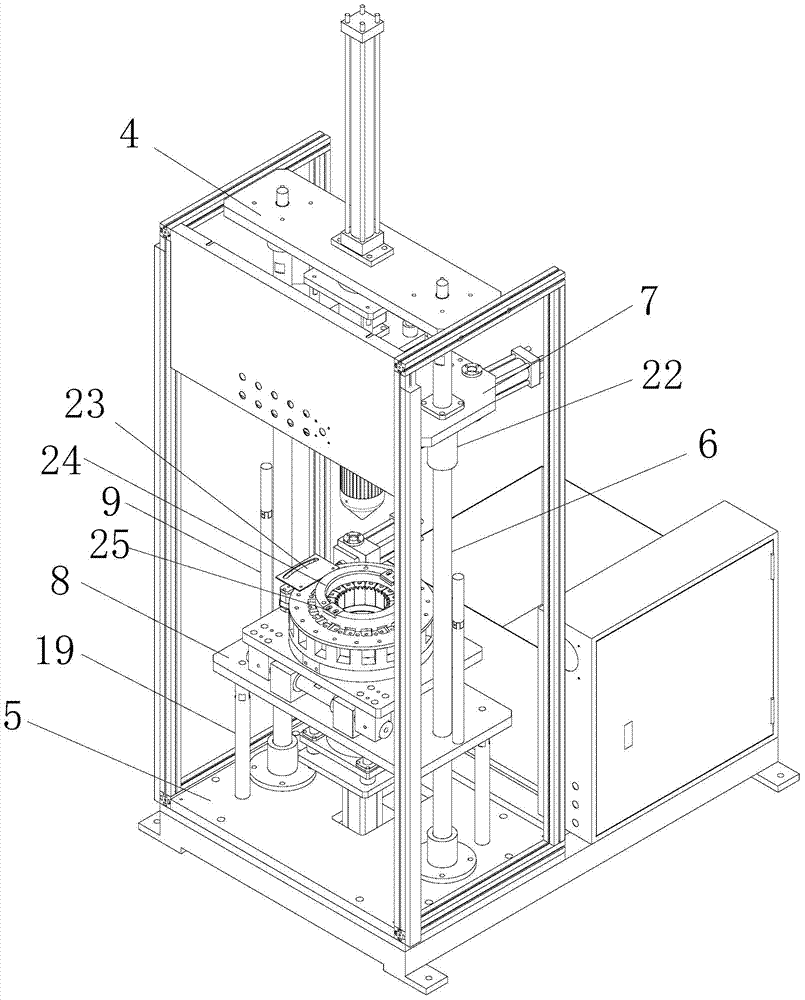

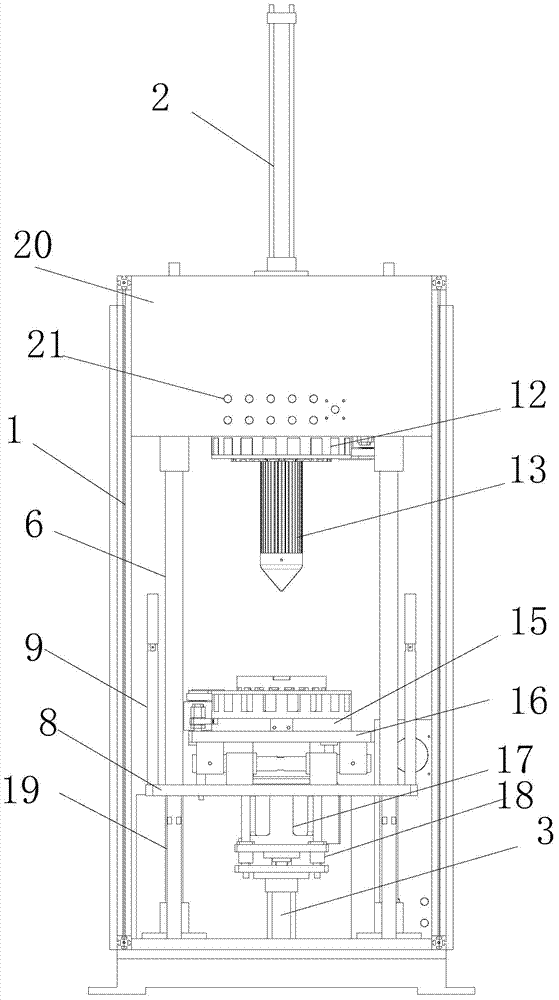

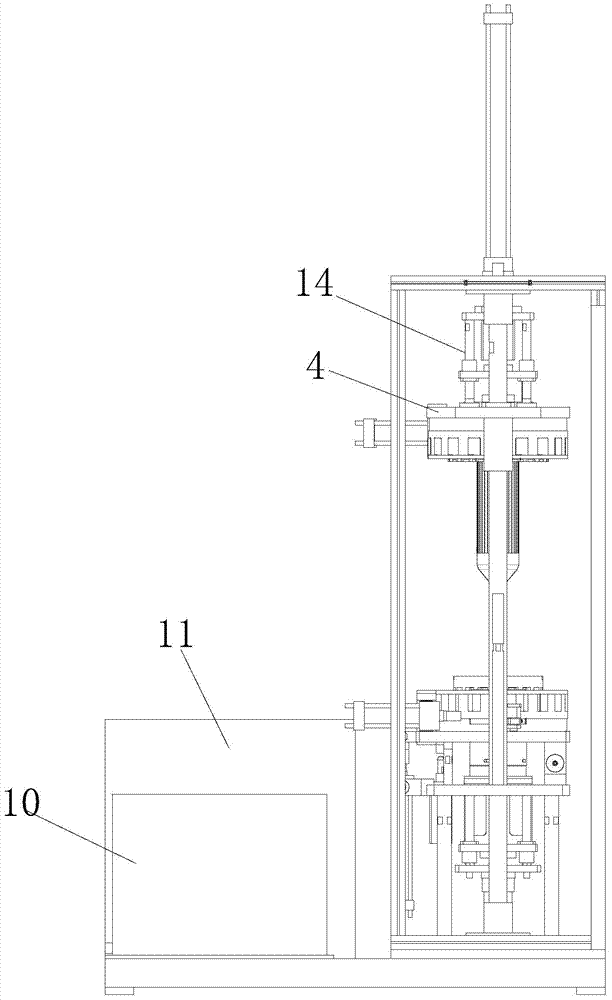

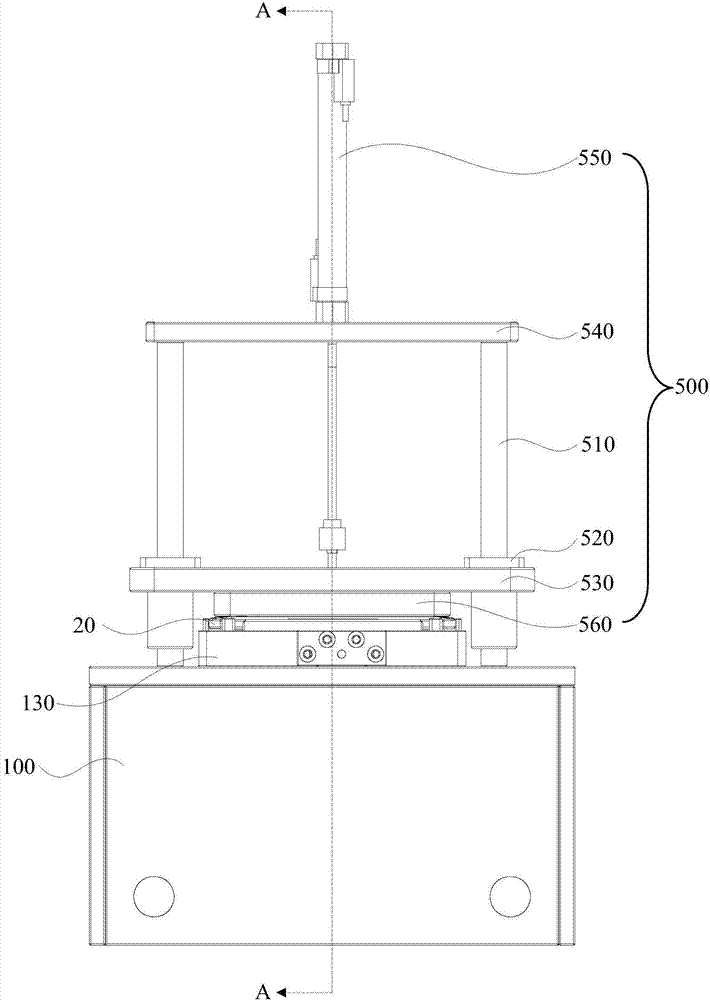

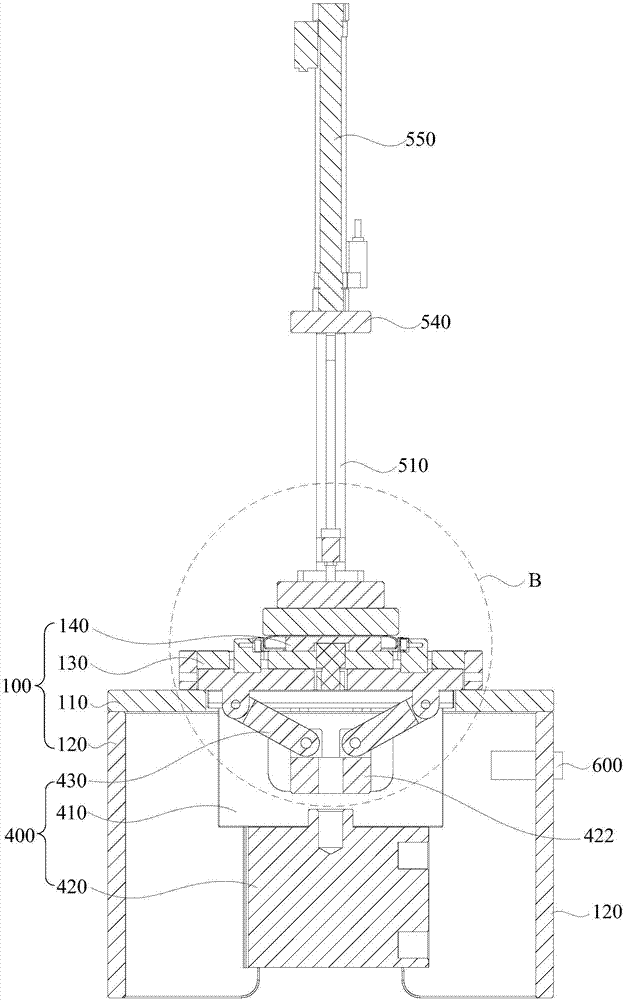

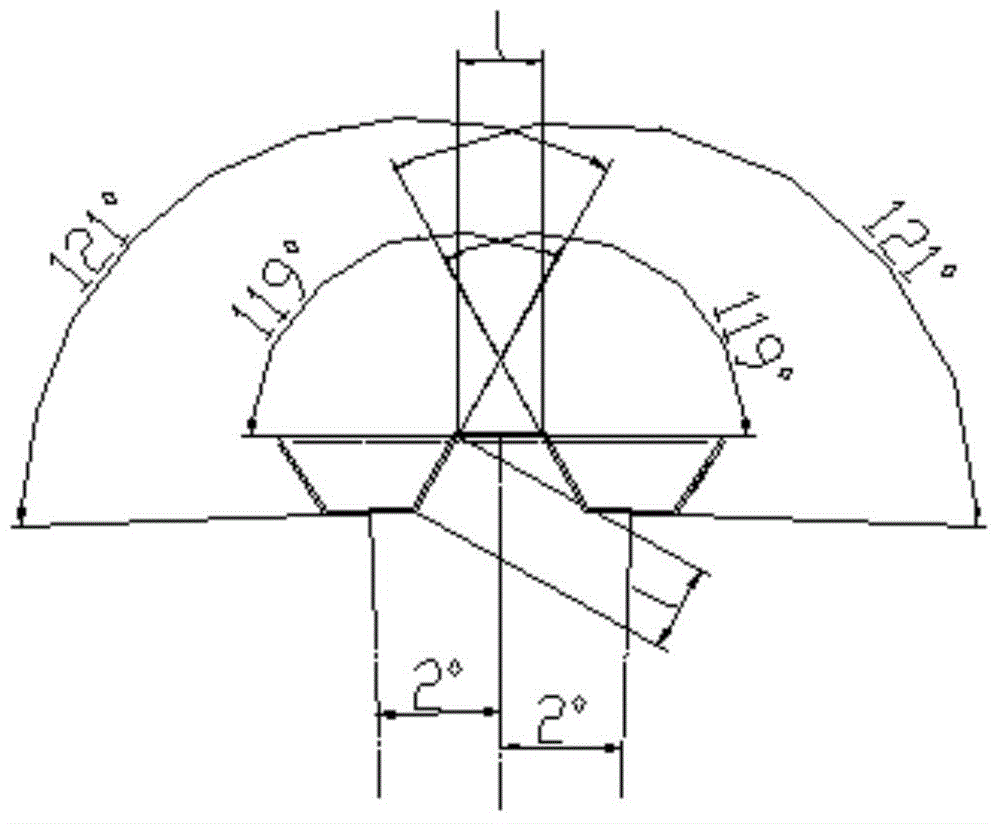

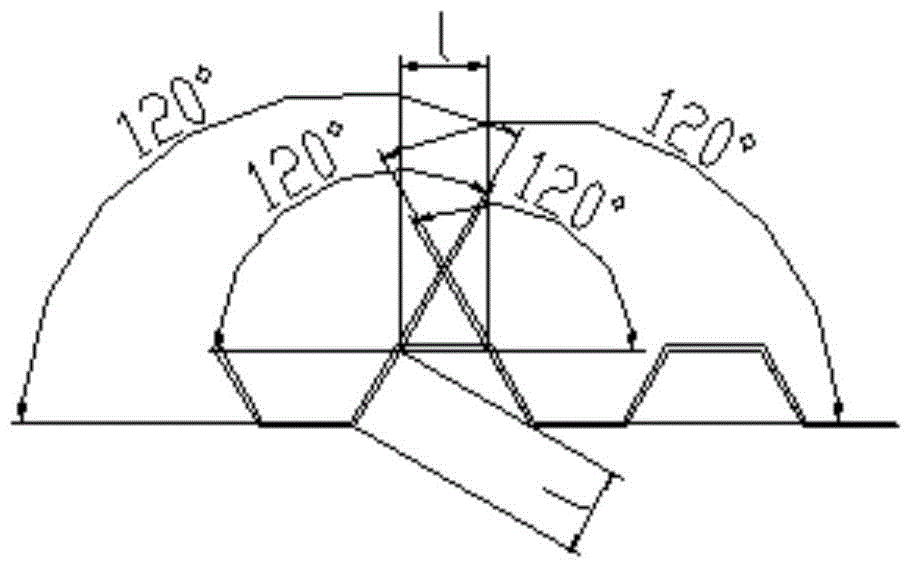

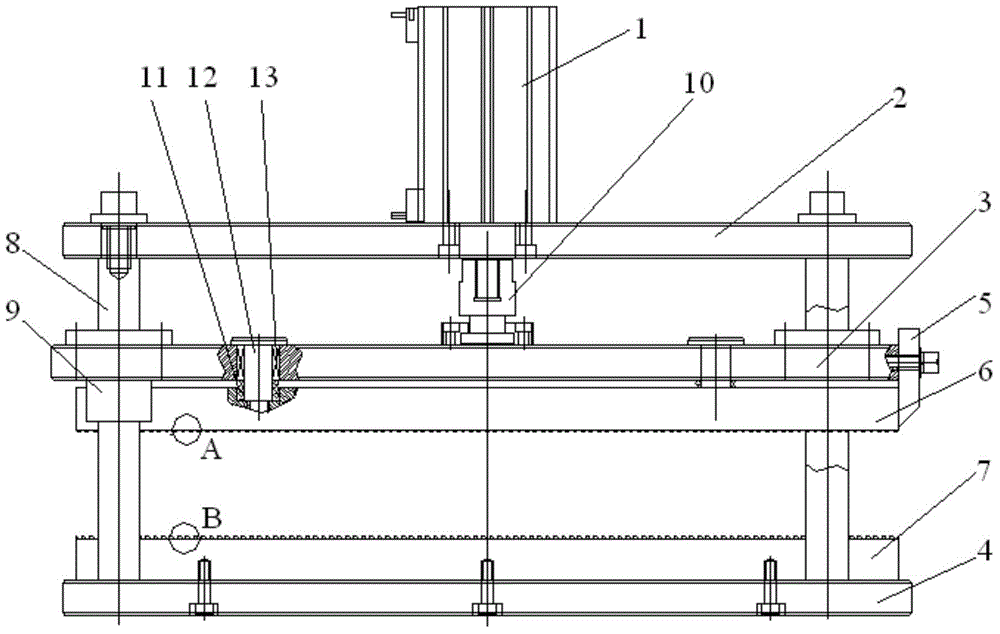

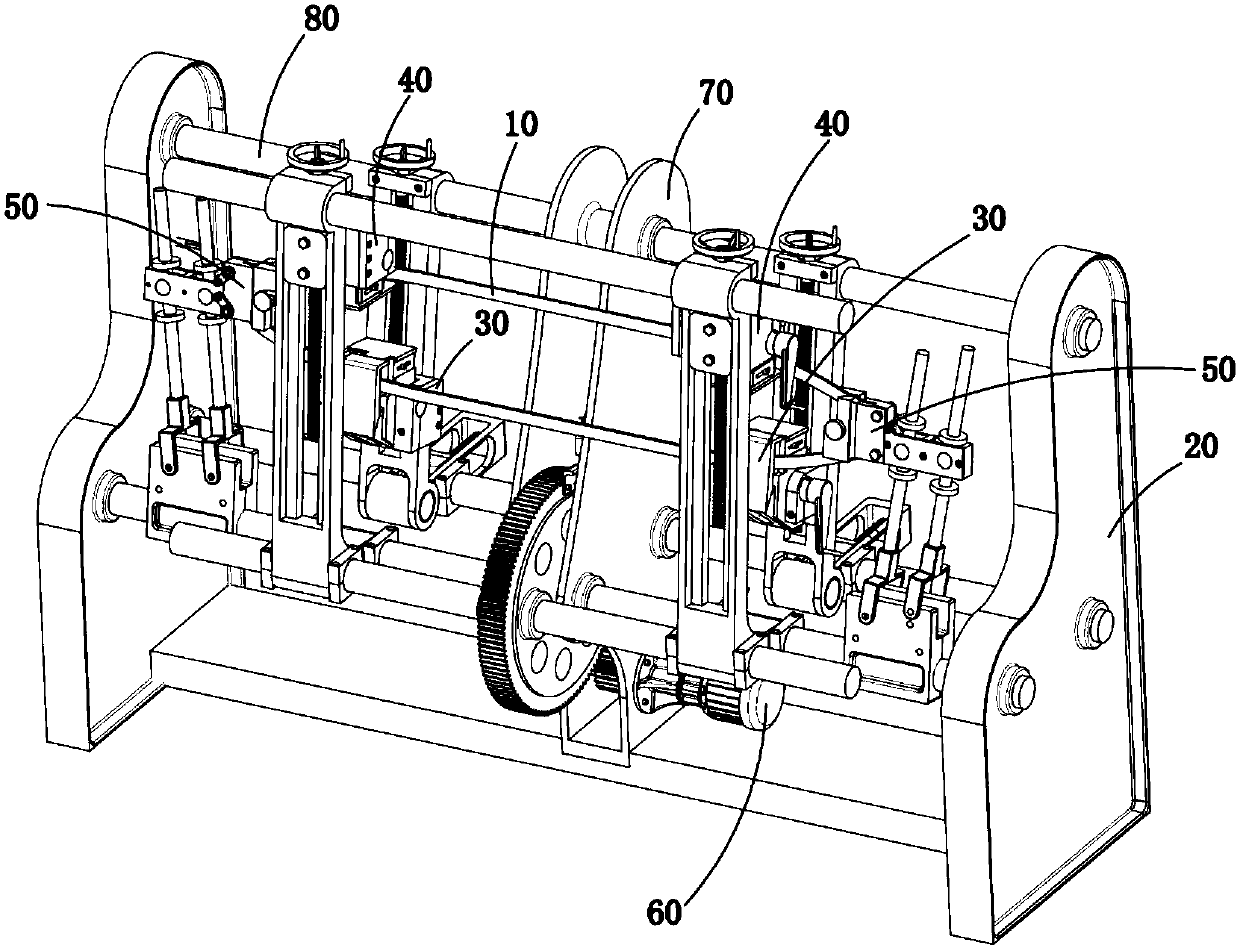

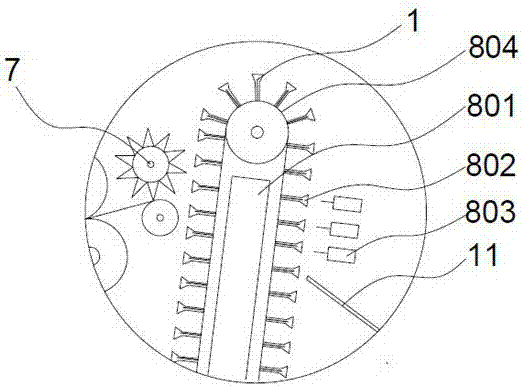

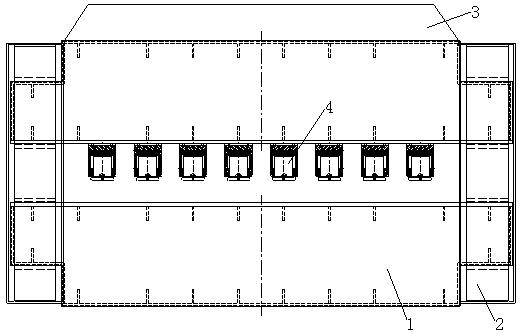

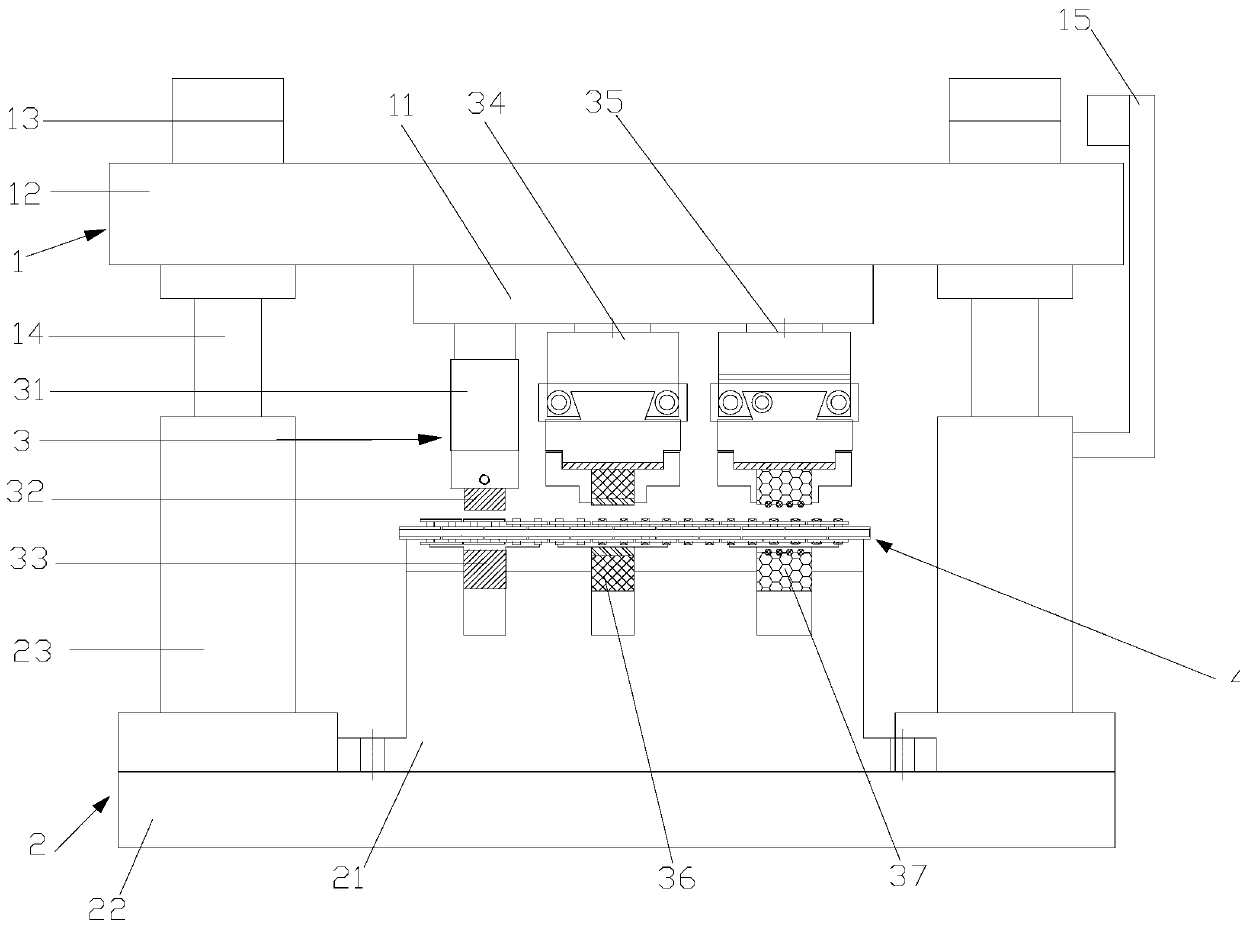

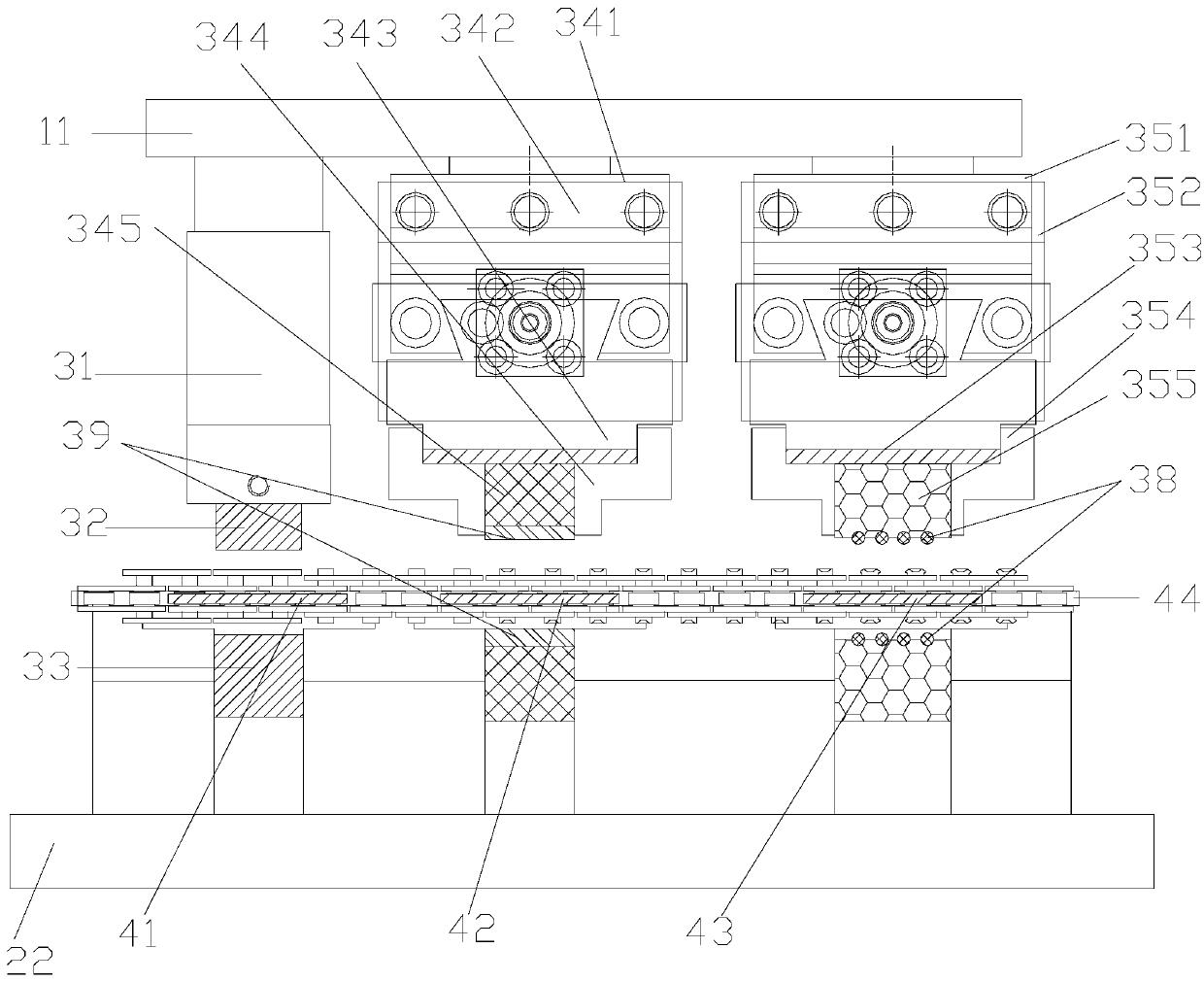

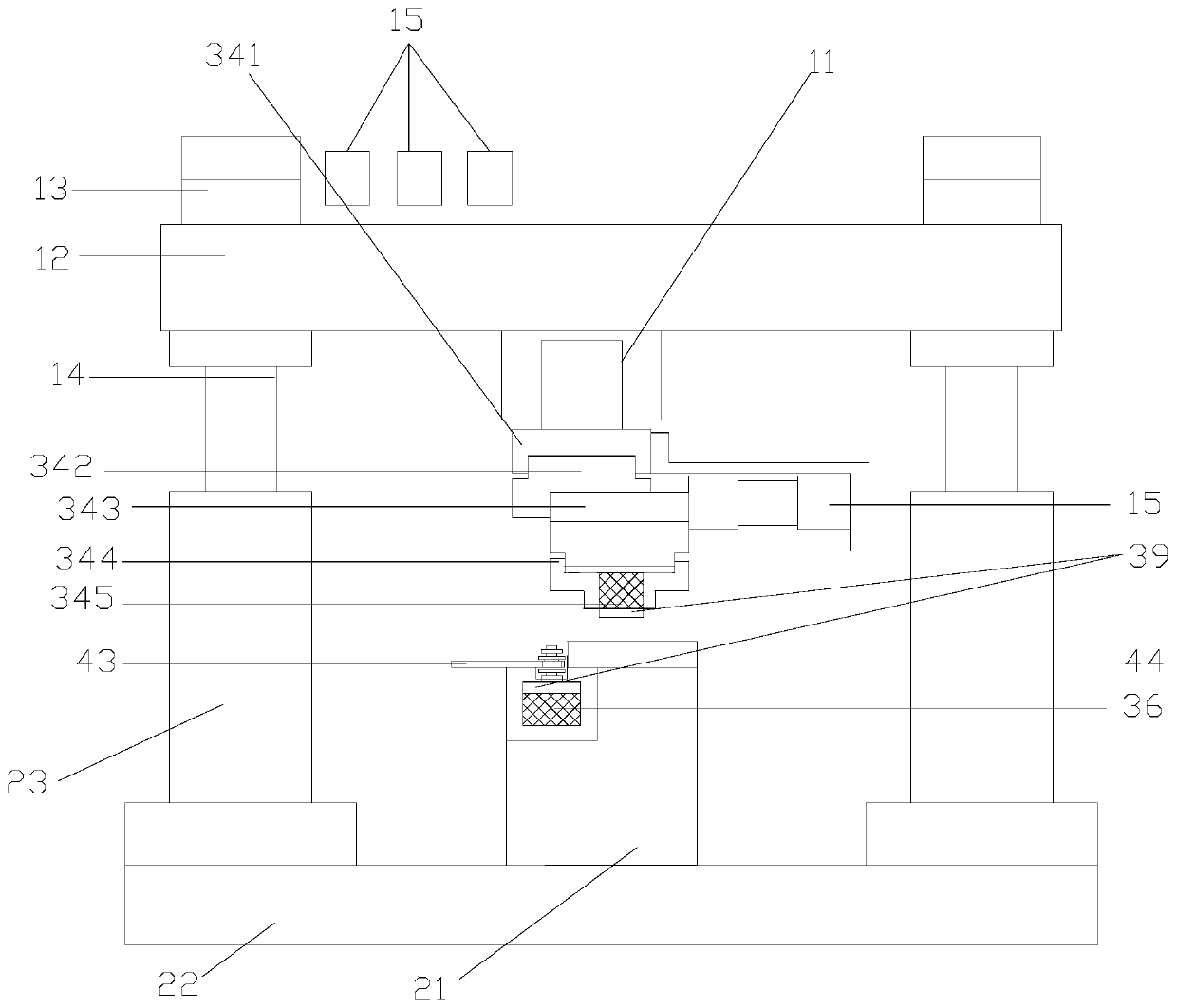

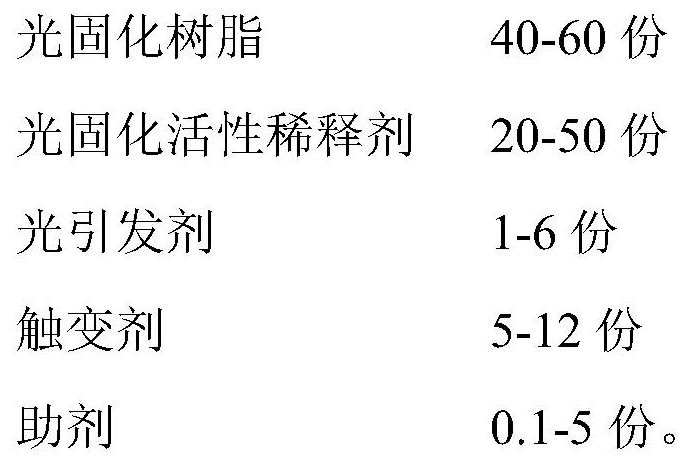

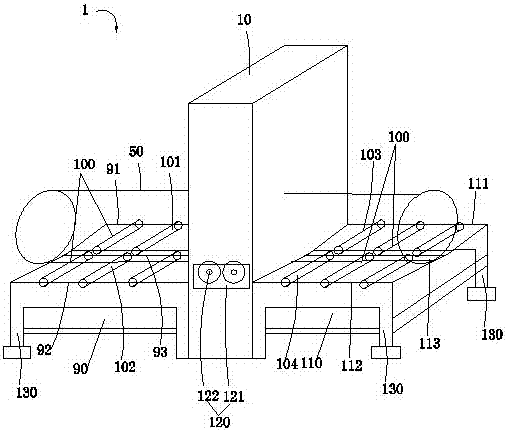

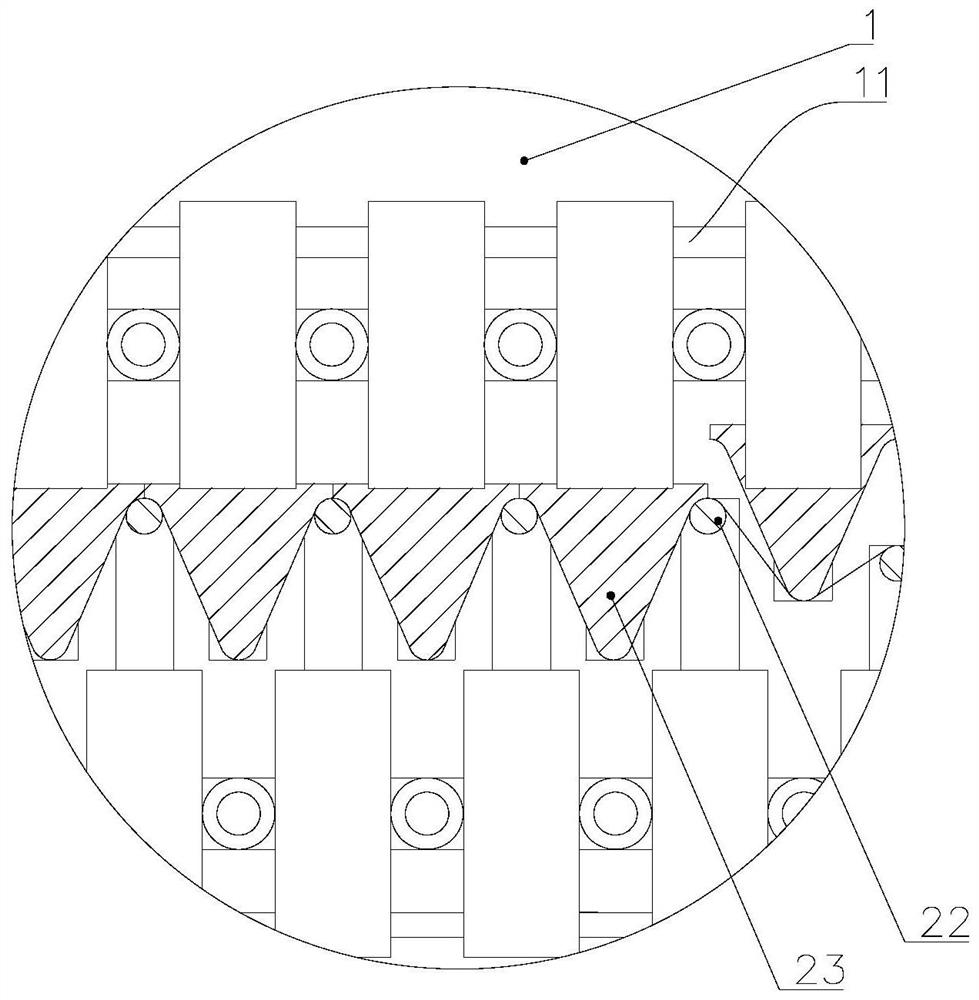

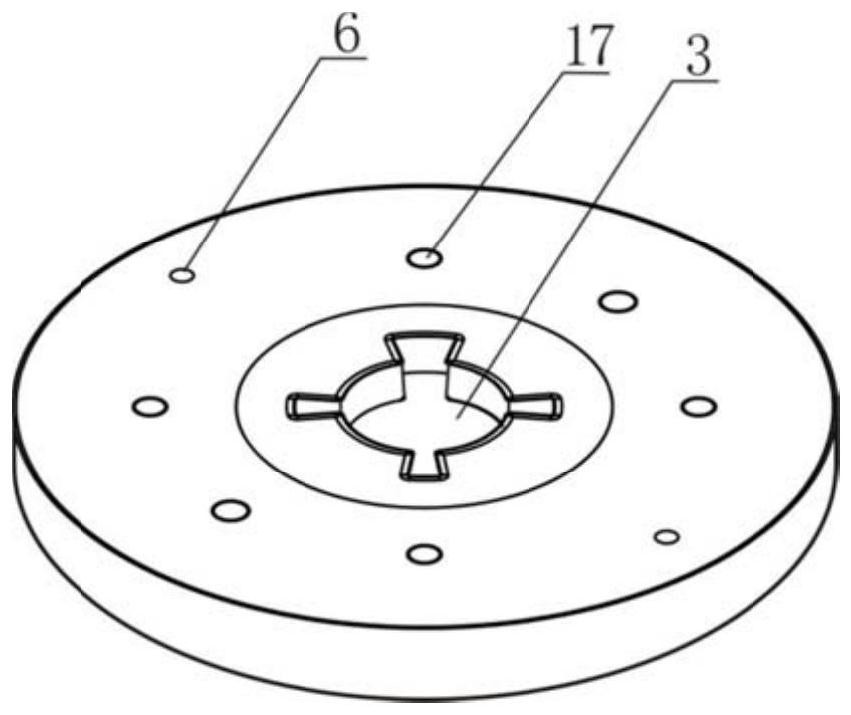

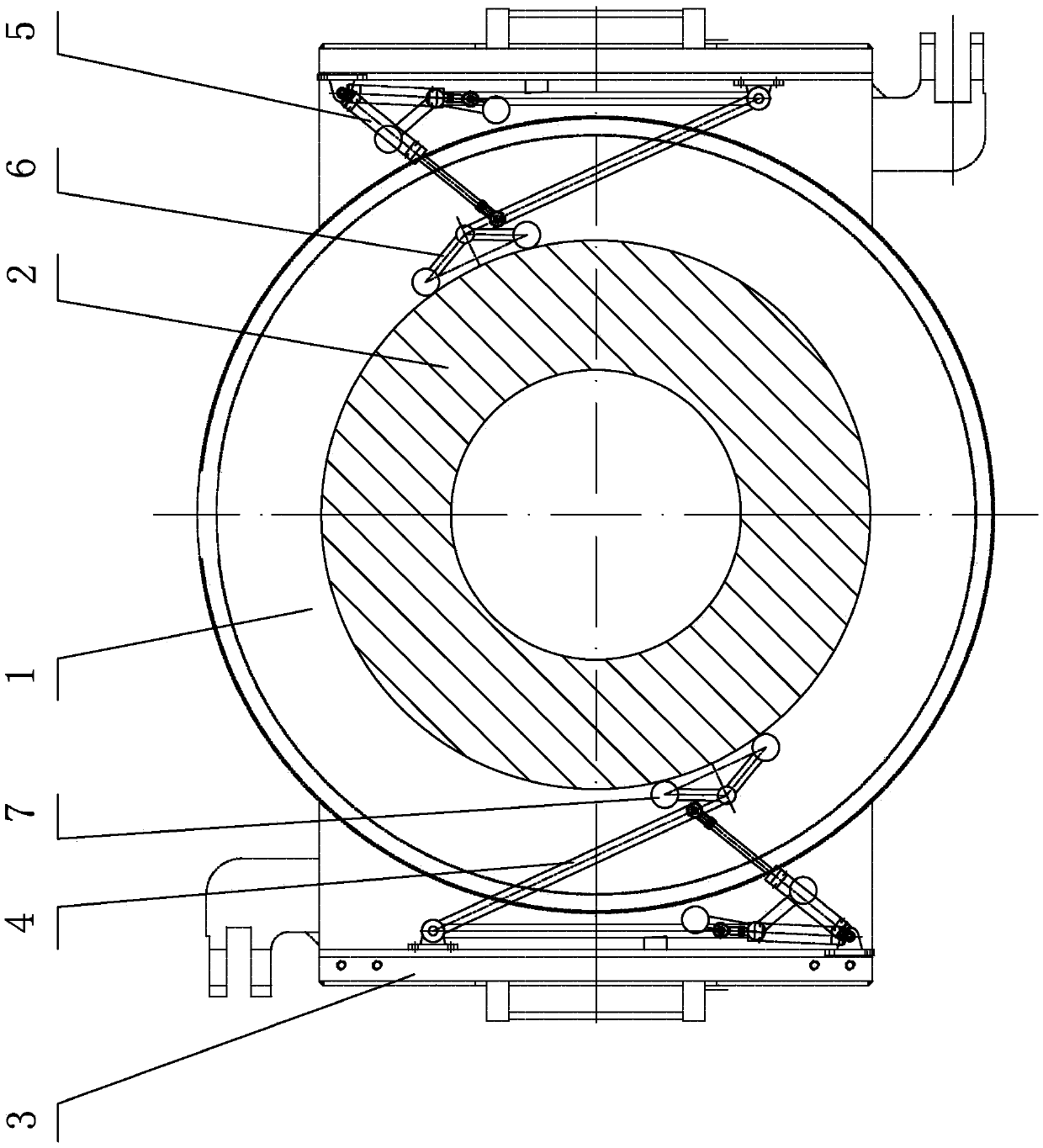

Motor stator shaping machine

InactiveCN104300741AImprove automationEffective shapingManufacturing dynamo-electric machinesEngineeringMechanical engineering

The invention relates to a motor stator shaping machine, which comprises a rack and is characterized in that the rack is internally provided with an upper shaping base and a lower shaping base located below the upper shaping base, a lower fixing plate with a supporting platform is arranged below the lower shaping base, the lower shaping base is arranged on the lower fixing plate, the rack is provided with an upper driving mechanism used for driving the upper shaping base to move up and down and a lower driving mechanism arranged at the lower end of the rack, the upper shaping base and the lower shaping base are provided with a clamping mechanism which can be clamped and loosened, the middle parts of the upper shaping base and the lower shaping base are respectively provided with assembling holes penetrating through the shaping bases, and a shaping core rod is fixedly arranged in the assembling hole of the upper shaping base. The motor stator shaping machine provided by the invention has the characteristics of simple operation, automatic operation and control, high shaping precision, good effect and the like.

