Man-machine isolated automatic milling shaping machining system and method

A processing system and milling technology, used in weapon accessories, ammunition, offensive equipment, etc., can solve problems such as hidden accidents, many manual control factors, and inability to quantitatively control, so as to reduce the incidence of plastic accidents, reduce human factors, and improve The effect of shaping precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

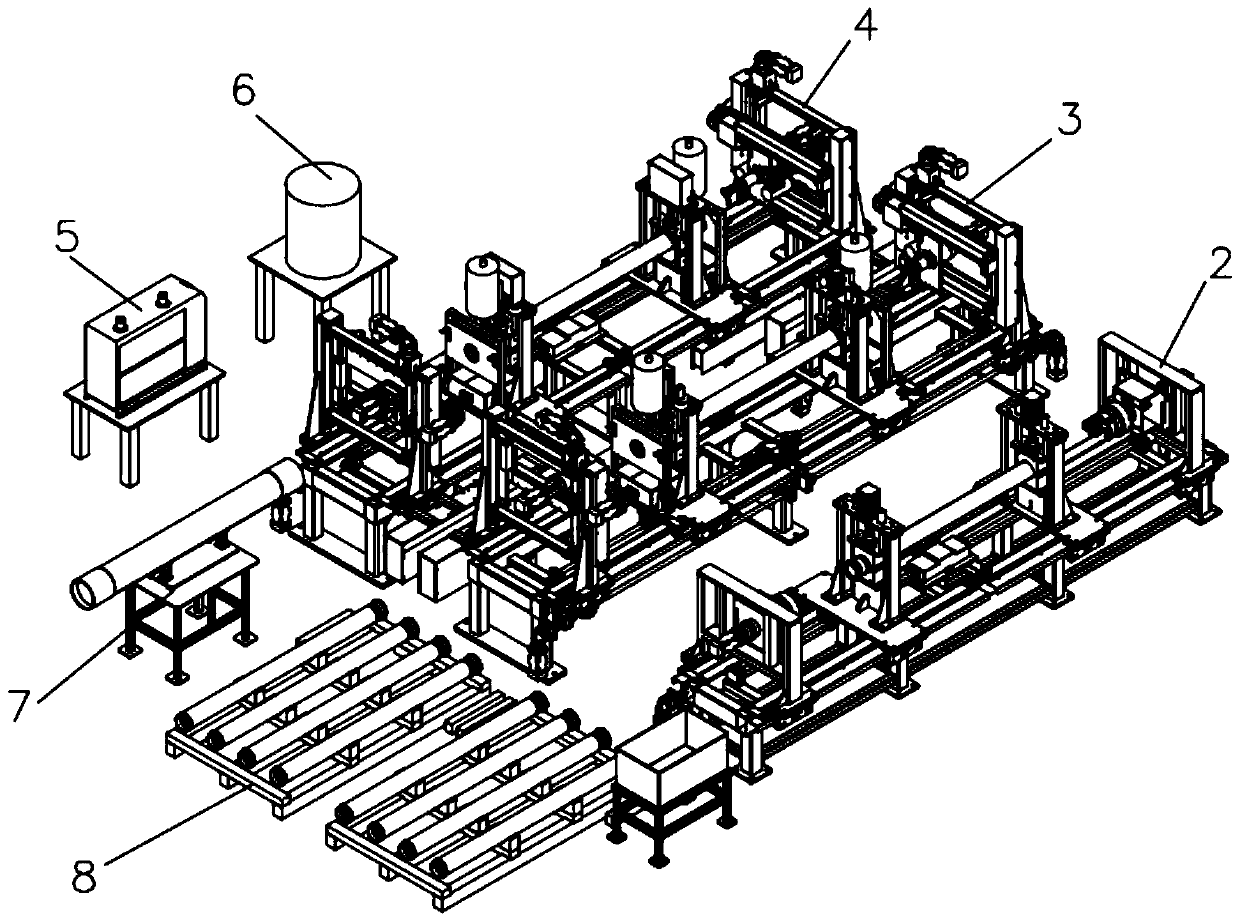

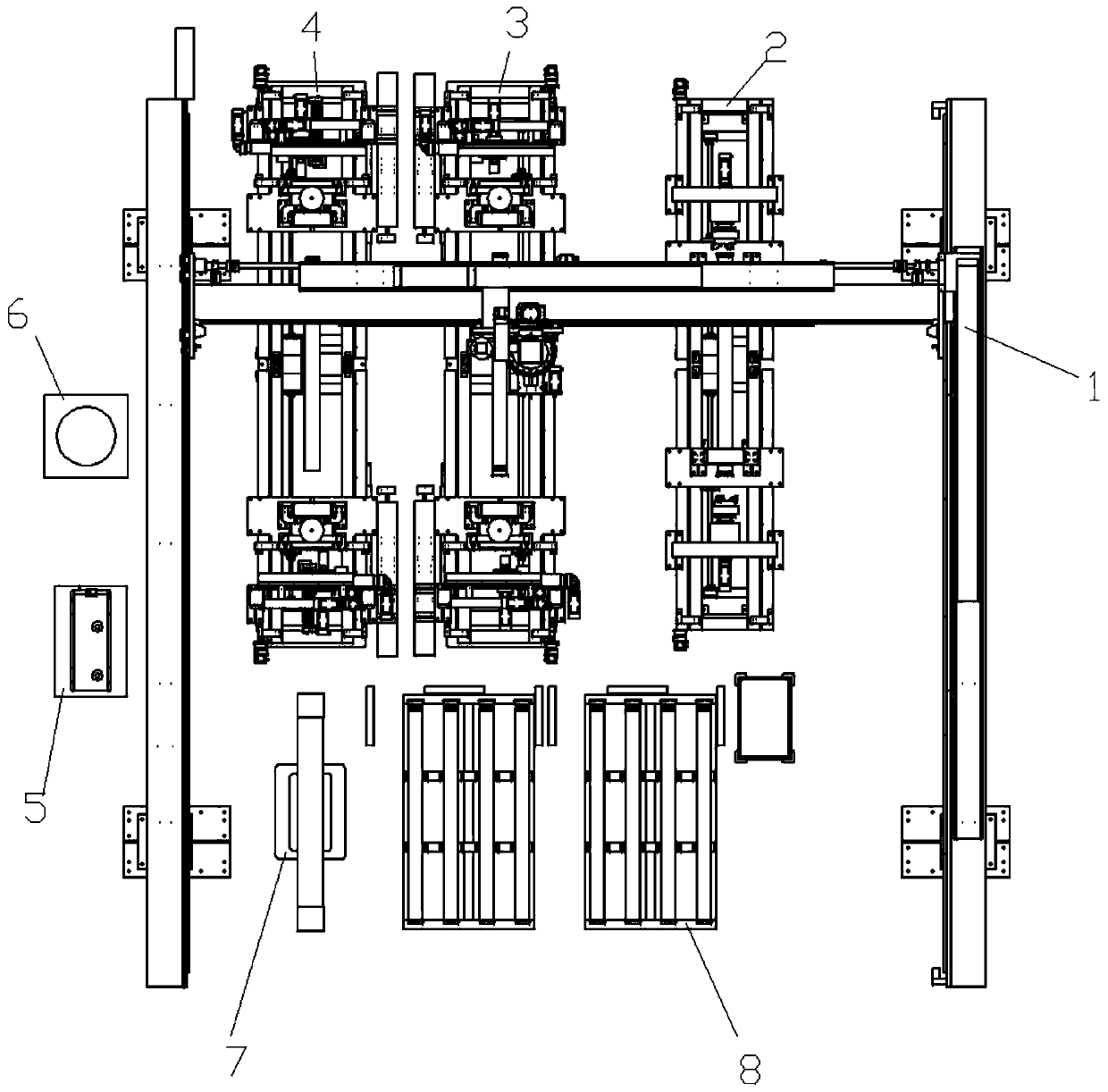

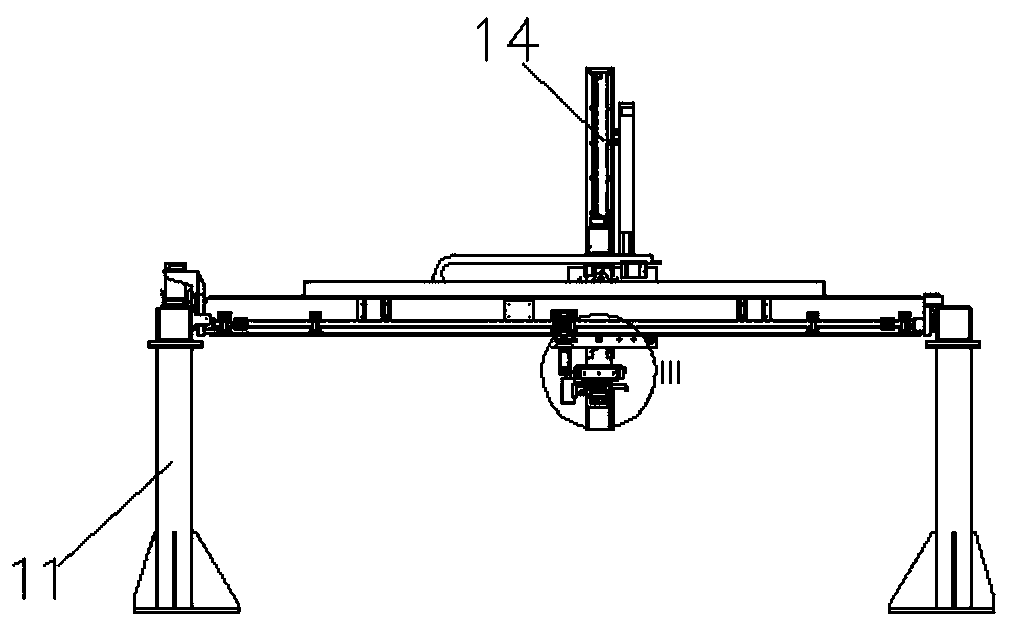

[0104] Such as figure 1 and figure 2 As shown, the human-machine isolation automatic milling and shaping processing system in this embodiment is mainly composed of a truss manipulator 1, a vision system, an end cover removal machine 2, a milling and shaping machine 3, a thread cleaning machine 4, an electric control cabinet, and an industrial computer. The processing program is stored in the industrial computer, and when the processing program is running in the processor, the following process is realized: control the truss manipulator 1 to carry the engine to be reshaped on the on-line and off-line tooling to the end cover removal machine 2, and the end cover removal machine 2 to position the engine Lock it tightly and remove the end caps at both ends at the same time. The truss manipulator 1 transports the engine with the end cover removed to the milling and shaping machine 3, then transports the end covers at both ends, and puts them into the end cover material frame. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com