Aluminum alloy thin plate precision shaping method and device based on electro-hydraulic forming

An electro-hydraulic forming and precision shaping technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as not being well solved, and achieve the effects of simplified structure, simple device and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

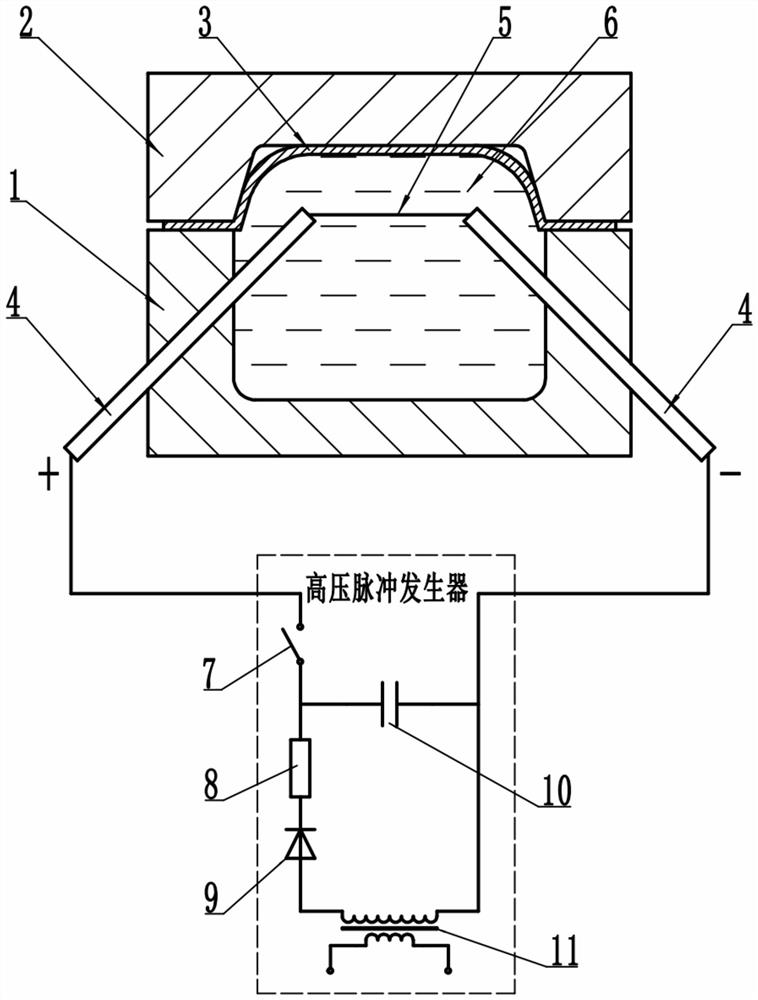

[0045] Such as figure 1As shown, the aluminum alloy sheet precision shaping device based on electro-hydraulic forming provided by the present invention includes: a punch liquid chamber 1, a shaping die 2, an electrode 4, a metal foil 5 and a high-voltage pulse generator;

[0046] The above-mentioned punch liquid chamber 1 can be filled with water medium 6 as a force transmission medium for electro-hydraulic forming;

[0047] The high-voltage pulse generator is composed of a discharge switch 7, a current limiting resistor 8, a rectifying element 9, a capacitor bank 10, and a step-up transformer 11;

[0048] Wherein the step-up transformer 11 is connected to an external voltage, and the positive electrode of the step-up transformer 11 is connected in series with a rectifying element 9, a current limiting resistor 8 and a discharge switch 7. The negative electrode of the voltage transformer 11 is connected to the negative electrode of the above-mentioned electrode 4 and is locat...

Embodiment 2

[0061] Consistent with the principle of the first embodiment above, the present invention also provides a second embodiment, by connecting two metal wires with different resistances in parallel between the positive and negative electrodes of the electrode 4 in the way of explosive wires, wherein, different materials can be selected Or metal wires of different lengths or different thicknesses to achieve the purpose of different resistances. By controlling the voltage of the high-voltage pulse generator to gradually increase the discharge, due to the difference in the resistance of the metal wires, two vaporizations and explosions will occur in a very short time. , and through the shock waves generated by the two vaporization explosions, the local unmolded parts of the aluminum alloy preform undergo high-speed deformation in a very short period of time and adhere to the concave mold cavity for shaping, and complete the precision of the local small features of the aluminum alloy sh...