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

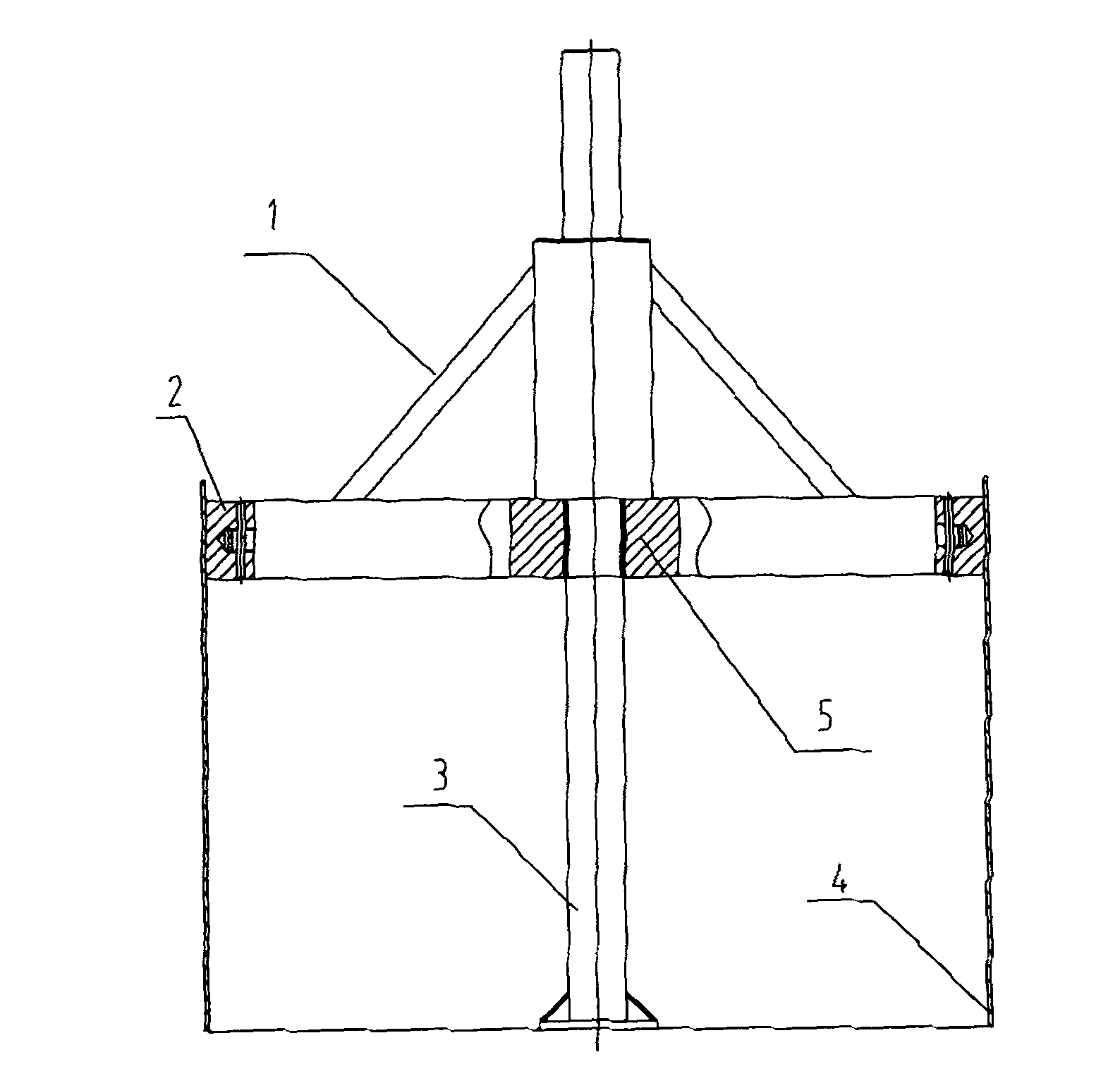

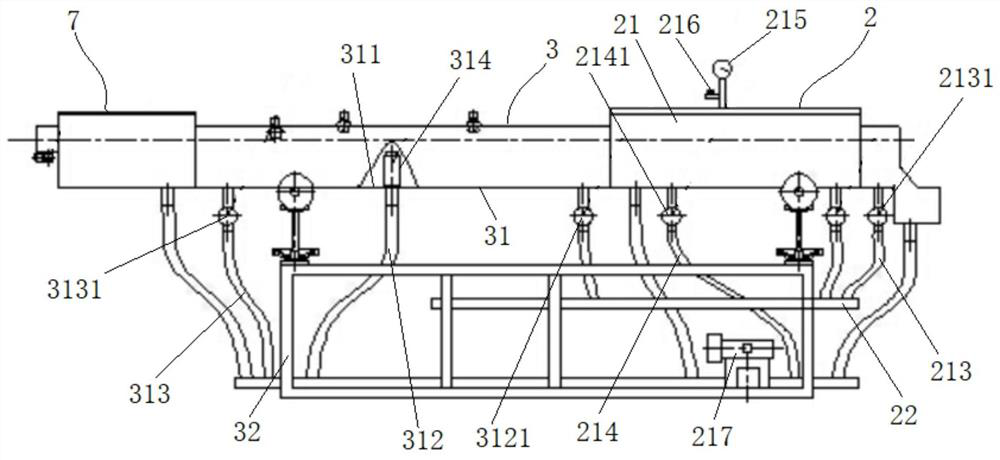

Hydraulic barrel shaper

A hydraulic barrel shaper comprises an upright column and a support frame. A combined oil cylinder is fixedly arranged on the upright column and comprises a first oil cylinder, a second oil cylinder, a third oil cylinder and a fourth oil cylinder, shaping blocks are correspondingly arranged on tops of piston rods of the first oil cylinder, the second oil cylinder, the third oil cylinder and the fourth oil cylinder in a connected manner, and the shaping blocks with different sizes can be replaced according to actual application conditions. The hydraulic barrel shaper has the advantages that the shaping blocks can be expanded by the aid of high-pressure oil pumps, so that a barrel can be effectively shaped, and the hydraulic barrel shaper can be operated easily and conveniently and is high in shaping precision.

Owner:JIANGSU PACIFIC HYDRAULIC MACHINERY MFGCO

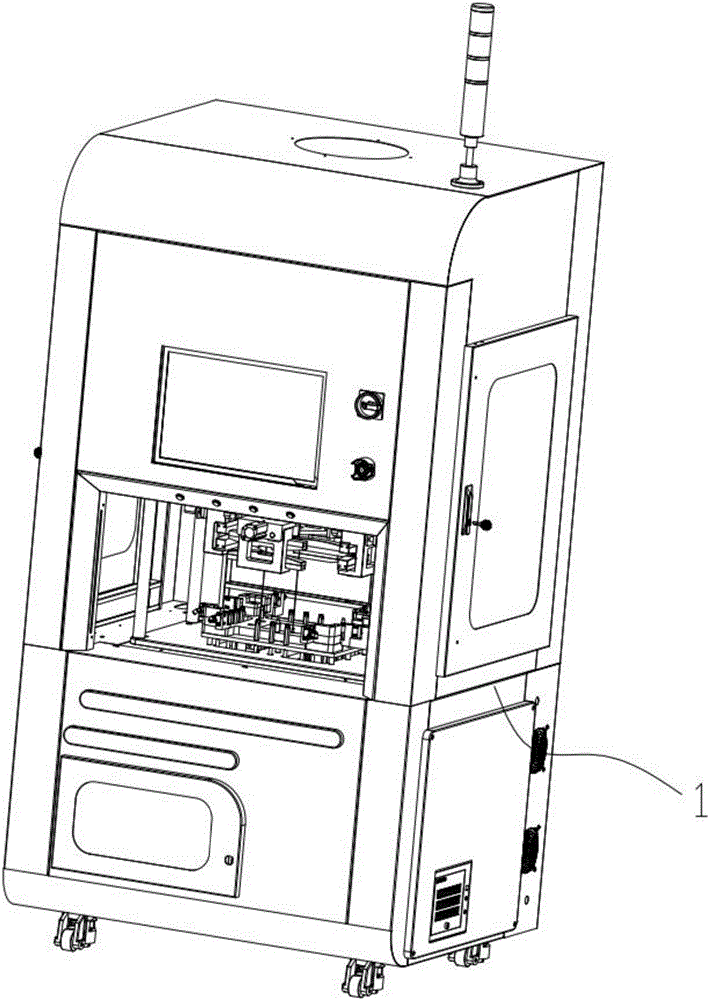

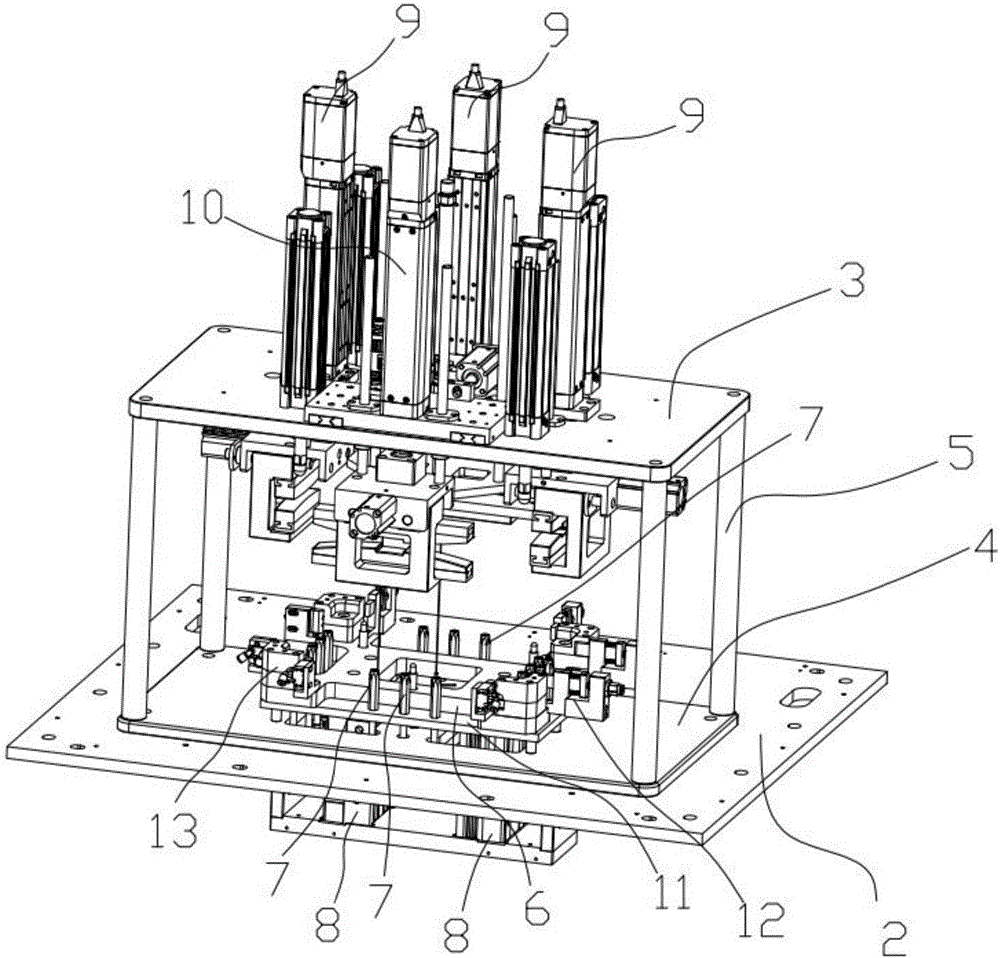

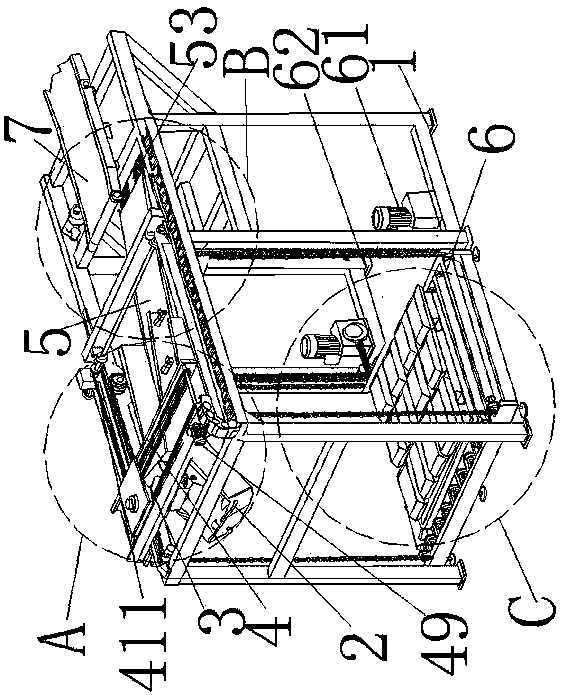

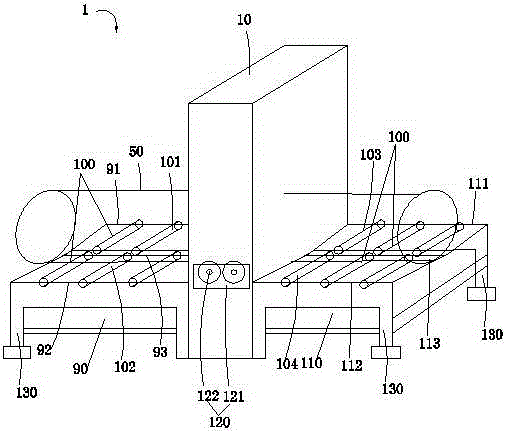

Intelligent detection, repairing and plastic recovery all-in-one machine

ActiveCN106345851AHigh shaping precisionMetal-working feeding devicesMetal working apparatusMultiple sensorEngineering

The invention provides an intelligent detection, repairing and plastic recovery all-in-one machine, comprising an enclosure, wherein a working table is set in the enclosure, a sensing carrying device is set on the working table;a plastic recovery device is set above the sensing carrying device; the sensing carrying device is connected with the plastic recovery device by a supporting frame; the sensing carrying device comprises a bearing base plate and multiple sensing pieces; two jacking cylinders are connected with the bottom of the bearing base plate; the plastic recovery device comprises three first pressing cylinders fixedly connected with the supporting frame and a second pressing cylinder movably connected with the supporting frame; the output end of the first pressing cylinder and the second pressing cylinder points to the sensing carrying device and is respectively connected with the plastic recovery mechanism; the surface radian condition of the enclosure can be detected in high precision by multiple sensors; the enclosure is fixed on the sensing carrying device by a limiting mechanism;the upper plastic recovery mechanism is shaped; the plastic head is adjusted during the plastic recovery process to shape the product in many angles, and the machine has high plastic precision.

Owner:SUZHOU KANGHONG INTELLIGENT EQUIP CO LTD

Dressing device

The invention relates to a dressing device. The dressing device comprises a machine rack, a positioning piece, dressing mechanisms and a power mechanism. The machine rack comprises an installation plates, a sliding groove is formed in the installation plate, and the positioning piece is arranged in the sliding groove. Each dressing mechanism comprises a slider and a press block, the sliders are arranged in the sliding groove in a sliding mode, the press blocks are arranged on the sliders respectively and used for extruding a workpiece. The power mechanism is arranged on the installation plate and used for driving the sliders to slide in the sliding groove. The dressing device controls the travel of each slider through the positioning piece and then controls the dressing feed rate, and the dressing device is high in dressing precision. The sliders slide in the sliding groove and drive clamp blocks to move respectively, the clamp blocks move smoothly, and the dressing device is high in dressing stability. The dressing device is good in dressing effect.

Owner:GUANGDONG EVERWIN PRECISION TECH

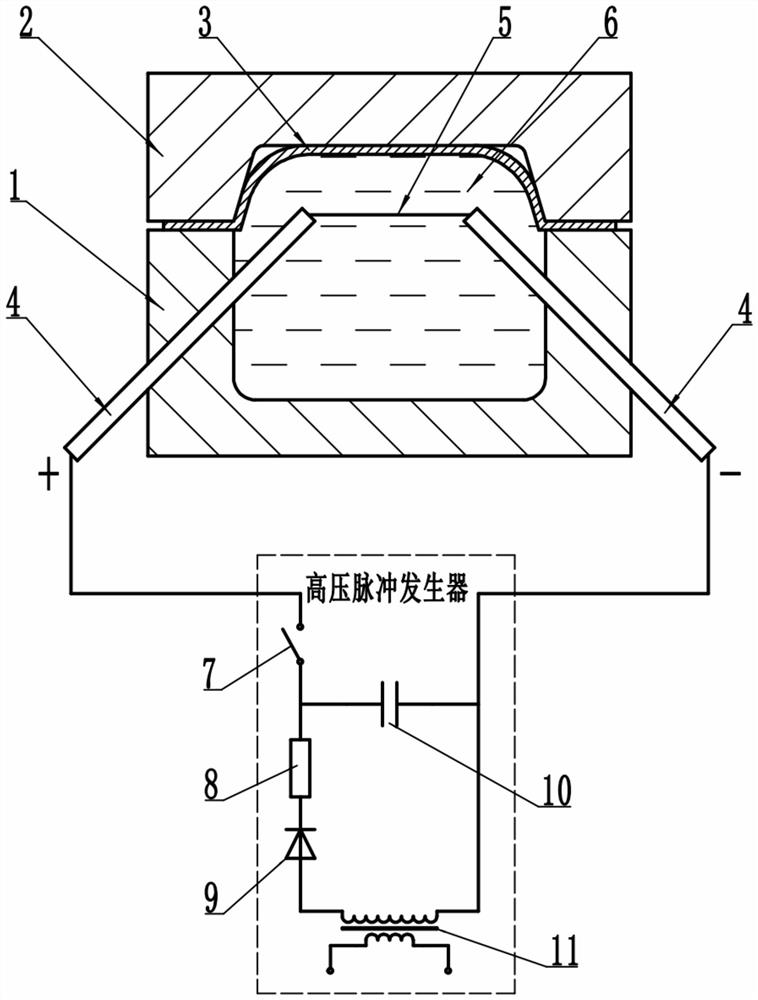

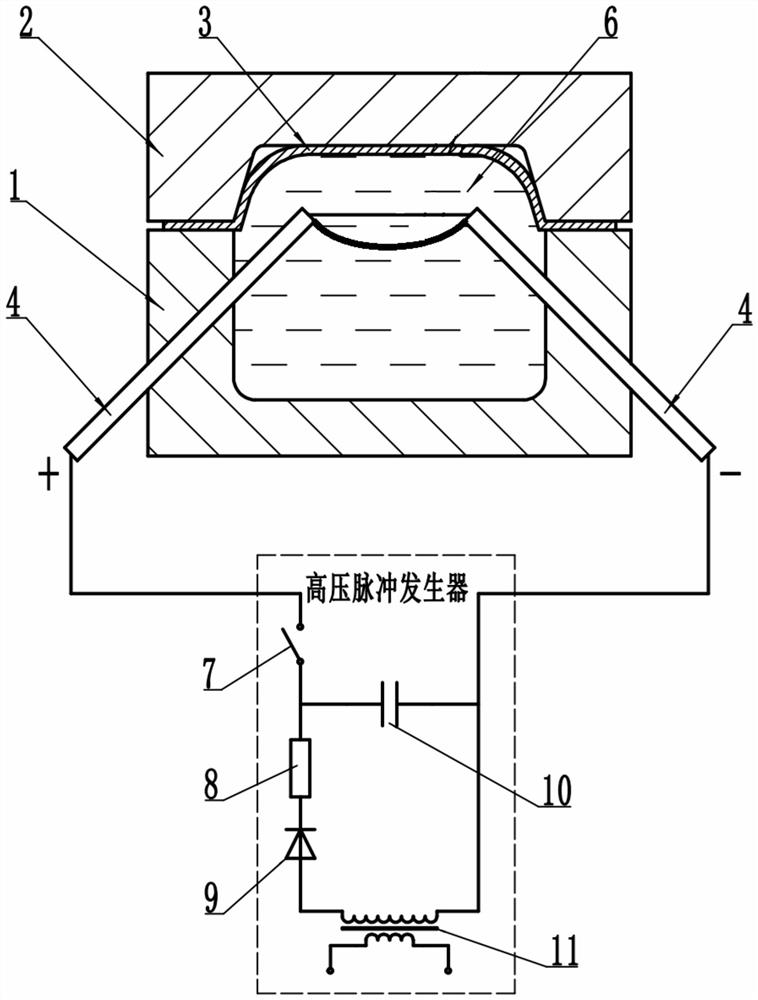

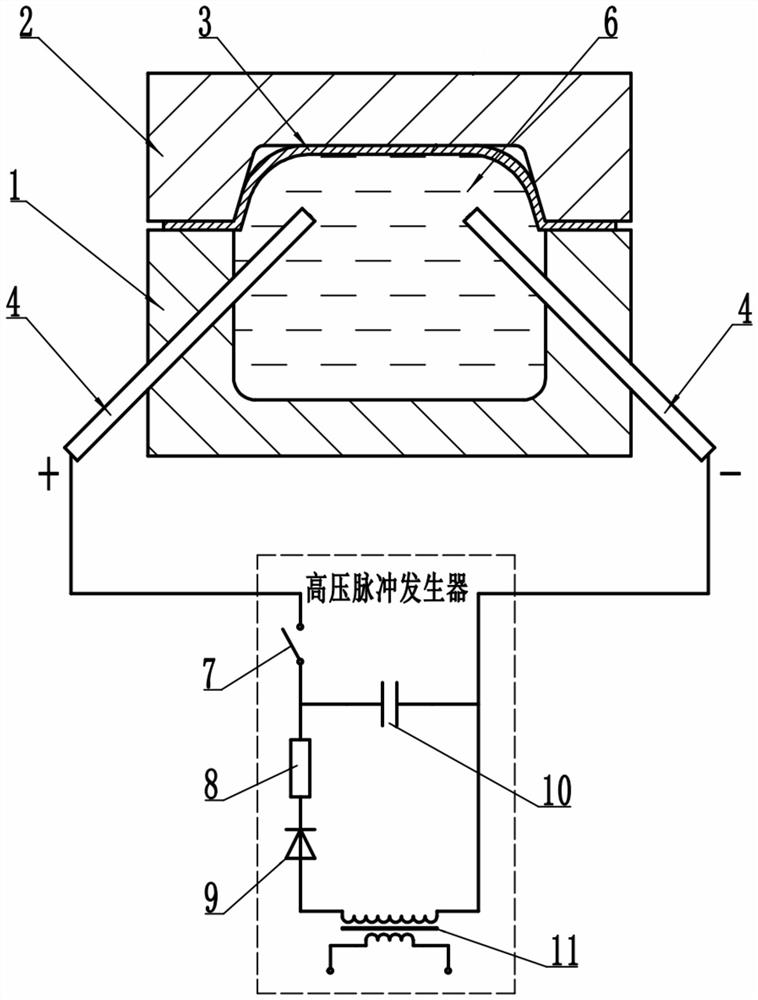

Aluminum alloy thin plate precision shaping method and device based on electro-hydraulic forming

