A multi-station jump riveting mechanism, jump riveting machine and chain assembly and processing line

An assembly processing and multi-station technology, applied in the direction of metal chains, etc., can solve the problems of large pressure load of chain assembly machines, affecting the service life of punching needles, and uneven chain accuracy, so as to reduce operation difficulty and improve work efficiency and strength. Good effect with hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

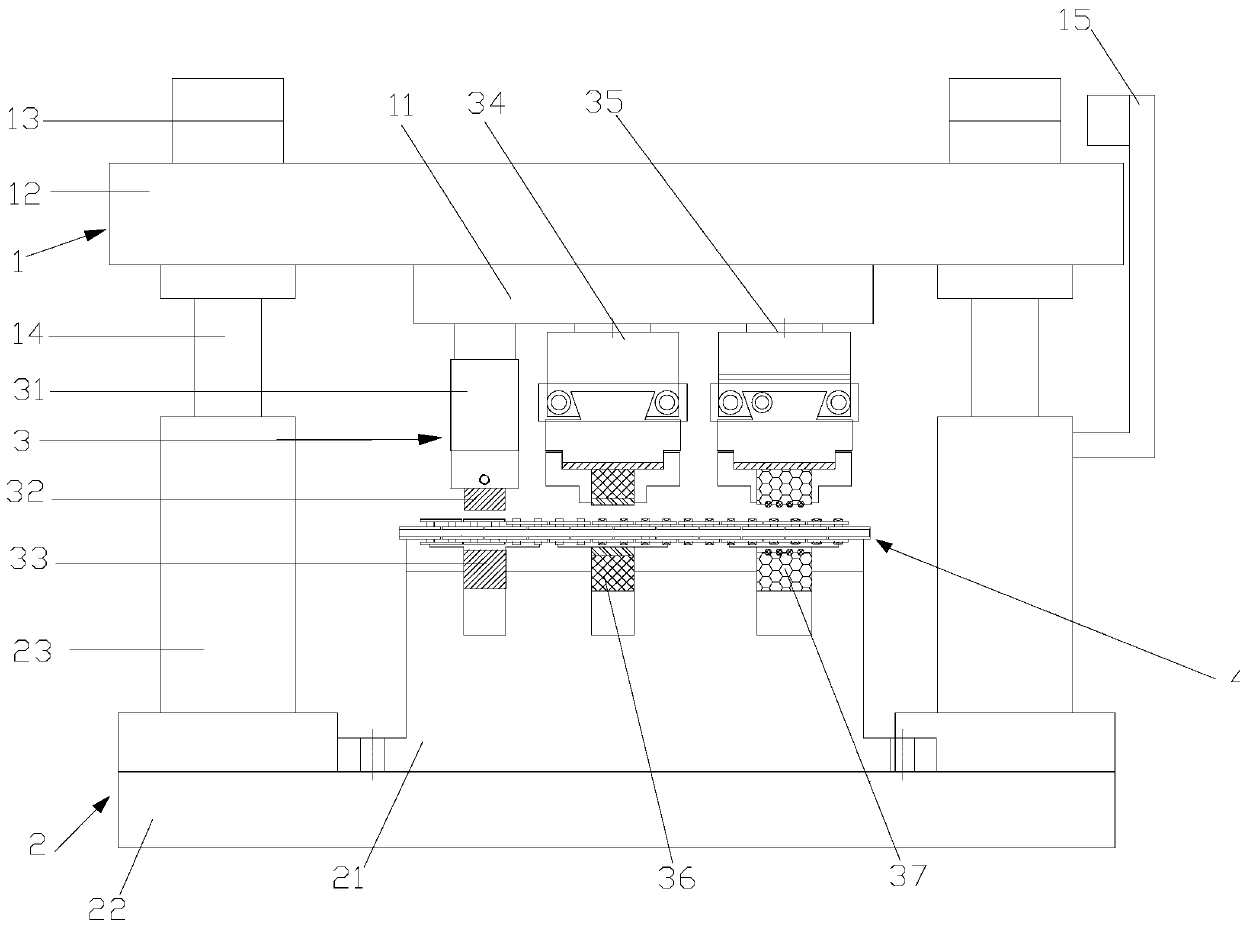

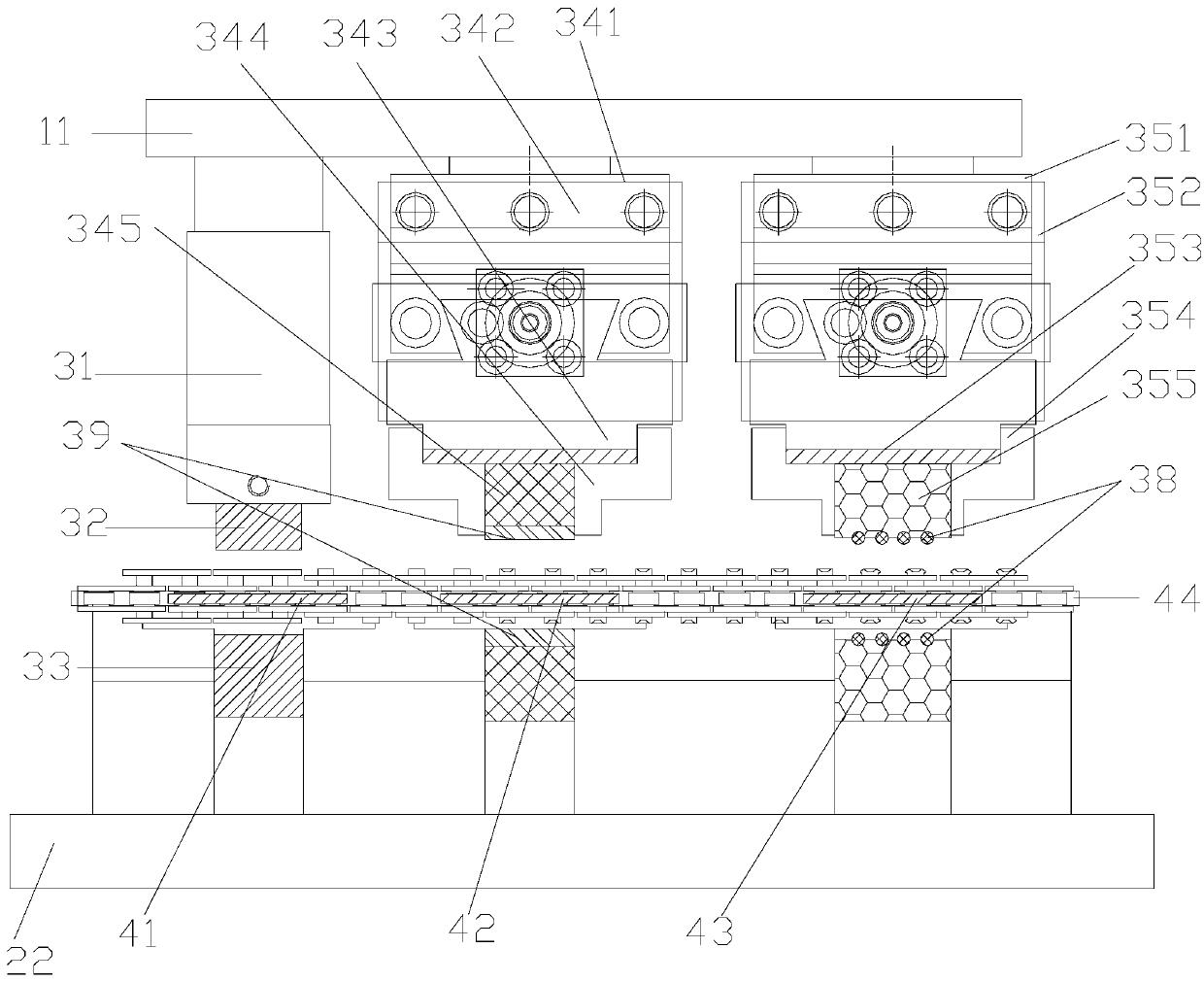

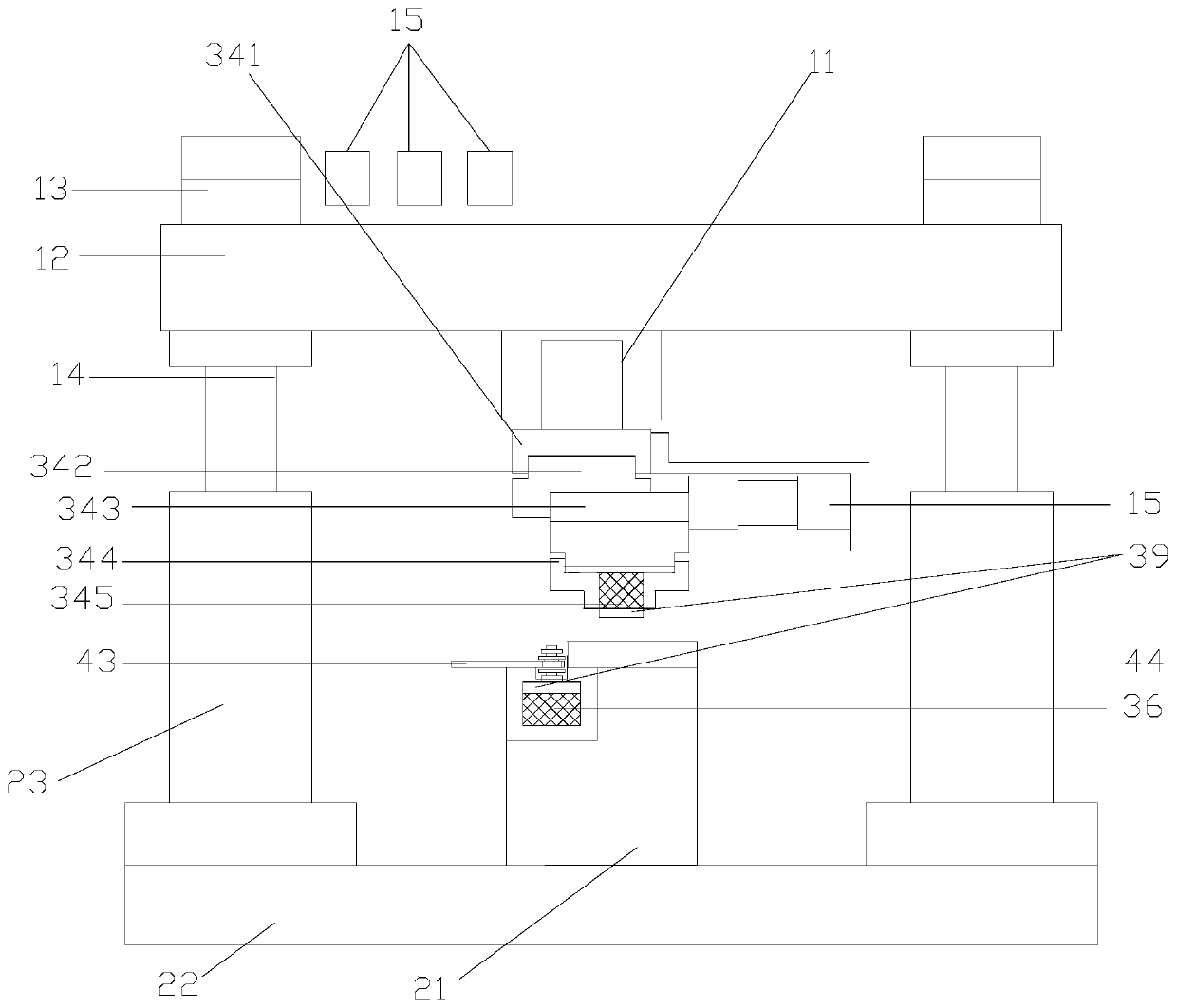

[0026]A multi-station jump riveting mechanism, jump riveting machine and chain assembly and processing line, as shown in Figure 1-3, includes an upper mold mechanism 1, and a lower mold mechanism 2 provided with the lower end of the upper mold mechanism 1, the upper mold mechanism Mechanism 1 includes an upper die base 11, an upper cross beam 12 that is arranged on the upper end of the upper die base 11 and is connected with the upper die base bolts, and an up and down movement strut nut 13 that is arranged on the upper cross beam 12 surface. The lower end of the strut nut 13 is provided with a