Manual core shaping machine and operation method thereof

An operation method and shaping machine technology, applied in the field of manual core shaping machines, can solve the problems of over-correcting and then re-finishing, product scrapping, and broken products, etc., to reduce labor intensity, high shaping precision, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

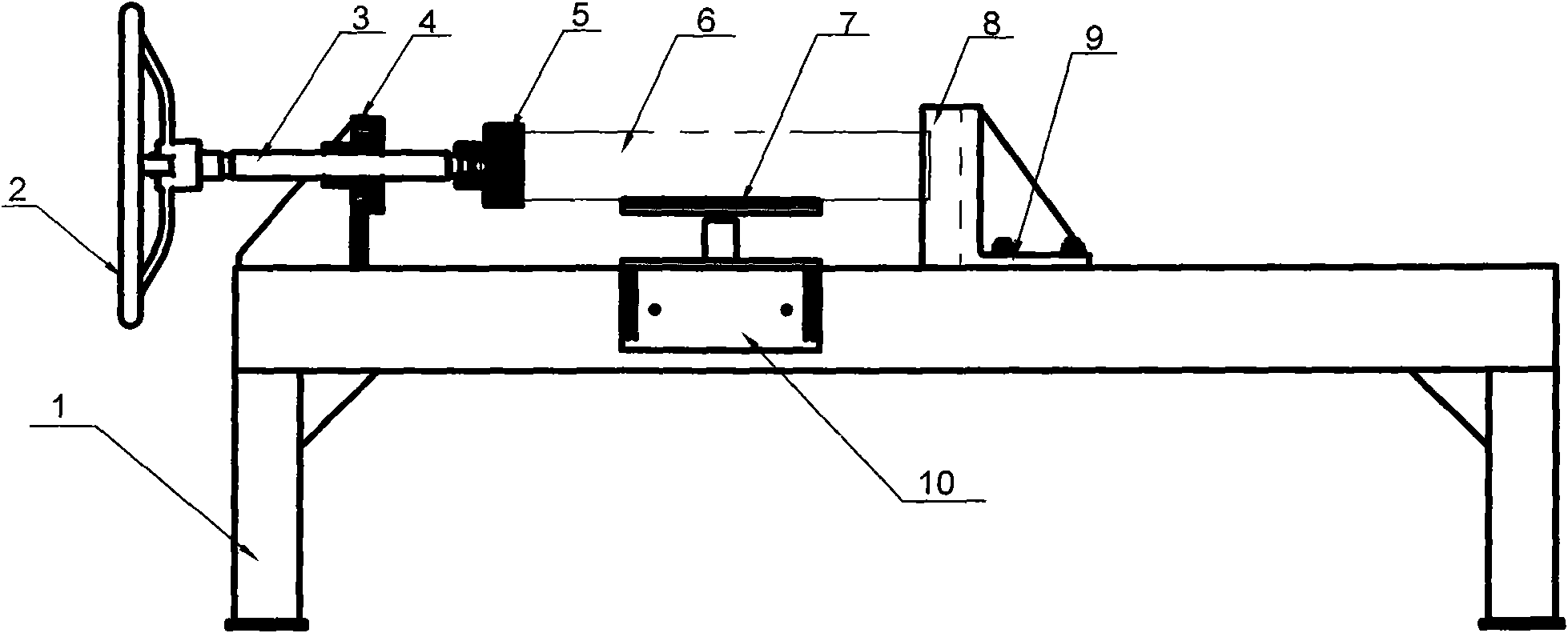

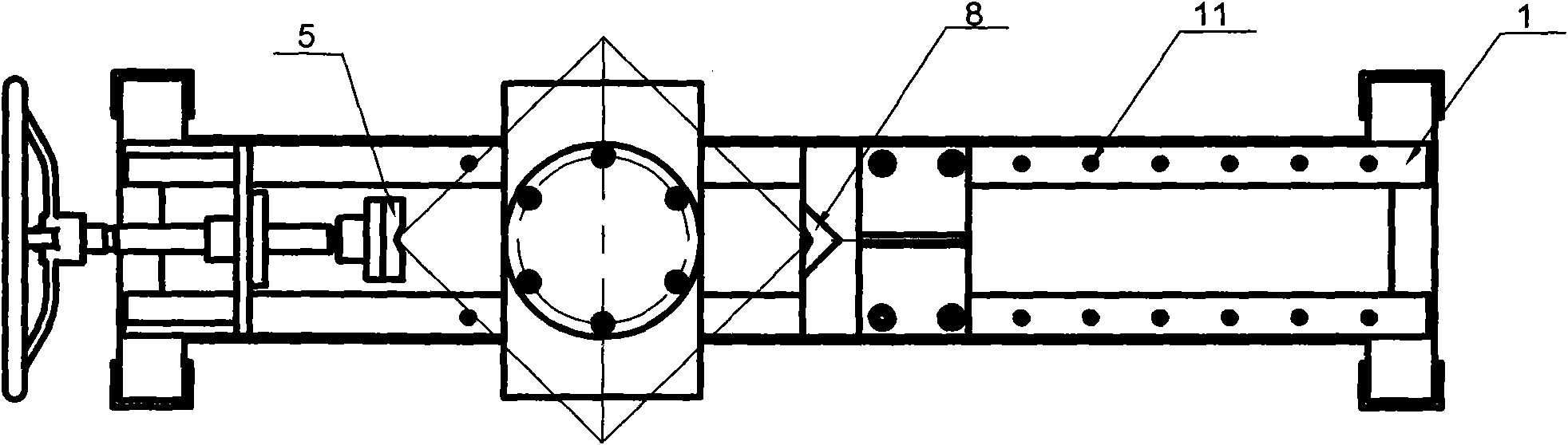

[0039] Such as figure 1 , figure 2 As shown, it is a manual core body diagonal shaping machine, including frame 1, hand wheel 2, screw rod 3, front fixing seat 4, replaceable V-shaped blocks 5 and 8, lifting platform 7, and dragging plate 10 And movable tail seat 9.

