Device and method used for producing cooling cured part

A firmware and cooling device technology, applied in biological packaging, sustainable packaging, sustainable manufacturing/processing, etc., can solve the problem of high difficulty in the production and processing of polylactic acid film, small contact area of smoke and gas attached to the paper tube, and adhesion. It can solve the problems of unclear pyrolysis products, etc., to achieve the effect of dimensional stability, increase in size, and stable extrusion pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

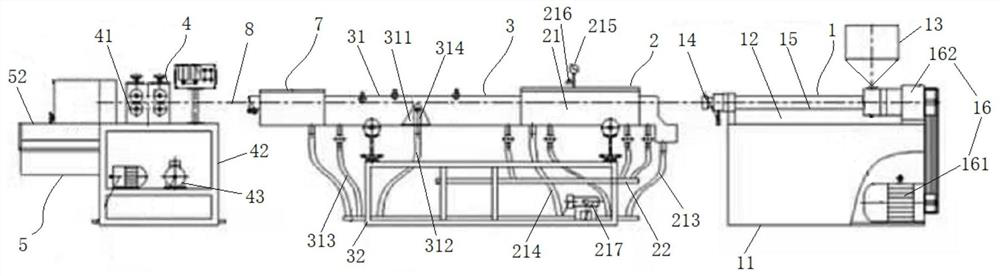

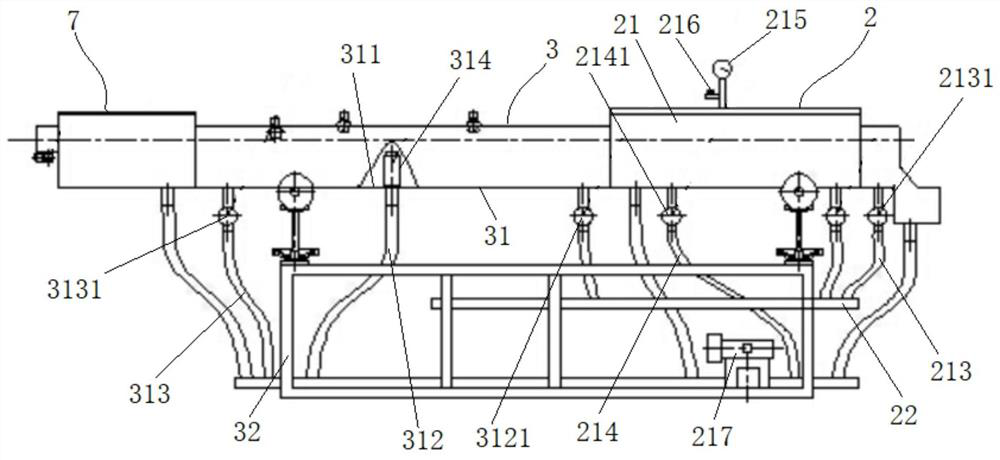

[0054] Such as figure 1 As shown, the device for producing cooling firmware of the present invention includes: an extruder 1 , a shaping device 2 , a cooling device 3 , a pulling device 4 and a cutting device 5 . in,

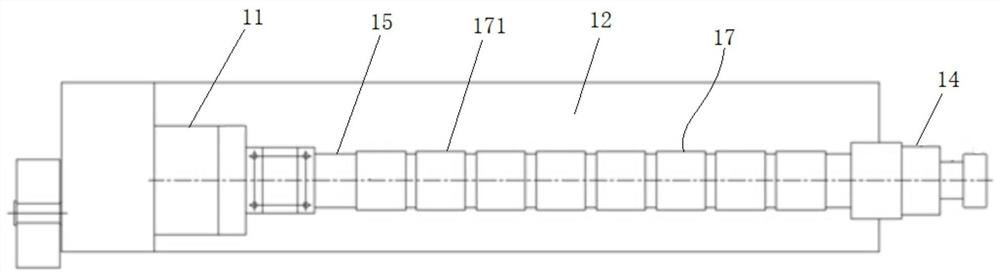

[0055] Extruder 1 comprises extruder body 11 (as figure 2 As shown), the interior of the extruder body 11 is provided with a housing cavity 12 . A feed port 13 communicating with the accommodating cavity 12 is provided on the first side wall of the extruder body 11 . An extrusion die 14 communicating with the accommodation cavity 12 is disposed on a second side wall different from the first side wall of the extruder body 11 . A screw 15 is arranged in the housing cavity 12, the first end of the screw 15 is connected to the power output end of the driving part 16, and the driving part 16 is used to drive the screw 15 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com