Large block removing device for bucket wheel machine

A bucket wheel machine and large block technology, which is applied in the field of bucket wheel machine removing large block devices, can solve the problems of bucket wheel machine cantilever belt and trestle belt scratches, increased maintenance workload and capital investment, large blocks are easy to scratch the belt, etc. , to achieve the effect of increasing sieving rate, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and details of the bucket wheel machine removal device proposed according to the present invention will be described. Its effect is described in detail below.

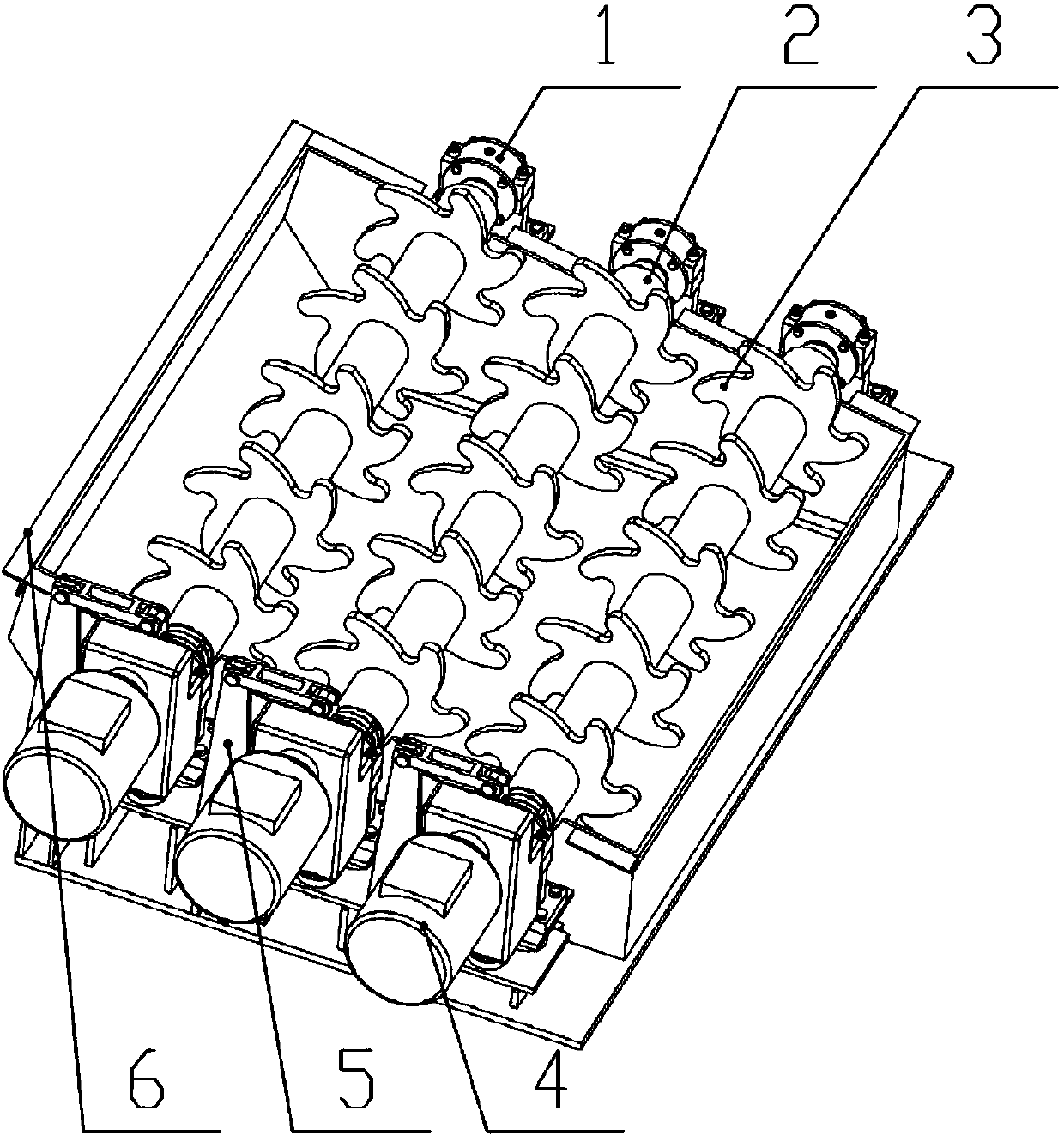

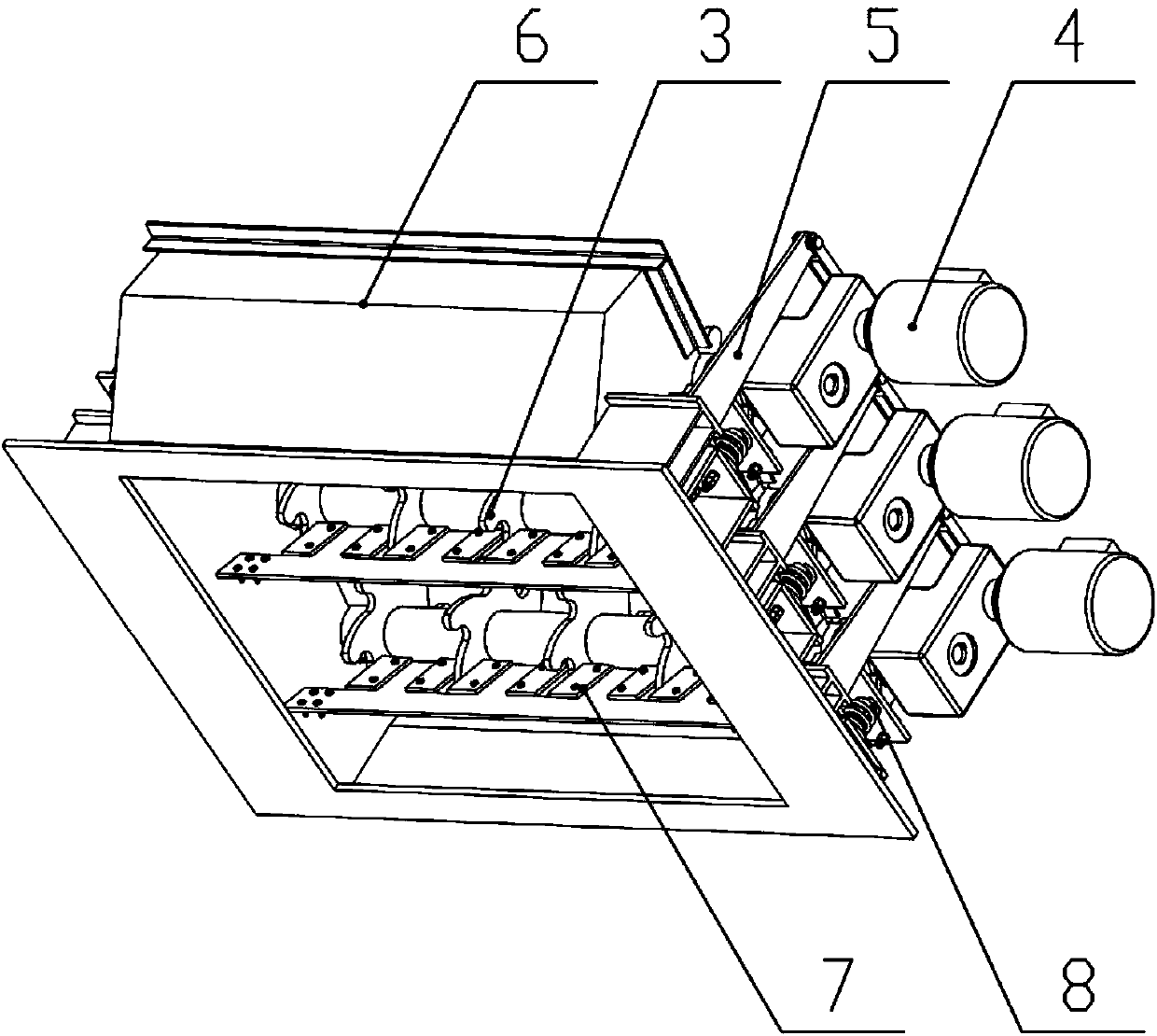

[0024] see figure 1 and figure 2 , a bucket wheel machine removing bulk device, which mainly includes a bearing support assembly, a drive shaft assembly, a plurality of impellers 3, a driving device assembly, a plurality of floating moment arms 5, an outer shell 6, and an elastic automatic cleaning device 7 , Multiple elastic buffer seats 8, electric control cabinet.

[0025] Wherein, a plurality of bearing supports 1 form the bearing support assembly; a plurality of drive shafts 2 form the drive shaft assembly; and a plurality of drive device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com