[0040] Whole frame 1 is long platform shape, and front holder 4 is installed on its one end, is provided with a plurality of apertures 11 on the other end, and movable tailstock 9 is detachably connected with frame 1 by aperture 11. The middle part of frame 1 is equipped with carriage 10, and lifting platform 7 is installed on carriage 10.

[0041] The hand wheel 2 is connected with the replaceable V-shaped block 5 through the trapezoidal screw rod 3, and the trapezoidal screw rod 3 is installed on the front fixed seat 4; the movable tailstock 9 is provided with a replaceable V-shaped block 8, which is connected with the trapezoidal screw rod 3 The changeable V-shaped block 5 symmetry, wherein the V-groove an...

Embodiment 2

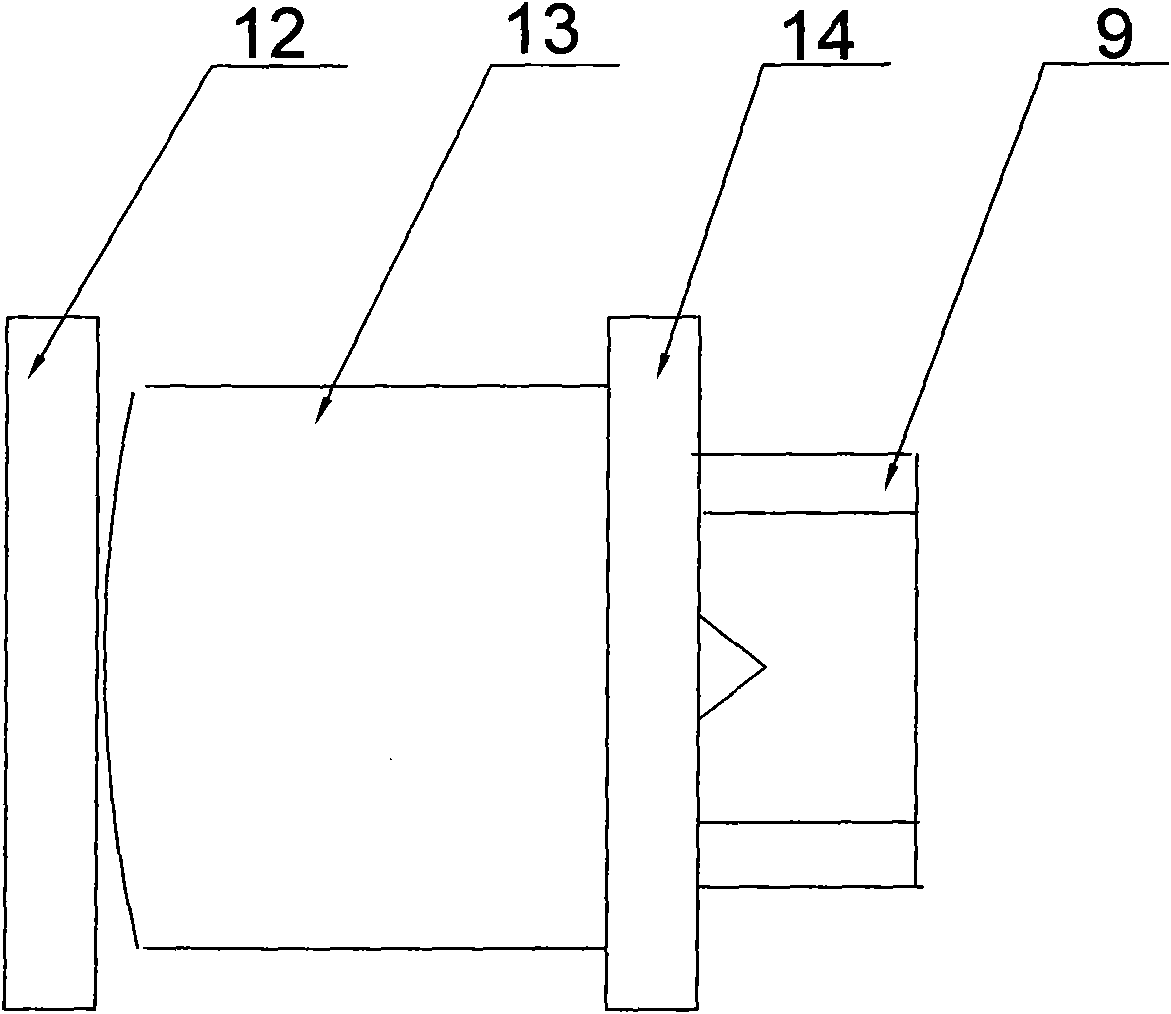

[0044] Such as image 3 Shown, be a kind of manual type core body four side straightness shaping machine, it is basically consistent with the structure of manual type core body diagonal line shaping machine in embodiment 1 (as figure 1 , 2 shown), the only difference is that the replaceable V-shaped blocks 5, 8 in Embodiment 1 are replaced with replaceable flat plates 12, 14, which can be used to shape the deformation core 13 for four-sided straightness.

[0045] During shaping, deformable core body 13 is placed on the lifting platform 7 in the middle, makes its deformed edge towards changeable plate 12, adjusts the lifting height of lifting platform 7, makes the center of the core body thickness of deformable core body 13 and trapezoidal screw rod The centers of 3 are close to each other, and the movable tailstock 9 is locked according to the side length of the deformed core body 6 core body, and then the hand wheel 2 is spun until the deformed edge is shaped into a straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com