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

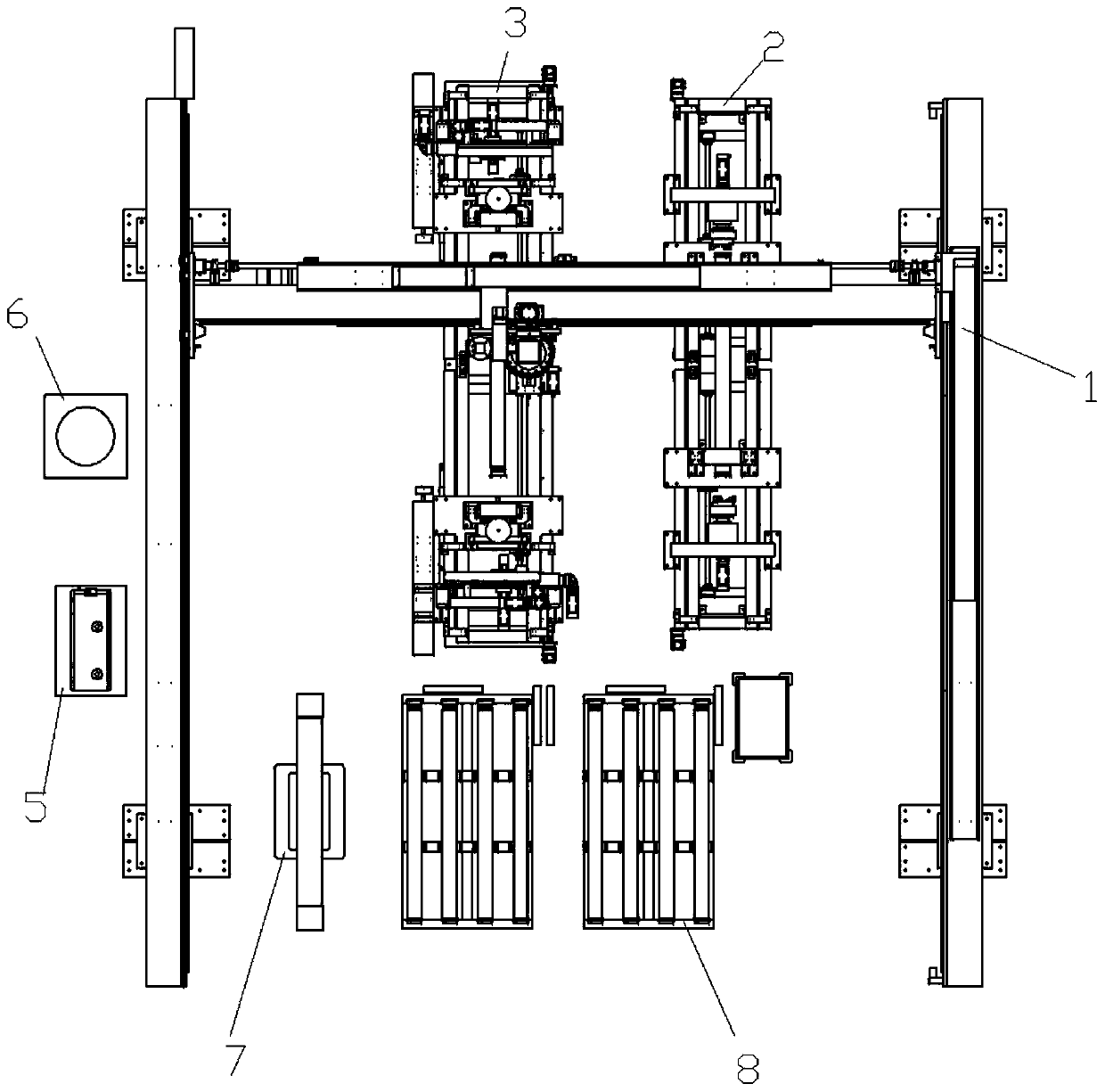

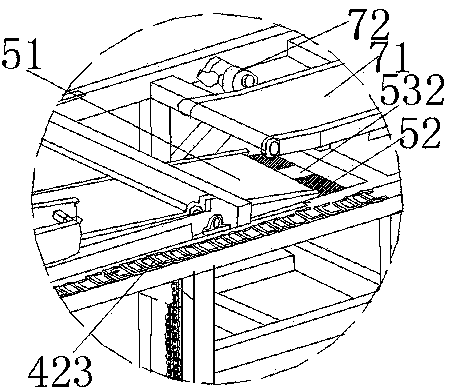

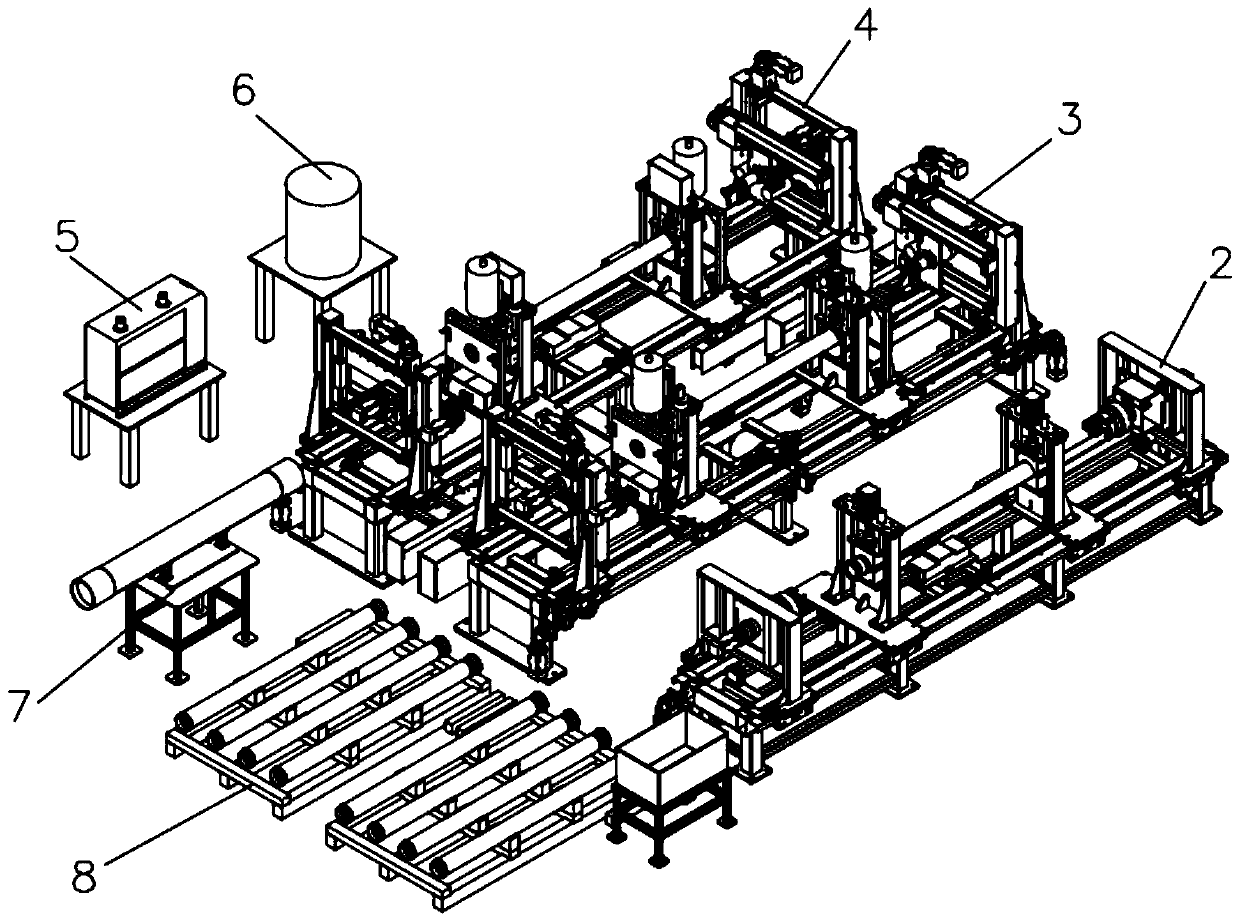

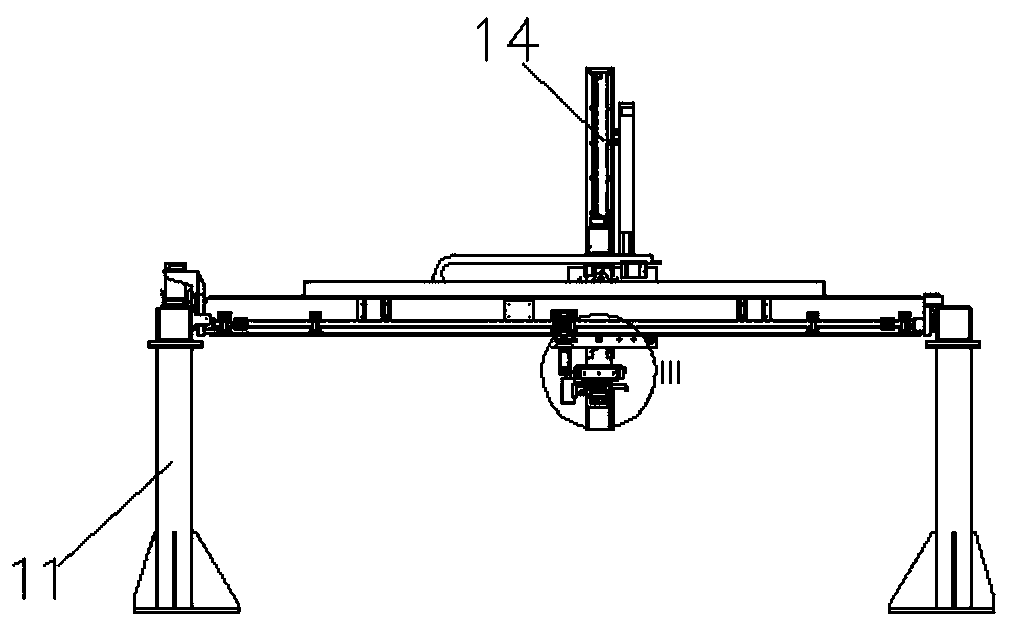

Man-machine isolation automatic cover-disassembling and milling-shaping machining system and method

ActiveCN110052652AHigh shaping precisionEnsure personnel safetyWork clamping meansMeasurement/indication equipmentsManipulatorControl system

The invention provides a man-machine isolation automatic cover-disassembling and milling-shaping machining system and method. The shaping machining system comprises a control system, a visual system,a truss mechanical arm, an end cover disassembling machine and a milling-shaping machining machine; during machining, the control system is used for controlling the truss mechanical arm to carry a to-be-shaped engine to the end cover disassembling machine according to the position information, collected by the visual system, of the to-be-shaped engine; then, the end cover disassembling machine iscontrolled to disassemble end covers of the two ends of the engine according to the set parameters; finally, the truss mechanical arm is controlled to carry the engine with the end covers disassembledto the milling-shaping machining machine, the milling-shaping machining machine is used for carrying out positioning and locking on the engine, and a milling main shaft cutter in the milling-shapingmachining machine is controlled to carry out milling on the end surfaces of the two ends of the engine according to the drawing requirement. According to the man-machine isolation automatic cover-disassembling and milling-shaping machining system and method, man-machine isolation, full-process automation and informatization are introduced into the field of milling-shaping machining systems for thefirst time, and the application prospect is very wide.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

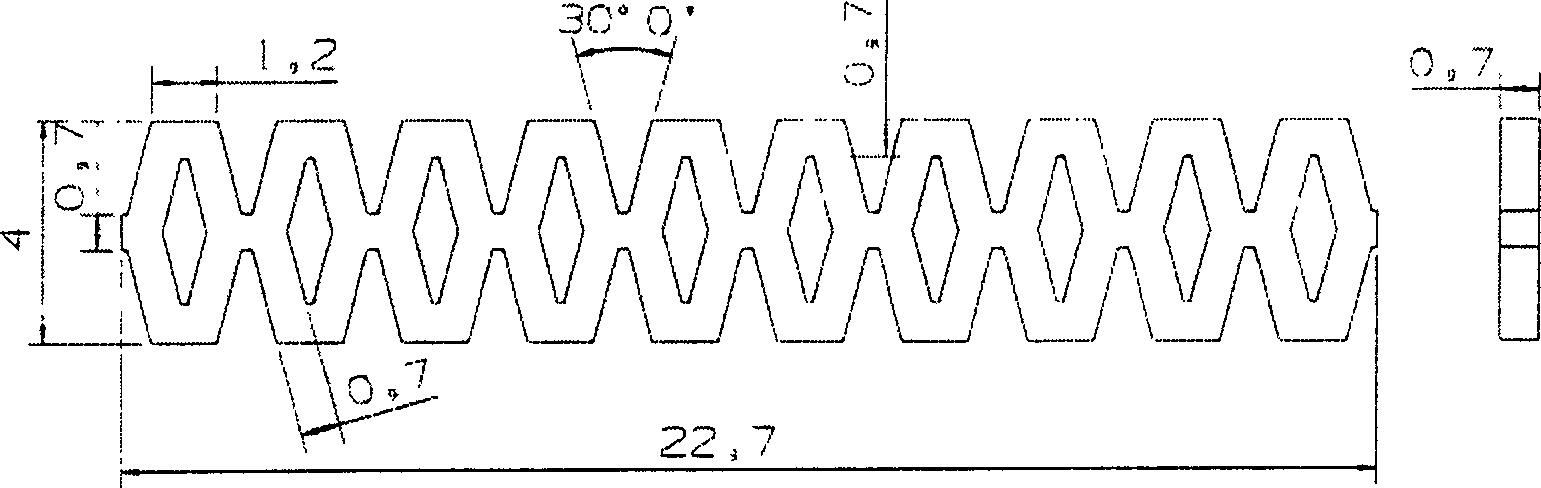

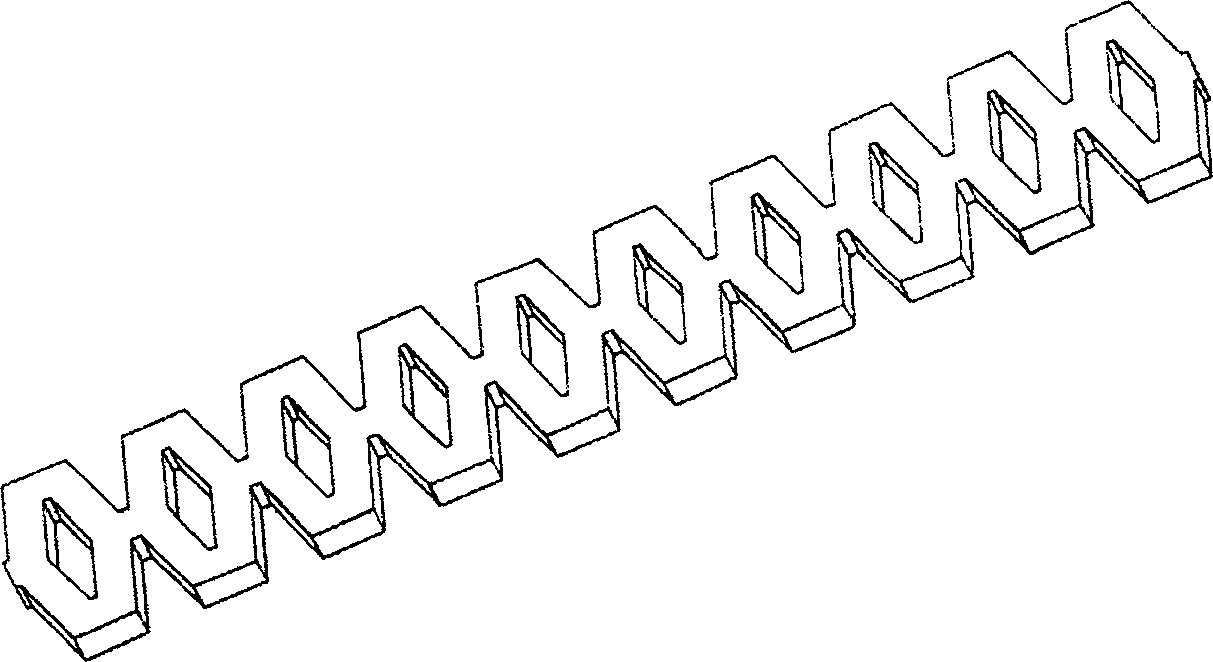

Semi-honeycomb steel strip shaping and cutting off machine ensuring evenness of forced convection flow field

ActiveCN104139208AAccurate shapeHigh shaping precisionShearing machinesOther manufacturing equipments/toolsHoneycombForced convection

The invention discloses a semi-honeycomb steel strip shaping and cutting off machine ensuring the evenness of a forced convection flow field. The semi-honeycomb steel strip shaping and cutting off machine comprises a top plate and a bottom plate, wherein the top plate and the bottom plate are horizontally arranged and are fixedly connected through a plurality of guide columns, and the guide columns are perpendicular to the top plate and the bottom plate. A press plate parallel to the top plate and the bottom plate is arranged between the top plate and the bottom plate, guide sleeves fixedly connected with the press plate are arranged on the press plate, the guide sleeves are in sliding fit with the guide columns through guide holes, a lower rack is arranged on the bottom plate, an upper rack is arranged on the press plate, the upper rack is meshed with the lower rack in a tooth shape when the press plate moves to the bottommost position, and the semi-honeycomb steel strip shaping and cutting off machine is provided with a press plate driving mechanism. According to the technical scheme, the tooth shape of a steel strip is accurately shaped, and the equipment shaping precision is high. The shaping work and the cutting off work are combined on one machine to be completed, shaping and cutting off can be conducted respectively or simultaneously through adjustment, and the semi-honeycomb steel strip shaping and cutting off machine is simple in structure and convenient to use and adjust.

