S-shaped bridge expansion joint positioning and shaping device

A shaping device and expansion joint technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding accuracy, high processing cost, large welding deformation, etc., and achieve good shaping effect and shaping accuracy. High and efficient work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing.

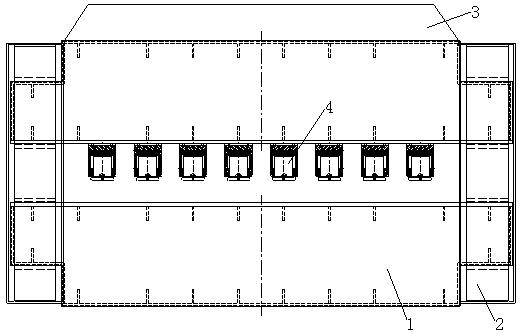

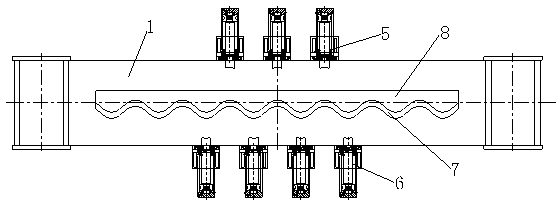

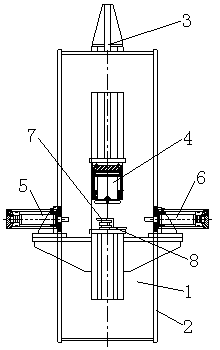

[0020] like Figure 1 to Figure 3 As shown, the S-shaped bridge expansion joint positioning and shaping device includes an upper beam 3 and a lower beam 1 installed on the load-carrying gantry 2 , and also includes a pressing cylinder 4 , a shaping cylinder 5 and a clamping cylinder 6 .

[0021] Compression cylinders 4 are provided with eight, equidistantly fixed on the bottom of the upper beam 3, and located on the center line of the upper beam 3, compression cylinders 4 are connected with the synchronous motor.

[0022] The pressing oil cylinder 4 realizes the synchronous action through the synchronous motor, respectively realizes the function of pressing the upper surface of the S-shaped steel semi-finished product 7 to prevent deformation from extending and destroying the external dimensions of the S-shaped steel semi-finished product 7 and pressing the vertical plate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com