Fully-automatic bagged goods stacking device

A palletizing device and fully automatic technology, which is applied in the stacking of objects, depalletizing, transportation and packaging of objects, etc., can solve the problems of poor conveyance of bagged goods, low shaping accuracy, and low stacking accuracy, etc. Achieve the effect of high shaping precision, reasonable structure design and smooth conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

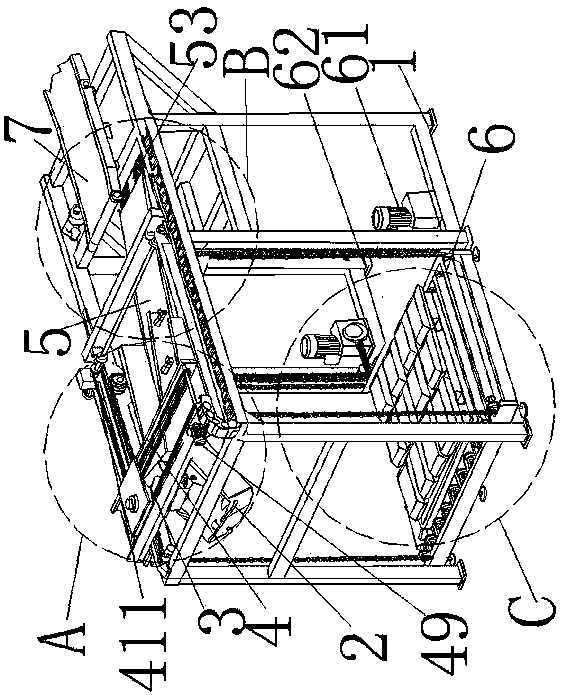

[0061] Example 1. Such as Figure 1-13 As shown, a fully automatic bagged goods palletizing device is characterized in that: it includes a frame body 1 and a movable feeding device 5 arranged on the frame body 1, a palletizing device, and a pallet lifting device 6, and the palletizing device is arranged on The top of the frame body 1; the pallet lifting device 6 is provided below the stacking device on the frame body 1.

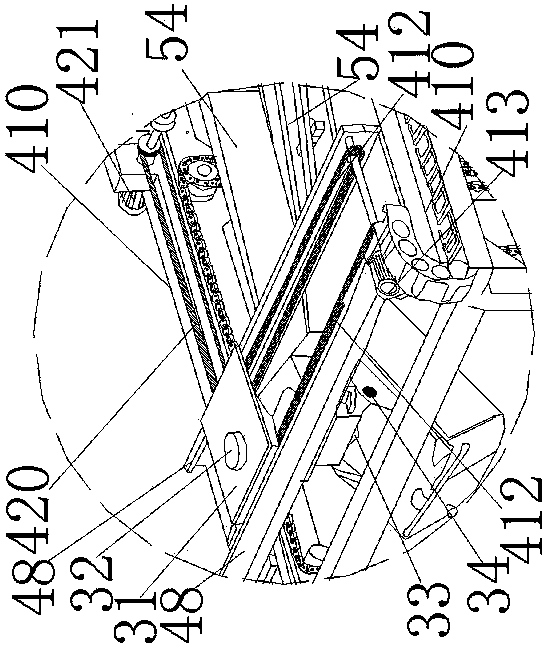

[0062] The palletizing device includes a hopper assembly 2 that can be opened and closed at the bottom, the hopper assembly 2 is hinged on the rotator assembly 3 through a hopper hinge shaft 34, and the rotator assembly 3 is provided with a driveable hopper assembly 2 The hopper assembly rotating drive device that rotates along the hopper hinge shaft 34; the rotator assembly 3 is installed on a rotator assembly vertical and horizontal motion drive device 4.

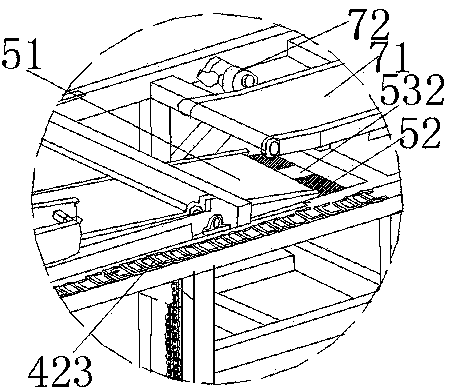

[0063]The movable feeding device 5 includes a movable feeding conveyor belt sliding support platfor...

Embodiment 2

[0080] Example 2. Such as Figure 15 As shown, the difference between this embodiment and Embodiment 1 is that the stacking device is arranged on the right side of the top of the frame body 1; It is a plane movable feeding conveyor belt sliding support platform; a movable feeding conveyor belt 51 is arranged between the movable feeding conveyor belt sliding supporting platform on the frame body and the vertical and horizontal motion driving device 4 of the rotator assembly; the movable feeding conveyor belt 51 The right end of the rotator assembly vertical and horizontal motion driving device 4 is hinged, and the left end of the movable feed conveyor belt 51 is hinged with the sliding block;

[0081] The longitudinal motion driving device 49 includes a longitudinally retractable device 414 arranged between two longitudinal guide rails 48. The longitudinally retractable device 414 is one of a hydraulic cylinder, a hydraulic oil cylinder, and an electric linear drive. The longi...

Embodiment 3

[0083] Example 3. Such as Figure 20 As shown, the difference between this embodiment and Embodiment 2 is that the pallet lifting device 6 includes four pallet lifting hydraulic cylinders 612 and a pallet frame 64, and the pallet lifting hydraulic cylinders 612 are installed under the pallet frame 64; There are a number of idler rollers 65 whose top surfaces are parallel to each other on the same plane, each idler roller 65 is provided with a sprocket 66, and the sprockets 66 of adjacent idler rollers 65 are connected by a transmission chain 67, and at least one idler roller 65 A transmission wheel 68 is arranged on it, and the transmission wheel 68 is connected with a power output wheel 610 of a roller rotation driving motor 69 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com