Owner:南通利联机床制造有限公司

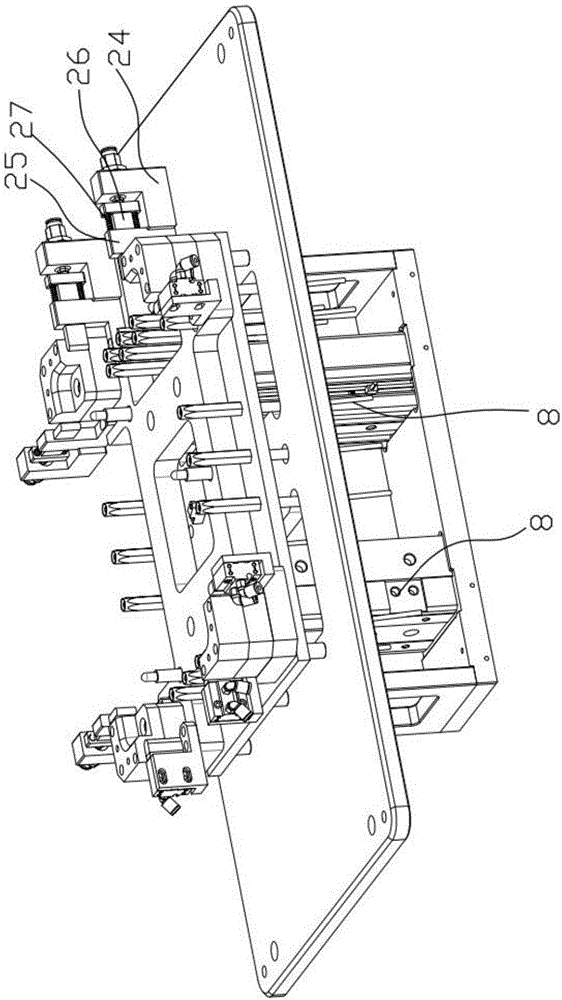

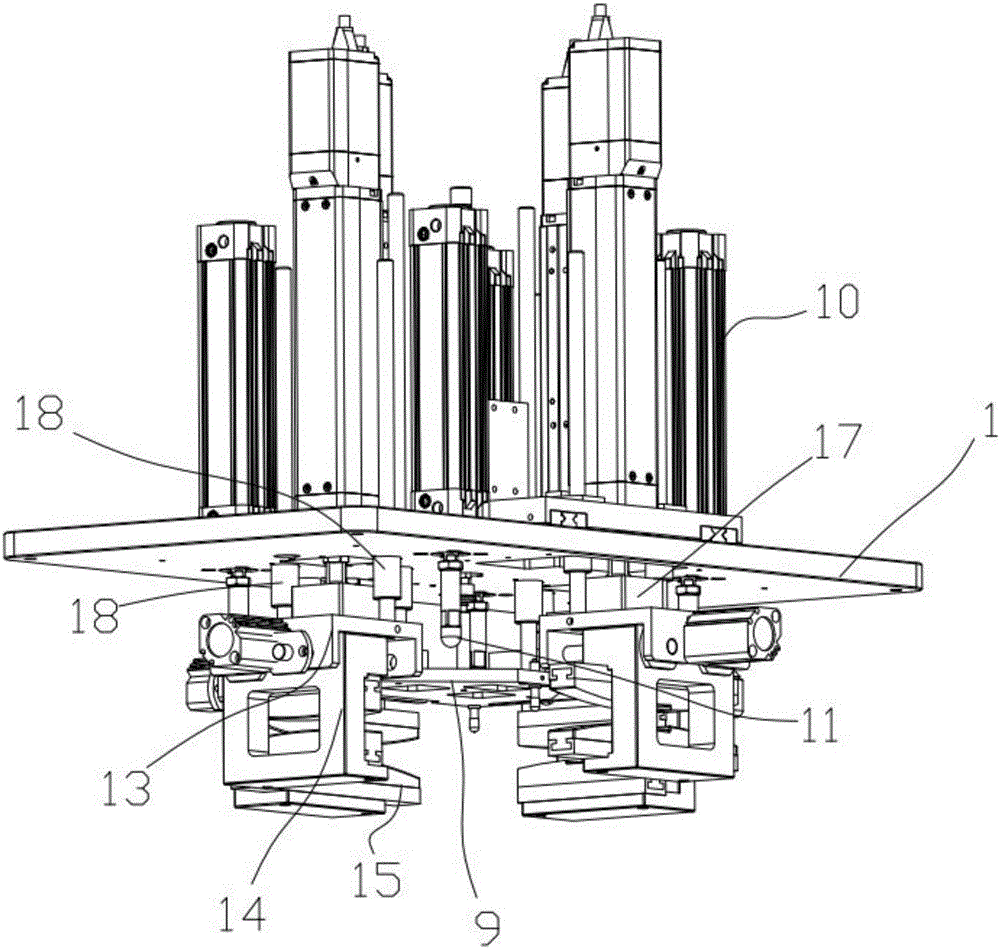

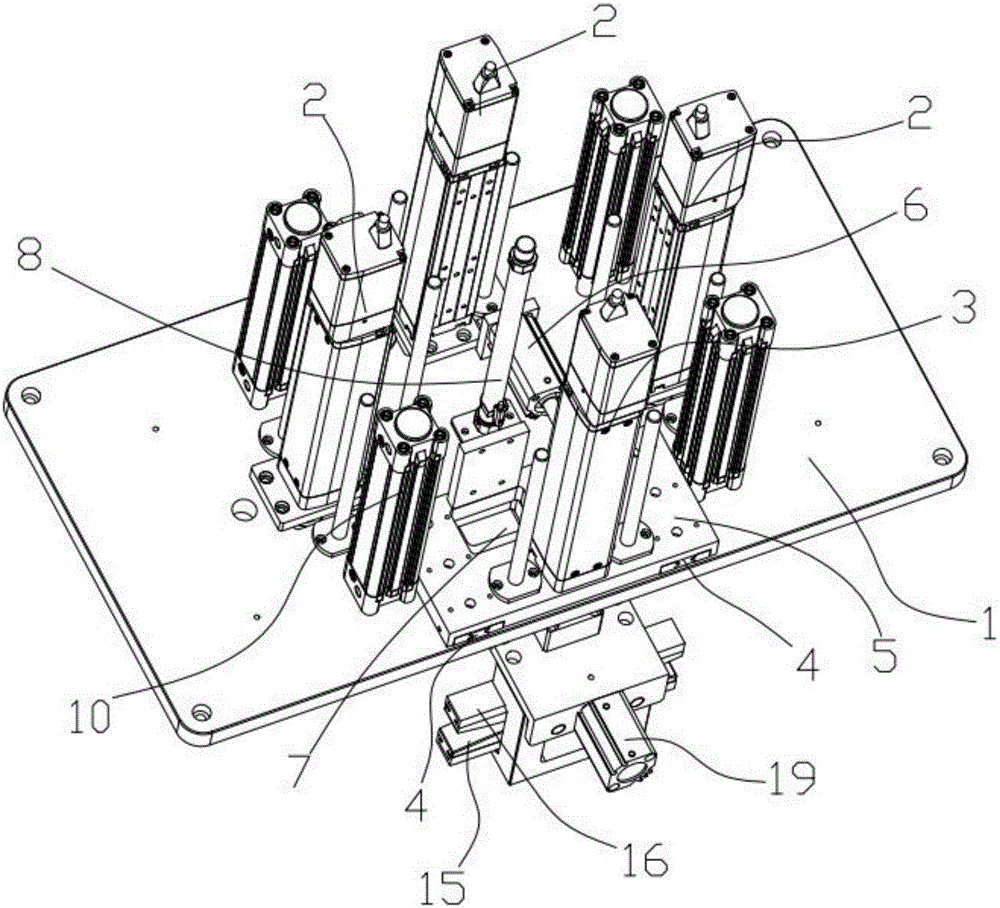

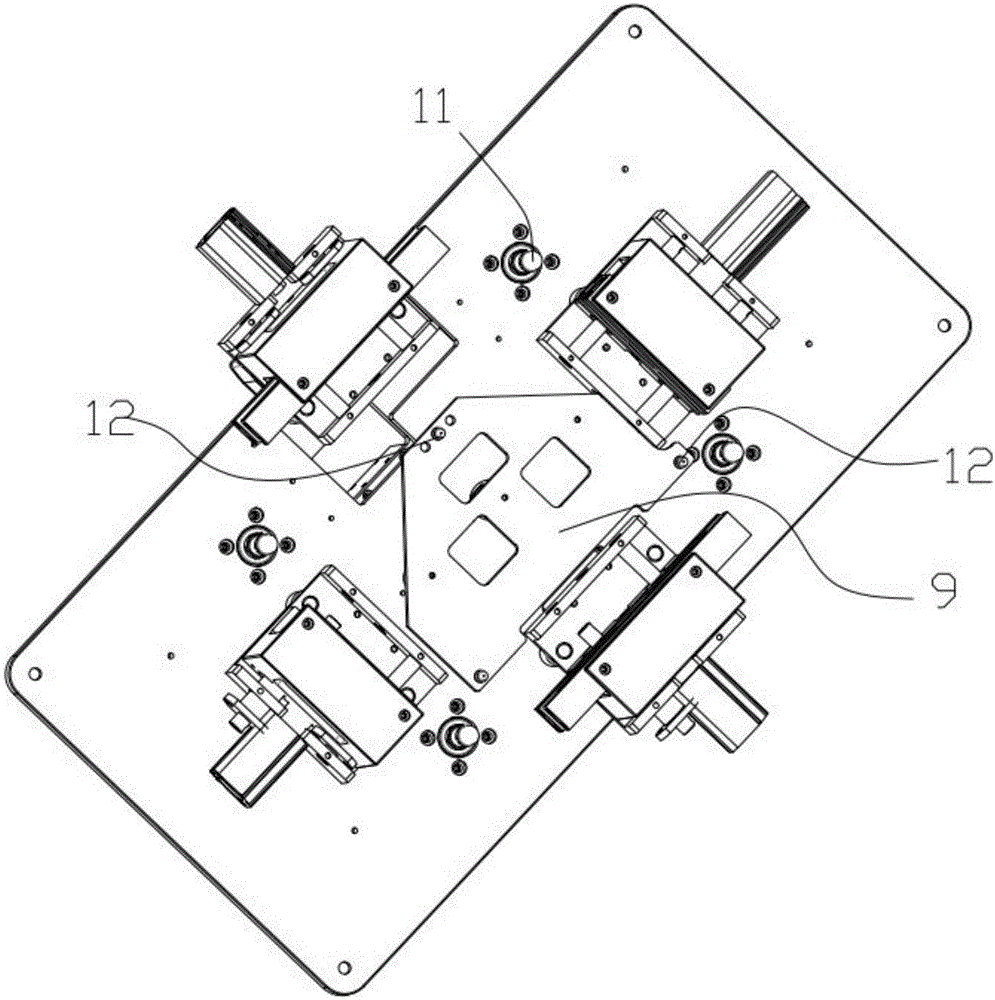

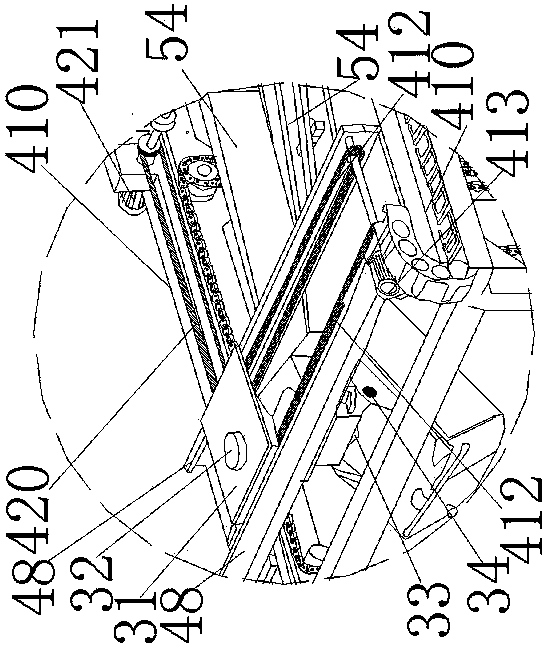

Intelligent-measurement shaping device

ActiveCN106180270AHigh shaping precisionPrevent crushingMetal-working feeding devicesMetal working apparatusSlide platePulp and paper industry

The invention provides an intelligent-measurement shaping device comprising a supporting plate. Three fixed cylinders and a movable cylinder are arranged on the supporting plate. The fixed cylinders are fixed to the supporting plate, and the output ends of the fixed cylinders penetrate the supporting plate. Two slide rails are arranged on the two sides of the portion, provided with the movable cylinder, of the supporting plate. A slide plate is arranged on the slide rails in a clamping manner. A horizontal cylinder is connected to the slide plate. The movable cylinder is fixed to the slide plate, and the output end of the horizontal cylinder penetrates the supporting plate. A corresponding movement opening is formed in the supporting plate. The output ends of the fixed cylinders and the output end of the movable cylinder are connected with shaping mechanisms. A positioning cylinder is arranged at the center of the supporting plate. The output end of the positioning cylinder penetrates the supporting plate and is connected with a pressing plate. Shaping heads are used in cooperation with a bearing mechanism arranged on the lower portion for positioning a product when moving up and down. During shaping, the shaping mechanisms on the upper portion downwards press, the product is fixed through the pressing plate, positioning points are arranged on the pressing plate so that the product can be prevented from being damaged by pressing, the upper shaping heads and the lower shaping heads can conduct shaping on the edge of the product, and therefore the shaping precision is high.

Owner:SUZHOU KANGHONG INTELLIGENT EQUIP CO LTD

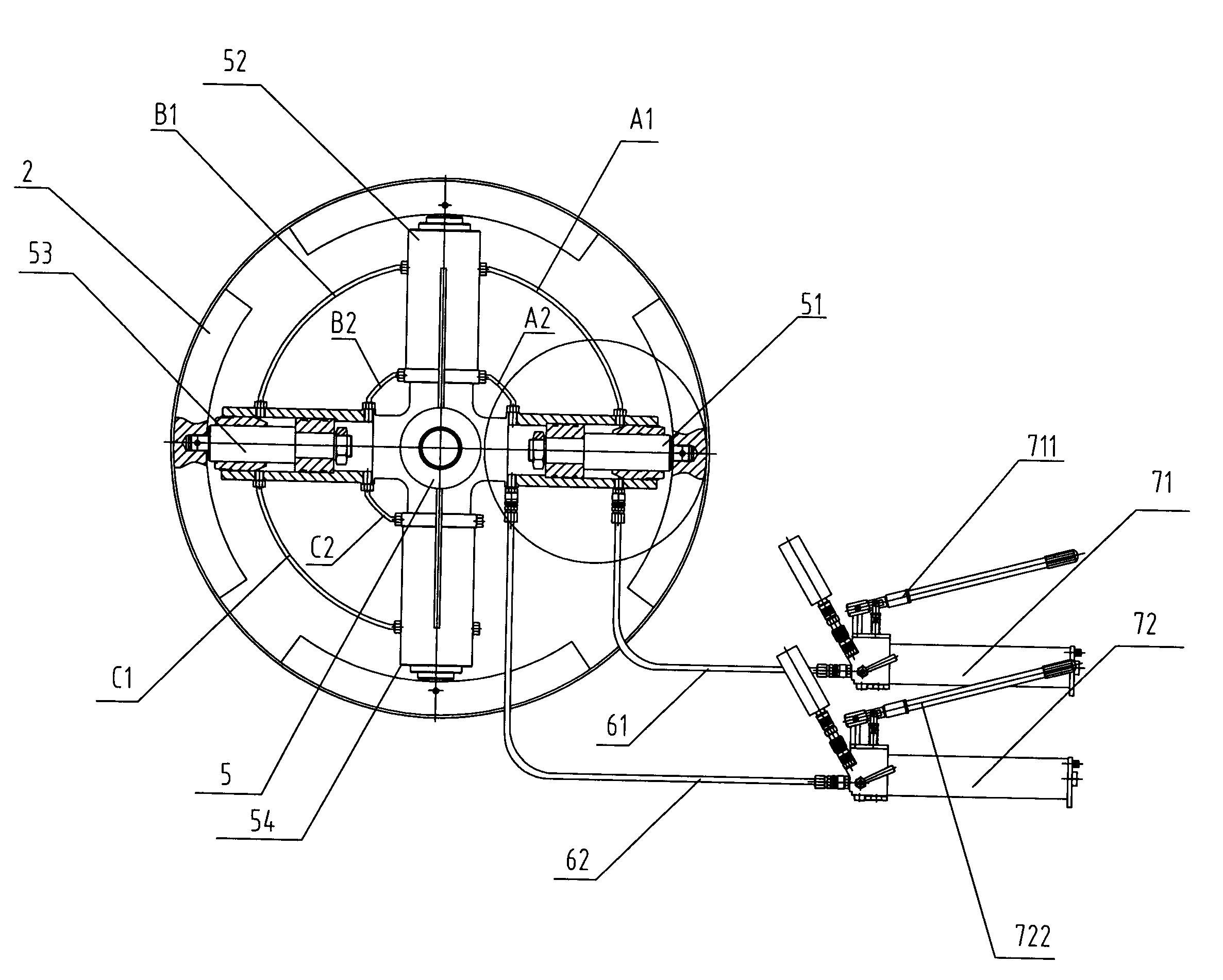

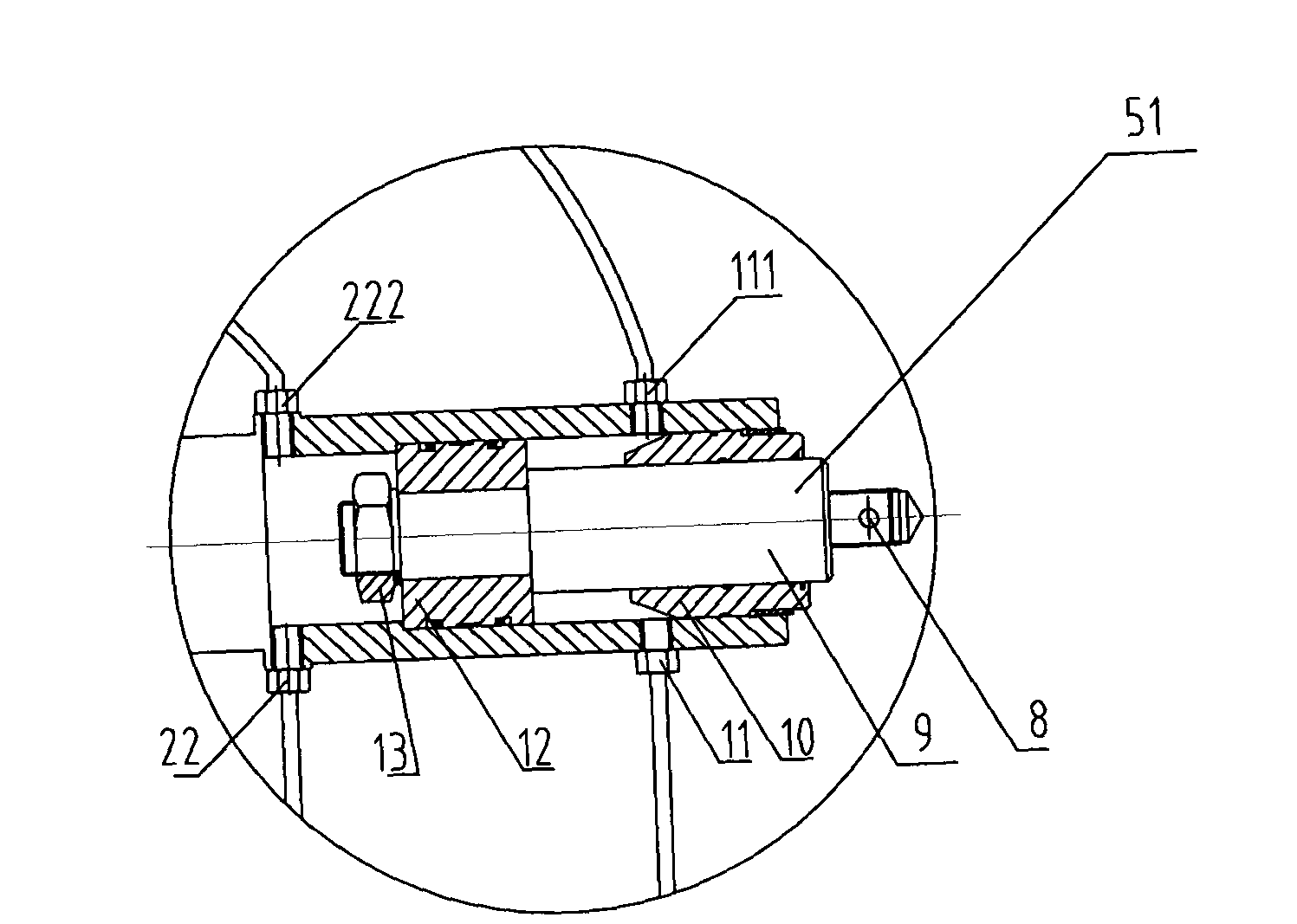

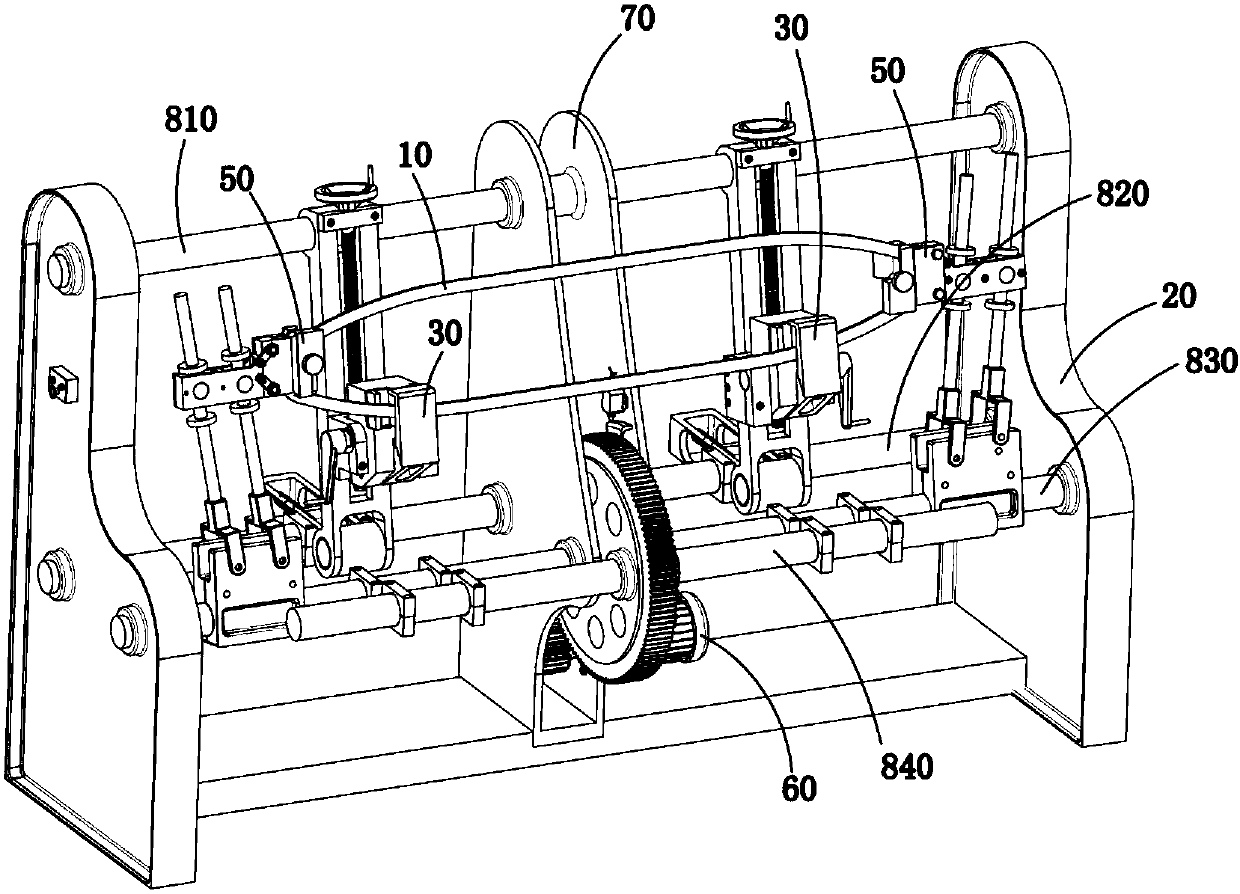

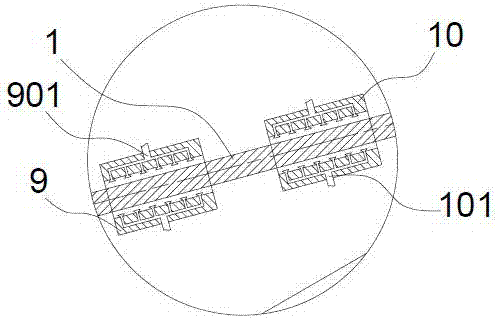

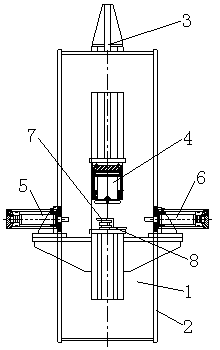

High-voltage motor coil shaping device

PendingCN107689718AHigh shaping precisionGuaranteed pass rateManufacturing dynamo-electric machinesElectric machineControl theory

The invention discloses a high-voltage motor coil shaping device which comprises a rack, a lower clamping mechanism mounted on the rack and an upper clamping mechanism. A middle clamping mechanism half arranged on one side of the left-right direction of the rack is mounted on the rack, the lower clamping mechanism is used for clamping a lower linear section of a to-be-shaped coil, the upper clamping mechanism is used for clamping an upper linear section of the to-be-shaped coil, the middle clamping mechanism is used for clamping the left end or the right end of the to-be-shaped coil, and a turning power mechanism capable of driving the upper clamping mechanism to turn is mounted on the rack; a connecting shaft component is mounted on the rack, a supporting frame is arranged at the center of the connecting shaft component, and the connecting shaft component comprises a shaft c and a shaft d which are in horizontal arrangement; the turning power mechanism comprises a power supply part, apower receiving part and a power output part, the power receiving part can receive power generated by the power supply part and transmit the part to the power output part, the power output part can rotate around own axis, the shaft c is fixed connected with the rack, and the shaft d is eccentrically arranged on the power output part.

Owner:LIUAN JIANGHUAI MOTOR

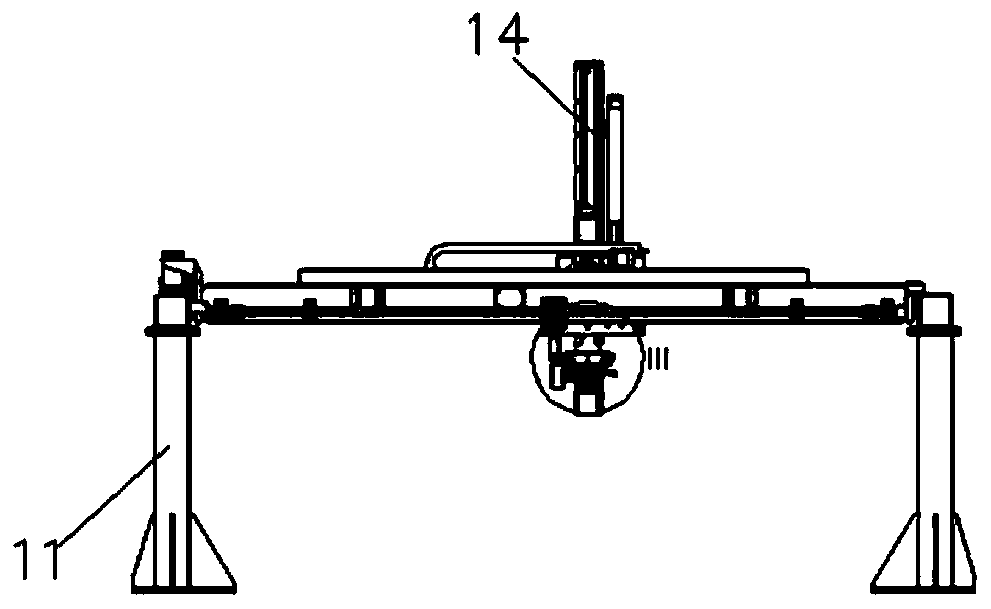

Automatic and efficient production line for chains

PendingCN110711838AHigh shaping precisionExtended service lifeMetal chainsProcess engineeringOil and grease

The invention discloses an automatic and efficient production line for chains in the field of chain production. The automatic and efficient production line comprises a feeding assembly mechanism, an assembly machine, a riveting machine, a double-static-load pre-pulling joint disassembling machine and an oil lubricating machine, wherein the feeding assembly mechanism is connected with the rivetingmachine; the double-static-load pre-pulling joint disassembling machine is mainly composed of a pre-tightening running-in area and a joint disassembling area; the riveting machine is connected with the pre-tightening running-in area; the pre-tightening running-in area is connected with the oil lubricating machine; and the oil lubricating machine is connected with the joint disassembling area. According to the automatic and efficient production line, automatic piece discharging of chain workpieces is achieved, the operation difficulty is lowered, the chain assembly precision is improved, and the service life of the chains is prolonged. The double pre-pulling efficiency is high, the service life of chain wheels is prolonged, and the quality of the chains is guaranteed. The constant temperature is controlled through the oil lubricating machine, grease does not age, oil gas is collected and treated, and the automatic and efficient production line is more environmentally friendly. The automatic and efficient production line is formed, the working efficiency is improved, and the production cost is reduced.

