Belt-type blade spiral mixing conveyor

A blade screw and conveyor technology, which is applied in the field of screw conveyors and belt-shaped blade screw mixing conveyors, can solve the problems of non-continuous output, intermittent, low production efficiency, etc., and achieves wide application, good conveying function, and cleaning and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

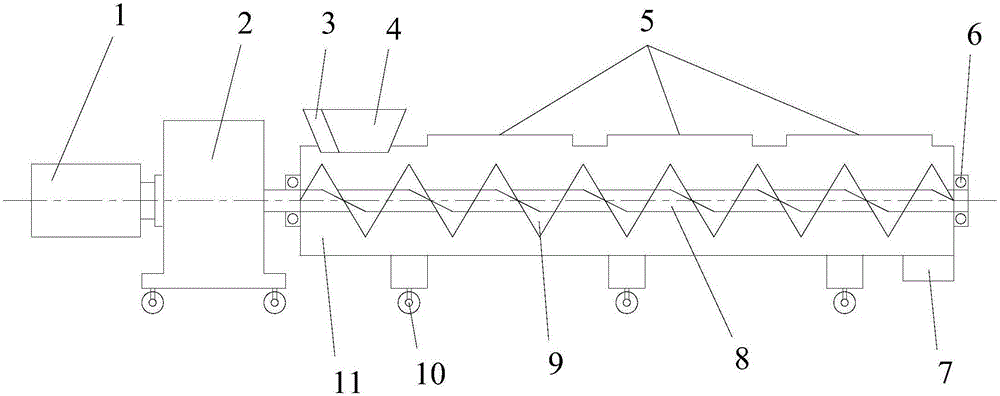

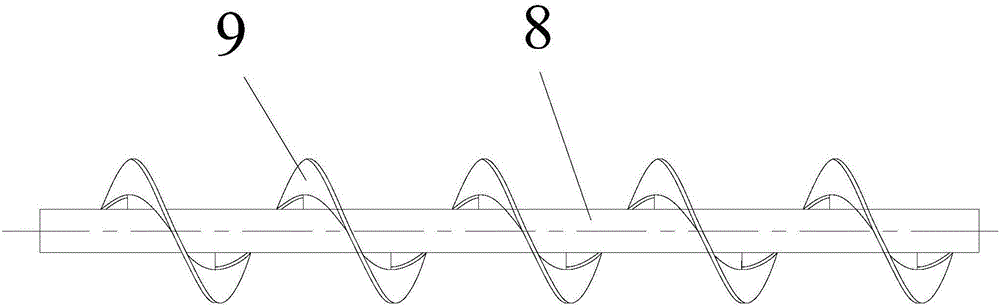

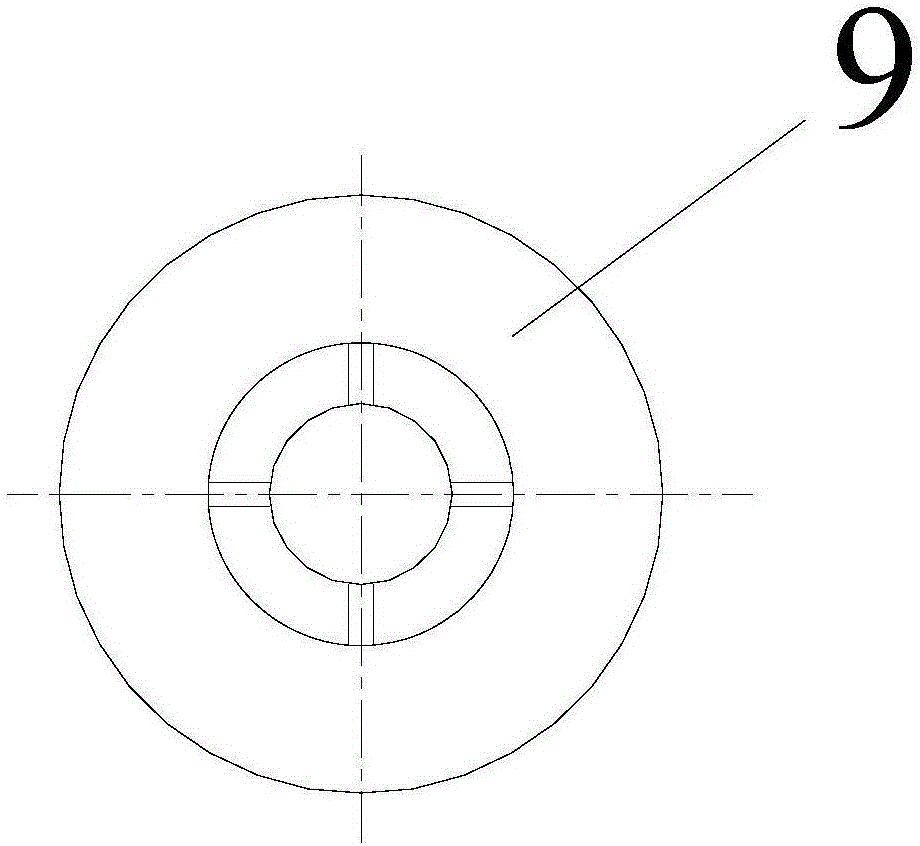

[0020] join figure 1 , The belt-shaped blade screw mixing conveyor of the present invention includes a motor 1, a reducer 2, a trough 11, a bearing 6, a screw shaft 8, a discharge port 7, and a screw blade 9. The input end of the reducer 2 and the motor 1 Connection, the output end is connected with the material chute 11, the material chute 11 is provided with a screw shaft 8, the screw shaft 8 is provided with a spiral blade 9, the left and right ends of the material chute 11 are provided with bearings 6, and the lower right end of the material chute 11 is provided with There is a discharge port 7, and also includes a window 5, a night material hopper 3, and a block material hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com