Embodiment 3

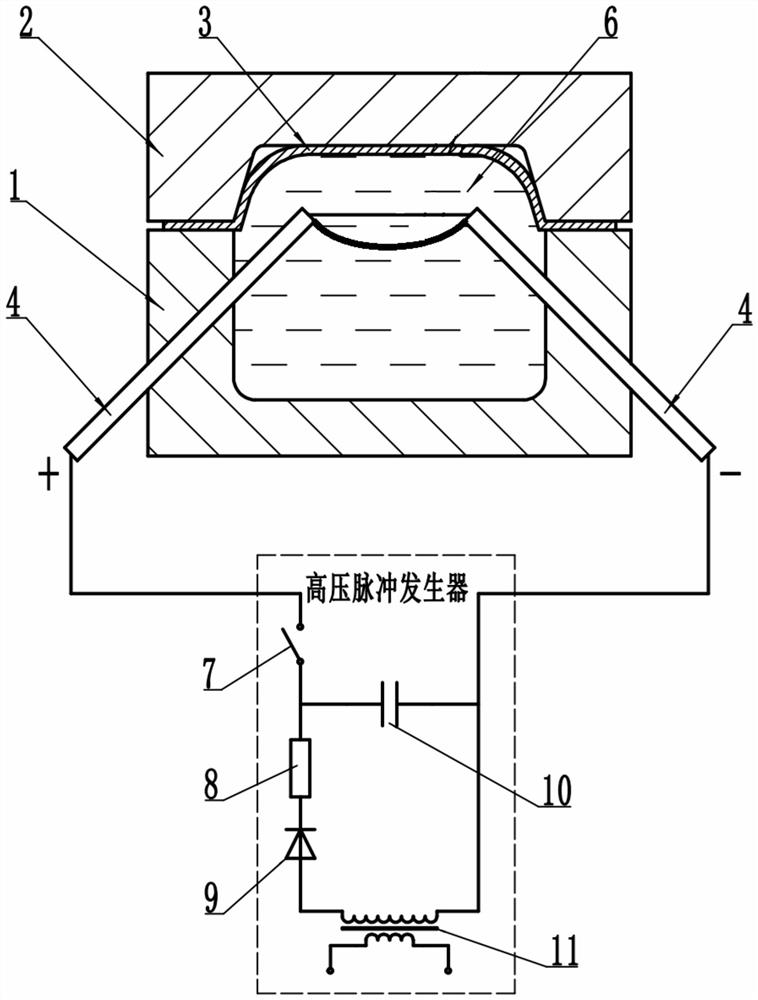

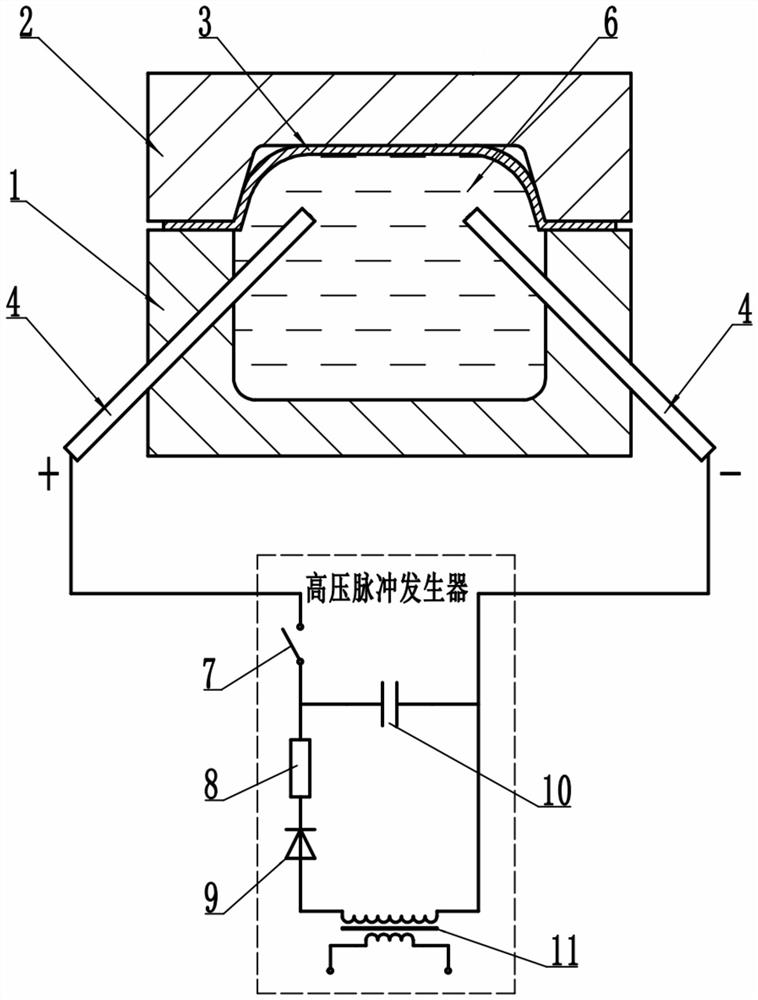

[0064] Embodiment 1 and Embodiment 2 provided by the present invention are based on the wire explosive electro-hydraulic forming method for precise shaping of aluminum alloy sheets. In practical applications, the electro-hydraulic precision shaping method for aluminum alloy thin Gap discharge electrohydraulic forming of metal foils, such as figure 2 The schematic diagram of the assembly of the preform and the mold before shaping based on the gap discharge electro-hydraulic forming method is shown. The device used includes the punch liquid chamber 1, the shaping die 2, the electrode 4, and the high-voltage pulse generator. The high-voltage pulse generator It is composed of a discharge switch 7, a current limiting resistor 8, a rectifier element 9, a capacitor group 10, and a step-up transformer 11. It is different from the device based on the wire explosion electro-hydraulic forming method in the first embodiment. The difference of this embodiment is that the positive electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com