Electrode wire for slow wire electric discharge machining and preparation method thereof

An electrical discharge machining and electrode wire technology, which is applied in the field of electrode wire for slow wire EDM and its preparation, can solve the problems of cutting speed limitation, fast electric corrosion speed, etc., so as to improve the processing speed, save the manufacturing cost, reduce the human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

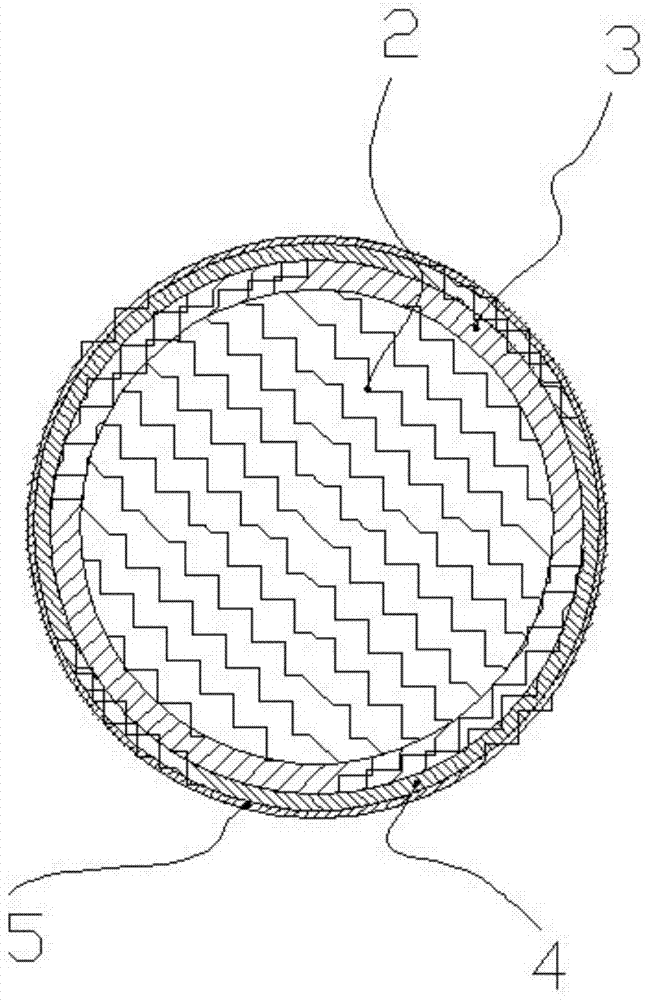

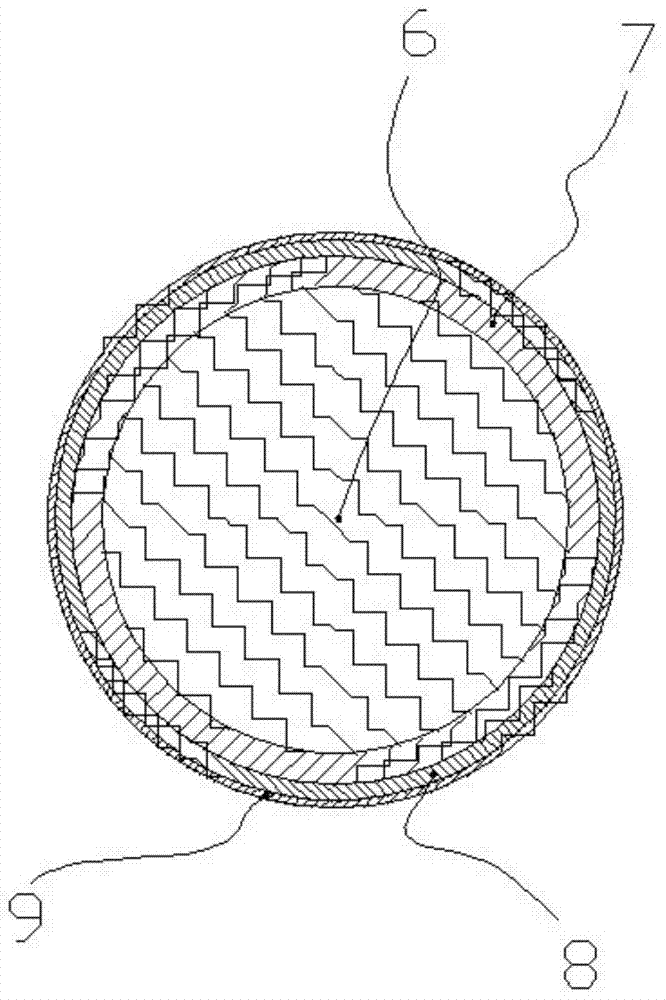

[0074] 1. Manufacture the electrode wire A whose diameter D0 of the electrode wire of the present invention is 0.25 mm. The transition layer 3 composed of β-phase copper-zinc alloy, the transition layer 3 includes a continuous continuous portion 3.1 and a discontinuous portion 3b formed by a β-phase copper-zinc alloy protruding from the continuous portion, and has a continuous portion embedded in the transition layer 3 3.1 Composition of gamma-phase copper-zinc alloy with a zinc content of 60wt% and pits and exposed β-phase with a zinc content of 47wt%;

[0075] 2. To this end, use the spraying method to electroplate a zinc coating with a thickness of 11 μm on a brass wire (mother core 6) with a diameter of 1.2 mm and a copper content of 80 wt %;

[0076] 3. Carry out stepped diffusion annealing in the annealing furnace on the silk sprayed in step 2. The annealing temperature in the low temperature section is 160°C, and the holding time is 3 hours to form the initial covering ...

Embodiment 2

[0087] 1. Manufacture the electrode wire B whose electrode wire diameter D0 of the present invention is 0.25 mm, the electrode wire includes a core 2 made of a brass alloy with a copper content of 63 wt%, and the core is covered with β Phase composition of the transition layer 3, and embedded in the transition layer 3 on the zinc content of 60wt% gamma phase and pits and exposed zinc content of 47wt% of the β phase composition;

[0088] 2. For this reason, use the hot-dip plating method to electroplate a zinc coating with a thickness of 10 μm for a brass wire (female core 6) with a diameter of 1.1 mm and a copper content of 63 wt %;

[0089] 3. Stretch the plated mother blank to 1.0mm;

[0090] 4. Carry out two stages of online continuous diffusion annealing on the 1.0mm mother blank. The annealing temperature of the first stage is 420°C, and the annealing distance is 3 meters, so that the mother core 6 and the surface layer of pure zinc diffuse each other to form the initial ...

Embodiment 3

[0100] 1. Manufacture the electrode wire C whose electrode wire diameter D0 is 0.25 mm. The electrode wire includes a core 2 made of a brass alloy with a copper content of 63 wt%. Phase composition of the transition layer 3, and embedded in the transition layer 3 on the zinc content of 60wt% gamma phase and pits and exposed zinc content of 47wt% of the β phase composition;

[0101] 2. For this reason, adopt the electroplating method to be that the copper content of diameter 1.0mm is the zinc plating layer of 63wt% brass wire electroplating thickness to be 7 μm;

[0102] 3. Stretch the plated mother blank to 0.95mm;

[0103] 4. Carry out step diffusion annealing for the 0.95mm wire billet in the furnace, the annealing temperature of the low temperature section is 175°C, the holding time is 2 hours, the annealing temperature of the high temperature section is 420°C, and the holding time is 2.5 hours;

[0104] 5. After cooling the wire billet to 70°C in the furnace, put it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com