Owner:JIANGSHAN JINLIAN PRECISION TECH

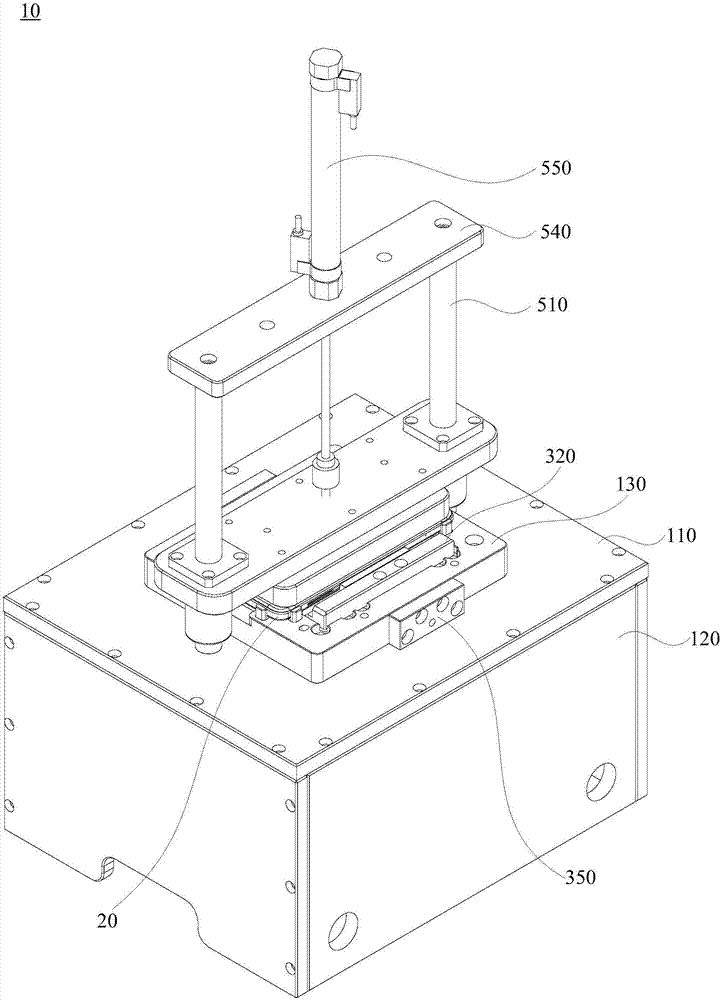

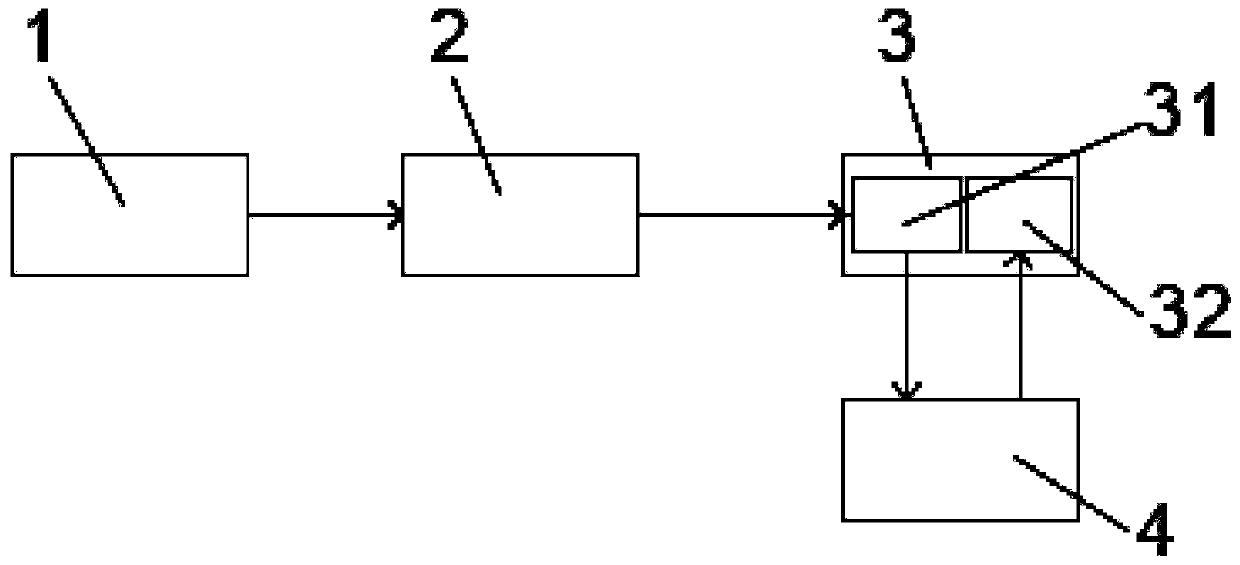

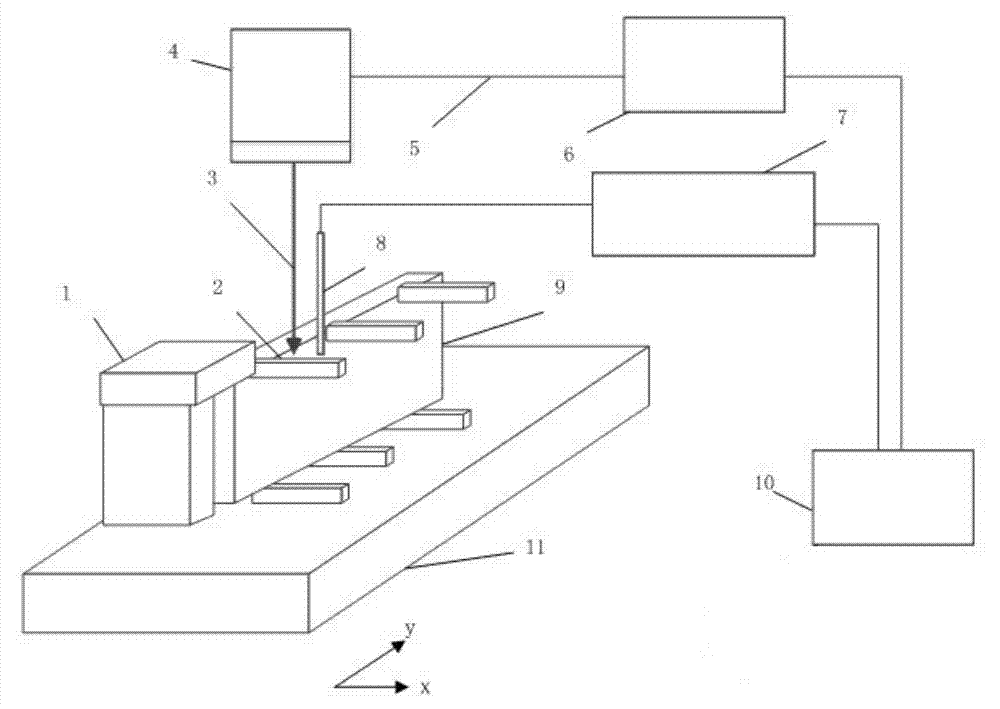

Chip pin shaping device and method based on laser thermal stress forming

ActiveCN104332428AEasy to detectAchieve shapingSolid-state devicesSemiconductor/solid-state device manufacturingState of artHeight difference

Disclosed are a chip pin shaping device and method based on laser thermal stress shaping, and the device and method belong to the field of a semiconductor. To overcome a defect, which exists in the prior art, that the consistency precision of pins after correction is not easy to control, a chip is fixed on the chip pin shaping device through a chip clamp and a two-dimension motion platform is enabled to carry out scanning motion along a diagramed y axis. Through a sensor probe, relative height differences of chip pins are measured and obtained. Through a sensor controller, the measurement result is transmitted to a computer. The relative position of focusing laser on the chip pins is adjusted so that the scanning direction of the focusing laser is parallel with the direction of the diagrammed y axis. According to measured target shaping heights of the chip pins, the laser power and the scanning speed of an optical-fiber laser are sent through the computer and laser shaping processing is carried out on the pins. The relative heights of the pins are measured again through the sensor probe and then the computer decides through a corresponding program to continue shaping processing on a current pin or to carry out shaping on a next pin until all the pins meet tolerance demands.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

Fully-automatic bagged goods stacking device

PendingCN111319991AStable deliveryHigh shaping precisionStacking articlesDe-stacking articlesControl theoryConveyor belt

The invention discloses a fully-automatic bagged goods stacking device. The fully-automatic bagged goods stacking device comprises a frame body and further comprises a movable feeding device, a stacking device body and a pallet lifting device which are arranged on the frame body, and the stacking device body is arranged at the top end of the frame body; the pallet lifting device is arranged belowthe stacking device body on the frame body; the movable feeding device comprises a movable feeding conveyor belt sliding supporting table arranged on one side of the stacking device body on the framebody; and a movable feeding conveyor belt is arranged between the movable feeding conveyor belt sliding supporting table on the frame body and a rotator assembly longitudinal and horizontal motion driving device. The fully-automatic bagged goods stacking device has the advantages of smooth bagged goods conveying, high shaping precision and high stacking precision.

Owner:臧群邦

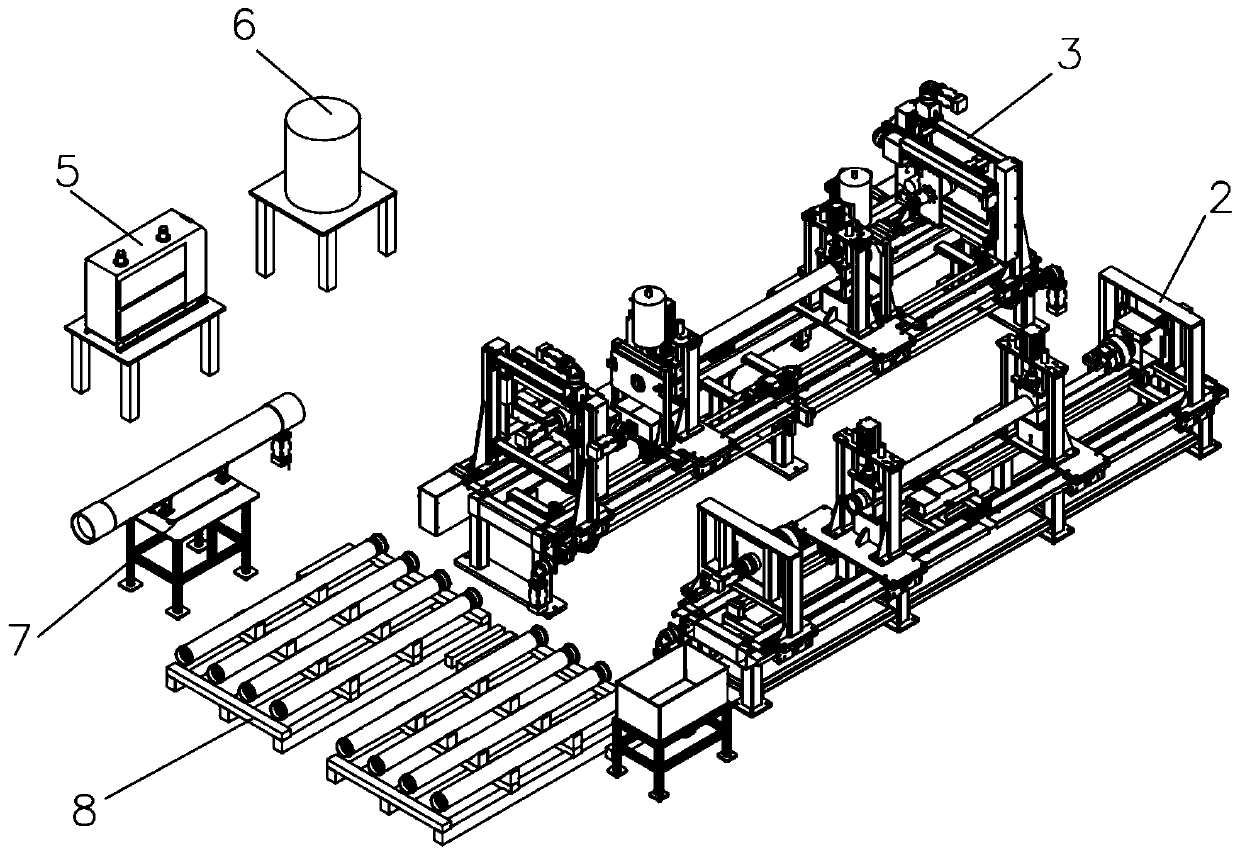

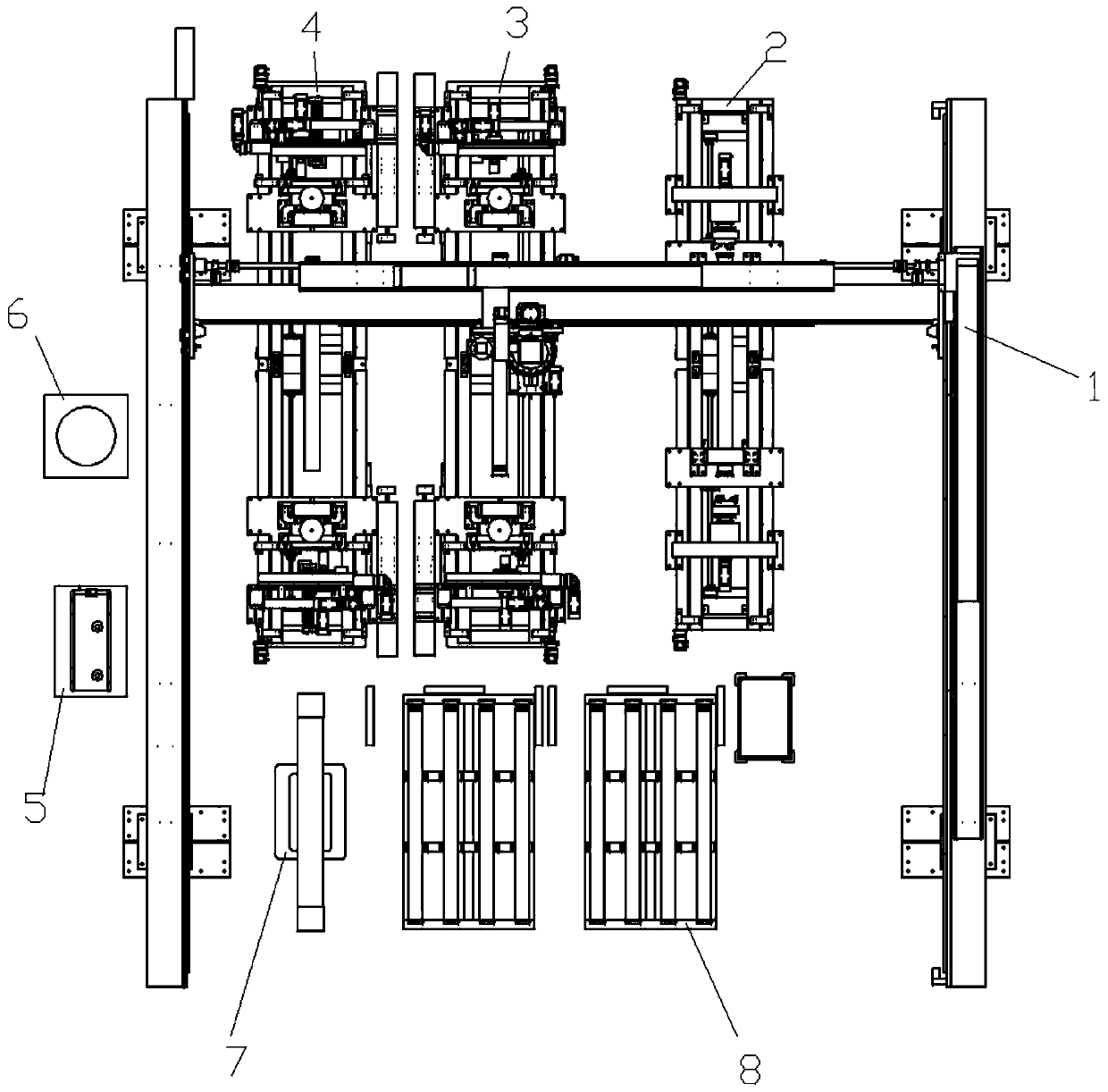

Man-machine isolated automatic milling shaping machining system and method

The invention provides a man-machine isolated automatic milling shaping machining system and method. The machining system comprises a control system, a vision system, a truss mechanical hand, an end cover detachment machine, a milling shaping machining machine and a thread cleaning machine. During machining, firstly, the control system controls the truss mechanical hand to carry a to-be-shaped engine to the end cover detachment machine; secondly, the end cover detachment machine is controlled to position and lock the engine, and after end covers at the two ends are detached, the truss mechanical hand is controlled to carry the end-cover-detached engine to the milling shaping machining machine, and milling machining is conducted on the engine; and finally, the truss mechanical hand carriesthe engine, where end face shaping is finished, to the thread cleaning machine, and the end faces of the two ends of the engine are cleaned. Man-machine isolation, full-process automation and informatization are introduced into the field of the milling shaping machining system for the first time, and application prospects are very wide.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Steel pipe shaping device

The invention relates to a steel pipe shaping device which comprises a fixing frame. The fixing frame is provided with a first supporting rod and a second supporting rod arranged on the two sides respectively. A transverse rod strides over the first supporting rod and the end, away from the ground, of the second supporting rod. A first side pressing base is arranged on the first supporting rod. A second side pressing base is arranged on the second supporting rod. An upper pressing base is arranged on the transverse rod. A first side pressing block is inserted into the first side pressing base. A second side pressing block is inserted into the second side pressing base. An upper pressing block is inserted into the upper pressing base. The first side pressing block, the second side pressing block and the upper pressing block stretch and retract relative to the first side pressing base, the second side pressing base and the upper pressing base respectively so as to achieve the shaping effect of a steel pipe to be shaped. Accordingly, due to the arrangement of the novel steel pipe shaping device, workloads of manual work are reduced, the working efficiency is improved, and the product shaping precision is improved.

