Semi-honeycomb steel strip shaping and cutting off machine ensuring evenness of forced convection flow field

A forced convection and honeycomb technology, which is applied in the fields of mechanical product processing equipment, cutting machines, and semi-honeycomb steel belt shaping, can solve the problems of openness, no technical solutions, and no mature products for cutting equipment, etc., and achieve convenient use and adjustment. Simple, high-precision equipment shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

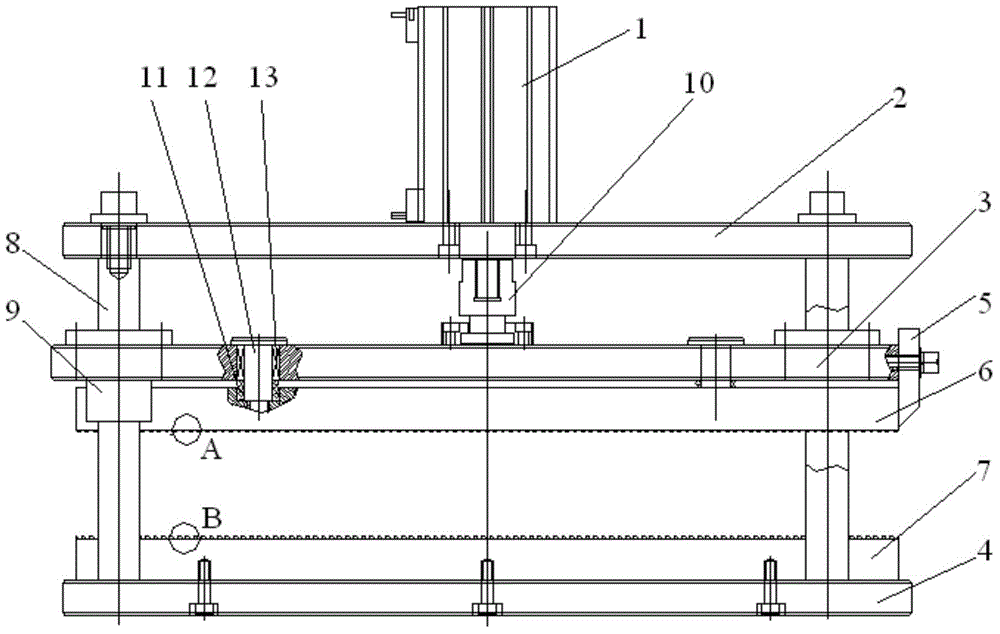

[0041] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

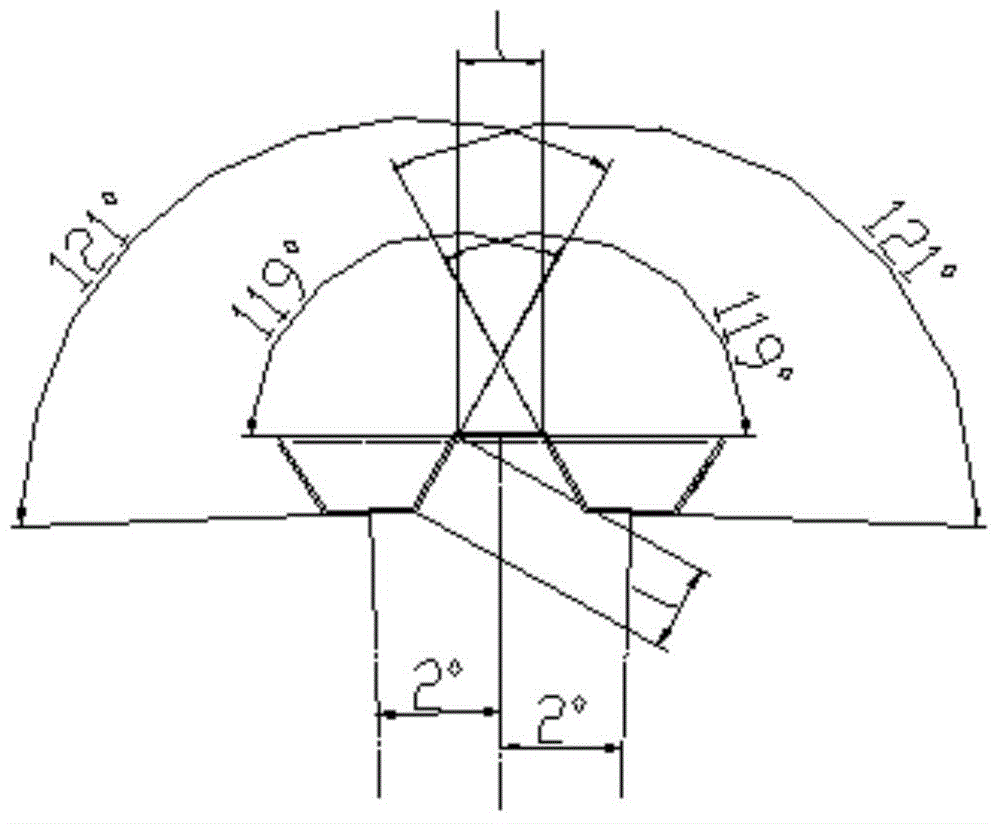

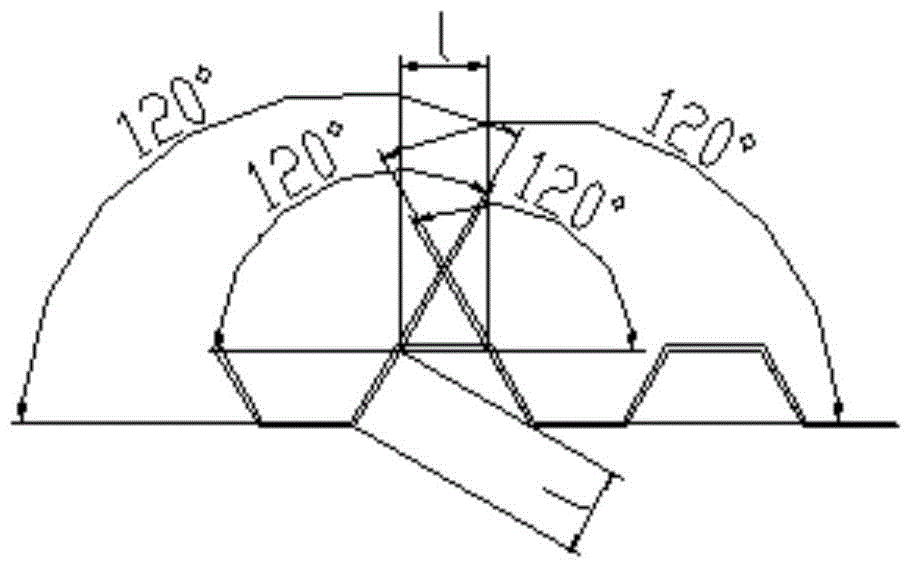

[0042] In order to improve the technical performance of the product, it is necessary to precisely shape the semi-honeycomb steel belt rolled out by the semi-honeycomb steel belt hobbing machine, so as to achieve figure 2 (after shaping) the requirements shown.

[0043] The tooth shape is designed to be half of the regular hexagon: the length of the three tooth sides is L, and the tooth tip angle is 60°. Considering the thickness δ of the extruded material, the side length of the tooth valley is: L+2δ×tan30°.

[0044] By analyzing the prior art, the equipment for shaping and cutting of the present invention should have the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com