sliding strut 14 moving up and down, and one side of the crossbeam 12 is provided with a detection device 15 connected with the crossbeam 12 bolts. The table panel 22 at the lower end and connected with the lower mold base 21 bolts, and the up and down movement sliding column sleeve 23 arranged on the upper surface of the table panel 22 for cooperating with the up and down movement slidi...

Embodiment 2

[0036] A multi-station jump riveting mechanism, jump riveting machine and chain assembly and processing line, including an upper mold mechanism 1, and a lower mold mechanism 2 provided with the lower end of the upper mold mechanism 1, and the upper mold mechanism 1 includes an upper mold base 11 , and the upper cross beam 12 that is arranged on the upper end of the upper die base 11 and is connected with the upper die base bolts, and the up and down movement strut nut 13 that is arranged on the surface of the upper cross beam 12, the lower end of the up and down movement strut nut 13 is provided with an up and down Motion sliding column 14, described crossbeam 12 one side is provided with the detection device 15 that is connected with crossbeam 12 bolts, and described lower mold mechanism 2 comprises lower mold holder 21, and is arranged on lower mold holder 21 lower end, and is connected with lower mold holder. 21 a bolt-connected table top 22, and an up and down movement slid...

Embodiment 3

[0046]A multi-station jump riveting mechanism, jump riveting machine and chain assembly and processing line, including an upper mold mechanism 1, and a lower mold mechanism 2 provided with the lower end of the upper mold mechanism 1, and the upper mold mechanism 1 includes an upper mold base 11 , and the upper cross beam 12 that is arranged on the upper end of the upper die base 11 and is connected with the upper die base bolts, and the up and down movement strut nut 13 that is arranged on the surface of the upper cross beam 12, the lower end of the up and down movement strut nut 13 is provided with an up and down Motion sliding column 14, described crossbeam 12 one side is provided with the detection device 15 that is connected with crossbeam 12 bolts, and described lower mold mechanism 2 comprises lower mold holder 21, and is arranged on lower mold holder 21 lower end, and is connected with lower mold holder. 21 a bolt-connected table top 22, and an up and down movement slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com