Owner:ZHEJIANG DADA STAINLESS STEEL

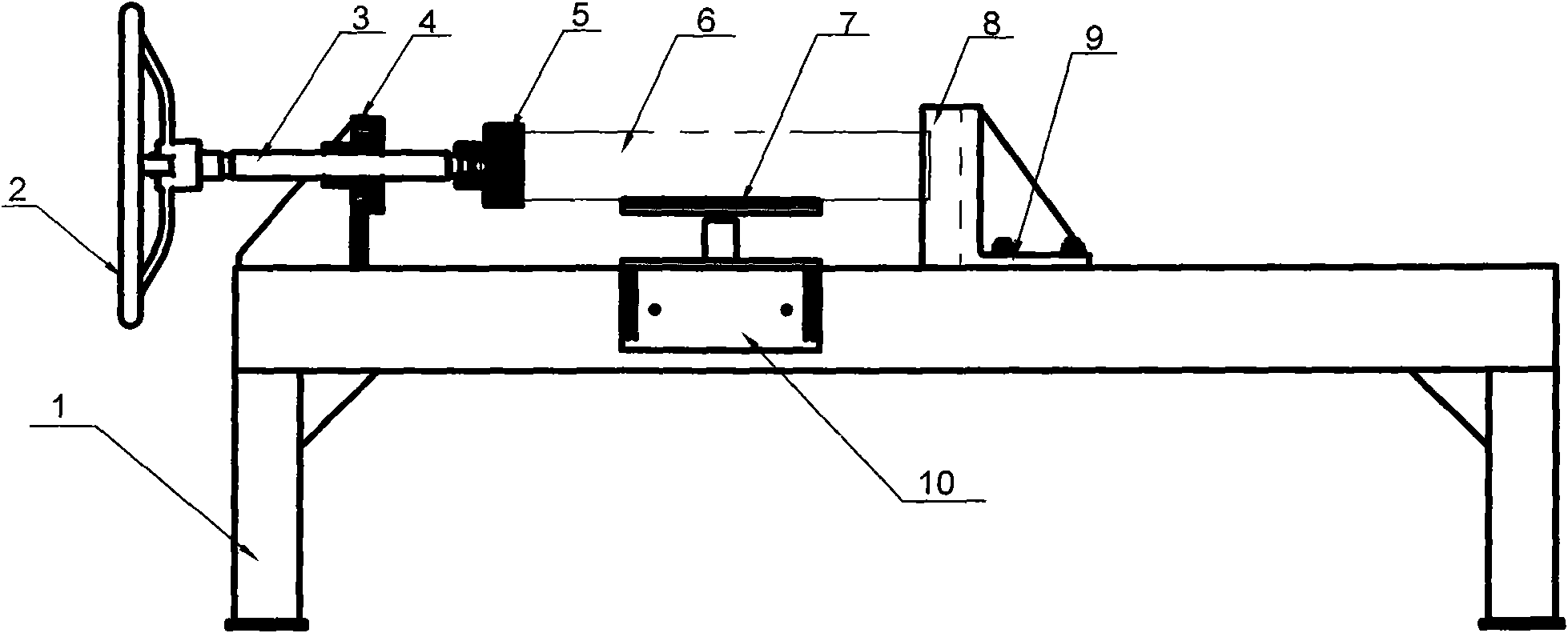

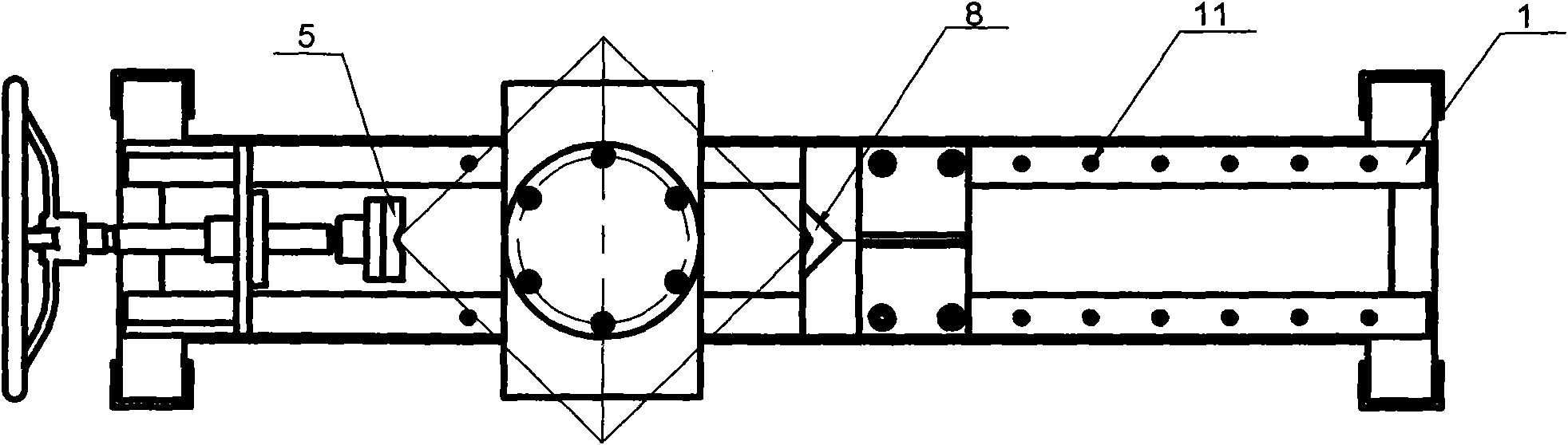

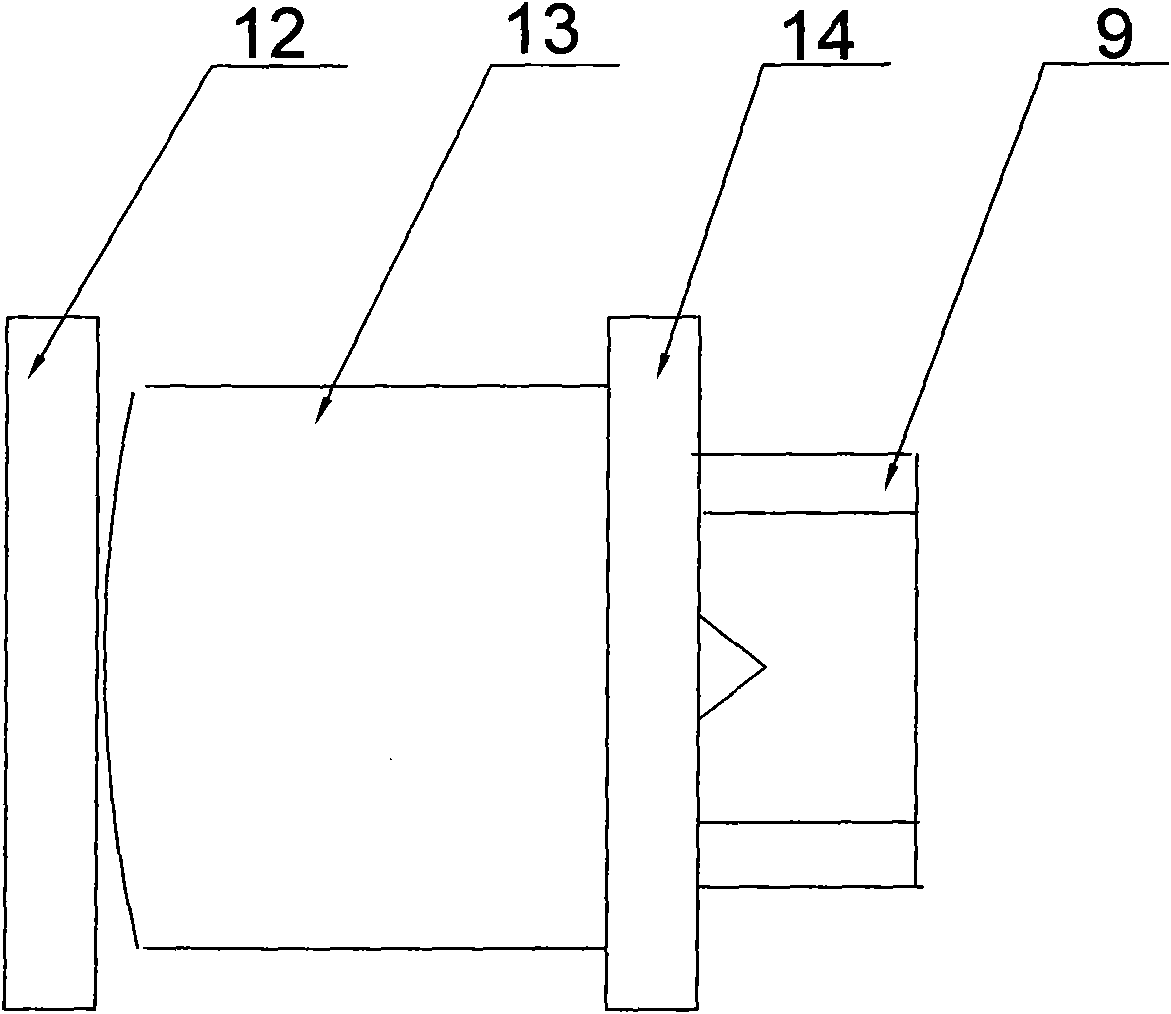

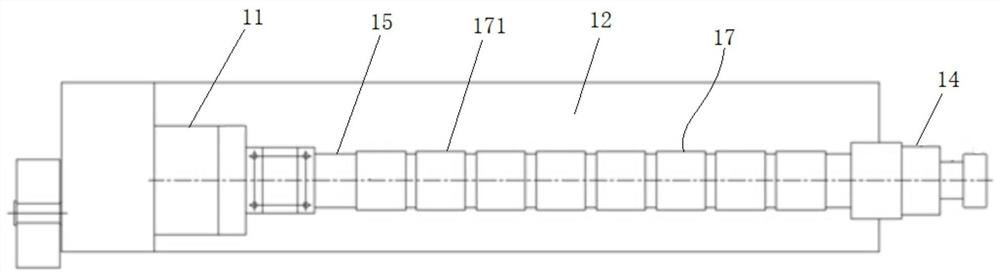

Manual core shaping machine and operation method thereof

The invention discloses a manual core shaping machine and an operation method thereof. The manual core shaping machine comprises a stand, a hand wheel, a lead screw, a front fixing seat, exchangeable V-shaped blocks or exchangeable flat plates, a lifting platform, a dragging plate and a movable tailstock, wherein the front fixing seat is installed on one end of the stand, and the movable tailstock is installed on the other end of the stand; the dragging plate is installed in the middle of the stand, and the lifting platform is installed on the dragging plate; the hand wheel is connected with the exchangeable V-shaped blocks or the exchangeable flat plates through the lead screw, and the lead screw is installed on the front fixing seat; the exchangeable V-shaped blocks or the exchangeable flat plates are also arranged on the movable tailstock, and the exchangeable V-shaped blocks or the exchangeable flat plates connected with the lead screw are symmetrically arranged. The exchangeable V-shaped blocks are utilized when diagonal lines of a core are shaped, and the exchangeable flat plates are utilized when the straightness of four sides of the core are shaped. When people operate, the shaping of the core can be realized through adjusting the dragging plate, the lifting platform, the movable tailstock, and the like. The invention has the advantages of less labor intensity, high shaping precision, high success ratio and convenience for operation.

Owner:无锡万盛换热器制造有限公司 +1

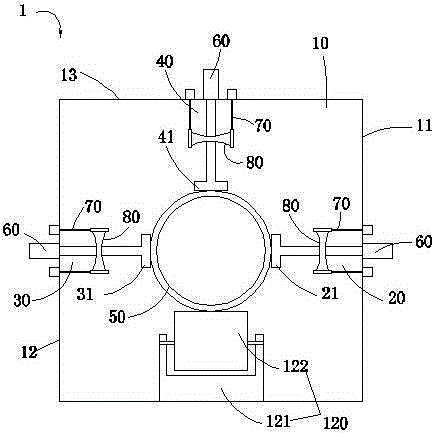

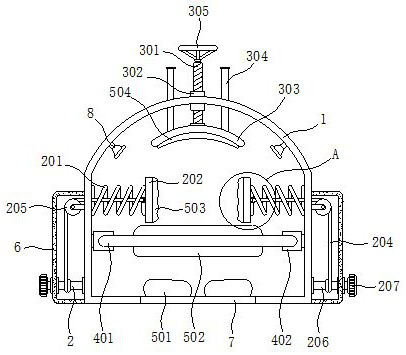

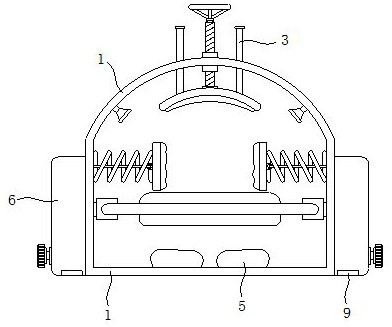

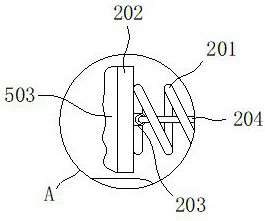

Face shaping device for improving shaping precision

The invention discloses a face shaping device for improving shaping precision, and relates to the technical field of face shaping. The face shaping device comprises a circular arch frame, wherein a head fixing mechanism, a forehead fixing mechanism, a chin fixing mechanism and a protection mechanism are arranged on the circular arch frame, outer walls of two sides of the circular arch frame are each fixedly provided with a set of protection shells, and a bearing plate is fixedly installed on a front side of the circular arch frame. The facial shaping device can simultaneously limit and fix theforehead, the head and the chin of a shaper, improve the fixation effect,reduce deviation of the shaper's head during a shaping process, facilitate the shaper to place the hair braid in between to avoid a situation that the hair braid is pressed by the shaper's head and affects balance of the shaper, jointly improve shaping accuracy, has a simple and fast fixing method, is convenient for fixing and relaxing the head of the shaper before and after the shaping process, and improves actual use experience effect.

Owner:重庆阿里乐乐科技发展有限公司

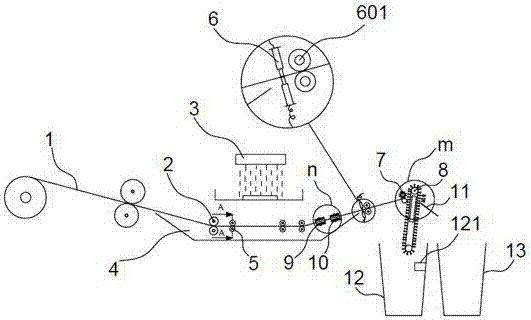

Metal magnetic line marker manufacture device for needlefish

InactiveCN107466941AReduce harmHigh shaping precisionAntifouling/underwater paintsSpraying apparatusNeedlefishScrap

The invention provides a metal magnetic line marker manufacture device for needlefish, and belongs to the technical field of artificial marker production. The device comprises an etching machine by which a line marker body can be etched, the etching machine is connected with a dowel drilling group by which the tail end of the segmented line marker body can be drilled, an etching tank is arranged below the etching machine, the interior of the etching tank is provide with a guide pulley group and shaping wheel groups; a spraying machine, a drying machine, a glue dispensing machine and a cutting hob are sequentially connected between the shaping wheel groups and the dowel drilling group, one side of the dowel drilling group is provided with the cutting hob, and the other side is provided with drilling machines; a line marker collecting barrel is arranged below the dowel drilling group; and a scrap guiding board is arranged below the drilling machines. According to the device provided by the invention, line material waste produced in a whole process is less, the surface of parts of the device is sprayed with an abrasion resistant layer, precision of the parts is not easy to reduce in a long-term usage process, marker serial numbers for etching are clear, production is rapid, energy consumption is low, batched production can be realized, and after manufactured line markers are injected into needlefish bodies, influences on needlefish activity are small.

Owner:ZHEJIANG OCEAN UNIV

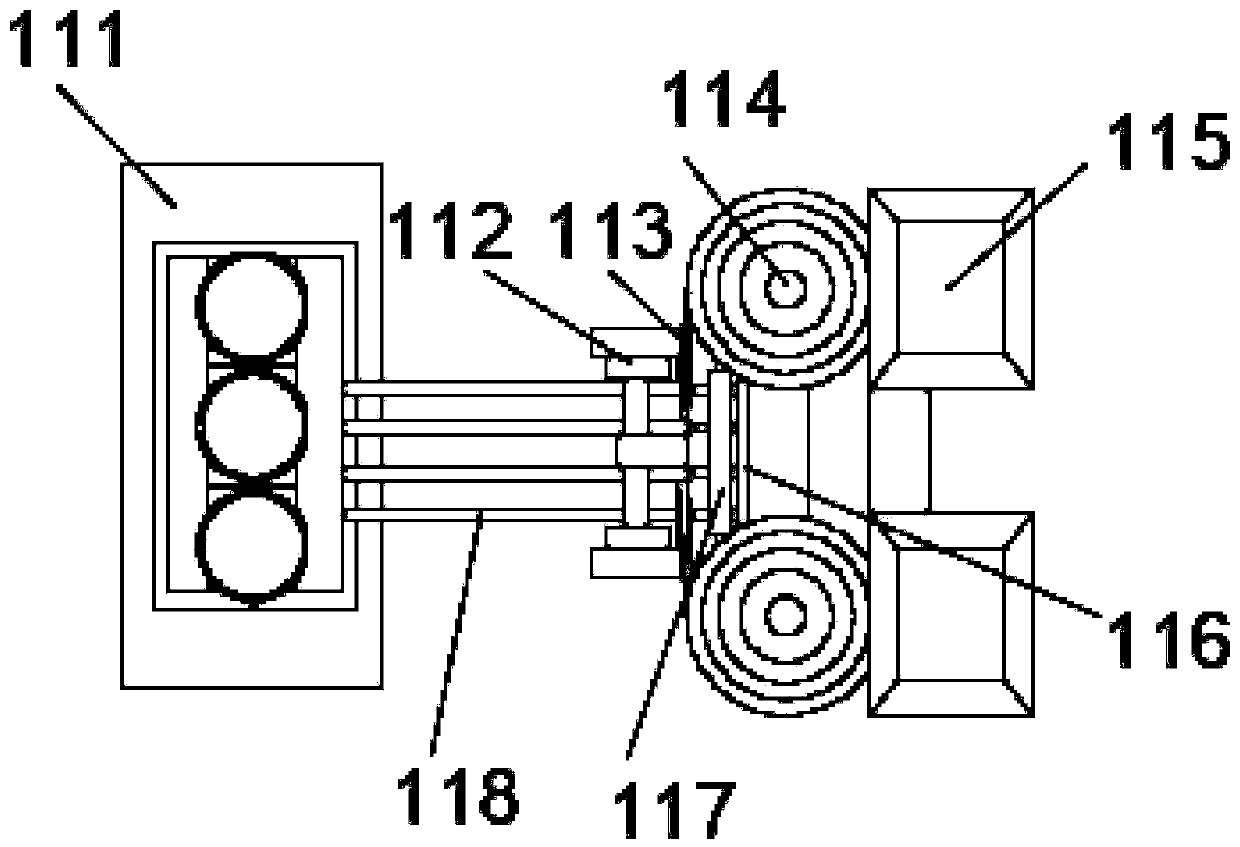

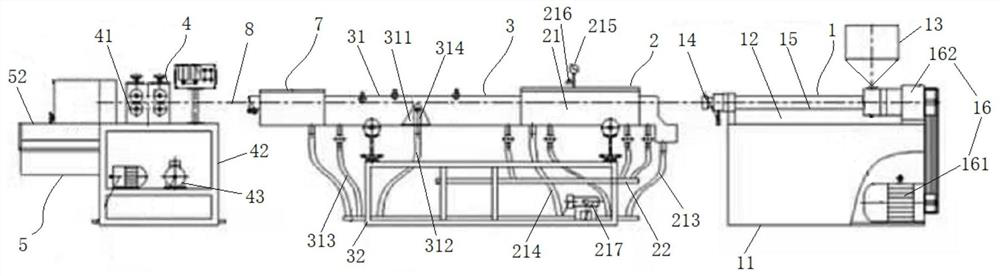

Device and method used for producing cooling cured part

The invention discloses a device and method used for producing a cooling cured part. The device comprises an extruder, a shaping device, a cooling device, a traction device and a cutting device. The device comprises a guide component, and the guide component is used for guiding a cooling cured part blank to sequentially pass through the shaping device, the cooling device and the traction device from the outlet end of an extrusion die head and enter the cutting device to be cut. By means of the device and method, the cooling cured part with the good cooling effect can be produced, operation isconvenient, and the production efficiency is high.

Owner:HUBEI CHINA TOBACCO IND

S-shaped bridge expansion joint positioning and shaping device

InactiveCN109396707ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWork in process

The invention relates to a welding tool of a bridge expansion joint and particularly relates to an S-shaped bridge expansion joint positioning and shaping device. The device includes not less than three pressing cylinders, shaping cylinders and clamping cylinders, wherein the pressing cylinders are fixed at the bottom of an upper beam and are arranged on the center line of the upper beam, the clamping cylinders are fixed in parallel at one side of the top of a lower beam, the shaping cylinders are fixed in parallel at the other side of the top of the lower beam, the pressing cylinders, the shaping cylinders and the clamping cylinders are equally spaced, the top of half-finished products of S-shaped steels is pressed and shaped by the pressing cylinders, both sides of the S-shaped steels are pressed by the clamping cylinders and the shaping cylinders, and linearity of the half-finished products of the S-shaped steels is adjusted. The device is advantaged in that the device is simple instructure, is convenient to use and has high shaping precision, good shaping effect, good consistency, small shaping deformation, high work efficiency and low production cost.

Owner:丁克芳

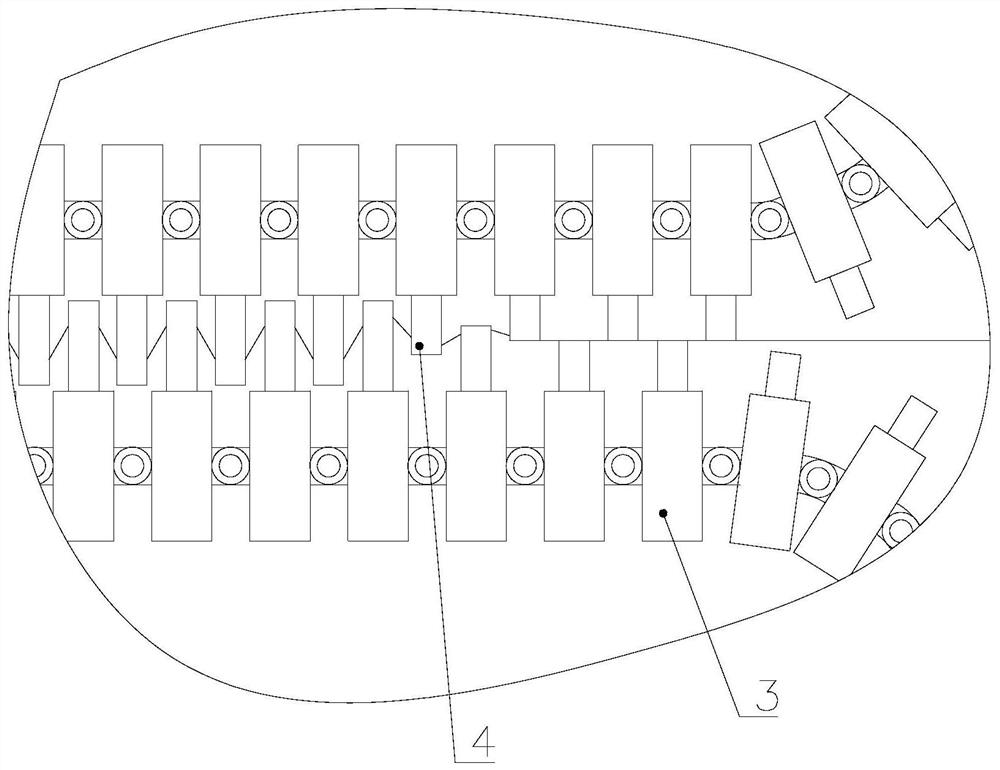

A multi-station jump riveting mechanism, jump riveting machine and chain assembly and processing line

Owner:JIANGSHAN JINLIAN PRECISION TECH

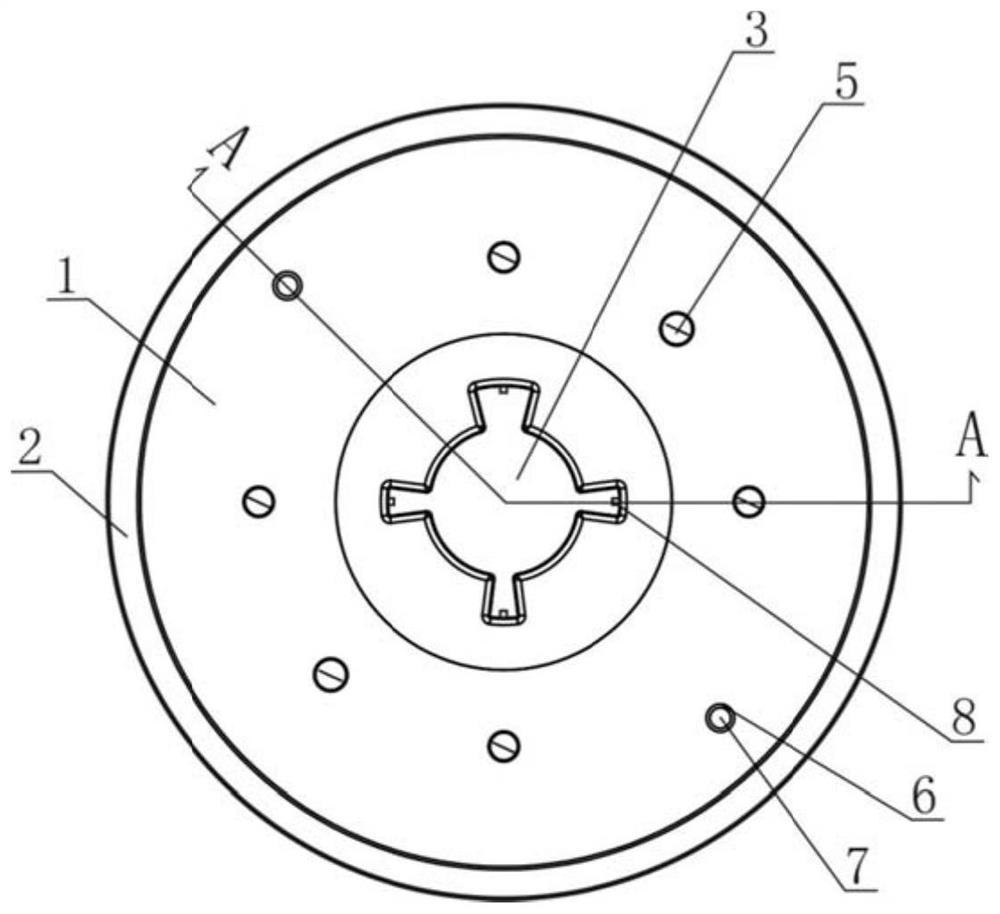

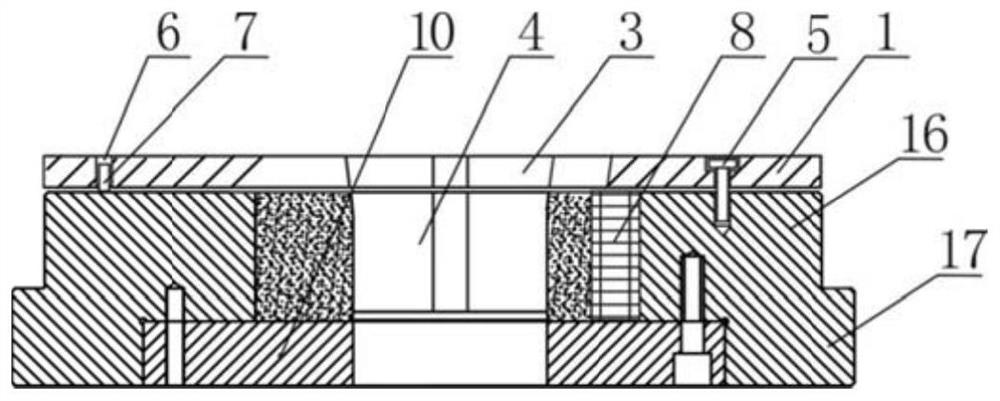

Mold for diffuser of automotive exhaust gas recirculation cooling system

The invention relates to the technical field of part processing of automotive exhaust gas recirculation systems, in particular to a mold for a diffuser of an automotive exhaust gas recirculation cooling system. The mold for the diffuser of the automotive exhaust gas recirculation cooling system comprises a fixed mold cavity insert, a pressing plate, a left cavity sliding block, guide sliding pins, a fixed mold plate, a moving mold cavity insert, balls, a moving mold plate, ball pushing rods, central large pushing rods, a supporting column and a right cavity sliding block. The mold has the benefits that the reshaping accuracy is high; a workpiece positioning block is positioned from the outer wall of a large circle opening, and the inner wall surface of the large circle opening is radially pushed by eight full circle sliding blocks under the action of a core rod, so that full circle processing of the wall of the large circle opening is completed.

Owner:LIUZHOU TONGWEI MACHINERY

Light-curing 3D printing material and its preparation method and application

ActiveCN108410162BImprove thixotropyHigh forming precisionAdditive manufacturing apparatusPolymer sciencePolyamide

The invention relates to a light-cured 3D printing material and its preparation method and application. The photocurable 3D printing material includes the following raw material components in parts by weight: 20-80 parts of photocurable resin, 10-60 parts of photocurable reactive diluent, 1-10 parts of photoinitiator, and 0.1-20 parts of thixotropic agent part, 0.1-5 parts of auxiliary agent; wherein, the thixotropic agent is at least one of attapulgite, montmorillonite, bentonite, fumed silica, polyamide wax, mica powder; the photocurable resin is At least one of aliphatic polyurethane and alicyclic epoxy resin. The light-curing 3D printing material has excellent thixotropy and can be applied to the FDM nozzle printing process. Compared with SLA, it can effectively reduce the production cost of 3D printing products, and has fast molding speed and high precision, and can perform complex contours or large-scale 3D printing. The production of products.

Owner:广州有得新材料科技有限公司

A steel tube shaping device

Owner:ZHEJIANG DADA STAINLESS STEEL

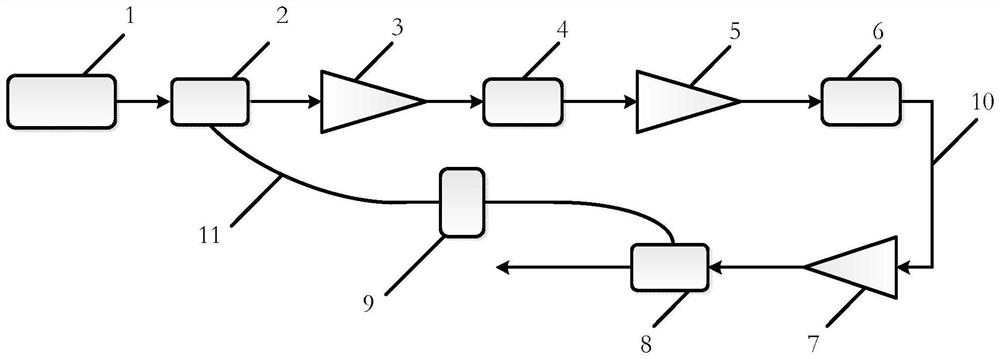

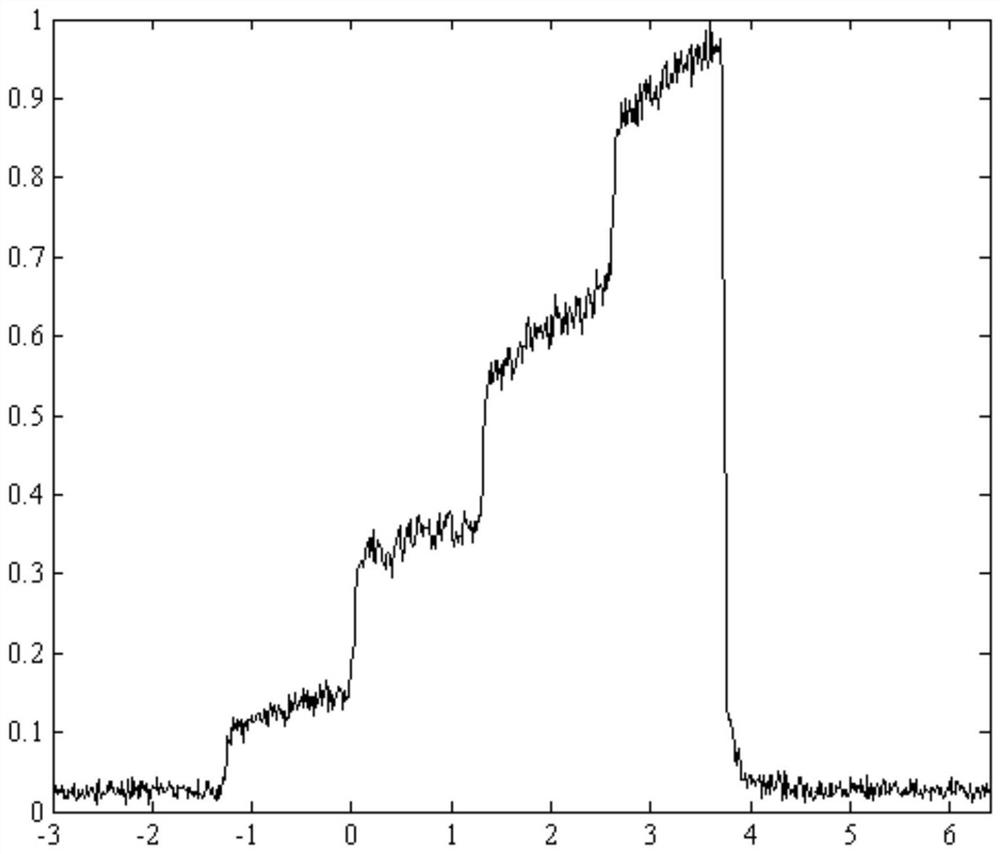

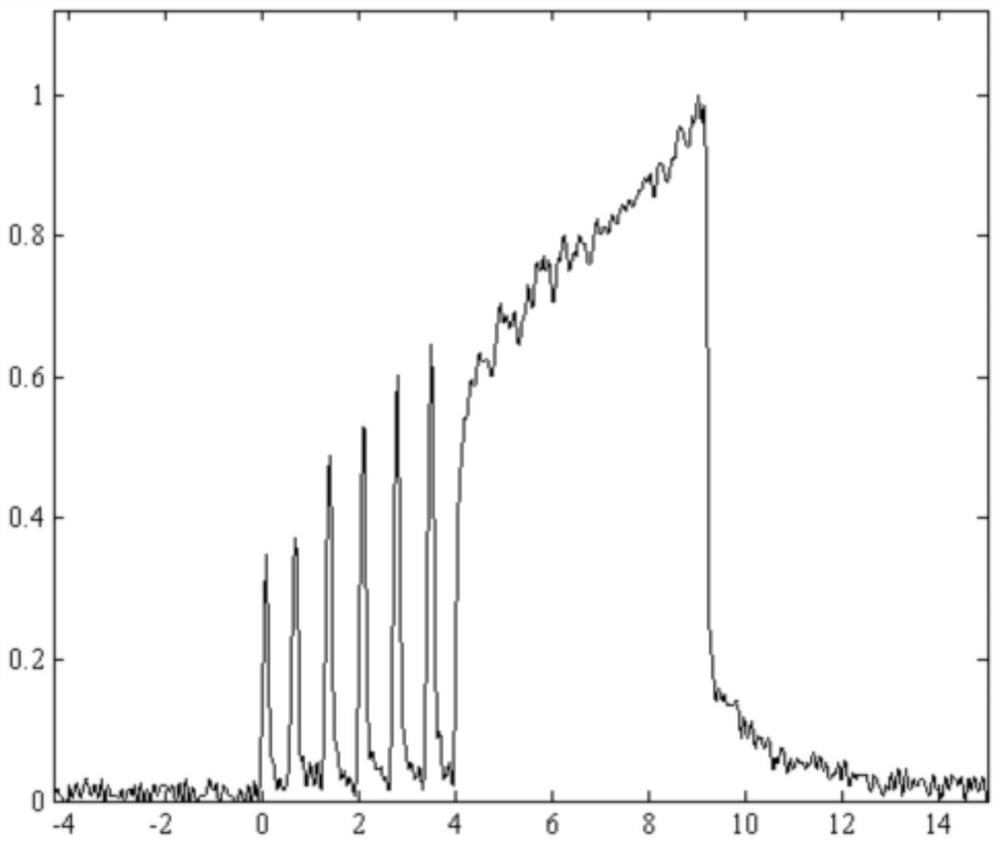

A laser shaping pulse acquisition device and acquisition method

ActiveCN106207737BHigh shaping precisionIncrease contrastActive medium shape and constructionNoise (radio)Engineering

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

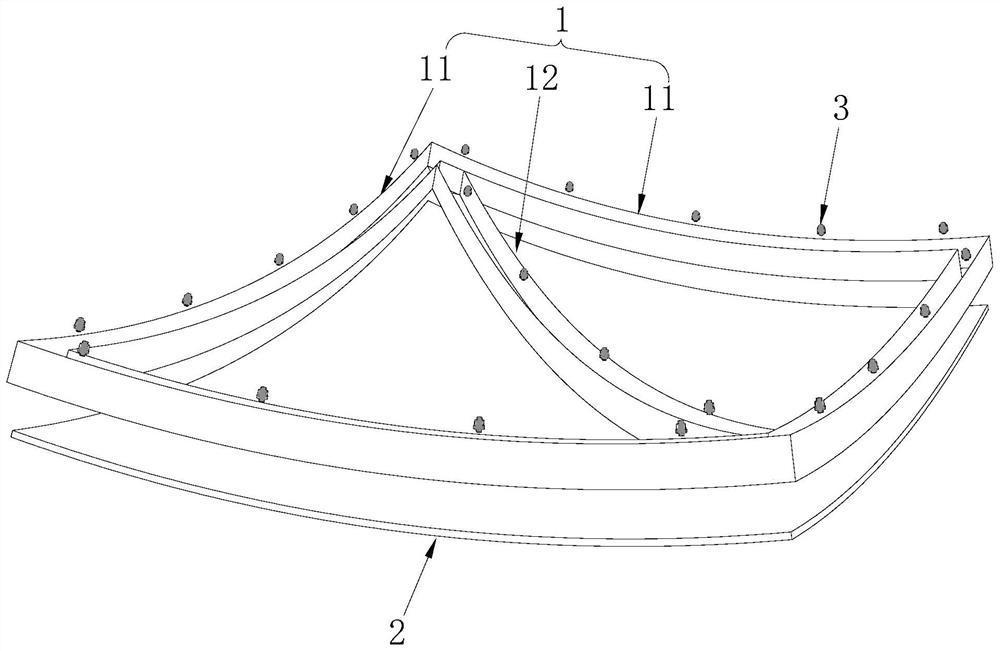

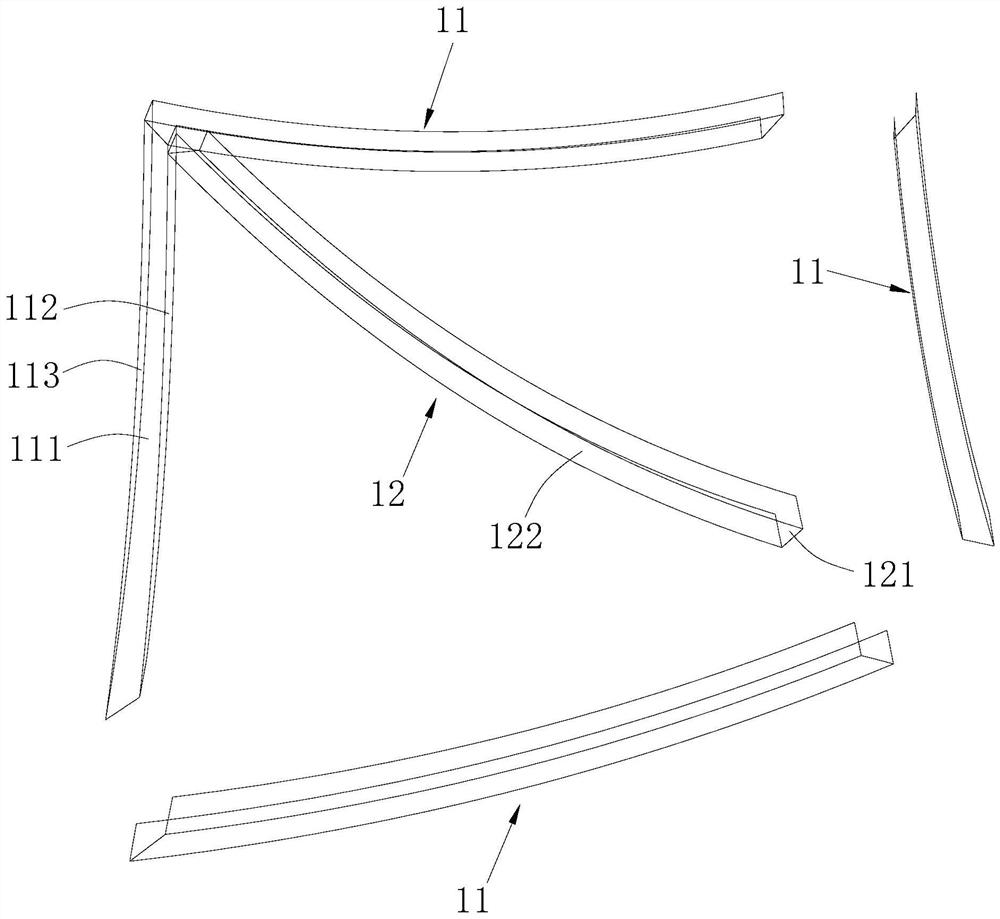

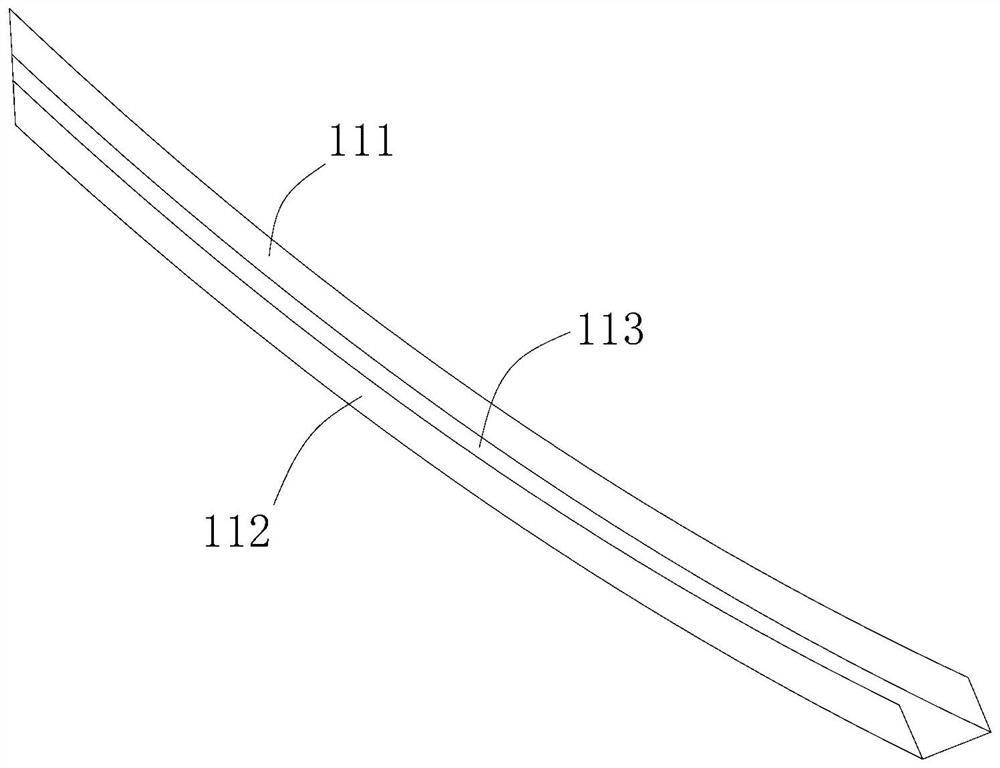

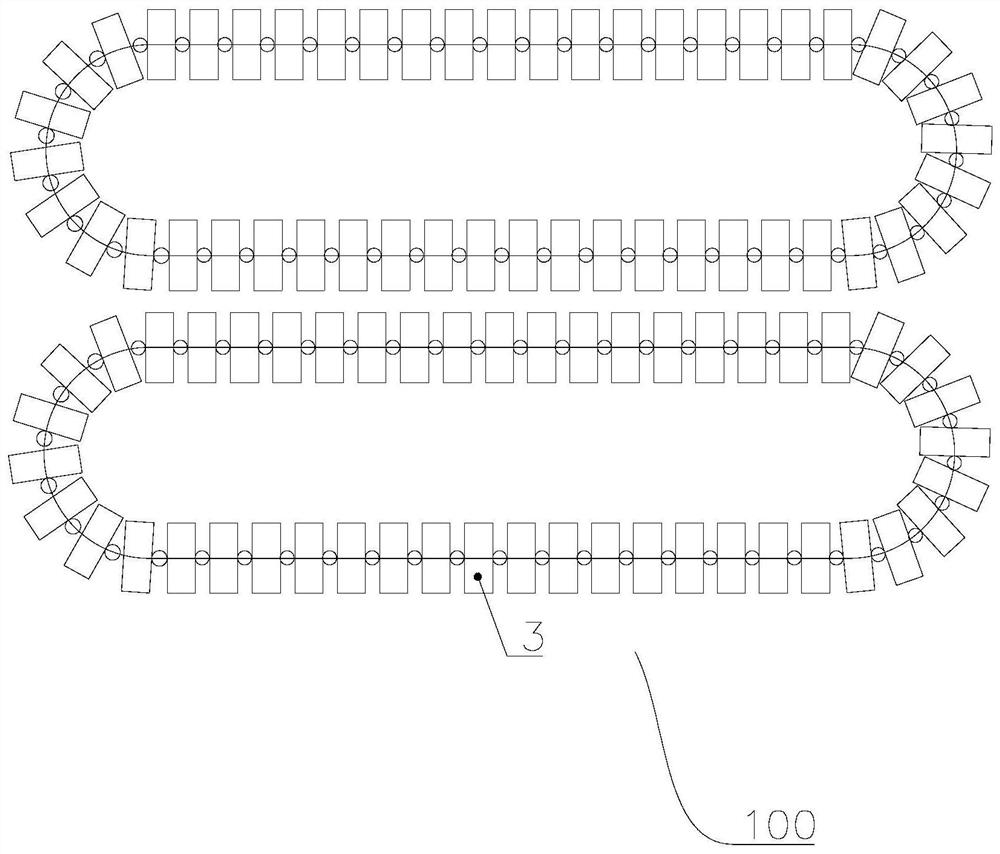

Curved surface shaping device of stainless steel plate, outer wall decoration structure and manufacturing method of outer wall decoration structure

ActiveCN114687523AImprove stylingHigh shaping precisionCovering/liningsLaser beam welding apparatusStructural engineeringSS - Stainless steel

The invention provides a curved surface shaping device of a stainless steel plate, an outer wall decoration structure and a manufacturing method of the outer wall decoration structure, the outer wall decoration structure comprises the stainless steel plate and the curved surface shaping device of the stainless steel plate, the curved surface shaping device comprises a plurality of first shaping parts, and all the first shaping parts are sequentially connected end to end to define a frame-shaped structure; each first shaping piece comprises a first attaching plate and at least two first side plates, and the first attaching plates and the first side plates are curved plates; the at least two first side plates are fixed to the back faces of the first attaching plates correspondingly, and the front faces of the first attaching plates are used for being attached and fixed to the peripheral edge position of the stainless steel plate so that the edge of the stainless steel plate can be shaped. The manufacturing method of the outer wall decoration structure is used for manufacturing the outer wall decoration structure. The curved surface shaping device for the stainless steel plate is used for bending and shaping the stainless steel plate to be shaped after being bent, so that the bending and shaping precision of the stainless steel plate is improved, and the curved surface shaping device for the stainless steel plate is simple in manufacturing process and low in manufacturing cost.

Owner:深圳市大地幕墙科技有限公司 +1

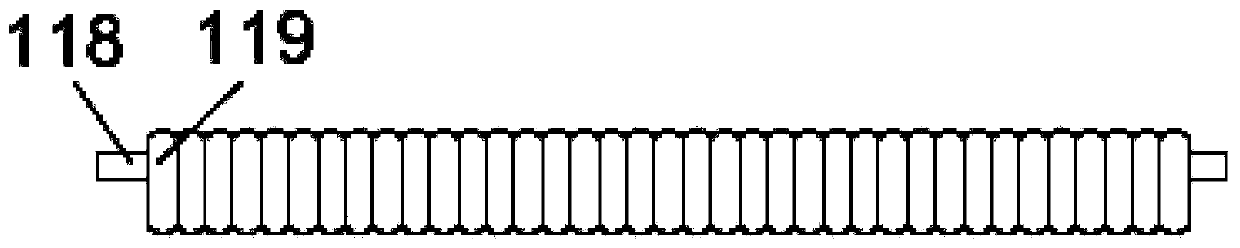

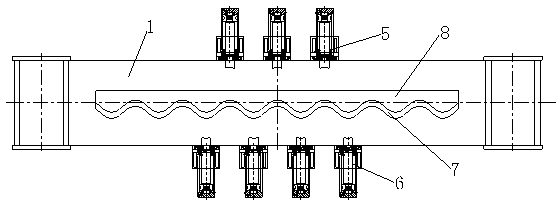

Processing equipment for wave-shaped filter cloth with framework and using method

InactiveCN113181712ALittle impact on operationImprove styling efficiencyAir-treating devicesDispersed particle filtrationAdhesive glueMechanical engineering

The invention discloses processing equipment for wave-shaped filter cloth with a framework and a using method. The processing equipment for the wave-shaped filter cloth with the framework comprises a rack, shaping rods and move grooves, wherein the shaping rods are arranged on the rack in the direction perpendicular to the length direction of the rack, each shaping rod comprise a lower shaping rod and an upper shaping rod, the lower shaping rods and the upper shaping rods are alternately arranged at equal intervals in the length direction of the rack, and the shaping rods can do translational motion in the direction perpendicular to the axis of the shaping rods and the length direction of the rack; the shaping rods can also do translational motion in the direction parallel to the length direction of the rack; the mold grooves are at least formed in the lower shaping rods or the upper shaping rods and are formed in the sides, which make contact with the wave-shaped filter cloth, of the shaping rods at equal intervals in the length direction of the shaping rods, and glue can be injected into the mold grooves. According to the device, the wave-shaped filter cloth can be shaped into a wavy shape, the shaping efficiency is high, the shaping precision is high, glue can be applied to the surface of the wave-shaped filter cloth and solidified into a framework, the forming effect is improved, the attractiveness is enhanced, and the automation degree is high.

Owner:昆山卓景电子科技有限公司

Rough and fine shaping integrated jig for rotor

The invention discloses a rough and fine shaping integrated jig for a rotor. The jig comprises a rough shaping die plate and a fine shaping die holder, wherein the rough shaping die plate and the fine shaping die holder are provided with a rough shaping rotor die hole and a fine shaping rotor die hole respectively, the rough shaping die plate is arranged on the fine shaping die holder, the rough shaping rotor die hole corresponds to the fine shaping rotor die hole, and the fine shaping rotor die hole corresponds to the rough shaping rotor die hole. The rough shaping die plate and the fine shaping die holder are fixed together through screws. As the rough shaping template is additionally arranged, the shaping precision is improved, and the shaping quality of the rotor is ensured. As the fine shaping die holder is improved, a protruding piece is improved to be of the plug-in type structure from an original structure integrally formed with the fine shaping die holder, the protruding piece is an easy-to-damage piece and can be replaced in time after being abraded, so that the service life of the fine shaping die holder is prolonged, and the production and machining cost is reduced.

Owner:FOSHAN IFIRST POWDER METALLURGY TECH

Auxiliary device for tire shaping and vulcanizing machines

The invention discloses shaping auxiliary device for tyre shaping vulcanizer. The shaping auxiliary device comprises that left and right handing mechanisms arranged on a vulcanizing chamber. The left handing mechanism is arranged on a left tilting mechanism which transferred from left front vulcanizing chamber and the right handing mechanism is arranged on a right tilting mechanism which transferred from the right front vulcanizing chamber. Or the left handing mechanism is arranged on the left tilting mechanism which transferred from the left rear vulcanizing chamber and the right handing mechanism is arranged on the right tilting mechanism which transferred from the right rear vulcanizing chamber. The left and right tilting mechanisms are arranged on left and right foundation frameworks on both sides of the vulcanizing chamber, respectively. Tire billets are located on the back vulcanizing chamber. Tilting mechanism synchronous motion support the opposite left and right handing mechanisms on tire billets and set it in middle. The shaping auxiliary device efficiently improves accuracy of tyre shaping press and tire quality and reduce waste defective rate, which enhance the economic benefits of engineering tire and giant tire.

Owner:GUILIN RUBBER MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com